As the demand for high-performance, sustainable piping systems grows, PPR (Polipropileno Copolímero Aleatorio) has become a go-to material across residential, commercial, and industrial plumbing projects in the United States. But if you’re a contractor, distributor, or project manager sourcing PPR piping, you may wonder:

What types of PPR systems do U.S. suppliers typically offer?

In this article, we’ll break down the most common types of PPR systems available from American suppliers, their applications, and what to look for when sourcing reliable products—especially if you’re considering bulk imports or OEM partnerships.

🧩 1. Hot and Cold Water PPR Piping Systems

This is the most widely used type of PPR system in the USA, designed for:

- Residential plumbing

- Commercial buildings

- Schools and hospitals

✅ Features:

- Temperature resistance up to 95°C (203°F)

- Excellent chemical and corrosion resistance

- Smooth inner surface for reduced pressure loss

U.S. suppliers typically offer:

- PN20 or PN25 pipes (for high-pressure hot water)

- Matching PPR fittings (elbows, tees, couplings)

- Green or white pipe color options

🌡️ 2. PPR HVAC & Central Heating Systems

PPR is an excellent material for central heating and HVAC due to its thermal efficiency.

These systems often include:

- PPR-aluminum composite pipes (PPR-AL-PPR) for added strength and thermal stability

- Special PPR fittings for boiler connections and radiator loops

- Insulated pipe versions for energy conservation

These systems are popular in northern U.S. states where hydronic heating is widely used.

💧 3. PPR Plumbing for Chemical and Industrial Use

Industrial facilities in the U.S. require PPR piping systems for:

- Compressed air

- Aggressive chemical transport

- Food and beverage production

✅ PPR offers:

- Excellent resistance to acids, alkalis, and organic solvents

- Non-toxic, hygienic properties (important for food-grade systems)

U.S. suppliers may offer reinforced PPR pipes and specialty fittings tailored for chemical resistance and durability.

🚿 4. PPR Drainage and Waste Systems

Although PPR is not as common in drainage as PVC or HDPE, some U.S. suppliers provide:

- Low-pressure PPR drainage systems for hospitals, labs, and commercial kitchens

- High-temperature waste discharge systems

These systems are ideal for applications requiring corrosion-free, odor-resistant drainage performance.

🔄 5. PPR-PVC Transition Systems

Many U.S. construction projects involve upgrading from PVC to PPR. To support this, suppliers often carry:

- PPR-PVC transition adapters

- Threaded unions and reducers

- Hybrid connectors

✅ These fittings help bridge the gap between existing infrastructure and modern PPR installations.

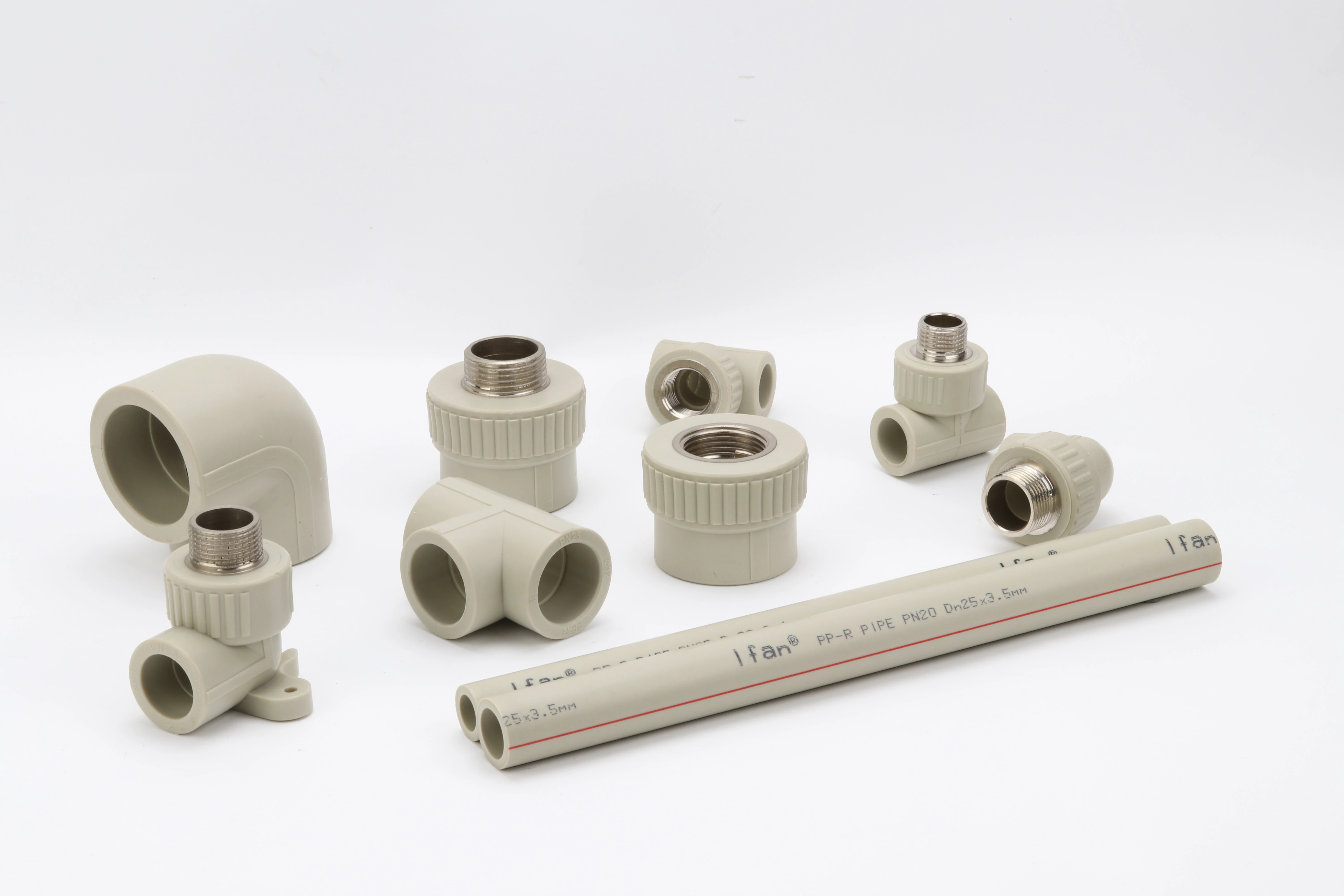

🛠️ 6. Complete Installation Kits and System Packages

Some American PPR suppliers offer complete system packages, including:

- Pipes + fittings + welding tools

- Mounting brackets and pipe clamps

- Installation guides and manuals

These bundles are convenient for plumbing contractors and project tenders, ensuring everything meets local standards.

📦 Sourcing Tip: Consider Importing from Certified Manufacturers

If you’re a U.S. distributor or contractor looking to optimize cost without compromising quality, importing from a reliable international partner like ifanpro can be a smart choice.

ifanpro, based in China, specializes in:

- Manufacturing full PPR pipe and fitting systems

- DIN 8077/8078 & ISO 15874 certified products

- OEM & private label customization

- Competitive wholesale pricing and fast global shipping

They are trusted by wholesalers, government contractors, and EPC companies across Europe, Latin America, and the USA.

🏁 Conclusion

U.S. PPR system suppliers offer a wide variety of solutions tailored for different applications—from residential hot water systems to industrial chemical piping. As the demand for sustainable, non-toxic, and long-lasting plumbing materials grows, PPR continues to gain traction in the American market.

Whether you source locally or import from certified international factories like ifanpro, choosing the right PPR system ensures performance, compliance, and long-term value for your project or business.

Comentarios recientes