Understanding PE Fittings and Their Role in Piping Systems

Introduction to PE Fittings

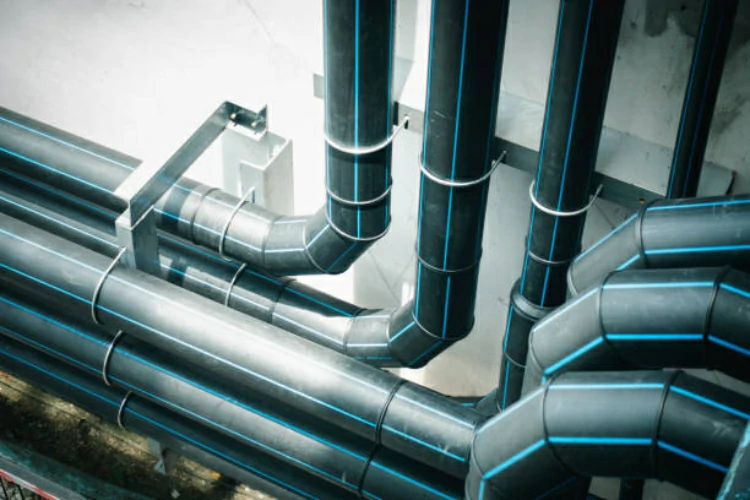

PE fittings, alternatively termed as Polyethylene fittings, serve as crucial components within numerous piping systems. They facilitate the connection of PE pipes, ensuring secure and leak-proof joints for a wide array of applications, including water supply, irrigation, gas distribution, and industrial processes.

Key Features of PE Fitting

PE fittings offer several distinctive features that set them apart from other pipe materials:

Flexibility and Durability

PE fittings exhibit flexibility and durability, enabling them to endure bending, impact, and environmental stresses without succumbing to cracking or breaking. This inherent flexibility renders PE fitting suitable for applications prone to ground movement or temperature variations.

Resistencia química

PE fitting exhibit excellent resistance to a wide range of chemicals, acids, and alkalis, making them ideal for use in corrosive environments such as chemical processing plants and wastewater treatment facilities. This chemical resistance ensures the longevity and reliability of PE fittings in harsh operating conditions.

Comparing PE Fitting with PVC and PPR Fitting

Material Composition and Properties

PE Fittings

PE fittings are made from high-density or low-density polyethylene, offering excellent strength, flexibility, and chemical resistance. It are lightweight and easy to handle, making them suitable for both above-ground and underground installations.

PVC Fittings

PVC fittings are constructed from Polyvinyl Chloride, a rigid plastic material known for its chemical resistance and affordability. While PVC fittings are lightweight and easy to install, they may become brittle over time and are susceptible to damage from UV exposure and harsh chemicals.

PPR Fittings

PPR fittings are made from Polypropylene Random Copolymer, a thermoplastic material known for its heat resistance and chemical stability. It offer good mechanical strength and are suitable for hot and cold water applications, but they may be more expensive than PE and PVC fittings.

Applications and Usage Scenarios

PE Fittings

PE fittings are commonly used in water supply, irrigation, gas distribution, and industrial piping systems. They are suitable for both above-ground and underground installations and can withstand a wide range of operating temperatures and environmental conditions.

PVC Fittings

PVC fittings are widely used in plumbing, drainage, and sewage systems due to their affordability and chemical resistance. However, PVC fittings may be less suitable for outdoor applications or environments with high temperatures, as they can become brittle and prone to cracking.

PPR Fittings

PPR fittings are commonly used in hot and cold water supply systems, as well as heating and cooling applications. They offer good chemical resistance and thermal stability, but they may be less flexible than PE fittings and require specialized tools for installation.

Installation and Maintenance Considerations

PE Fittings

PE fittings are relatively easy to install, requiring simple solvent welding or mechanical joining methods. They require minimal maintenance and are resistant to corrosion, rust, and biological growth, reducing the risk of leaks or failures over time.

PVC Fittings

PVC fittings are easy to install using solvent cement or threaded connections, but they may require additional support or protection in outdoor installations to prevent damage from UV exposure or temperature fluctuations. Regular inspection and maintenance are essential to prevent deterioration and ensure the longevity of PVC fittings.

PPR Fittings

PPR fittings require heat fusion welding for installation, which may require specialized equipment and training. While PPR fittings offer good chemical resistance and durability, they may be more susceptible to damage from high temperatures or mechanical stress, requiring careful handling and installation.

Conclusión

In conclusion, PE fittings offer several advantages compared to PVC and PPR fittings, including flexibility, durability, and chemical resistance. While each type of fitting has its own unique properties and applications, PE fitting are well-suited for a wide range of piping systems due to their versatility, reliability, and ease of installation. By understanding the differences between PE, PVC, and PPR fitting, industries can make informed decisions when selecting fitting for their specific needs, ensuring optimal performance and longevity in piping systems.

IFAN es un fabricante chino de tuberías, accesorios y válvulas de plástico con 30 años de experiencia. Si está interesado en IFAN accesorios de cobre, válvulas de cobre, tuberías y accesorios de plástico, póngase en contacto con nosotros. IFAN le ofrece una variedad de tuberías estándar para satisfacer sus necesidades específicas. Haga clic a continuación para obtener más información sobre la amplia gama de productos de válvulas y productos relacionados con sistemas de tuberías asequibles y rentables de IFAN.

Responderemos a su correo electrónico o fax en 24 horas.

Puede llamarnos en cualquier momento si tiene alguna duda sobre nuestra producción.

Para más información, visite nuestra página web https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Comentarios recientes