We once had a client struggling with chronic flow issues and vibration in a critical system. Switching the standard tees to DOUBLE Y fittings solved both problems immediately, proving that the right fitting design is crucial.

A DOUBLE Y TEE offers significantly better flow than a standard tee. Its smooth, branched design guides fluid with minimal disruption, drastically reducing turbulence and pressure drop. For systems requiring efficient splitting or combining of flow with low energy loss, the DOUBLE Y TEE is the superior hydraulic choice.

This difference impacts system performance, energy costs, and longevity. Let’s break down exactly why the DOUBLE Y TEE outperforms the traditional standard tee.

What Are the Key Design Differences Between a DOUBLE Y TEE and a Standard Tee?

The first time you hold both fittings, the physical difference is obvious. One forces fluid to make a sharp turn; the other guides it gently.

The key design difference is in the branch connection. A standard tee has a 90-degree branch that creates a sharp, abrupt corner for the fluid. A DOUBLE Y TEE, often called a “lateral” or “true Y,” features a branched outlet that is angled typically at 30, 45, or 60 degrees, creating a smooth, gradual diversion path for the fluid flow.

A Closer Look at Geometry

The shape of a pipe fitting directly controls how fluid behaves inside it. Think of it like road design: a sharp 90-degree turn forces all cars to slow down drastically, while a gentle, banked curve allows them to maintain speed.

A standard tee is like that sharp 90-degree turn. The fluid traveling through the main run hits a sudden wall when it needs to go into the branch. This creates an immediate area of high impact and chaos. Conversely, fluid coming into the branch from the main run must make an abrupt right-angle turn, which is very inefficient.

Internal Flow Path Analysis

Now, look at the DOUBLE Y TEE. Its design mimics natural flow patterns. The angled branch (or branches, if it’s a double pattern) allows fluid to divert from or merge into the main stream gradually. This geometry is inspired by nature—like the branching of rivers or blood vessels—where smooth transitions minimize energy loss.

The internal surface area is also a factor. The sharp corner in a standard tee can sometimes have a slight ridge or uneven material from the manufacturing process, which further disrupts flow. The smoother contour of a DOUBLE Y TEE is easier to manufacture uniformly, promoting a cleaner internal surface.

Side-by-Side Design Comparison

The table below summarizes the core physical differences:

| Design Feature | Standard Tee | DOUBLE Y TEE |

|---|---|---|

| Branch Angle | 90 degrees | Typically 30°, 45°, or 60° |

| Flow Path | Abrupt, sharp turn | Smooth, gradual diversion |

| Internal Geometry | Contains a sharp corner/crevice | Contoured, blended radius |

| Primary Hydraulic Effect | Creates high turbulence and eddies | Promotes laminar, guided flow |

| Typical Manufacturing | Easier to cast/mold | Often requires more complex molding or fabrication |

The Impact on Fluid Behavior

These design differences are not minor. They define the fitting’s purpose. The standard tee is excellent for one thing: creating a perpendicular connection point, regardless of flow efficiency. It’s a structural choice. The DOUBLE Y TEE, however, is an aerodynamic (or rather, hydrodynamic) choice. Its entire form is dedicated to moving fluid from one path to another with the least possible resistance. This fundamental distinction in intent is why the DOUBLE Y TEE wins in any application where flow efficiency or pressure preservation is important.

How Does the DOUBLE Y TEE Geometry Improve Flow and Reduce Pressure Drop?

Clients often ask for proof of better flow. We explain it using the principle of energy conservation: every sharp turn wastes pump energy as noise, heat, and vibration.

