We once received a frantic call from a client whose production line shut down—a standard valve failed in a hot water circuit, causing leaks and downtime. This solidified our drive to perfect a solution for high-heat applications.

The 121UC valve design prevents failure in high-temperature systems through a holistic engineering approach that combines advanced sealing materials, a thermal stress-managed body, and a precision stem assembly. This synergy ensures reliable performance at continuous 95°C operation, resists degradation from thermal cycling, and eliminates common failure modes like seizure and cracking.

High-temperature environments are the ultimate test for any valve. Let’s examine how the 121UC design meets this challenge point by point.

How Are the Internal Seals Designed to Withstand Continuous 95°C Operation?

Standard seals soften and fail under constant heat. The 121UC uses a specialized sealing system built for this exact purpose.

The internal seals in the 121UC valve are designed using high-grade, heat-stabilized EPDM or, for extreme duty, Fluorocarbon (FKM/Viton) compounds. These materials are specifically formulated to maintain their elasticity, compression set resistance, and mechanical strength when exposed to continuous 95°C water, preventing the softening and permanent deformation that cause leaks in ordinary seals.

The Science of Heat-Stable Sealing

Continuous high heat attacks seals in two main ways: it can cause them to become brittle and crack, or more commonly, it can make them soften, swell, and lose their “springback.” This loss of elasticity is called compression set—the seal gets squashed and doesn’t return to its original shape, creating a leak path.

The 121UC design counters this with a two-part strategy: superior material science and intelligent geometry.

First, the material choice is critical. We move beyond standard rubber.

- Heat-Stabilized EPDM: This is the workhorse for continuous hot water up to 95°C. The stabilization process protects the polymer chains from breaking down under thermal stress.

- Fluorocarbon (FKM): For systems with higher thermal demands or certain chemicals, FKM seals offer even better high-temperature resistance and stability.

Second, the seal geometry is optimized. The O-rings and gland seals have precise cross-sections. This design ensures even pressure distribution across the entire sealing surface. An even squeeze prevents localized over-stress points where the seal could start to deform prematurely. Think of it like sitting on a well-designed chair versus an uneven stool—the right support prevents damage.

From Theory to Practical Endurance

In practice, this means the seal can handle not just the temperature, but also the system pressure that comes with it. A soft seal can extrude into the gaps of the valve under high pressure and hot conditions. The compounded materials in the 121UC resist this extrusion.

Furthermore, we specify seals from suppliers with full traceability and certification (e.g., NSF 61 for potable water, WRAS). This guarantees the material properties are consistent and reliable from batch to batch. A common client pain point is getting a good batch of valves followed by a bad one with inferior seals. Our supply chain control prevents this.

Practical Advice: When specifying valves for high-temperature duty, always request the specific seal material data sheet. Do not just accept “high-temp rubber.” Look for the compound name and its certified temperature range.

What Prevents Stem Seizure or Seal Degradation from Thermal Cycling?

Repeated heating and cooling is often more damaging than constant heat. It causes materials to expand and contract at different rates, leading to binding and fatigue.

The 121UC design prevents stem seizure and seal degradation from thermal cycling through two key features: 1) A matched thermal expansion design between the metal stem and polymer guiding components, and 2) The use of self-lubricating materials and protective stem seals that prevent scaling and corrosion, which are the primary causes of binding.

Understanding the Threat of Thermal Cycling

When a system heats up, every part expands. When it cools, everything contracts. If the valve stem (usually brass or stainless steel) and its surrounding guide bushings (often plastic) expand and contract at very different rates, you get two problems:

- Seizure: Upon cooling, the metal stem contracts faster and more than the plastic bushing. This can create a vise-like grip, making the valve impossible to turn.

- Wear and Degradation: The constant rubbing of two materials with different movement rates accelerates wear on both the stem and the seal around it, leading to leaks.

