I once saw a plumbing project stall because the crew didn’t have the right size adapter. A simple 2″x1.5″ reducer could have saved them a day of delays.

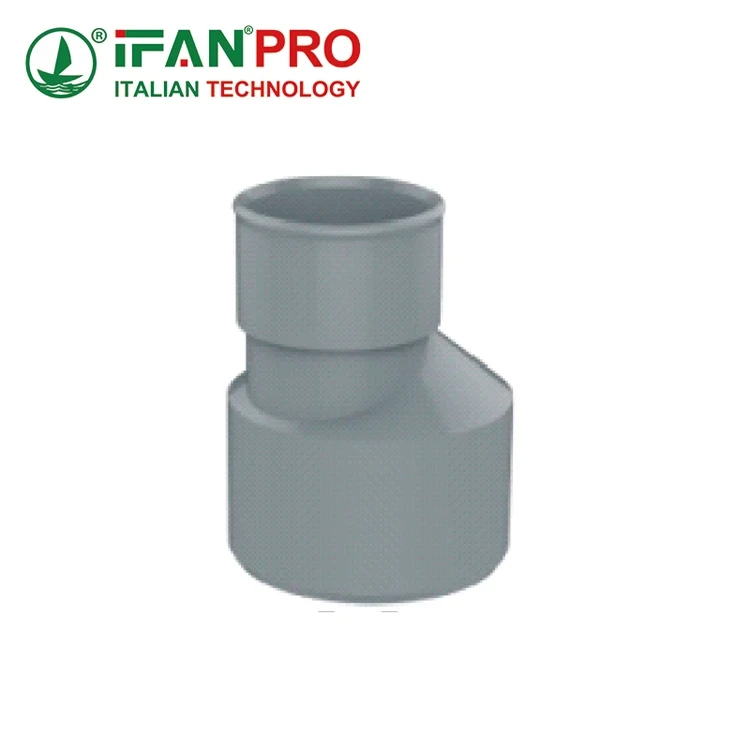

A 2 Inch Female to 1.5 Inch Male threaded PVC reducer connects a larger female-threaded port to a smaller male-threaded pipe. It is commonly used to adapt pump outlets, water heater connections, and filter systems, or to step down pipe sizes within a pressurized irrigation, industrial, or residential plumbing system.

Let’s take a closer look at where you will find this essential fitting and how to use it correctly.

Where are female to male PVC reducers commonly used in plumbing systems?

You might think this is a niche fitting, but in our daily work at IFAN, we see them solving connection problems everywhere.

Female-to-male PVC reducers are commonly used at transition points where equipment with a fixed port size needs to connect to a different sized pipe. Typical spots include pump discharges, water heater inlets/outlets, pressure tank connections, filter housings, and reducing main lines to smaller branch lines in both irrigation and building supply systems.

Connecting to Equipment and Appliances

This type of reducer is a problem-solver. Its design lets you connect two different threaded sizes while also switching between female (internal) and male (external) threads.

First, think about water pumps. Many pumps come with a specific discharge outlet size, like a 2-inch female threaded port. But your existing pipeline might be 1.5 inches. Screwing a 2″ female x 1.5″ male reducer directly into the pump allows you to connect the smaller pipe seamlessly. You will see the same situation with water heaters, pressure tanks, and large filter canisters. These appliances often have larger ports, and you need to reduce down to the standard pipe size in your house or facility.

Managing System Pressure and Flow

Second, these reducers are key for managing water flow and pressure in a system. For example, in an irrigation system, the main supply line from the source might be 2 inches to carry a high volume of water. When that line needs to feed a smaller zone with sprinklers that use 1.5-inch pipes, you install a reducer. Placing it at the branch point efficiently steps down the line size. This is more reliable and leak-proof than trying to connect mismatched sizes with other methods.

Common Use Case Scenarios

Here is a table of common specific uses we see for the 2″x1.5″ size:

| Application | Typical Use | Reason for Reducer |

|---|---|---|

| Water Pump Setup | Connecting a 2″ pump outlet to a 1.5″ discharge pipe. | Pumps often have larger outlets for efficiency; plumbing may be smaller. |

| Water Heater Connection | Adapting the 1.5″ heater port to a 2″ supply line, or vice-versa. | Heater and home pipe sizes often don’t match perfectly. |

| Irrigation Mainline | Reducing from a 2″ main line to a 1.5″ lateral line. | Controls flow and pressure to different zones. |

| Industrial Filtration | Connecting a 2″ filter housing to smaller process piping. | Equipment ports are standardized; plant piping is custom. |

Finally, they are invaluable for repairs and modifications. If you need to replace a section of old 2-inch galvanized pipe with new 1.5-inch PVC, a threaded reducer makes this connection straightforward. The female end screws onto the old pipe, and the new PVC pipe screws into the male end. This avoids the need to completely re-thread or replace entire sections of pipe.

How do you ensure a tight seal when installing a threaded PVC reducer?

A leaking threaded connection is a common headache. I’ve learned that the right technique is everything for a permanent seal.

