What Are AL-PEX Pipes?

AL-PEX pipes combine aluminum and cross-linked polyethylene (PEX) technology. This hybrid design delivers superior performance for plumbing and heating systems. The aluminum layer provides structural strength. The PEX layers offer flexibility and corrosion resistance.

These pipes excel in residential and commercial applications. They handle hot water distribution efficiently. Cold water systems also benefit from their durability.

Why Choose Factory Direct AL-PEX Pipes?

Unbeatable Pricing

Factory direct purchasing eliminates middleman costs. You save 30-50% compared to retail prices. Our manufacturing facility produces pipes at scale, reducing per-unit expenses.

Bulk orders unlock even greater savings. Custom specifications don’t increase base pricing significantly.

Quality Control at the Source

Direct factory access means rigorous quality oversight. Every pipe undergoes multi-stage testing. We control materials, production processes, and final inspection.

ISO certifications validate our manufacturing standards. Third-party testing confirms pipe performance metrics.

Customization Capabilities

Standard sizes don’t always fit your project needs. Our factory offers custom diameter options. Length specifications match your exact requirements.

Special fittings integrate seamlessly with custom pipes. Color coding helps with installation identification.

AL-PEX Pipe Advantages

Superior Temperature Resistance

AL-PEX pipes handle extreme temperature ranges. Hot water systems operate safely up to 95°C (203°F). Cold applications maintain flexibility down to -40°C (-40°F).

Thermal expansion remains minimal due to aluminum reinforcement. This reduces stress on connections and joints.

Excellent Pressure Ratings

Working pressure reaches 10 bar (145 PSI) consistently. Burst pressure exceeds safety requirements by significant margins. Long-term pressure resistance maintains system integrity.

Corrosion Protection

The aluminum barrier prevents oxygen infiltration. This eliminates metal corrosion in heating systems. PEX layers resist chemical degradation from water additives.

Scale buildup becomes virtually impossible. Flow rates remain consistent over decades.

Applications and Use Cases

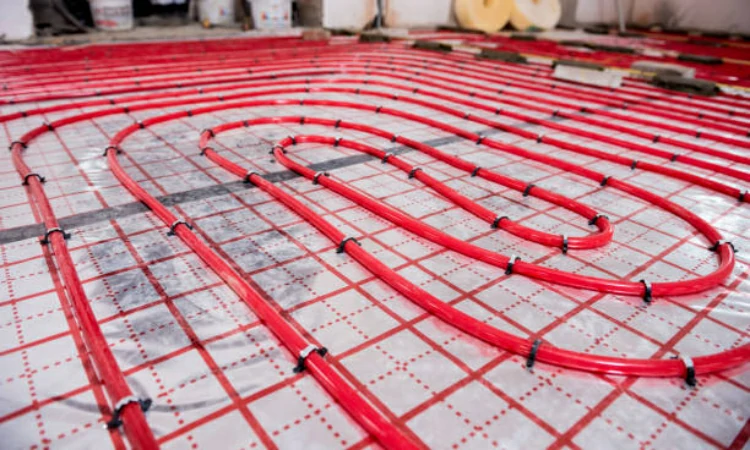

Radiant Floor Heating

AL-PEX pipes excel in underfloor heating installations. Heat distribution occurs evenly across surfaces. The aluminum layer conducts thermal energy efficiently.

Installation complexity decreases with flexible routing options. Fewer joints reduce potential leak points.

Plumbing Distribution Systems

Hot and cold water distribution benefits from AL-PEX technology. Residential homes experience consistent water pressure. Commercial buildings handle higher flow demands easily.

Retrofit projects become simpler with bendable pipes. Wall and ceiling installations require fewer fittings.

Industrial Process Lines

Manufacturing facilities rely on AL-PEX for process cooling. Chemical compatibility covers most industrial fluids. Temperature stability maintains production consistency.

Maintenance costs drop significantly compared to metal alternatives.

Installation Benefits

Faster Installation Times

Flexible pipes bend around obstacles naturally. Complex routing doesn’t require multiple fittings. Installation crews complete projects 40% faster on average.

