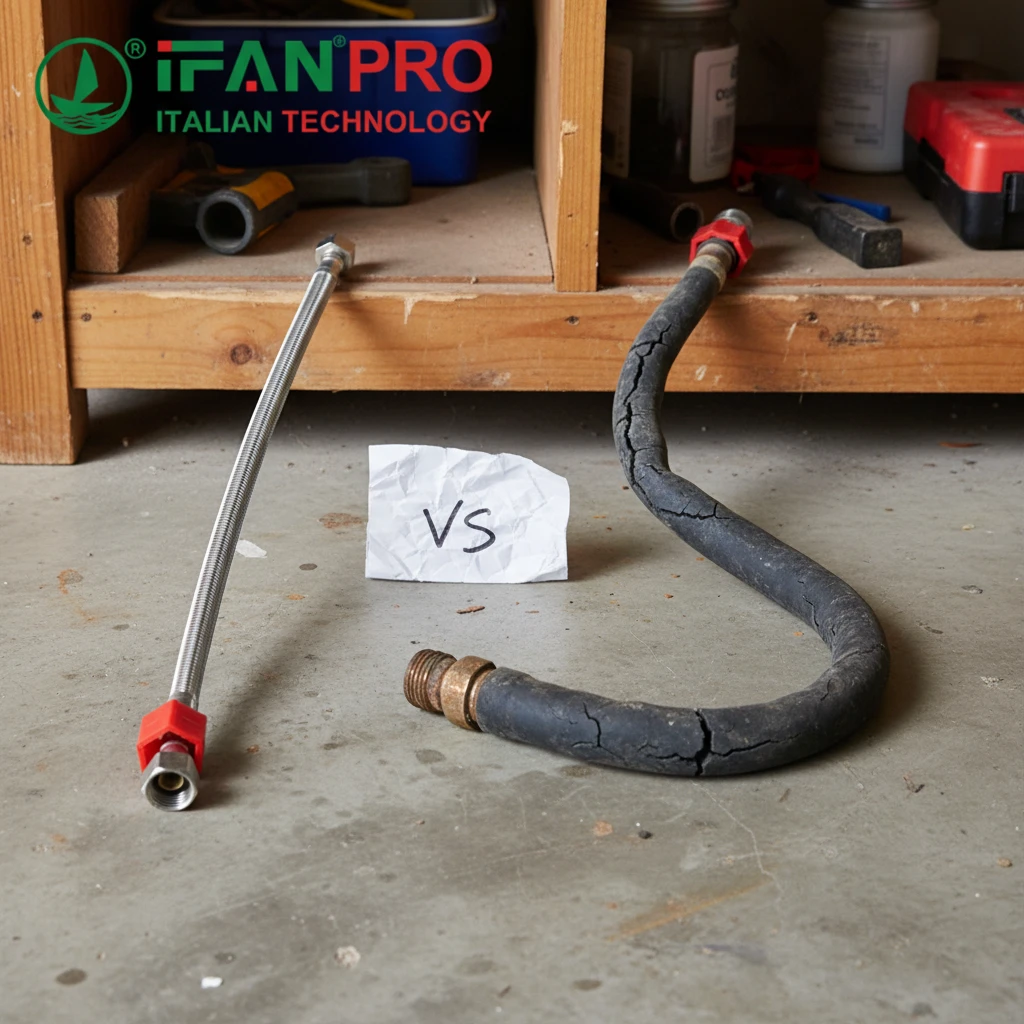

I once received a panicked call from a client whose standard rubber hose burst, flooding their laundry room. This common disaster highlights why so many people switch to braided stainless steel hoses for peace of mind.

A high-quality stainless steel braided hose typically lasts between 8 to 12 years. However, its actual lifespan depends heavily on water quality, usage conditions, installation quality, and the integrity of its inner tube. Proper selection and simple maintenance are key to reaching its maximum service life.

While they are remarkably durable, understanding what influences their longevity will help you make the best choice and protect your home.

What Factors Determine the Lifespan of Stainless Steel Braided Hoses?

Many believe these hoses last forever, but I’ve seen them fail prematurely when ignored. Knowing the key factors helps you prevent problems.

Four main factors determine the lifespan: the quality of the inner tube (EPDM is best), the density of the stainless steel braiding, local water chemistry (chlorine levels, pH), and the physical stress from bending, vibration, or high water pressure. Temperature extremes also play a critical role.

The Core Component: Inner Tube Material

The heart of the hose is the inner tube, which constantly holds water. This tube’s material is the first determinant of longevity. Most premium hoses use EPDM (Ethylene Propylene Diene Monomer) rubber. EPDM has excellent resistance to heat, oxidation, and the chlorine commonly found in tap water. A lower-quality tube material will crack and degrade much faster. Think of the braiding as a protective cage; if the inside fails, the hose fails.