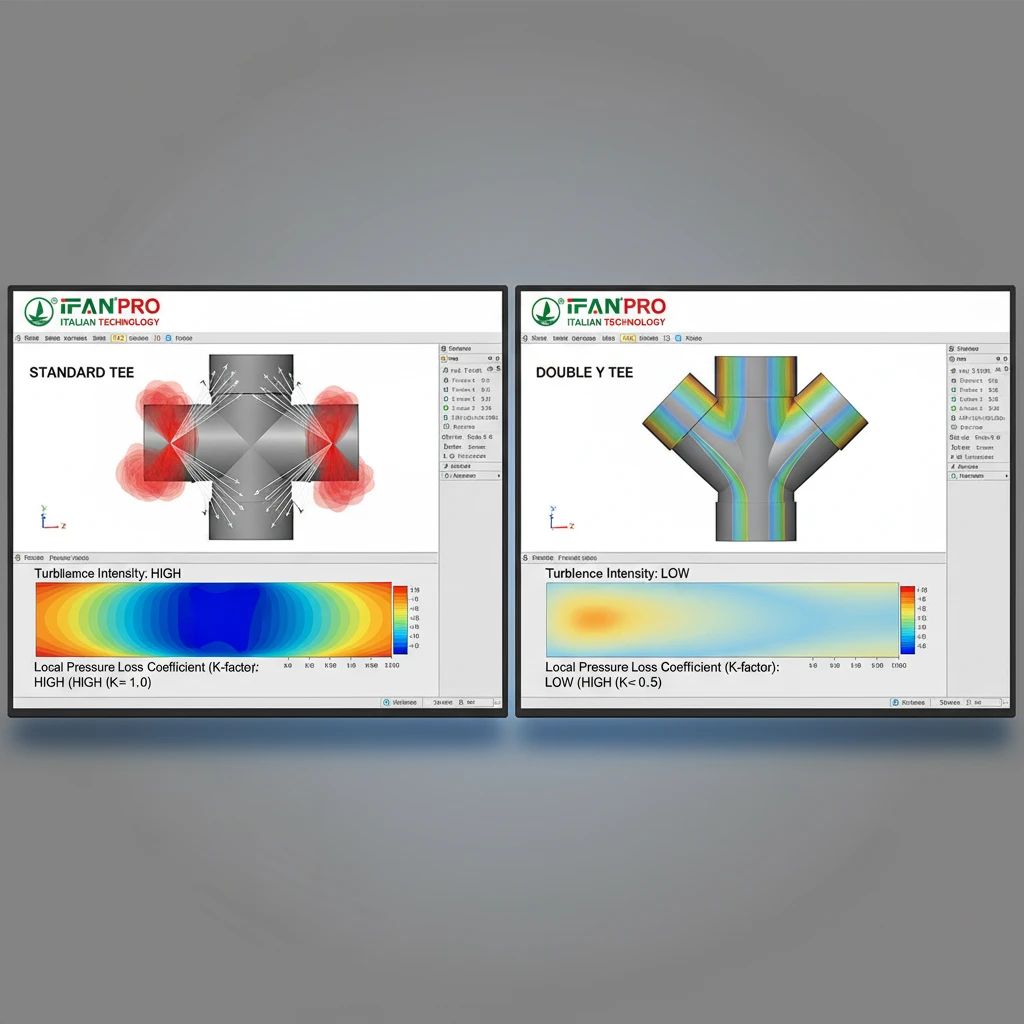

The angled geometry of a DOUBLE Y TEE improves flow by guiding fluid smoothly, which minimizes flow separation and the creation of turbulent eddies. This streamlined path significantly reduces friction and the energy loss associated with it, leading to a much lower pressure drop compared to the sudden direction change in a standard tee.

Understanding Pressure Drop

First, let’s understand pressure drop. In a piping system, the pump provides energy (seen as pressure) to push the fluid. Every valve, bend, and fitting resists the flow a little, using up some of that energy. This loss of energy is the pressure drop. A high pressure drop means your pump works harder, using more electricity, to achieve the same flow rate at the outlet.

A standard tee is a major source of pressure drop. When fluid hits the dead-end corner of the tee, it has to scramble to change direction. This causes the flow to “separate” from the pipe wall and create violent, swirling pockets called eddies. These eddies do nothing but create friction and convert useful pump energy into wasted heat and vibration.

The Streamlining Effect of the Y-Branch

The DOUBLE Y TEE attacks this problem directly. Its gradual angle encourages the fluid to follow the contour of the pipe wall. This is known as “guided flow.” There is no sudden stop or sharp corner for the fluid to crash into. Because the direction change is gentle, the flow remains attached to the wall, and separation is minimized or eliminated.

With less separation, there are far fewer turbulent eddies. The flow remains smoother, or more “laminar.” A laminar flow has much lower internal friction than a turbulent one. Therefore, the energy loss (pressure drop) is significantly reduced. This means more of the pump’s energy is used to move the fluid where you want it to go, not to fight the fitting.

