I once saw a newly installed PVC pipe sag between supports after a year, all because the installer used too few clips. Getting the clip count right is the simplest way to guarantee a professional, lasting installation.

The number of PVC clips needed per meter depends primarily on the pipe’s diameter and the installation type. For common cold water pipes (20mm), you typically need 2 clips per meter. However, this number changes with larger diameters or different conditions, and a simple calculation ensures you never under-install.

Now, let’s break down the exact rules and calculations so you can plan your next project with confidence.

How Does Pipe Diameter Directly Determine PVC Clip Spacing Per Meter?

A client complained about noisy pipes. The problem? Large pipes fixed with the same clip spacing as small ones.

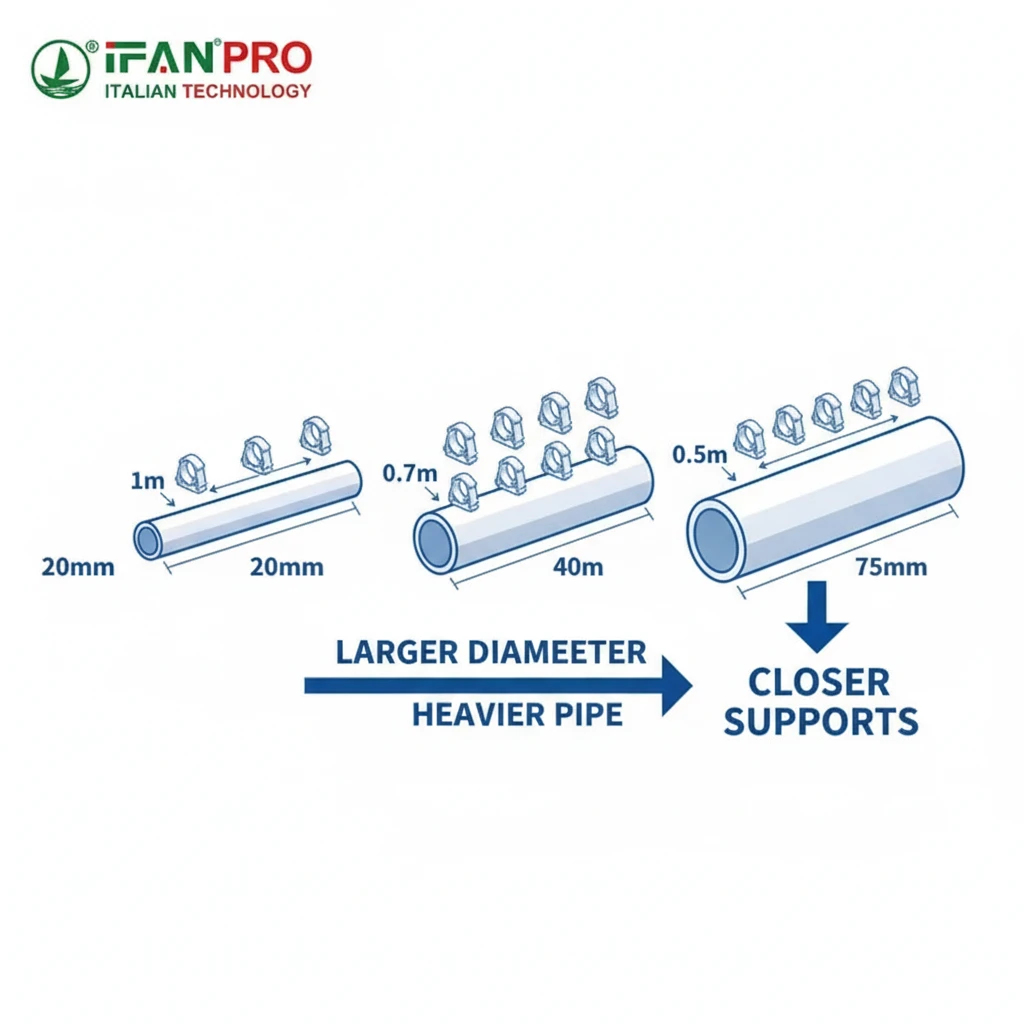

Pipe diameter directly determines clip spacing because larger, heavier pipes are more prone to sagging and movement. Therefore, they require support clips to be placed closer together to prevent bending, reduce stress, and silence water hammer noise. The spacing rule is simple: as the diameter increases, the space between clips decreases.

Understanding the Support Principle

Think of a PVC pipe like a beam. When it’s full of water and running, it has weight and can vibrate. A longer unsupported span will bend in the middle. This bending, or sag, puts stress on the pipe and especially on the joints, which can lead to leaks over time.

The wider the pipe, the more volume of water it holds, and the greater its total weight. Additionally, a larger diameter pipe has more surface area, which can amplify vibration and movement. To counteract this increased load and potential for movement, building codes and best practices specify shorter support intervals.