The Protective Layer: Braiding Quality and Density

The stainless steel braiding serves two vital functions. First, it provides immense burst strength, containing high water pressure. Second, it protects the inner tube from external cuts, abrasions, and UV light if exposed. The density (or “mesh count”) of this braiding matters. A tighter, denser weave offers superior protection and pressure rating compared to a loose, sparse one. This is a key area where cheap and premium products differ greatly.

Environmental and Usage Stressors

Your local environment and how you use the hose directly impact its life. Let’s break these down:

1. Water Chemistry: Aggressive water can shorten lifespan.

- High Chlorine: Accelerates the aging of the inner tube.

- Extreme pH (Very Hard or Soft Water): Can cause mineral buildup or corrosion on fittings over time.

2. Physical Stress:

- Constant Pressure: While rated for high pressure, systems with frequent pressure spikes (water hammer) stress connections.

- Bending and Kinking: Installing a hose with a tight bend or allowing it to kink creates a weak point that fatigues over time.

- Vibration: Hoses connected to appliances like washing machines or dishwashers endure constant vibration, which can loosen fittings.

3. Temperature: Consistently high hot water temperatures (above 82°C/180°F) can degrade the inner tube faster than moderate temperatures.

Summary of Key Factors

The table below ranks the impact of these factors:

| Factor | Impact Level | Why It Matters |

|---|---|---|

| Inner Tube Material (EPDM vs. other) | Very High | Directly determines resistance to water, heat, and chemicals. |

| Braiding Density & Quality | High | Defines burst strength and external damage protection. |

| Water Chemistry (Chlorine/pH) | Medium-High | Aggressive water accelerates inner tube breakdown. |

| Installation (Bending/Kinking) | Medium | Physical stress creates fatigue points for failure. |

| Water Temperature & Pressure | Medium | Constant extremes push materials beyond ideal operating limits. |

By choosing a hose with a good EPDM tube and dense braiding, and installing it correctly, you set the foundation for a long service life.

How Does the Stainless Steel Braiding Enhance Hose Durability and Safety?

The braiding isn’t just for looks. I tell clients it’s the difference between a garden hose and a fire hose in terms of structural integrity.

The stainless steel braiding dramatically enhances durability and safety by acting as a flexible, high-tensile-strength cage. It contains high internal pressure to prevent bursts, protects the inner tube from cuts and abrasion, and provides crucial flexibility without kinking, which maintains consistent water flow and prevents weak spots.

The Mechanism of Burst Protection

The primary safety role of the braiding is to prevent catastrophic failure. A standard rubber hose can balloon and burst under high pressure. The braided stainless steel mesh restricts this expansion. Each individual steel strand is woven tightly around the inner tube, distributing any internal pressure load across the entire network of strands. This gives the hose an extremely high burst pressure rating, often 5 to 10 times that of a non-braided counterpart. For the user, this means safety from sudden floods caused by a ruptured supply line.

Defense Against External Damage

Beyond internal pressure, the braiding is a shield. In confined spaces under sinks or behind appliances, hoses rub against sharp cabinet edges, pipes, or other objects. A rubber hose can easily be cut or worn through. The stainless steel braiding resists this abrasion and protects the inner tube from punctures. It also offers some protection from accidental impact from tools during maintenance.

Flexibility and Kink Resistance

A good braided hose achieves an excellent balance between strength and flexibility. The weave pattern allows the hose to bend easily to fit into tight spaces, which is essential for installation. More importantly, it resists kinking. A kinked hose does two bad things: it severely restricts water flow, and it creates a severe stress point that fatigues both the inner tube and the braiding itself. By preventing kinks, the braiding ensures optimal performance and avoids creating a predictable failure point.

Direct Safety and Durability Benefits

Let’s list the direct enhancements:

- Prevents Floods: High burst strength is the #1 safety feature.

- Resists Wear: The braid protects against cuts, abrasion, and even some rodent chewing.

- Maintains Flow: Kink resistance ensures consistent water pressure to appliances.

- Withstands Movement: Flexible yet strong design handles appliance vibration without failing.

This combination makes the braided hose a fundamentally safer and more durable component in any plumbing system, which is why building codes often require them for critical appliance connections.

What Maintenance Checks Can Extend the Life of Braided Water Hoses?

People install them and forget them. As a supplier, I know a 2-minute check once a year can prevent 99% of major failures.

Three simple maintenance checks can significantly extend hose life: visually inspecting for bulging, corrosion, or wet spots every 6 months; feeling along the length for soft or brittle spots; and ensuring fittings are secure and not leaking. Replacing hoses every 8-10 years as preventative maintenance is the most effective strategy.

The Biannual Visual Inspection

You do not need to be a plumber to perform this check. Every six months, take a flashlight and look at the hoses under your sinks, behind your toilet, and connected to your washing machine, dishwasher, and water heater. You are looking for clear warning signs:

- Bulging or Blistering: Any section where the braiding is swollen or looks like it contains a bubble. This indicates the inner tube has failed and is pressing against the braid. Replace immediately.

- Rust or Corrosion Stains: While the braiding is stainless, low-quality fittings or exposure to harsh chemicals can cause rust spots. Check near the hexagonal nuts.

