Introduction:

Radiant floor heating systems have long been cherished for their ability to provide consistent warmth and comfort while reducing energy consumption. With the advent of PEX (Cross-linked Polyethylene) pipeline technology, these systems have undergone a remarkable transformation. PEX pipelines offer enhanced performance, durability, and versatility. In this article, we’ll explore how PEX pipelines have revolutionized radiant floor heating systems. We will also discuss how they have made these systems more efficient, cost-effective, and environmentally friendly.

Flexibility and Versatility of PEX Pipeline

1.1 PEX: The Ideal Material for Radiant Heating

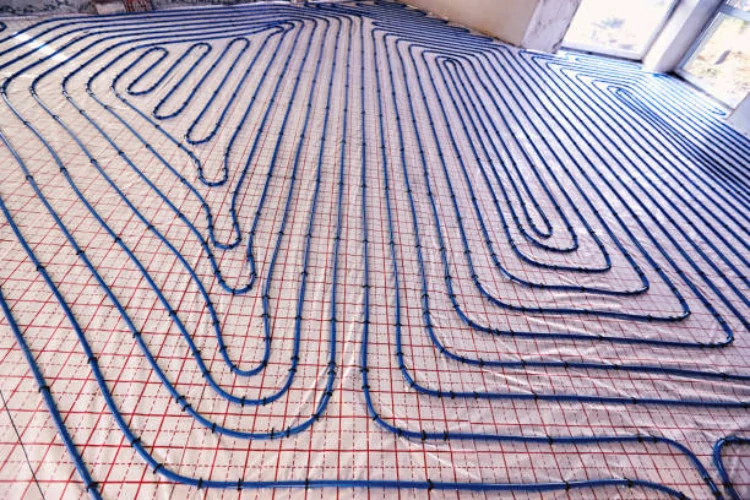

PEX pipeline’s flexibility and versatility make it an ideal choice for radiant floor heating systems. Unlike rigid metal pipes, PEX can be easily bent and curved to conform to the contours of any space, whether it’s a residential home, commercial building, or industrial facility. This flexibility allows for seamless installation under flooring materials such as tile, wood, laminate, or carpet, without the need for extensive modifications or structural changes.

1.2 Customizable Layouts and Zoning Options

Another advantage of PEX pipeline in radiant heating systems is its ability to accommodate customizable layouts and zoning options. With PEX, installers can design intricate piping configurations tailored to the specific heating requirements of each room or area. This zoning capability enables independent temperature control and energy management, allowing occupants to optimize comfort levels while minimizing energy waste and operating costs.

1.3 Compatibility with Various Heat Sources

PEX pipeline works with various heat sources, such as traditional boilers, geothermal heat pumps, solar collectors, and waste heat recovery systems. This adaptability makes PEX ideal for new construction and retrofit projects, allowing property owners to integrate radiant floor heating into existing HVAC systems or renewable energy setups seamlessly.

Enhanced Performance and Energy Efficiency

2.1 Uniform Heat Distribution and Comfort

A key benefit of PEX in radiant heating systems is its ability to deliver uniform heat distribution across the entire floor. Unlike forced-air systems that create temperature stratification and uneven heating, radiant floor heating provides consistent warmth from the ground up, eliminating cold spots and maximizing comfort.

2.2 Energy Efficiency and Cost Savings

PEX pipeline contributes to the energy efficiency of radiant heating systems by minimizing heat loss and reducing energy consumption. The thermal conductivity of PEX allows heat to transfer efficiently from the circulating water to the floor surface, maximizing heat output while minimizing energy input. This efficiency translates into lower utility bills and reduced environmental impact, making radiant floor heating an eco-friendly and sustainable heating solution.

2.3 Enhanced Durability and Longevity

In addition to performance benefits, PEX pipeline offers enhanced durability and longevity compared to traditional metal pipes. PEX is highly resistant to corrosion, scale buildup, and chemical degradation, ensuring long-term reliability and maintenance-free operation. With proper installation and routine maintenance, PEX radiant heating systems can provide decades of trouble-free service, offering property owners peace of mind and a solid return on investment.

Conclusion:

PEX pipeline has transformed radiant floor heating systems with its flexibility, efficiency, and performance. Customizable layouts, zoning options, energy efficiency, and durability have redefined heating in homes, businesses, and institutions. As demand for sustainable heating grows, PEX remains at the forefront, advancing comfort, efficiency, and environmental stewardship. Embracing PEX technology offers superior comfort, lower energy costs, and a greener future.

IFAN es un fabricante chino de tuberías, accesorios y válvulas de plástico con 30 años de experiencia. Si está interesado en IFAN accesorios de cobre, válvulas de cobre, tuberías y accesorios de plástico, póngase en contacto con nosotros. IFAN le ofrece una variedad de tuberías estándar para satisfacer sus necesidades específicas. Haga clic a continuación para obtener más información sobre la amplia gama de productos de válvulas y productos relacionados con sistemas de tuberías asequibles y rentables de IFAN.

Responderemos a su correo electrónico o fax en 24 horas.

Puede llamarnos en cualquier momento si tiene alguna duda sobre nuestra producción.

Para más información, visite nuestra página web https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Comentarios recientes