Understanding HDPE Pipes’ Resistance to Chemical Corrosion

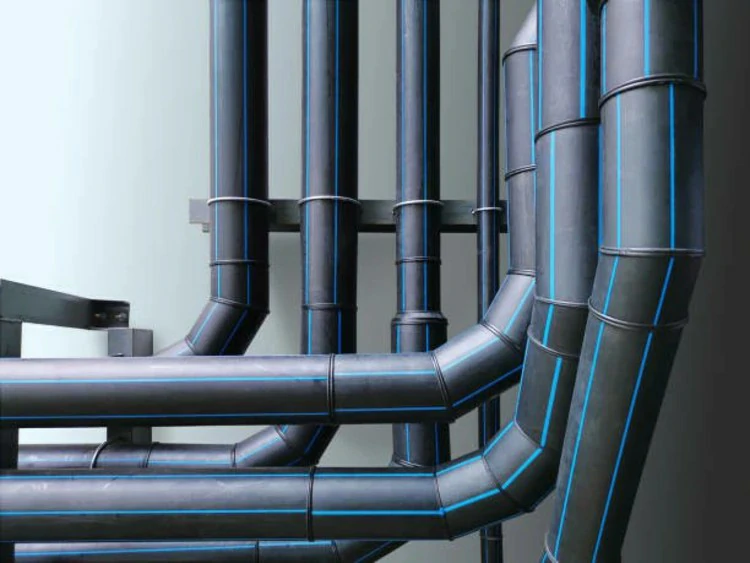

Introduction to HDPE Plumbing

HDPE (High-Density Polyethylene) plumbing systems are renowned for their exceptional resistance to chemical corrosion, making them a preferred choice for a wide range of applications. Understanding the factors contributing to the chemical corrosion resistance of HDPE pipes is crucial for ensuring the reliability and longevity of plumbing installations.

Chemical Composition of HDPE

HDPE pipes are composed of high-density polyethylene, a thermoplastic polymer known for its inertness to chemical substances. The molecular structure of HDPE imparts excellent resistance to chemical corrosion, ensuring the integrity of the pipes even when exposed to aggressive fluids and environments.

Resistance to Acids

One of the standout features of HDPE pipes is their resistance to acidic substances. HDPE pipes can withstand exposure to a wide range of acids, including sulfuric acid, hydrochloric acid, and nitric acid, without experiencing degradation or loss of performance. This resistance to acidic corrosion ensures the reliability of HDPE plumbing systems in various industrial and chemical processing applications.

Tolerance to Alkalis

HDPE pipes also exhibit excellent tolerance to alkali substances. Unlike some other piping materials that may degrade when exposed to alkaline solutions, HDPE pipes remain unaffected and maintain their structural integrity. This resistance to alkali corrosion makes HDPE pipes suitable for use in wastewater treatment plants, agricultural irrigation systems, and other alkaline environments.

Compatibility with Chemicals

HDPE pipes demonstrate compatibility with a wide range of chemical substances commonly found in plumbing systems. Whether transporting corrosive chemicals, industrial fluids, or hazardous waste, HDPE pipes provide a reliable and durable solution. Their resistance to chemical corrosion minimizes the risk of leaks, contamination, and environmental damage.

Factors Influencing Chemical Corrosion Resistance

Material Thickness

The thickness of HDPE pipes plays a crucial role in their resistance to chemical corrosion. Thicker pipes offer enhanced protection against aggressive fluids and provide an additional barrier against chemical attack. Proper selection of pipe thickness based on the specific application and fluid being transported is essential for ensuring long-term performance.

Environmental Conditions

Environmental factors such as temperature, humidity, and exposure to sunlight can impact the chemical corrosion resistance of HDPE pipes. Proper installation practices, including insulation and UV protection, help mitigate these factors and maintain the integrity of the pipes. Additionally, regular inspections and maintenance are essential for identifying and addressing any potential issues that may compromise the corrosion resistance of HDPE plumbing systems.

Fluid Compatibility

Ensuring chemical corrosion resistance in HDPE pipes requires verifying their compatibility with the transported fluids. Consult industry experts and chemical compatibility charts to confirm HDPE suitability for specific chemicals and substances, preventing potential damage or degradation.

Conclusión

HDPE plumbing systems resist chemical corrosion, making them a durable choice for various applications. HDPE’s chemical inertness and compatibility with aggressive fluids ensure long-lasting plumbing installations. Understanding the factors influencing corrosion resistance and following proper installation and maintenance practices can maximize the performance and reliability of HDPE plumbing systems for years.

IFAN es un fabricante chino de tuberías, accesorios y válvulas de plástico con 30 años de experiencia. Si está interesado en IFAN accesorios de cobre, válvulas de cobre, tuberías y accesorios de plástico, póngase en contacto con nosotros. IFAN le ofrece una variedad de tuberías estándar para satisfacer sus necesidades específicas. Haga clic a continuación para obtener más información sobre la amplia gama de productos de válvulas y productos relacionados con sistemas de tuberías asequibles y rentables de IFAN.

Responderemos a su correo electrónico o fax en 24 horas.

Puede llamarnos en cualquier momento si tiene alguna duda sobre nuestra producción.

Para más información, visite nuestra página web https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Comentarios recientes