Quantitative Performance Comparison

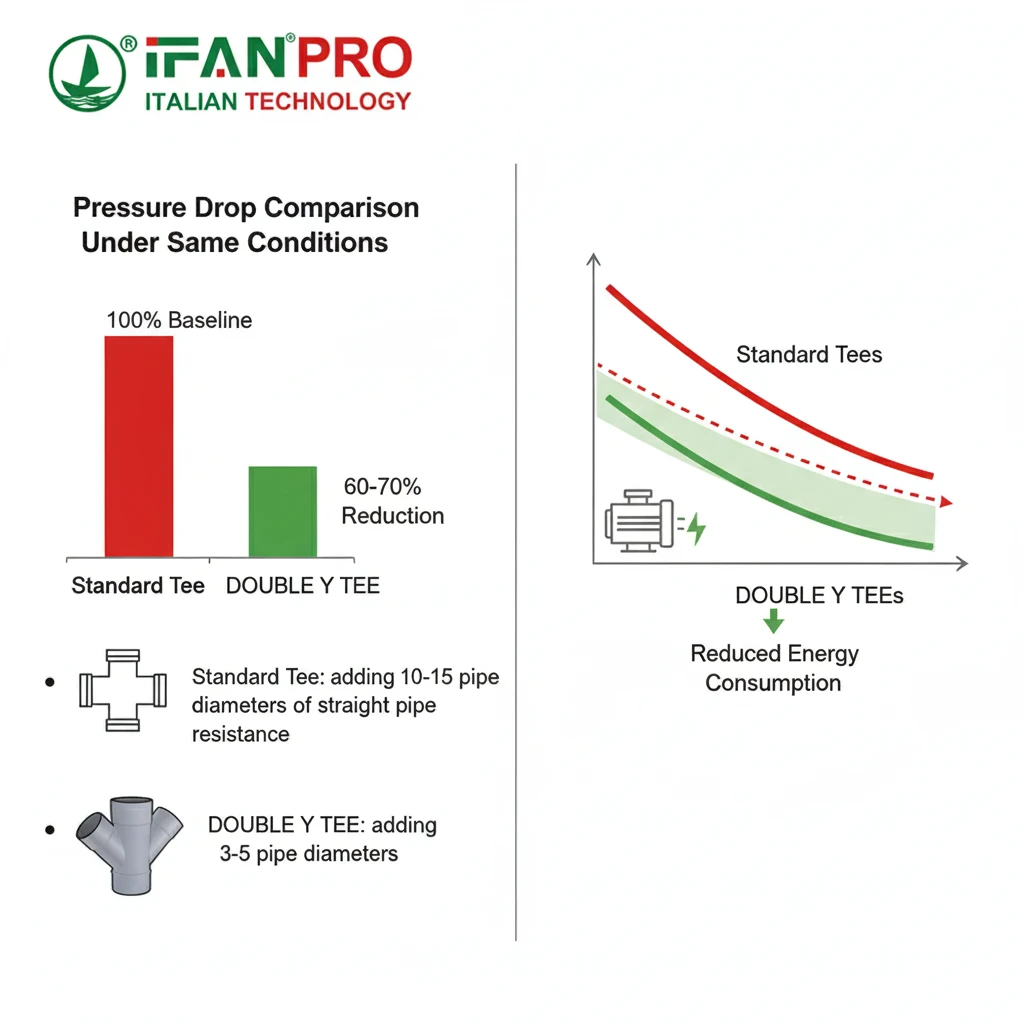

The difference can be measured. Engineers use a “K-factor” or “resistance coefficient” to quantify the pressure drop of a fitting. A lower K-factor means less resistance.

| Fitting Type (for equal pipe size) | Typical Resistance Coefficient (K-factor)* | Estimated Pressure Drop Relative to Standard Tee |

|---|---|---|

| Standard Tee (through branch) | 1.0 – 1.3 | Baseline (100%) |

| DOUBLE Y TEE (45° lateral) | 0.3 – 0.5 | Approx. 60-70% lower |

| Long-Radius Elbow (for comparison) | 0.2 – 0.3 | Even lower than a Y-Tee |

*Note: Exact values depend on size, angle, and flow rate. This table shows general relationships.

Real-World System Benefits

This lower pressure drop has real consequences. For example, you might be able to use a smaller, less expensive pump. Or, your existing pump can achieve a higher flow rate. It also reduces wear on the pump and the entire system. Most importantly, it cuts down on the “water hammer” effect and vibration caused by turbulent impacts in a standard tee, leading to a quieter and longer-lasting piping system. In short, the DOUBLE Y TEE’s geometry turns a problem point into an efficient transition.

What Are the Installation and Space Advantages of Using a DOUBLE Y TEE?