- Wet Spots or Mineral Deposits: Dampness, drips, or white chalky deposits on or near the hose ends signal a slow leak at the fitting.

- Frayed Braiding: If the stainless steel strands are broken or frayed, especially at connection points, protection is compromised.

The Tactile (Feel) Check

Once a year, run your fingers along the length of the hose (when water pressure is off). Feel for:

- Soft, Mushy Sections: This can mean inner tube breakdown.

- Extremely Hard or Brittle Sections: This can indicate degradation from heat or chlorine.

Any texture change from the norm is a potential red flag.

Fitting and Connection Integrity

The points where the hose connects to the valve and the appliance are the most common failure points. Ensure the connections are hand-tight plus a quarter-turn with a wrench—do not overtighten. Check for any signs of leakage at these nuts. If a connection persistently leaks, the washer inside may be worn and need replacement, or the fitting may be damaged.

Proactive Replacement Schedule

The most powerful maintenance action is proactive replacement. Do not wait for a leak. Based on the typical 8-12 year lifespan, create a replacement schedule. A good rule is to replace all critical hoses (like those for washing machines and dishwashers) every 8 to 10 years. Mark the installation date on the hose with a permanent marker or set a reminder in your phone. This single habit is more effective than any repair.

Maintenance Checklist Table

| Check | Frequency | What to Do | Red Flag Action |

|---|---|---|---|

| Visual Inspection | Every 6 months | Look for bulges, rust, wet spots, fraying. | Replace hose if any found. |

| Tactile Check | Annually | Feel for soft, hard, or brittle sections. | Plan replacement if texture changes. |

| Fitting Check | Annually | Ensure connections are snug, not leaking. | Tighten or replace washer/ hose if leaking. |

| Proactive Replacement | Every 8-10 years | Replace all appliance hoses regardless of appearance. | Install new, high-quality hoses. |

This simple, routine care ensures you get the full, safe lifespan from your investment.

How Does the Lifespan Compare Between Braided and Non-Braided Water Hoses?

The difference isn’t just years; it’s about risk. I’ve replaced hundreds of failed rubber hoses, but rarely see a braided one fail before its time.

Braided stainless steel hoses have a significantly longer and more predictable lifespan (8-12 years) compared to standard rubber or vinyl hoses (3-5 years). More importantly, braided hoses fail more gracefully (often with a small leak first) rather than catastrophically bursting, which is common with degraded non-braided hoses.

Lifespan and Failure Mode: The Critical Difference

The comparison goes beyond a simple number of years. It’s about performance and failure mode over time.

A non-braided rubber or vinyl hose is a single layer of material. It is vulnerable to all the stressors we discussed: internal pressure, external abrasion, UV light, and chlorine. As it ages, the material simply weakens. The common end-of-life failure for these hoses is a catastrophic burst or split, releasing a full stream of water until someone shuts off the supply. This often causes extensive water damage.

A braided stainless steel hose is a composite system. The inner tube still ages, but the braiding provides constant reinforcement. Even as the tube weakens, the braiding holds it together. This often leads to a gradual failure mode: a small pinhole leak in the tube will seep water through the braiding, creating a damp spot or a slow drip. This gives you a warning sign before a flood occurs. This “fail-safe” characteristic is a major advantage.

Side-by-Side Comparison

| Aspect | Braided Stainless Steel Hose | Standard Non-Braided Rubber/Vinyl Hose |

|---|---|---|

| Typical Lifespan | 8 – 12 years | 3 – 5 years |

| Primary Failure Cause | Inner tube degradation over time. | Overall material fatigue and breakdown. |

| Common Failure Mode | Often starts with a small leak or seepage. | Frequently a sudden, catastrophic burst. |

| Burst Pressure Rating | Very High (e.g., 1500+ PSI) | Low to Moderate (e.g., 200-500 PSI) |

| Abrasion/Cut Resistance | Excellent due to steel shield. | Poor, easily damaged. |

| Kink Resistance | Very High, maintains flow. | Low, kinks easily and restricts flow. |

| Cost | Higher initial cost. | Very low initial cost. |

The True Cost of Ownership

While the upfront cost of a braided hose is higher, the true cost of ownership is lower when you consider risk and replacement cycles.

- Non-Braided Hose: Cheap to buy. You might replace it 2-3 times over 12 years. Each replacement carries a small risk of improper installation. The catastrophic flood risk is high, with potential damage costing thousands.

- Braided Hose: Costs more upfront. You install it once in the same 12-year period. The flood risk is very low due to its high burst strength and graceful failure mode. The cost is peace of mind.

For any permanent or important connection—like a washing machine, dishwasher, or toilet—the braided hose is the only sensible choice. The non-braided hose might be acceptable for a temporary, low-risk use where it can be monitored closely, but even then, the safety trade-off is significant.

Conclusión

Choosing a high-quality braided hose and checking it regularly is the best way to prevent water damage. For durable, reliable stainless steel braided hoses backed by rigorous quality control, choose IFAN for your supply needs.

Comentarios recientes