I once saw a project delayed for weeks because a small, inexpensive valve failed. The wrong seal material swelled and blocked the line, halting a whole production batch. This taught me that choosing the right mini valve is critical.

To select a mini valve for specific media and pressure, you must systematically match the valve body and seal materials to your fluid, verify the valve’s pressure and temperature ratings exceed your application’s maximums, calculate the required flow coefficient (Cv) to size the valve correctly, and ensure it meets relevant connection standards and industry certifications for safety and compatibility.

This process may seem detailed, but each step prevents costly failures. Let’s break it down into clear, actionable parts.

How Do You Match Valve Body and Seal Material to Your Fluid Media?

Choosing the wrong material is the fastest way to valve failure. I recall a client using a standard rubber seal with a solvent; the seal dissolved in days, causing a leak.

You match valve body and seal material by first identifying all chemicals in your fluid media, including concentrations and temperatures, then consulting chemical compatibility charts from valve manufacturers. The goal is to select materials that are inert and will not corrode, degrade, or contaminate the fluid over the system’s operational life.

Start by Identifying Your Fluid

The first and most important step is to know exactly what fluid will flow through the valve. This seems obvious, but mistakes happen often. You need to list every chemical in the media. Also, note the concentration (percentage in water or solution) and the temperature of the fluid when it contacts the valve. A material that is compatible with a mild acid at room temperature might not be compatible with the same acid at 80°C.

For example, deionized water is very pure, but it can be surprisingly aggressive to some metals. Hydraulic oil has different properties than coolant. Always get the full chemical specification.

Understanding Body and Seal Materials

Next, understand the common options. The valve body provides the main structure, while the seal (often an O-ring, diaphragm, or seat) provides the shut-off.

Common Valve Body Materials:

- Stainless Steel (e.g., SS316): Excellent for a wide range of chemicals, water, and steam. It resists corrosion and is strong. This is a very safe and common choice for industrial applications.

- Brass: Good for water, air, oil, and gas in non-corrosive environments. It is cost-effective but can corrode with certain chemicals like ammonia.

- Plastics (PVC, PP, PTFE): Excellent resistance to many acids, bases, and salts. They are lightweight and cost-effective for corrosive media but have lower pressure and temperature limits than metals.

Common Seal/Elastomer Materials:

- Nitrile (NBR) Rubber: A good general-purpose seal for water, oils, and fuels. It is inexpensive but not suitable for ozone, ketones, or strong acids.

- Ethylene Propylene Diene Monomer (EPDM): Excellent for hot water, steam, alcohols, and mild acids. It is often used in food and pharmaceutical applications.

- Fluorocarbon (FKM/Viton®): Outstanding for high temperatures, oils, fuels, acids, and many chemicals. It is a premium, high-performance material.

- Polytetrafluoroethylene (PTFE): Nearly chemically inert. It works with almost all aggressive chemicals but is less elastic, so it’s often used as a seat material rather than a dynamic seal.

Using Compatibility Charts

Do not guess. Always use a chemical compatibility chart provided by reputable manufacturers. These charts rate materials from ‘Excellent’ to ‘Not Recommended’ for hundreds of chemicals.

Example Material Compatibility Table:

| Fluid Media | Recommended Body Material | Recommended Seal Material | Materials to Avoid |

|---|---|---|---|

| Compressed Air | Brass, Stainless Steel | NBR, EPDM, FKM | Avoid brass with ammonia-laden air. |

| Hot Water (90°C) | Brass, Stainless Steel | EPDM | Avoid NBR (degrades with heat). |

| Hydraulic Oil | Steel, Stainless Steel | NBR, FKM | Avoid EPDM (swells in oil). |

| Mild Acid Solution | Stainless Steel 316, PVC | FKM, PTFE | Avoid brass (corrodes). |

| High-Purity Water | Stainless Steel 316, PP | EPDM, PTFE | Avoid brass (can leach metals). |

A Practical Tip from Experience

When in doubt, or if your fluid is a complex mixture, request a sample of the seal material from your supplier for immersion testing. Soak it in your actual media at operating temperature for a week and check for swelling, cracking, or softening. This small test can prevent a major system failure.

What Pressure and Temperature Limits Must Be Checked for Your Application?

Valves have clear ratings; ignoring them leads to leaks or catastrophic bursts. A pump surge exceeding a valve’s pressure rating once caused a dangerous failure in a system I audited.