On a crowded construction site, every millimeter matters. We’ve seen projects where using DOUBLE Y fittings simplified layouts that were once a tangled maze of pipes and supports.

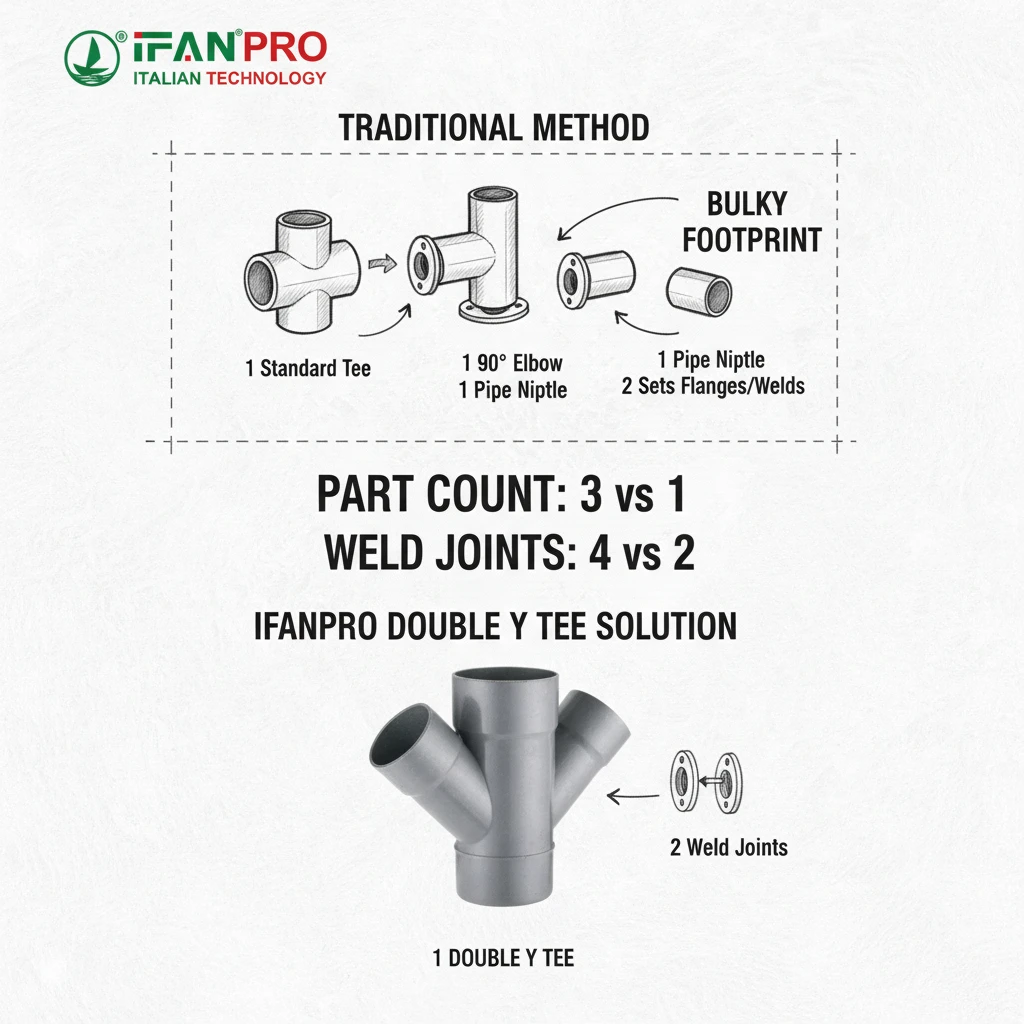

The main installation advantage of a DOUBLE Y TEE is that it often eliminates the need for extra elbows and pipe spools. This results in fewer welds or joints, saving labor time and reducing potential leak points. Its compact, integrated design can also save valuable space in tight mechanical rooms or pipe racks.

Reducing Component Count and Joints

Think about how you would create a branched line with a standard tee. The flow comes in, makes a 90-degree turn into the branch, and then, very often, you immediately need a 90-degree elbow to direct that flow where it actually needs to go. That’s one tee and one elbow, requiring two separate fusion joints or threaded connections.

Now, with a DOUBLE Y TEE, the angled branch is built-in. The fitting itself performs the directional change. You go from needing two fittings (tee + elbow) to just one. This has a cascade of benefits:

- Fewer Joints: Every joint is a potential future leak. Reducing the number of joints directly increases the system’s overall reliability.