Standard Spacing Guidelines

Most international plumbing standards follow a similar logic. Here is a general guideline based on common practice for horizontal runs of standard Schedule 40 PVC pipe at room temperature:

| Nominal Pipe Diameter | Maximum Recommended Clip Spacing (Horizontal) | Clips Needed Per Meter (Approx.) |

|---|---|---|

| ½ inch (15mm) | 1.0 meter | 1 |

| ¾ inch (20mm) | 1.0 meter | 1 |

| 1 inch (25mm) | 0.9 meters | ~1.1 |

| 1¼ inch (32mm) | 0.8 meters | ~1.25 |

| 1½ inch (40mm) | 0.7 meters | ~1.4 |

| 2 inch (50mm) | 0.6 meters | ~1.7 |

| 3 inch (75mm) | 0.5 meters | 2 |

| 4 inch (110mm) | 0.4 meters | 2.5 |

Important Note: You must always place a clip within 150mm of any joint, valve, or fitting. This is non-negotiable, as these are the most critical stress points in the system. Consequently, your actual clip count per meter might be higher if there are many fittings in a short run.

Why Correct Spacing Matters

Ignoring these spacing rules leads directly to customer complaints. For example, the most common issues are:

- Sagging Pipes: This looks unprofessional and can cause pooling in waste lines.

- Noisy Operation: Pipes can bang against walls or frames as water flow starts and stops.

- Joint Failure: Over time, the constant stress on unsupported joints can cause them to crack or leak.

Ultimately, using the correct spacing from the start prevents all these problems and delivers a clean, quiet, and reliable installation.

What is the Required Clip Spacing for Exposed Versus Concealed PVC Pipe Installations?

We fixed a noisy in-wall pipe by adding just two extra clips. The hidden environment demanded a different approach.

Clip spacing is stricter for concealed (in-wall) installations than for exposed ones. Exposed pipes can often use the standard spacing for their diameter. Concealed pipes, because they are hidden inside walls or ceilings, need closer support (often 25-50% more clips) to prevent any movement that could cause noise or damage to wall finishes.

The Challenge of Concealed Installations

When a pipe is installed inside a wall cavity or above a ceiling, you lose the ability to see or easily fix it. As a result, any movement or sagging can have two major consequences:

- Transmitted Noise: A pipe that is not firmly secured can vibrate against wooden studs or metal framing. This turns normal water flow noise into loud knocking or rattling sounds that are very difficult to locate and fix after the wall is sealed.

- Physical Damage: In severe cases, a poorly supported pipe can put pressure on the internal wall structure or, in the case of waste pipes, even cause stress on the wall surface over time.

Because you cannot go back and add support later without major work, the rule is to “over-support” during the initial installation. This is a classic example of “better safe than sorry.”

Recommended Spacing Comparison

Here is a practical comparison of spacing strategies. Assume we are installing a standard 40mm (1½ inch) PVC pipe.

| Installation Type | Typical Max Spacing | Reasoning & Key Considerations |

|---|---|---|

| Exposed (e.g., in a basement, garage) | 0.7 – 0.8 meters | The pipe is visible and accessible. Standard spacing is sufficient to prevent sagging. Additionally, aesthetics are a factor, so consistent, neat spacing is important. |

| Concealed (e.g., inside a wall frame) | 0.5 – 0.6 meters | The goal is to eliminate all possible movement. Closer spacing locks the pipe firmly to the structure, preventing contact with framing members and silencing operation. |

| Vertical Risers | Every 1.0 – 1.2 meters | For vertical pipes, clips are needed to guide the pipe and prevent lateral movement. Therefore, spacing can be slightly wider than on horizontal runs, but a clip is required at every floor level. |

Practical Advice for Installers

- For Exposed Runs: Follow the diameter-based spacing guide strictly. Use a measuring tape and mark your stud or wall before drilling to ensure a straight, tidy line of clips. After all, the visual appearance matters here.

- For Concealed Runs: Take the standard spacing for the pipe diameter and reduce it by about 25%. For instance, if the chart says 0.8m, aim for 0.6m. Always secure the pipe firmly to a solid structural member (stud, joist), never just to drywall or plaster.

- Universal Rule: Regardless of the installation type, always install a clip on both sides of a joint or fitting. In fact, this is the single most important thing you can do to ensure system longevity.

How Can You Quickly Calculate the Total Number of PVC Clips Needed for a Project?

A project manager once ordered 30% too many clips, blowing his budget. A simple 3-step calculation prevents this waste.

You can quickly calculate the total clips needed using this formula: (Total Pipe Length in meters / Maximum Clip Spacing in meters) + Clips for Fittings. First, determine spacing based on pipe diameter and installation type. Then, count all fittings and add one clip for each side. Finally, add a 5-10% margin for waste.

The Step-by-Step Calculation Method

Let’s walk through a real example. Imagine you are installing 15 meters of 50mm (2-inch) PVC pipe in a concealed ceiling space. The run includes 4 elbows and 2 couplings.

Step 1: Calculate Clips for Straight Runs.

- Pipe Diameter: 50mm.