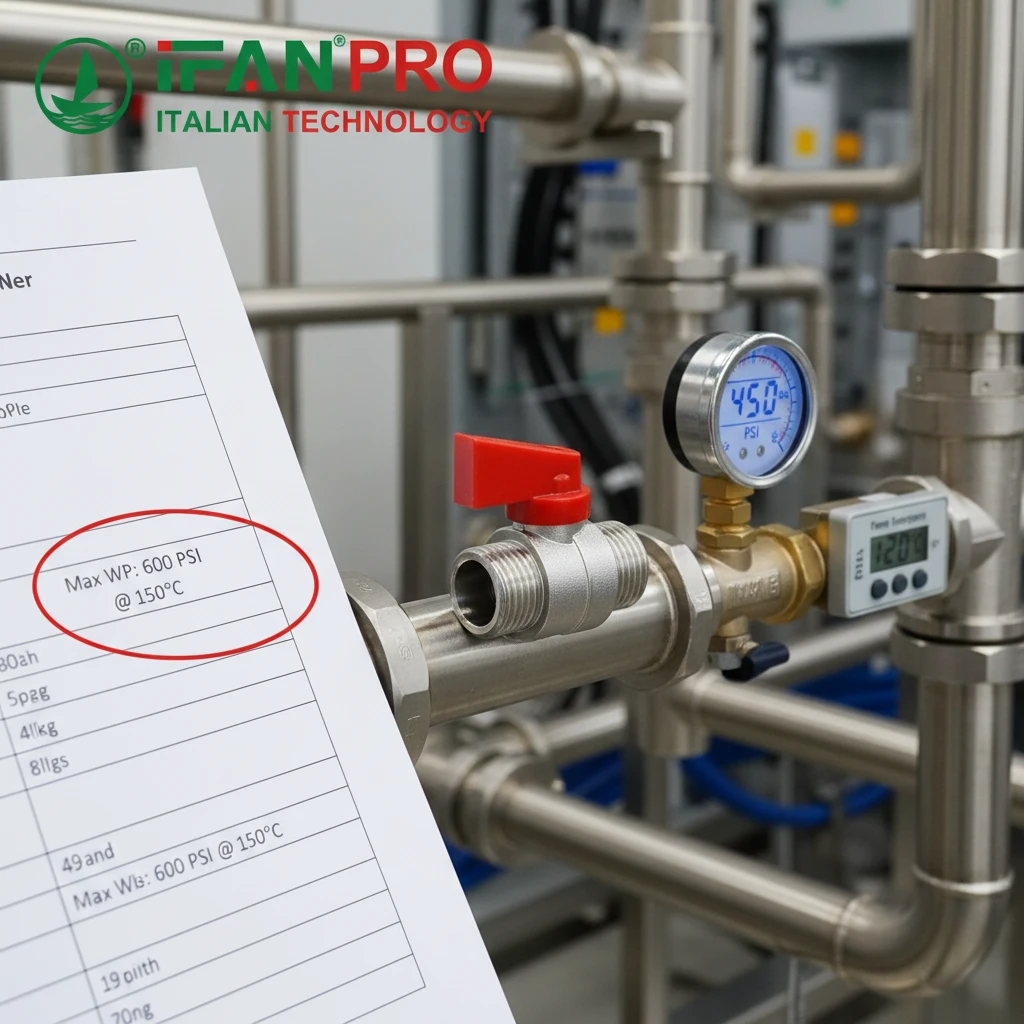

You must check that the valve’s maximum working pressure (PSI or bar) and temperature ratings are higher than the highest expected pressure and temperature in your system. Always include a safety margin, and consider both constant conditions and short-term spikes from surges or startup.

Understanding Valve Ratings

Every proper mini valve comes with clearly stated ratings from its manufacturer. These are not suggestions—they are limits.

- Maximum Working Pressure (MWP): The highest continuous pressure the valve can safely handle.

- Maximum Temperature: The highest fluid temperature the valve materials can withstand without losing strength or sealing ability.

Crucially, pressure and temperature ratings affect each other. A valve rated for 150 PSI at 20°C might only be rated for 100 PSI at 100°C because heat weakens materials. Always check the manufacturer’s chart that shows the pressure rating at your specific operating temperature.

Calculating Your System’s Requirements

To apply these ratings, you must know your own system’s numbers.

