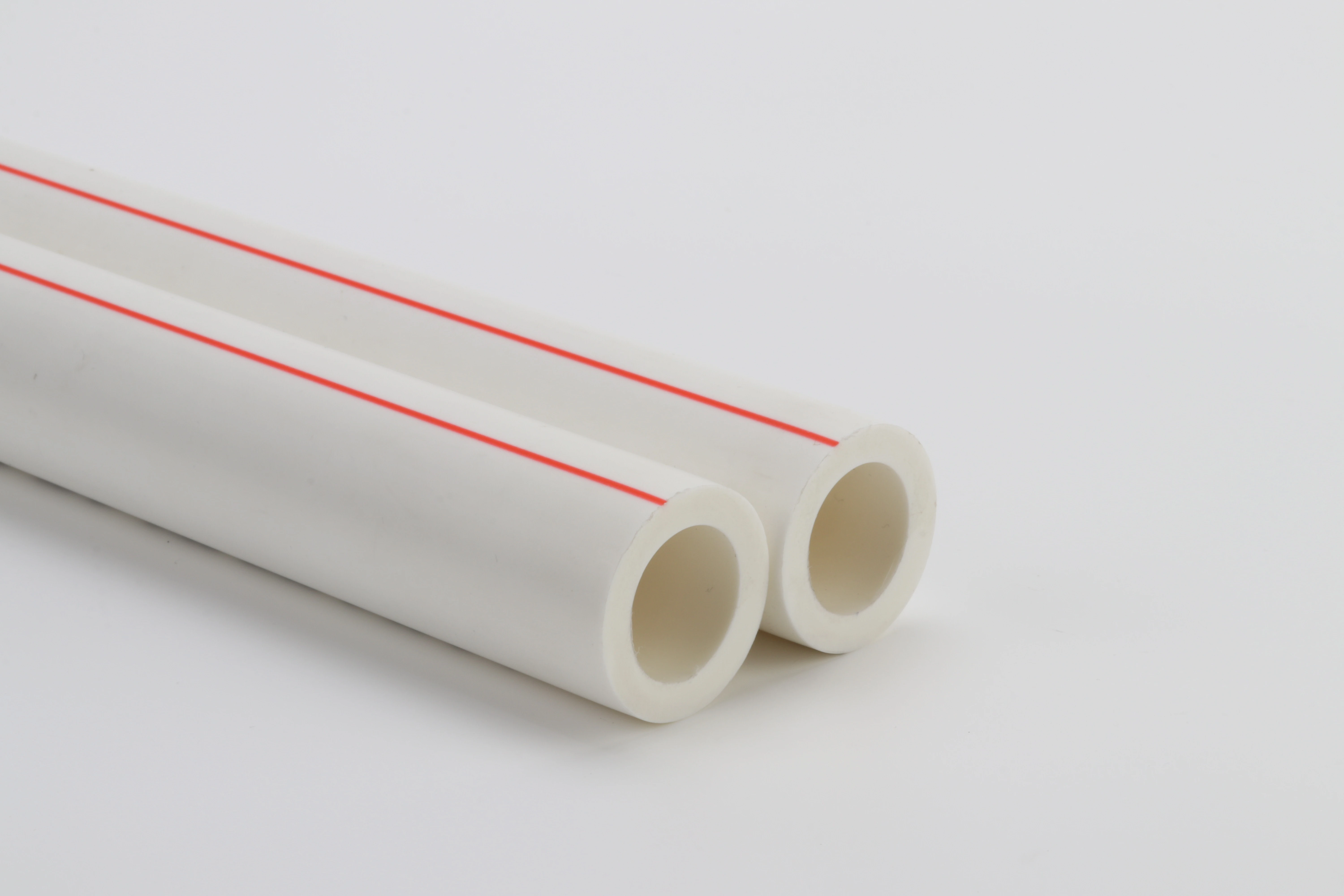

When choosing pipes for your project, strength matters. PPR (Polypropylene Random Copolymer) and PVC (Polyvinyl Chloride) pipes dominate the market. But which material offers superior strength?

PPR pipes generally provide better overall strength than PVC in most applications. The answer depends on how you define “strength.”