To ensure a tight seal, first wrap PTFE thread seal tape or apply a quality pipe thread sealant (pipe dope) clockwise around the male threads. Then, hand-tighten the connection as much as possible before using a wrench for the final 1-2 turns, being careful not to over-tighten and crack the PVC fitting.

The Importance of Proper Sealing

Threaded PVC connections are not naturally watertight. The threads are designed to hold the pieces together, but the spirals create tiny paths for water to escape. Your job is to fill these gaps with a sealing material. Doing this wrong is a major cause of leaks and callbacks.

First, you must choose the right sealant. For PVC threads, you have two good options:

- PTFE Tape (Thread Seal Tape): This is a white, non-sticky tape. It is clean, easy to use, and doesn’t harden, allowing for future adjustments. It’s ideal for most residential applications.

- Liquid Pipe Thread Sealant (“Pipe Dope”): This is a paste. Use a sealant labeled for use with plastic pipes. Some standard sealants can contain chemicals that degrade PVC over time. Paste can be better for irregular threads or higher pressure.

Step-by-Step Sealing Process

Here is the reliable process we recommend to our clients:

Step 1: Prepare the Threads. Make sure the male and female threads are clean, dry, and free of dirt or old sealant. A quick wipe with a cloth is enough.

Step 2: Apply the Sealant.

- If using PTFE Tape: Hold the male thread end facing you. Start wrapping at the second thread from the end. Wrap the tape clockwise (as you look at the end). This direction ensures the tape doesn’t unravel when you screw the fitting on. Overlap each wrap by about 50%. Use 3-5 wraps for a good seal.

- If using Pipe Dope: Apply a steady, even bead around all the male threads. Don’t block the first thread at the very end, as this can cause the sealant to squeeze into the pipe.

Step 3: Make the Connection. Start by screwing the fitting together by hand. You should be able to turn it several times easily. If it gets hard immediately, you may have cross-threaded it. Stop, unscrew, and start again.

Step 4: Final Tightening. Once hand-tight, use a wrench. Grip the hex base of the reducer fitting, not the pipe. Give it a final turn or two—just enough to seat it firmly. A common mistake is to over-tighten. PVC is strong but can crack under extreme stress. You should not need to use excessive force.

Tools and Materials Checklist

| Item | Purpose | Consejo |

|---|---|---|

| PTFE Tape | Creates a lubricating, gap-filling seal. | Use the pink or blue “high-density” tape for a better seal. |

| Pipe Dope for Plastic | Paste sealant for threads. | Ensure it says “Safe for Plastic” or “For All Pipes.” |

| Adjustable Wrench | For final tightening. | Use a second wrench to hold the opposing fitting steady. |

| Clean Rag | To wipe threads clean. | Essential for a good bond with the sealant. |

Remember, the goal is a seal that holds under pressure, not the absolute tightest physical connection. A properly sealed joint will last for years without issue.

What are the compatibility considerations for PVC reducers with other pipe materials?

Mixing pipe materials incorrectly is a recipe for failure. We help clients avoid this costly mistake every day.

Key compatibility considerations include thread standards, thermal expansion rates, and galvanic corrosion. PVC reducers can connect to metals like steel or brass using the right sealant, but direct connection to CPVC for hot water may fail. Always use a dielectric union when connecting PVC to dissimilar metals to prevent electrolytic corrosion.

Understanding Thread Standards

Not all 2-inch threads are the same. The most important rule is to match the thread type. PVC fittings in the US and many other markets typically use NPT (National Pipe Taper) threads. This means the threads themselves are slightly tapered, which helps create a tighter seal as you screw them together.

If you try to connect a PVC NPT fitting to a fitting with straight (parallel) threads or a different thread standard (like BSPP common in some regions), it will not seal properly and will almost certainly leak. Before you buy, confirm the thread standard of both the equipment and the reducer. At IFAN, we clearly label all our products with their thread standard to prevent this confusion.

Connecting to Different Materials

PVC reducers often act as a bridge between different materials. Here’s what you need to know:

Connecting to Metal (Steel, Brass, Copper): This is common. You can screw a PVC male thread into a female metal port, or a metal male thread into a PVC female port. However, you must be cautious:

- Sealant: Use a sealant compatible with both materials. PTFE tape is usually safe.

- Over-tightening: Metal is much harder than PVC. If you use a wrench on the metal part to tighten, you can easily crack the PVC. Always grip the PVC fitting’s hex base with your wrench when tightening.

- Corrosion (The Biggest Risk): When dissimilar metals are in contact in water, they can create a galvanic cell, causing the more active metal (like steel) to corrode rapidly. Even though PVC is not a metal, the water inside can carry ions.

The Critical Role of Dielectric Unions

The solution is a dielectric union. This is a special fitting with a plastic sleeve or rubber gasket that physically separates the metal and plastic, breaking the electrical path that causes corrosion. Whenever you connect PVC piping directly to a steel pipe, water heater, or pump, installing a dielectric union is a standard best practice and often required by code.

