I once consulted on a failed industrial heating line. The culprit was a pipe that couldn’t handle constant heat and pressure, a costly lesson in why material ratings matter.

The 121UC rating is suitable for demanding applications because it certifies that a plastic pipe can withstand continuous internal pressure at 121°C (250°F) for its entire 50-year design life. This dual guarantee of extreme temperature and long-term pressure resistance makes it a reliable choice for the most challenging hot water and industrial fluid systems.

This rating isn’t just a marketing term; it’s a promise backed by rigorous science. Therefore, let’s explore what this number truly means and why it separates ordinary pipes from those built to last.

What Long-Term Strength Tests Define the “UC” (Long-term Hydrostatic Strength) Class?

When clients ask about pressure ratings, I show them test data, not just a brochure. The “UC” class is earned through one of the most demanding tests in plastics.

The “UC” (Ultra Constant) class is defined by long-term hydrostatic strength tests per the ISO 15874 standard. Pipes are subjected to constant, high internal water pressure at elevated temperatures (like 110°C) for thousands of hours. The test data predicts the material’s strength over a 50-year lifespan at its rated temperature and pressure, ensuring it won’t fail prematurely.

The Science Behind the 50-Year Promise

You cannot fast-forward 50 years to see if a pipe will last. So, how do we know? Engineers use a principle called “time-temperature superposition.” They stress the material at higher temperatures to accelerate the aging process. For example, a pipe that survives 1,000 hours under extreme conditions provides data to predict its performance for decades under normal use.

The test for a UC-rated pipe, such as one classified as 121UC, involves multiple stages. First, technicians test pipes at different high temperatures (e.g., 95°C, 110°C). Next, at each temperature, they apply a constant internal water pressure. Then, they record how long it takes for the pipe to rupture at each temperature-pressure combination. Finally, using this data, they plot a graph (a stress regression line) that predicts the maximum sustained pressure the pipe can handle at its rated temperature (121°C) for 50 years (438,000 hours).

Understanding the “Class” System

The “UC” is part of a broader classification system (Class 0, 1, 2, 3, 4, 5) for hot water pipes. Generally, a higher class number indicates a higher rated temperature for long-term use. For example:

- Class 1: Rated for 60°C for 49 years, 80°C for 1 year.

- Class 5: Rated for 90°C for 49 years, 100°C for 1 year.

- 121UC (Beyond Class 5): Rated for 110°C for 49 years, with a peak capability of 121°C for 100 hours. This is for specialized, high-demand applications.

This table simplifies the key differences:

| Test Parameter | Standard Hot Water Pipe (e.g., Class 5) | 121UC Rated Pipe |

|---|---|---|

| Long-Term Test Temperature | Lower (e.g., 90°C) | Significantly Higher (110°C) |

| Predicted Lifespan at Rated Temp | 50 years | 50 years |

| Peak/Surge Temperature Rating | Lower (e.g., 100°C) | 121°C |

| Intended Use | Domestic hot water, underfloor heating | Industrial process lines, high-temperature central heating, demanding commercial systems |

In short, the UC classification is a data-driven guarantee. It tells you that the pipe has been tortured under extreme lab conditions to prove it will perform safely for a lifetime in your most demanding application.

How Does the 121°C Temperature Rating Account for Safety Margins and Peaks?

In real-world systems, temperatures are never perfectly constant. The 121°C rating provides a crucial buffer for these unpredictable moments.