Connection systems use simple compression or crimp fittings. Special tools aren’t necessary for basic installations.

Reduced Material Waste

Continuous pipe runs eliminate unnecessary joints. Coil packaging allows custom length cutting. Project waste typically drops below 5%.

Long-Term Reliability

Properly installed AL-PEX systems last 50+ years. Warranty coverage extends up to 25 years from quality manufacturers. Maintenance requirements remain minimal throughout service life.

Sizing and Specifications

Standard Dimensions Available

- 16mm x 2.0mm (1/2″ equivalent)

- 20mm x 2.0mm (3/4″ equivalent)

- 25mm x 2.5mm (1″ equivalent)

- 32mm x 3.0mm (1-1/4″ equivalent)

Custom sizing accommodates special project requirements. Wall thickness options vary based on pressure needs.

Performance Specifications

- Operating temperature: -10°C to 95°C

- Working pressure: 10 bar at 20°C

- Oxygen permeability: <0.1 mg/L/day

- Thermal conductivity: 0.43 W/m·K

Cost Comparison Analysis

Initial Investment

AL-PEX pipes cost 15-25% more than standard PEX initially. However, aluminum reinforcement eliminates expansion issues. This reduces fitting and support requirements significantly.

Total system costs often equal or beat standard alternatives.

Long-Term Savings

Energy efficiency improves due to better heat transfer. Maintenance calls decrease by 60% compared to metal pipes. Replacement cycles extend beyond 50 years typically.

Insurance premiums may decrease due to leak resistance.

Quality Assurance Standards

Manufacturing Certifications

ISO 9001:2015 quality management systems guide production. ISO 15875 standards govern AL-PEX pipe specifications. CE marking confirms European compliance requirements.

Third-party testing validates all performance claims. Quality documentation accompanies every shipment.

Testing Procedures

Hydrostatic testing occurs at 1.5x working pressure. Thermal cycling tests simulate decades of use. Chemical resistance testing covers common water treatments.

Burst testing exceeds international safety margins consistently.

Custom Manufacturing Services

Tailored Solutions

Standard products don’t always meet specific project needs. Our factory accommodates custom diameter requests. Special length requirements eliminate field cutting waste.

Pre-insulated options reduce installation labor significantly.

Engineering Support

Technical specifications receive thorough review before production. Installation guidance helps optimize system performance. Compatibility assessments prevent costly mistakes.

Design consultation services support complex projects.

Ordering and Logistics

Minimum Order Quantities

Factory direct pricing starts at reasonable minimum volumes. Custom specifications may require higher quantities. Bulk pricing tiers offer significant savings opportunities.

Shipping and Packaging

Protective packaging prevents damage during transport. Coil sizes optimize shipping container utilization. International shipping documentation includes all certifications.

Delivery schedules accommodate project timelines reliably.

Technical Support Services

Installation Guidance

Detailed installation manuals accompany all orders. Video tutorials demonstrate proper connection techniques. Technical hotline provides real-time assistance when needed.

Troubleshooting Resources

Common installation issues receive comprehensive coverage. Field problem resolution happens quickly through expert support. Warranty claims process efficiently with proper documentation.

Consideraciones medioambientales

Sustainability Benefits

AL-PEX pipes require less energy to manufacture than metal alternatives. Recycling programs handle end-of-life materials responsibly. Carbon footprint remains lower throughout product lifecycle.

Health and Safety

NSF certification confirms drinking water safety. No harmful chemicals leach into water supplies. Installation creates no hazardous waste concerns.

Conclusión

Factory direct AL-PEX pipes deliver exceptional value for modern plumbing and heating systems. Superior performance characteristics justify the investment. Quality manufacturing ensures decades of reliable service.

Custom manufacturing capabilities accommodate unique project requirements. Professional support services guide successful installations.

Contact our factory directly for competitive pricing on your next project. Experience the advantages of dealing with the manufacturer directly.

Comentarios recientes