Connecting to Other Plastics (CPVC, PEX):

- CPVC: You can thread PVC and CPVC together, but remember their temperature ratings differ. CPVC handles hotter water. This joint is fine for cold water, but for hot water lines, using a CPVC adapter might be safer long-term.

- PEX: PEX is not threaded. To connect a PVC reducer to PEX, you need a PEX adapter—a fitting that has male or female threads on one end and a barbed or compression connection for PEX on the other.

Compatibility Quick Guide

| Tipo de conexión | Compatible? | Key Consideration | Recommended Solution |

|---|---|---|---|

| PVC to Steel Pipe | Yes, with caution. | Risk of galvanic corrosion and over-tightening. | Use a dielectric union. Hand-tighten + 1-2 wrench turns on PVC side only. |

| PVC to Brass Fitting | Yes. | Brass is softer; less risk of cracking PVC. Still, avoid over-tightening. | Use PTFE tape. Grip the PVC fitting during tightening. |

| PVC to CPVC | Yes, for threads. | Temperature rating mismatch for hot water. | Ensure application is within PVC’s temperature limit (<140°F/60°C). |

| PVC to PEX | Not directly. | PEX requires a different connection method. | Use a threaded PEX adapter between the reducer and PEX tubing. |

How can you verify the quality and pressure rating of a PVC threaded reducer?

A failed fitting under pressure can cause major damage. Never just assume it’s strong enough—always verify.

You verify quality and pressure rating by checking for clear markings on the fitting itself, reviewing the manufacturer’s certification documents, and inspecting the product for defects. Look for the ASTM standard (like D2464 or D2466), the pressure rating (e.g., SCH 80), the manufacturer’s name, and the NSF certification mark for potable water use.

Reading the Physical Markings

A reputable manufacturer molds crucial information directly onto the fitting. Before you install it, take a moment to look for these marks, usually found on the hex body:

- Material Standard: This will be something like “ASTM D2464” or “ASTM D2466“. D2464 is the standard for Schedule 80 threaded fittings, which are thicker and stronger. D2466 is for Schedule 40 fittings. Schedule 80 is the standard for pressure applications and is what we primarily supply at IFAN for threaded products.

- Size Designation: It should clearly say “2 x 1.5” or similar.

- Pressure Rating: It may say “SCH 80” or include a pressure rating like “220 PSI @ 73°F“. This is the cold water pressure rating. Remember, the rating drops significantly with hot water.

- Manufacturer’s Name/Logo: A known brand or trademark is a good sign.

- Certification Marks: For drinking water applications, look for the NSF-pw or NSF-61 mark. This means the material is certified not to leach harmful chemicals into water.

Inspecting for Manufacturing Quality

Good markings mean little if the product is poorly made. Conduct a simple visual and physical inspection:

- Visual Check: Look for consistent color and a smooth finish. There should be no discoloration, burn marks (from overheating during molding), or excessive “flash” (thin, ragged edges of plastic along the seam lines).

- Thread Inspection: The threads should be clean, sharp, and even. Run your finger over them (carefully). They should feel consistent, not stripped, crossed, or malformed. Try screwing a compatible fitting on by hand; it should start smoothly.

- Wall Thickness: While you can’t measure it precisely, a Schedule 80 fitting should feel substantially heavier and more robust than a thin, cheap imitation.

Understanding Pressure Ratings and Standards

The pressure rating is not a random number. It comes from strict testing outlined in the ASTM standard. A fitting marked “SCH 80” has a defined minimum wall thickness and is pressure-rated accordingly. Here is a simplified comparison:

| Fitting Type | Common ASTM Standard | Typical Pressure Rating (Cold Water) | Best Use Case |

|---|---|---|---|

| Schedule 40 Threaded | D2466 | Lower (e.g., 120-150 PSI) | Low-pressure drainage, some non-critical irrigation. |

| Schedule 80 Threaded | D2464 | Higher (e.g., 220-315 PSI) | Standard for pressurized water lines, irrigation, industrial use. |

| Gray Electrical PVC | Not for pressure | NOT RATED FOR PRESSURE | Electrical conduit only. Never use for plumbing. |

A Critical Warning: Never use electrical conduit PVC fittings (usually gray) for plumbing. They are made to different standards, have thinner walls, and can catastrophically fail under water pressure. Always use white or cream-colored fittings marked for pressure.

Requesting Documentation

For large B2B projects, your supplier should provide documentation. Ask for:

- Material Test Certificates (MTC): These lab reports confirm the material meets the claimed ASTM standard.

- NSF Certification Proof: Documentation showing the product is certified for potable water.

At IFAN, we provide these documents to our professional clients as part of our quality assurance service, giving you total confidence in the product’s specifications.

Conclusión

Choosing the right threaded reducer ensures a leak-free, durable, and safe connection. For reliable, clearly marked, and certified Schedule 80 PVC fittings like these reducers, source your project from IFAN. We provide the quality documentation and expert support you need.

Comentarios recientes