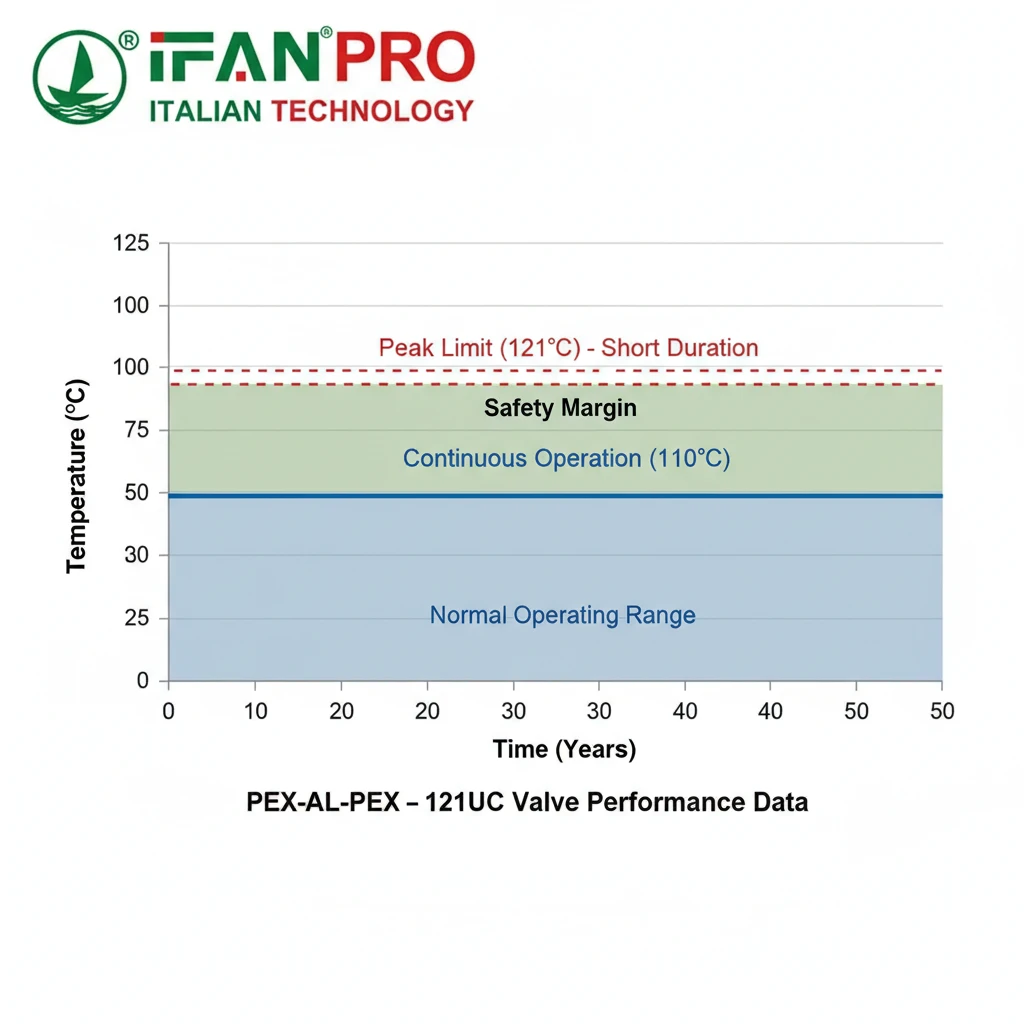

The 121°C temperature rating incorporates a safety margin by defining two limits: a long-term maximum operating temperature (110°C for 49 years) and a short-term peak temperature (121°C for up to 100 hours). This design accounts for system malfunctions, heat spikes, and sterilization cycles without causing permanent damage to the piping.

The Two-Tiered Safety Approach

A pipe rated only for a continuous temperature would be risky. Boiler thermostats can stick, solar thermal systems can stagnate, or industrial processes can have brief surges. Therefore, the 121UC rating is engineered for these realities.

- The Long-Term Floor (110°C): This is the continuous service temperature. The pipe is designed and tested to operate at this temperature for virtually its entire 50-year life with no significant loss of strength. Consequently, your system should be designed to run below this point for normal operation.

- The Short-Term Ceiling (121°C): This is the emergency or peak rating. It allows the system to survive temporary over-temperature events. The standard typically allows for this peak to occur for up to 100 hours over the pipe’s lifetime. This covers scenarios like a pump failure causing water stagnation in a solar loop, or a quarterly high-temperature flush in a process line.

Why This Margin is Critical for System Design

This built-in safety margin solves major pain points for engineers and facility managers. For instance, it prevents catastrophic failure. Without this peak rating, a small temperature excursion could lead to immediate pipe softening, deformation, and burst. Additionally, it reduces maintenance costs by allowing the system to survive minor control errors without needing pipe replacement. Finally, it enables practical design, giving designers flexibility. They don’t have to specify a vastly over-designed system just to handle once-a-year peak events.

Consider a hospital’s hot water system for sterilization. Normally, it runs at 105°C. But during a periodic super-heat cycle to ensure complete sterilization, the temperature might spike to 118°C. A standard Class 5 pipe (rated for 100°C peaks) would be at risk. In contrast, a 121UC pipe operates comfortably within its proven safety margin, ensuring reliability and safety.

Why is This Rating a Benchmark for Quality in Pressurized Hot Water Systems?

In our projects, specifying 121UC-rated components ends debates about pipe quality. It’s an objective, international standard that separates proven performers from the rest.