- Less Labor: Each fusion weld or threaded connection takes time. One fitting is faster to install than two.

- Lower Material Cost: While a DOUBLE Y TEE may cost slightly more than a single standard tee, it is almost always cheaper than buying a tee plus an elbow plus the extra pipe nipple needed to connect them.

Gaining Space Efficiency

The physical footprint of the piping layout also shrinks. The assembly of a tee plus an elbow is long and bulky. A DOUBLE Y TEE accomplishes the same direction change in a much more compact form. This is a critical advantage in modern buildings where mechanical spaces are tightly designed.

For example, in a suspended ceiling or a crowded utility corridor, the more compact layout can be the difference between a feasible design and one that conflicts with other systems like ductwork or electrical conduits. It also allows for cleaner, straighter, and more organized pipe runs, which makes future maintenance and identification easier.

Installation Workflow Comparison

Let’s compare the steps to create a 45-degree branch line from a main, assuming a 6-inch pipeline:

| Task | Using Standard Tee + Elbow | Using 45° DOUBLE Y TEE |

|---|---|---|

| 1. Fittings Required | One standard tee, one 90° elbow, one pipe nipple. | One DOUBLE Y TEE. |

| 2. Alignment | Must carefully align three components (tee, nipple, elbow) in two planes. | Only need to align one fitting to the main pipe run. |

| 3. Number of Joints | Two joints (tee-to-nipple, nipple-to-elbow). | One joint (main pipe to Y-branch body). |

| 4. Welding/Fusion Time | Twice the joint preparation and welding/cooling time. | Half the joint preparation and welding/cooling time. |

| 5. Final Space Used | Longer, more cumbersome assembly. | Compact, streamlined assembly. |

This efficiency translates directly into lower installed cost and a more robust system. For contractors, it means faster project completion. For plant owners, it means a simpler, more maintainable system from day one.