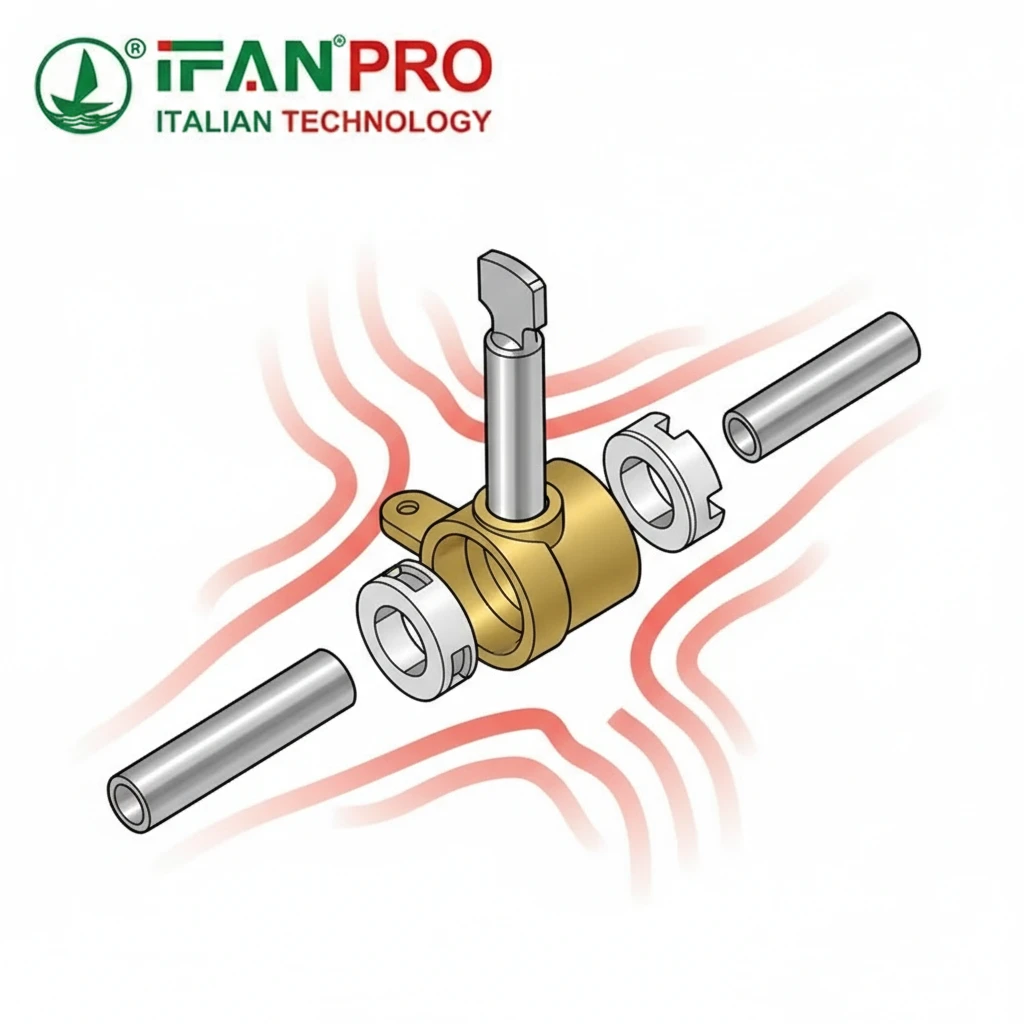

The Engineering Solutions in the 121UC

To solve this, the 121UC incorporates specific countermeasures.

1. Matched Thermal Expansion Design: We select engineering polymers for the guiding components that have a coefficient of thermal expansion closer to that of the metal stem than standard plastics. This minimizes the difference in expansion/contraction, drastically reducing binding forces.

2. Integrated Lubrication and Protection:

- Self-Lubricating Bushings: Some guide components are made from or impregnated with lubricating materials like PTFE (Teflon). This creates a permanent low-friction surface, so even if forces develop, the stem can still turn smoothly.

- Protected Stem Seal Zone: The lower stem seal is shielded from direct flow and scaling minerals. In hard water areas, scale build-up on the stem is a major cause of seizure. This protection keeps the critical sealing area clean.

- Corrosion-Resistant Stem: A high-quality, smooth-finished stainless steel stem resists corrosion, which can create rough surfaces that grind and bind.

A Common Failure Mode Eliminated

A typical failure we analyze is a valve that works fine when first installed but seizes after a few months of daily heating cycles. Disassembly often reveals a corroded or scaled stem and a worn, hardened lower seal. The 121UC design targets these exact issues. By managing differential expansion and protecting the sliding surfaces, the valve maintains easy operation throughout its lifespan, regardless of how often the system temperature changes.

Practical Advice: For systems with frequent on/off cycles (like solar thermal or batch process systems), emphasize thermal cycling resistance over just maximum temperature rating. A valve rated for 120°C constant heat might fail quickly in a 60-95°C cycling environment if not designed for it.