The 121UC rating is a benchmark for quality because it is an internationally standardized (ISO) performance grade, not a brand name. It provides a universal, comparable standard for engineers and buyers. It signals that the manufacturer uses high-grade virgin materials and advanced production processes to achieve this top-tier performance level.

A Universal Language for Engineers

Imagine an engineer in Germany, a contractor in the Middle East, and a buyer in Southeast Asia working on the same project. They need a common reference point for quality. The 121UC rating provides exactly that. Essentially, it’s a specification that is understood globally, ensuring everyone is aligned on the minimum performance requirements.

This standardization prevents the “apples to oranges” problem when comparing quotes. For example, one supplier might claim their pipe is “good for high heat,” while another offers a 121UC-rated pipe. The latter provides a clear, testable claim, while the former is just a vague promise.

What It Reveals About Manufacturing

Achieving the 121UC rating is not easy. Specifically, it requires:

- Premium Raw Materials: Only high-quality, heat-stabilized polypropylene random copolymer (PP-R) can pass the long-term hydrostatic tests at 110°C.

- Precision Production: The pipe extrusion must be incredibly consistent. Any variation in wall thickness or material density will create a weak point that fails during the prolonged test.

- Rigorous In-House Testing: Reputable manufacturers like IFAN conduct these long-term tests internally to validate their products before seeking external certification.

Therefore, when you see the 121UC rating, you are not just seeing a performance number. More importantly, you are seeing evidence of a manufacturer’s commitment to material science, process control, and quality assurance. As a result, it shifts the conversation from subjective claims to objective, verified engineering data.

Which Industries and Standards Mandate the Use of 121UC Rated Components?

This rating isn’t for every home bathroom. It’s specified where failure is not an option, driven by strict industry codes and painful lessons learned.

Industries and standards mandate 121UC rated components where system failure poses high safety, financial, or operational risks. Key sectors include industrial process piping, district energy systems, healthcare facilities, and naval/shipping. Standards like ISO 15874, DIN 8077/78, and various national building codes for high-temperature applications often reference or require such performance classes.

High-Stakes Industries that Rely on 121UC

The cost of a pipe failure in these environments goes far beyond the price of the pipe itself.

- Industrial Process Piping: Chemical plants, food & beverage processing, and manufacturing facilities often have closed-loop systems carrying hot water, glycol solutions, or mild chemicals at high temperatures. A leak can stop production, cause product loss, and create safety hazards.

- District Heating & Cooling (DHC) Networks: These are the arteries of centralized heating for cities or large campuses. Pipes are buried underground, often under streets and buildings. A failure requires massively expensive excavation and repair, disrupting service to hundreds or thousands of users. Thus, the 121UC rating ensures long-term integrity.

- Healthcare & Laboratory Facilities: Hospitals need reliable high-temperature water for sterilization (CSSD), laundry, and infection control. Labs use it for clean steam and process lines. System downtime directly impacts patient care and critical research.

- Marine & Offshore Applications: On ships and offshore platforms, space is tight, and systems are exposed to vibration and critical service conditions. Pipes must be extraordinarily reliable to prevent failures that could endanger the vessel or crew.

Governing Standards and Codes

These industries don’t operate on guesswork. Instead, they follow strict codes. While the 121UC classification itself comes from ISO 15874, it is invoked or required by many other specifications:

| Industry / Application | Relevant Standards/Codes | Why 121UC is Specified |

|---|---|---|

| General High-Temp Plumbing | ISO 15874, ASTM F2389 | Provides a clear, high-tier performance criterion for system designers. |

| District Heating Pipes | EN 14111, National DHC Guidelines | Ensures 50-year lifespan for buried, inaccessible assets with high thermal stress. |

| Tuberías industriales | Owner-specific Engineering Specifications (based on ASME B31.3 etc.) | Meets the demanding “fit-for-purpose” requirements for process safety and reliability. |

| Marine Applications | Ship Classification Society Rules (e.g., DNV, ABS, Lloyd’s Register) | Satisfies stringent material approval processes for critical shipboard systems. |

For procurement managers and engineers, specifying “121UC per ISO 15874” in your tender documents immediately filters out suppliers who cannot meet this proven, high-performance standard. Ultimately, it de-risks the project from the very beginning.

Conclusión

In summary, the 121UC rating guarantees exceptional long-term strength and temperature resistance for critical systems. For reliable 121UC-rated PP-R pipes and fittings that meet global standards, choose IFAN for your demanding industrial and commercial projects.

Comentarios recientes