Tensile Strength: PPR Takes the Lead

PPR pipes offer higher tensile strength than standard PVC. PPR typically withstands 25-35 MPa of tensile stress. Standard PVC handles 20-25 MPa.

This difference matters during installation. PPR pipes resist cracking under stress better than PVC. They handle thermal expansion without failure.

Impact Resistance: PPR Wins Again

Cold weather reveals a crucial difference. PPR maintains flexibility at low temperatures. PVC becomes brittle below 0°C.

A frozen PPR pipe rarely shatters. A frozen PVC pipe often cracks completely. This makes PPR ideal for outdoor applications.

Pressure Resistance: Both Perform Well

Both materials handle standard water pressure effectively. PPR systems typically operate at 16-25 bar pressure. PVC systems handle 10-16 bar safely.

PPR’s advantage shows in hot water applications. It maintains pressure ratings at higher temperatures. PVC pressure ratings drop significantly when heated.

Chemical Resistance: Material-Specific Advantages

PPR resists most household chemicals excellently. It handles acids, bases, and solvents without degradation. PVC offers good chemical resistance but has limitations.

Certain organic solvents can soften PVC over time. PPR remains stable against these chemicals. This makes PPR better for industrial applications.

Thermal Strength: PPR’s Clear Victory

Temperature performance separates these materials dramatically. PPR operates safely up to 95°C continuously. PVC starts softening around 60°C.

Hot water systems demand PPR’s thermal strength. PVC cannot handle sustained high temperatures. This limitation restricts PVC to cold water applications.

Installation Strength: Different Approaches

PPR uses heat fusion welding for joints. This creates seamless, leak-proof connections. The welded joint often exceeds pipe strength.

PVC relies on solvent welding or mechanical fittings. These joints can become weak points. Proper installation determines long-term strength.

Long-Term Durability Comparison

PPR pipes last 50+ years with minimal degradation. UV radiation barely affects buried PPR systems. Surface exposure requires UV protection.

PVC pipes offer 25-50 year lifespans typically. UV exposure degrades PVC faster than PPR. Indoor installations perform better than outdoor ones.

Cost vs. Strength Analysis

PVC costs less initially than PPR. However, PPR’s superior strength reduces replacement costs. Fewer repairs mean lower lifetime expenses.

PPR’s strength justifies higher upfront investment. The material pays for itself through reliability. Professional installers prefer PPR for critical applications.

Application-Specific Strength Requirements

Choose PPR when you need:

- Hot water distribution

- Industrial chemical transport

- Outdoor installations

- Maximum impact resistance

- Long-term reliability

Choose PVC when you need:

- Cold water systems

- Budget-conscious projects

- Standard residential plumbing

- Easy availability

- Simple repairs

Manufacturing Quality Matters

Not all PPR or PVC pipes offer equal strength. Manufacturing standards vary significantly between producers. Premium manufacturers deliver consistent quality.

Quality control during production affects final strength. Raw material purity impacts performance. Professional pipe manufacturers test every batch thoroughly.

Professional Installation Impact

Proper installation maximizes material strength potential. PPR requires specialized welding equipment. Trained installers ensure optimal joint strength.

PVC installation seems simpler but requires precision. Incorrect solvent application weakens joints permanently. Professional installation protects your investment.

Making the Right Choice

PPR offers superior strength in most measurable categories. Higher tensile strength, better impact resistance, and excellent thermal performance make PPR the stronger choice.

However, “stronger” doesn’t always mean “better” for every application. Consider your specific requirements, budget, and installation conditions.

For hot water systems, PPR’s strength advantage is essential. For cold water applications, both materials provide adequate strength.

Expert Recommendation

Professional pipe manufacturers recommend PPR for demanding applications. The material’s comprehensive strength profile justifies the investment.

Quality matters more than material choice sometimes. Choose reputable manufacturers regardless of material selection. Proper installation ensures maximum strength realization.

Need custom pipe solutions? Professional manufacturers can engineer PPR and PVC systems for specific strength requirements. Custom specifications ensure optimal performance for unique applications.

Looking for high-quality PPR or PVC pipes? Professional pipe manufacturers offer custom solutions, technical support, and reliable products for all applications. Contact experienced suppliers for project-specific recommendations.

Comentarios recientes