- For Pressure: Identify the normal operating pressure from your pump or system specs. Then, add the potential pressure spike. Water hammer, pump surge, or thermal expansion can create spikes much higher than normal pressure. A good rule is to select a valve with an MWP at least 1.5 times your normal system pressure. For systems with large pumps, a factor of 2 or 3 is safer.

- For Temperature: Note the maximum fluid temperature, not the average. Consider startup conditions, process cycles, or external heat sources. Does ambient temperature near an engine or oven affect the valve? The valve’s rating must be above this maximum.

Valve Type and Pressure Drop

The type of valve also impacts pressure handling. A full-port ball valve has a very low pressure drop across it, meaning the pressure on the downstream side is almost the same as upstream. A needle valve or a small-port valve creates a significant pressure drop, which converts pressure energy into heat and turbulence. Ensure the valve body and seal can handle the localized stress and heat from this drop.

Common Mini Valve Pressure/Temperature Guide:

| Valve Type | Typical Max Pressure Range | Typical Max Temp Range (Seal Dependent) | Notes |

|---|---|---|---|

| Mini Ball Valve | High (up to 6000 PSI for steel) | Medium-High | Robust, good for on/off. Low pressure drop. |

| Mini Needle Valve | Very High (up to 10,000 PSI) | High | For precise flow control. High pressure drop. |

| Mini Check Valve | Medium-High | Medium | Pressure rating must exceed system pressure to seal. |

| Plastic Ball Valve | Low-Medium (up to 150 PSI) | Low | Great for corrosive media, but mind the ratings. |

The Importance of Safety Margin

Never select a valve where your maximum operating pressure equals the valve’s maximum rating. This leaves no room for error, sensor inaccuracy, or unexpected events. The safety margin is your insurance policy against unpredictable conditions and ensures a longer, safer valve life.

How Do Flow Rate Requirements Influence the Choice of Valve Size and Type?

Oversizing a valve wastes money and can cause poor control; undersizing it strangles your system. I helped a lab fix a sluggish fluidic system simply by calculating and installing correctly sized valves.

Flow rate requirements directly determine the required valve size through the flow coefficient (Cv) calculation. A higher required Cv means a larger valve port. The flow rate also influences the valve type: needle valves for precise, low-flow control; ball valves for full, fast flow; and check valves to prevent reverse flow at specific rates.

The Key Concept: Flow Coefficient (Cv)

This is the most important number for sizing a valve. The Cv value is defined as: the number of US gallons per minute (GPM) of water that will flow through the valve with a pressure drop of 1 PSI. In simple terms, a valve with a Cv of 1.0 will allow 1 GPM of water to flow if you have 1 PSI of pressure difference from the inlet to the outlet.

You need to calculate the Cv your application requires. The basic formula is:

Cv = Q / √(ΔP / SG)

- Q = Flow Rate (in GPM or L/min)

- ΔP = Pressure Drop across the valve (in PSI or bar)

- SG = Specific Gravity of the fluid (1.0 for water)

Step-by-Step Sizing Process

- Define Your Flow (Q): Determine the maximum flow rate your system needs. This comes from your process requirements (e.g., “deliver 5 liters per minute to the cooling jacket”).

- Define Allowable Pressure Drop (ΔP): How much pressure loss can your system tolerate across the valve? This is critical. In a low-pressure system, a large ΔP is unacceptable. You often work backwards from available pump pressure.

- Calculate Required Cv: Plug your Q and ΔP into the formula. The result is the minimum Cv your valve must have.

- Select Valve Size: Consult manufacturer charts. They list the Cv for each valve size and type (e.g., a 1/4″ needle valve might have a Cv of 0.1, while a 1/4″ full-port ball valve might have a Cv of 3.0). Choose a valve whose Cv is equal to or slightly greater than your calculated requirement.

Example Cv Reference Table:

| Valve Size | Valve Type | Approx. Cv Value | Best For |

|---|---|---|---|

| 1/8″ | Needle Valve | 0.05 – 0.2 | Very precise, low flow control (e.g., instrumentation). |

| 1/4″ | Ball Valve | 2.0 – 4.0 | Full on/off service where minimal flow restriction is needed. |

| 1/4″ | Check Valve | 0.5 – 1.5 | Preventing backflow in lines with moderate flow. |

| 3/8″ | Ball Valve | 5.0 – 8.0 | Higher flow rates for coolant or air lines. |

How Flow Rate Dictates Valve Type

- Needle Valves: These are for fine control of low flow rates. The threaded stem allows you to make tiny adjustments. They have low Cv values. Choose these when you need to carefully meter or throttle flow, like in a sampling line or calibration system.