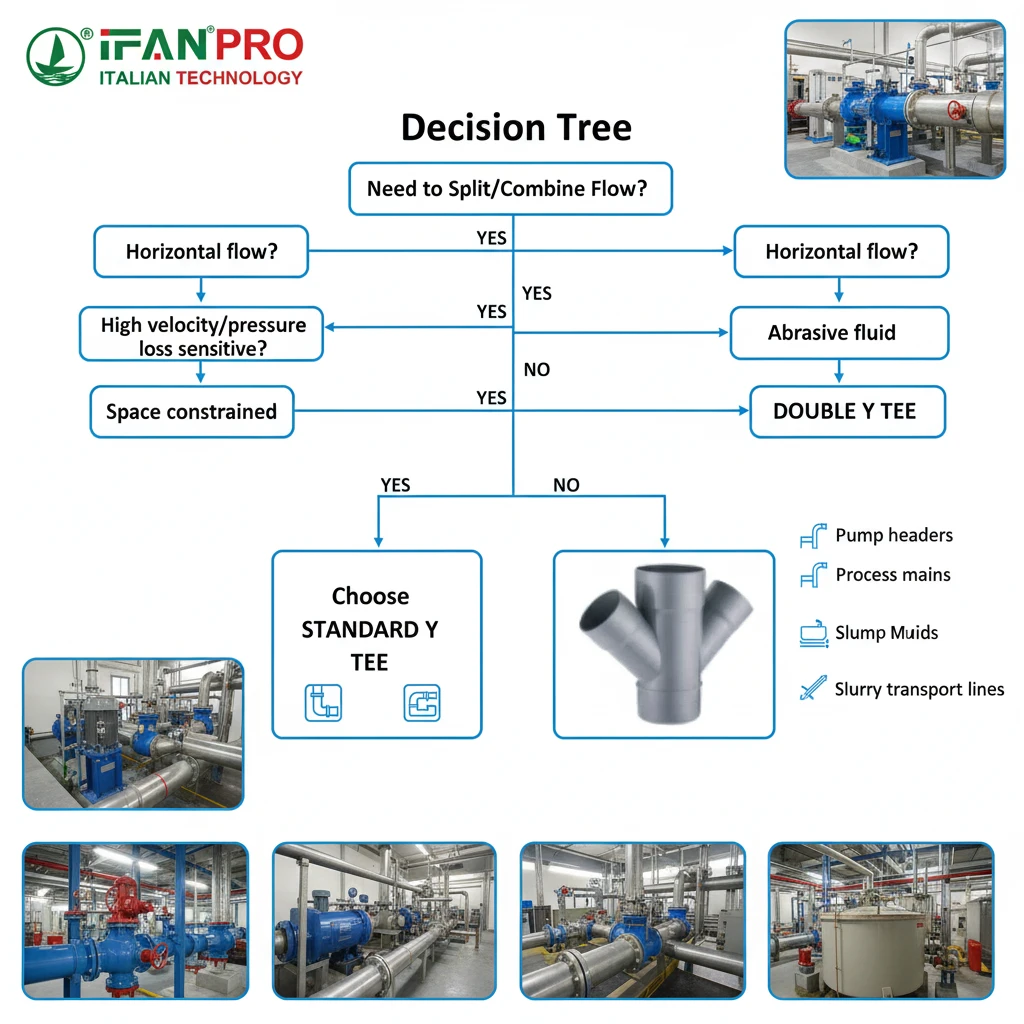

When Should You Choose a DOUBLE Y TEE Over a Standard Tee for Your Piping System?

The choice isn’t always automatic. Based on our projects, we guide clients using a simple rule: prioritize flow and efficiency, not just connection points.

You should choose a DOUBLE Y TEE over a standard tee when your system priority is hydraulic efficiency, low pressure drop, minimal turbulence, or vibration control. This is critical in applications like pump discharge, suction headers, slurry transport, HVAC main lines, and any system where energy costs or flow consistency are major concerns.

Evaluating Your System’s Priorities

Not every connection in a pipe network is critical. The choice between a standard tee and a DOUBLE Y TEE is an engineering decision based on cost versus benefit. Ask these questions about the specific connection point:

- Is flow rate or pressure preservation critical here? If yes, the Y-TEE is better.

- Is the fluid abrasive, slurry, or prone to settling? Turbulence in a standard tee can accelerate wear or cause buildup. The smooth flow of a Y-TEE is protective.

- Is system vibration or noise a concern? The turbulent “hammering” inside a standard tee can transmit noise and vibration. A Y-TEE creates a quieter operation.

- Is this a high-velocity or high-flow main line? The negative impact of a standard tee grows exponentially with flow velocity. On main lines, Y-TEEs are almost always justified.

Specific Application Recommendations

Based on IFAN’s experience across thousands of projects, here are clear scenarios where the DOUBLE Y TEE is the recommended choice:

- Pump Systems: On both the discharge and suction sides of pumps. On the discharge, it reduces energy loss from the pump. On the suction side, it is crucial for preventing turbulent flow that can cause cavitation and damage the pump impeller.

- Slurry and Abrasive Pipelines: For mining, dredging, or wastewater with solids. The smooth transition minimizes localized wear at the fitting, which is a severe problem with standard tees.

- HVAC Chilled/Hot Water Loops: In primary and secondary mains where efficient distribution is key to system balancing and energy efficiency.

- Industrial Process Lines: Where consistent flow and pressure are needed for chemical reactions, mixing, or heat exchange.

- Any Long-Distance Transmission Line: Where cumulative pressure drop from multiple fittings can dictate pump size and operating cost.

Decision-Making Guide Table

Use this table to help guide your specification:

| System Condition or Requirement | Recommended Fitting | Primary Reason |

|---|---|---|

| Non-critical drain line, vent line, or low-flow branch | Standard Tee | Lower initial fitting cost is the main driver. |

| High flow rate or velocity in the main line | DOUBLE Y TEE | To minimize severe pressure drop and turbulence. |

| Abrasive fluids (slurries, ash) | DOUBLE Y TEE | To reduce turbulent wear and extend fitting life. |

| Pump suction or discharge header | DOUBLE Y TEE | To improve pump efficiency and prevent cavitation. |

| System with vibration/noise issues | DOUBLE Y TEE | To eliminate a source of turbulent-induced pulsation. |

| Space-constrained installation | DOUBLE Y TEE | For its compact, integrated design vs. tee+elbow. |

| Budget-sensitive project with low flow | Standard Tee | Where hydraulic performance is not a priority. |

In summary, view the standard tee as a general-purpose connector and the DOUBLE Y TEE as a performance-optimized component. Investing in Y-TEEs for key points in your system pays back through energy savings, reduced maintenance, and greater reliability.

Conclusión

For smoother flow, lower energy costs, and quieter systems, the DOUBLE Y TEE is the superior choice over standard tees in critical applications. For high-performance DOUBLE Y TEE fittings, trust IFAN’s certified product range.

Comentarios recientes