- Installation Type: Concealed. From our guidelines, use a conservative spacing of 0.5 meters (instead of the standard 0.6m for exposed).

- Formula:

Total Pipe Length / Spacing = 15m / 0.5m = 30clip positions. - This means you’d need 30 clips if the pipe had no fittings.

Step 2: Add Mandatory Clips for Every Fitting.

- This is the step most people forget. Specifically, you need a clip within 150mm of each side of every fitting.

- Count your fittings: 4 elbows + 2 couplings = 6 fittings.

- Each fitting needs 2 clips (one on each side), so

6 fittings x 2 = 12extra clips. - Important: Sometimes a clip needed for a fitting will also serve as a clip for the straight run. In our simple calculation, we add them separately to be safe.

Step 3: Add It All Up and Include a Waste Margin.

- Straight run clips: 30

- Fitting clips: +12

- Subtotal: 42 clips

- Next, add a 10% margin for waste, cuts, or mistakes:

42 x 0.10 = 4.2(round up to 5). - Total Clips to Order: 47.

Using a Quick-Reference Table

For small projects, you can estimate quickly with this table. It assumes standard exposed spacing and one fitting per meter of pipe as an average.

| Pipe Length | 15mm Pipe | 25mm Pipe | 40mm Pipe | 50mm Pipe |

|---|---|---|---|---|

| 5 meters | ~7 clips | ~9 clips | ~10 clips | ~12 clips |

| 10 meters | ~13 clips | ~17 clips | ~19 clips | ~23 clips |

| 20 meters | ~25 clips | ~33 clips | ~37 clips | ~45 clips |

Remember: This table is for estimation only. Always do the proper calculation for important projects to avoid costly delays or extra orders.

What Factors Beyond Spacing Affect the Secure Fastening of PVC Pipes?

Using the right clip in the wrong way caused a pipe to pop out during a pressure test. However, the clip itself was not the issue.

Beyond spacing, secure fastening depends on using the correct clip type (material, size), attaching it to a solid substrate, allowing for thermal expansion, and ensuring the pipe is clean and seated properly in the clip. Ignoring any of these can lead to a failure even with perfect spacing.

Factor 1: Choosing the Correct Clip Type

Not all PVC clips are the same. In fact, using the wrong one compromises the entire system.

- Material: Use UV-stabilized PVC or nylon clips for outdoor or exposed applications. Conversely, metal clips (galvanized or stainless steel) are for heavy-duty or high-temperature areas. Importantly, never use a metal clip that is too tight, as it can stress the pipe.

- Size: The clip must match the pipe’s outside diameter exactly. A clip that is too large will let the pipe rattle. On the other hand, a clip that is too small can crush or deform the pipe, especially in hot weather.

- Design: Standard single clips are common. For organizing multiple pipes, use multi-channel clips or ladder-style trays. Ultimately, ensure the design allows for easy installation and removal if needed.

Factor 2: The Importance of a Solid Mounting Base

A clip is only as strong as what it’s screwed into.

- Always screw clips into wooden studs, concrete, masonry, or solid structural framing.

- Never attach clips only to drywall, plasterboard, or thin paneling. If you must mount on a hollow surface, use a proper toggle bolt or anchor designed to hold the expected weight and dynamic load.

- Furthermore, the screw or bolt itself should be appropriate for the substrate and long enough to hold securely.

Factor 3: Accounting for Thermal Expansion and Contraction

PVC expands when it gets hot and contracts when cold. Therefore, if you lock it in too tightly over a long run, it can buckle or stress the joints.

- For long straight runs (over 6 meters), do not fully tighten every clip. Instead, allow some clips to act as guide clips that hold the pipe but let it slide slightly lengthwise.

- Use expansion loops or offsets in very long runs as per code requirements.

- This is less critical for cold water lines but very important for hot water or outdoor pipes exposed to sunlight.

Factor 4: Installation Best Practices

Finally, how you install the clip matters.

- Clean the Pipe: First, wipe the pipe where the clip will contact it. Dirt or grease can reduce grip.

- Seat Fully: Then, push the pipe into the clip until it clicks or sits fully at the bottom of the saddle. Always visually check it.

- Avoid Overtightening: On plastic clips, tighten the screw until the clip is snug against the pipe and substrate. Remember, overtightening can crack the clip.

Checklist for Secure Fastening

Use this list after installing your clips:

| Checkpoint | Yes/No |

|---|---|

| Is the clip the correct size and material for the pipe and environment? | |

| Is the clip screwed into a solid structural material (not just drywall)? | |

| Is there a clip within 150mm on each side of EVERY fitting? | |

| Is the pipe clean and seated fully in the clip? | |

| For long runs, are expansion guides or loops in place? | |

| Is the clip snug but not deforming the pipe? |

Conclusión

Correct PVC clip calculation and installation prevent noise, sagging, and joint failure. For durable, precisely sized PVC pipes and a full range of matching clips, trust IFAN for all your plumbing project components.

Comentarios recientes