- Ball Valves: These are for on/off control and higher flow rates. They offer a straight-through port with very little restriction when open (high Cv). They are not designed for precise flow adjustment; they are either open or closed.

- Check Valves: These are for directing flow in one direction only. The cracking pressure (the pressure needed to open them) and the flow rate affect their performance. A swing check valve for high flow behaves differently than a small spring-loaded check for low flow.

Practical Sizing Advice

A common mistake is picking a valve based only on pipe thread size (e.g., “I have a 1/4″ tube, so I need a 1/4″ valve”). The port size inside the valve is what matters for flow. Two 1/4″ valves can have wildly different Cv values. Always select based on the calculated Cv, then confirm the connection size is compatible with your tubing or pipe.

What Connection Standards and Industry Certifications Should Guide Selection?

Ignoring standards leads to leaks and rejected shipments. We helped a client avoid a costly recall by ensuring their valves had the correct certifications for the European market.

Connection standards (like NPT, BSPP, SAE) ensure the valve physically fits your system without leaks. Industry certifications (like ISO, CE, FDA, UL) prove the valve is manufactured to quality and safety standards suitable for your specific industry, such as food processing, pharmaceuticals, or high-pressure hydraulics.

The Critical Role of Connection Types

The best valve is useless if it cannot be connected properly. Thread standards define the shape, angle, and pitch of the threads to ensure a tight seal.

Key Connection Standards for Mini Valves:

- NPT (National Pipe Tapered): Common in North America. The threads themselves are tapered and create a seal when tightened with thread sealant tape or paste. Denoted as, for example, “1/4 NPT”.

- BSPP (British Standard Pipe Parallel): Common in Europe and Asia. The threads are straight/parallel. The seal is made by compressing a washer or O-ring against a flat face, not by the threads. Denoted as “G1/4”.

- BSPT (British Standard Pipe Tapered): Similar to NPT but with a different thread pitch. Common in some Asian markets.

- SAE / JIC: Common in hydraulic systems. Uses a 37-degree flared seating surface to create a metal-to-metal seal.

- Compression Fittings: Used with soft tubing (copper, plastic). The nut compresses a ferrule onto the tube for a grip-and-seal action.

Mixing NPT and BSPP threads will damage the fittings and cause leaks. Always verify the thread standard on your existing equipment before ordering valves.

Essential Industry Certifications

Certifications are your assurance of quality, safety, and material integrity. They are not just paperwork.

| Certification | What It Means | Why It Matters |

|---|---|---|

| ISO 9001 | Certifies the manufacturer has a consistent quality management system. | Ensures reliable, repeatable product quality. A baseline for trust. |

| CE Marking | Indicates conformity with health, safety, and environmental standards for the European Economic Area. | Mandatory for selling products in the EU. |

| FDA Compliance | Materials are safe for contact with food and beverages (per US FDA regulations). | Essential for valves used in food, dairy, beverage, or pharmaceutical processing. |

| UL Listing | Product has been tested by Underwriters Laboratories for specific safety standards. | Often required for valves in electrical panels (solenoid valves) or specific industrial applications in North America. |

| 3-A Sanitary Standards | Specifically for equipment used in dairy, food, and beverage processing, focusing on cleanability. | Critical for valves in sanitary processing lines where hygiene is paramount. |

How to Use Standards and Certs in Selection

- Map Your Requirements: Start with your industry. A medical device has different needs than a construction air compressor.

- Match the Connection: Check your system’s drawings or physically measure the threads. This is the first filter in your selection.

- Filter by Certification: Use required certifications as a non-negotiable filter. If you need a valve for a drinking water system, NSF/ANSI 61 certification is crucial. This step instantly narrows down potential suppliers to those who serve your market seriously.

- Documentation: Always request the manufacturer’s certification documents and material test reports for your records. This is vital for your own quality audits and liability protection.

Choosing a valve with the right certifications may cost a little more upfront, but it prevents massive costs from system contamination, regulatory non-compliance, or field failures.

Conclusión

Selecting the right mini valve requires careful attention to material compatibility, pressure/temperature limits, flow sizing, and standards. For reliable mini valves that meet precise specifications and global certifications, consider IFAN’s range of precision fluid control products.

Comentarios recientes