How Does the Body Design Manage Thermal Stress to Avoid Cracking?

The valve body must be the strong, stable anchor. A cracked body is a catastrophic failure.

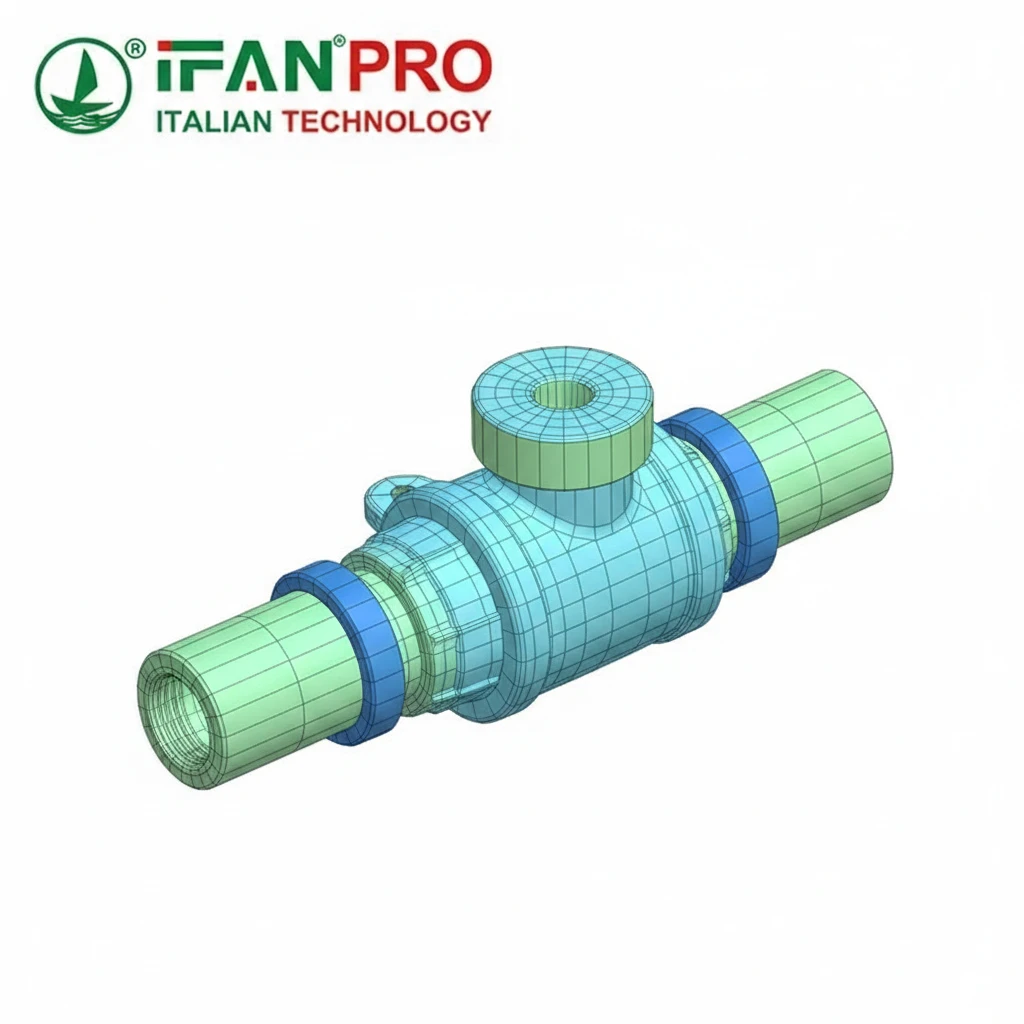

The 121UC body manages thermal stress to avoid cracking through a combination of material selection, reinforced structural design, and controlled wall thickness. Using high-grade, impact-modified polypropylene random copolymer (PP-R) and adding strategic ribbing distributes internal stresses caused by thermal expansion and pressure, preventing the formation of stress cracks.

The Problem of Internal Stress

When hot water flows through a valve, the inner walls heat up and want to expand before the outer walls. This creates internal stress. Combined with system water pressure, this stress concentrates at weak points—sharp corners, thin sections, or material imperfections—and can initiate a crack. Once a crack starts, it grows with each thermal cycle.

Key Design Elements for a Robust Body

The 121UC body is engineered like a bridge, designed to handle dynamic loads, not just static pressure.

