The Great Debate: PEX vs Copper in Modern Plumbing

Professional plumbers increasingly favor PEX piping over traditional copper for most residential applications. This shift reflects practical considerations including installation speed, cost efficiency, and performance reliability.

Recent industry surveys show 68% of plumbers now recommend PEX for new construction projects. The preference stems from tangible benefits that directly impact job profitability and customer satisfaction.

Why Plumbers Choose PEX: Key Advantages

Installation Speed and Efficiency

PEX installation requires significantly less time than copper. A typical bathroom rough-in takes 3-4 hours with PEX versus 6-8 hours with copper soldering.

The flexible material bends around corners without fittings. This eliminates multiple joints that could potentially leak. Fewer connections mean faster installation and reduced labor costs.

Cost Considerations for Contractors

Material costs favor PEX substantially. Copper prices fluctuate with commodity markets, often creating budget uncertainty for large projects.

PEX maintains stable pricing year-round. This predictability helps plumbers provide accurate estimates and maintain profit margins.

Labor savings compound the cost advantage. Reduced installation time allows contractors to complete more jobs per week.

When Plumbers Still Prefer Copper

Commercial and High-End Applications

Copper remains the preferred choice for commercial buildings and luxury residential projects. Building codes often mandate copper for specific applications.

Many high-end clients specifically request copper for perceived quality and longevity. The material’s track record spans decades in challenging environments.

Exposed Piping Situations

Visible plumbing installations favor copper’s aesthetic appeal. The material develops an attractive patina over time.

PEX requires protection from UV exposure and physical damage. Copper handles exposed applications without degradation concerns.

Performance Comparison: Real-World Experience

Freeze Resistance

PEX expands without bursting when frozen, while copper pipes crack under freeze conditions. This advantage proves crucial in cold climate installations.

Repair costs for frozen copper pipes often exceed $1,000 per incident. PEX typically returns to normal function after thawing.

Pressure Ratings and Durability

Both materials handle standard residential water pressure effectively. PEX offers 160 PSI working pressure at 73°F.

Copper provides 250+ PSI capacity but requires proper installation to prevent pinhole leaks. Improper flux application creates long-term failure points.

Resistencia química

PEX resists acidic water conditions that corrode copper systems. Areas with aggressive water chemistry see extended PEX service life.

Copper performs well in neutral pH conditions but suffers in acidic environments. Water treatment may be necessary to prevent premature failure.

Regional Preferences and Code Requirements

Building Code Variations

Local codes influence material selection significantly. Some jurisdictions restrict PEX in certain applications.

Professional plumbers stay current on regional requirements. Code compliance drives material choices regardless of personal preference.

Climate Considerations

Northern climates favor PEX for freeze resistance. Southern regions show more mixed preferences based on other factors.

Coastal areas with aggressive water conditions often prefer PEX for corrosion resistance.

Installation Challenges and Solutions

PEX Installation Best Practices

Proper support spacing prevents sagging that reduces flow capacity. Installers must account for thermal expansion in long runs.

UV protection requirements add complexity to exposed installations. Planning prevents premature material degradation.

Copper Installation Expertise

Soldering skill levels vary among plumbers. Poor joints create immediate and long-term problems.

Lead-free solder requirements increased installation difficulty. Proper flux application becomes more critical with modern materials.

Cost Analysis: Total Project Economics

Initial Investment Comparison

PEX material costs run 25-40% less than copper for equivalent applications. Installation labor savings add another 30-50% project cost reduction.

Fitting costs favor PEX systems significantly. Crimp and expansion fittings cost less than copper solder joints.

Long-Term Value Considerations

Copper offers proven 50+ year service life in appropriate conditions. PEX provides 25-year manufacturer warranties with expected longer service.

Maintenance requirements differ substantially. PEX systems rarely require service while copper may need joint repairs over time.

Professional Recommendations by Application

New Construction Projects

Most plumbers recommend PEX for new residential construction. Speed advantages allow faster project completion.

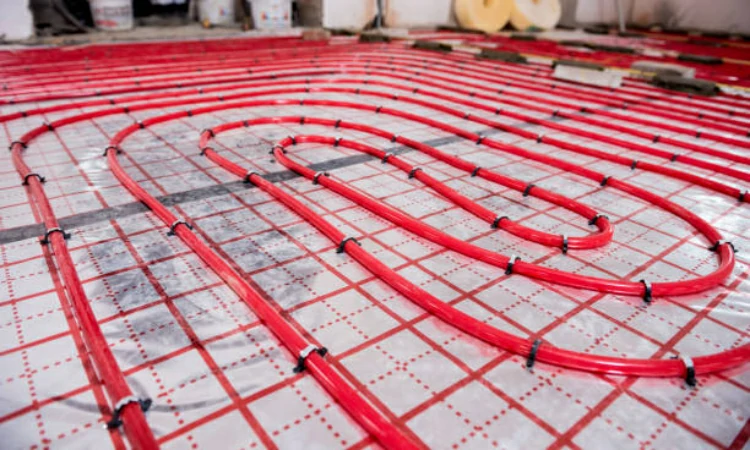

Whole-house manifold systems provide individual fixture control. This modern approach simplifies future maintenance and repairs.

Retrofit and Repair Work

Existing copper systems often receive copper repairs for consistency. Mixed material systems require transition fittings.

PEX works well for targeted renovations where new runs are needed. The material navigates existing structures easily.

Commercial Applications

Commercial projects typically specify copper for durability and code compliance. Many commercial codes haven’t adopted PEX approval.

Professional buildings favor copper’s proven track record. Long-term reliability outweighs installation cost considerations.

Future Trends in Plumber Preferences

Technology Advancements

Improved PEX formulations address early concerns about chemical leaching. Third-generation materials meet strict health standards.

Installation tools continue improving efficiency. Better crimping and expansion tools reduce installation errors.

Market Direction

Industry training programs emphasize PEX installation techniques. New plumbers learn PEX-first approaches to residential work.

Manufacturer support drives adoption through training and warranty programs. Technical assistance helps contractors avoid common mistakes.

Making the Right Choice for Your Project

The PEX versus copper decision depends on specific project requirements. Professional plumbers evaluate multiple factors before recommending materials.

Budget constraints often favor PEX for residential applications. Commercial projects may require copper regardless of cost considerations.

Local code requirements override personal preferences. Always consult current building codes before material selection.

Water chemistry testing helps determine optimal material choice. Aggressive water conditions may favor one material over another.

Need custom piping solutions for your project? Professional manufacturers provide engineered systems for specific applications. Custom fabrication ensures optimal performance and code compliance for unique installations.

Looking for reliable pipe manufacturing and custom solutions? Contact experienced manufacturers who understand both PEX and copper applications for professional guidance on your next project.

Comentarios recientes