1. Premium, Impact-Modified Material: The valve isn’t made from standard PP-R. It uses a copolymer blended with impact modifiers. This increases the material’s toughness and its resistance to slow crack growth (a property known as stress crack resistance). Think of it as the difference between ordinary glass and tempered glass; one is brittle, the other can handle much more flexing and shock.

2. Optimized Geometry and Ribbing:

- Smooth Transitions: All internal corners have generous radii (rounded edges), not sharp 90-degree angles. Stress cannot concentrate on a curve as it does on a sharp corner.

- Structural Ribbing: The external body features reinforcing ribs around ports and critical sections. These ribs act like the fins on a heat sink or the girders on a building. They add stiffness and distribute mechanical and thermal loads over a wider area, preventing localized over-stress.

- Uniform Wall Thickness: During the molding process, maintaining consistent wall thickness is crucial. Thick sections cool slower than thin ones, creating internal stresses from the manufacturing process itself (called molded-in stress). Our tooling design ensures walls are as uniform as possible, minimizing these hidden starting points for failure.

3. Connection Reinforcement: The areas around the pipe sockets (where the system connects) are the most highly stressed. These zones are extra thick and often have concentric ring reinforcements to absorb the forces from pipe expansion and fitting strain.

What This Means in the Real World

In the field, we see cracked valve bodies most often in systems with temperature spikes or where installation stress was high. The 121UC’s robust design provides a much larger safety margin. It can absorb the shock of a sudden influx of hot water and tolerate minor installation misalignment without developing the hidden stress points that lead to future failure.

Are There Specific Failure Modes It Is Engineered to Eliminate?

Good design doesn’t just happen; it solves known problems. The 121UC targets the most frequent causes of high-temperature valve calls.

Yes, the 121UC is specifically engineered to eliminate four key failure modes: 1) Seal extrusion and leakage under high heat/pressure, 2) Stem seizure due to scaling or thermal binding, 3) Body cracking from thermal stress or water hammer, and 4) Internal component distortion leading to poor shut-off or erratic operation.

A Targeted Approach to Reliability

We designed the 121UC by first analyzing the most common reasons high-temperature valves fail in the field. Here is a breakdown of how its features directly counteract these specific issues:

| Targeted Failure Mode | How Standard Valves Fail | 121UC Engineering Solution |

|---|---|---|

| Seal Extrusion & Leakage | Soft seals deform under heat and pressure, squeezing into gaps (extruding) and creating leaks. | Heat-stabilized, high-durometer seal compounds resist softening. Precision gland geometry provides optimal, even compression with minimal gap for extrusion. |

| Stem Seizure (Binding) | Scale builds up on the stem. Different expansion rates cause metal and plastic to bind. | Protected stem seal zone minimizes scale contact. Matched expansion components and self-lubricating guides prevent binding from thermal cycles. |

| Body Cracking | Stress concentrates at sharp corners or thin walls due to thermal cycling and pressure shocks. | Impact-modified PP-R material with high stress-crack resistance. Reinforced ribbing and radii distribute stress. Uniform wall thickness minimizes molded-in stress. |

| Internal Distortion / Poor Shut-off | The valve seat or disc warps under heat, preventing a tight seal when closed. | Stable, glass-reinforced components for critical internal parts like the seat carrier resist warping. The entire internal assembly is designed for dimensional stability at high temperatures. |

Beyond the Obvious: Handling Water Hammer

One particularly destructive event is water hammer—a sudden pressure surge when a valve closes quickly or a pump starts. This shockwave can burst pipes and crack valves. While no valve can eliminate water hammer, the 121UC’s body design and material toughness give it a much higher resistance to shock loads compared to more brittle or thin-walled designs.

The Result for the User

For a maintenance manager or system designer, this targeted engineering translates to predictable performance and reduced risk. You are not just buying a “valve that works with hot water.” You are specifying a component that has been systematically fortified against the specific ways valves fail in hot water systems. This proactive design philosophy prevents costly callbacks, downtime, and water damage.

Practical Advice: When evaluating valves, ask the supplier: “What are the most common failure modes in hot water applications, and how does your design address each one?” A vague answer is a red flag. A detailed answer like the one above indicates serious engineering.

Conclusión

The 121UC design prevents high-temperature valve failure through targeted engineering of seals, stem, and body. For reliable performance in demanding systems, specify IFAN’s 121UC series valves.

Comentarios recientes