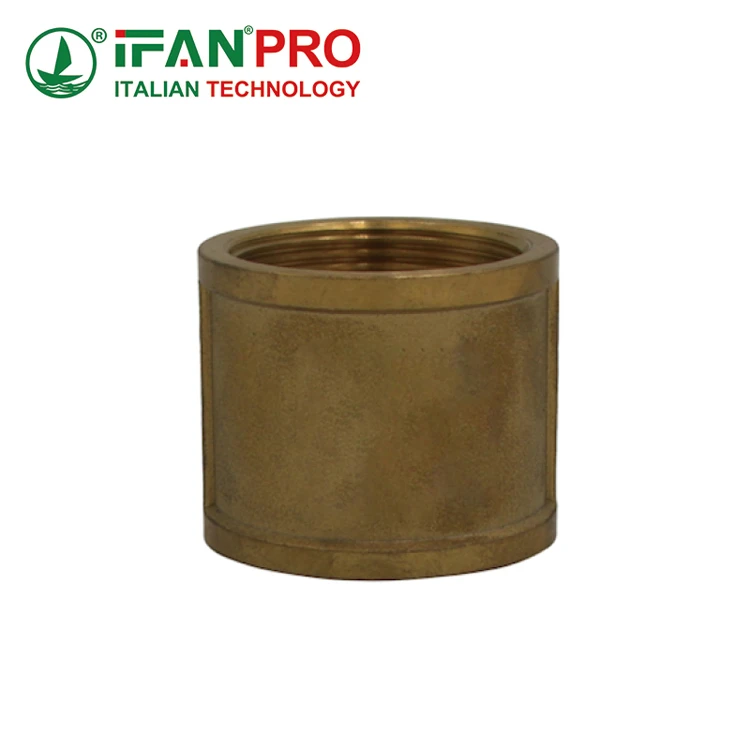

What Makes Socket 407 Brass Pipes Superior?

Socket 407 brass pipes represent the pinnacle of industrial piping solutions. These pipes combine durability with precision engineering. Manufacturers rely on them for critical applications where failure isn’t an option.

The unique socket design ensures leak-proof connections. This feature eliminates common joint failures that plague inferior products. Professional contractors choose Socket 407 for projects demanding reliability.

Key Features of High-Quality Socket 407 Brass Pipes

Corrosion Resistance

Brass composition provides exceptional corrosion resistance. The material withstands harsh chemicals and extreme temperatures. This durability extends service life significantly beyond standard alternatives.

Precision Socket Design

The 407 socket configuration offers superior joint integrity. Machined tolerances ensure perfect fits every time. This precision reduces installation time and labor costs.

Material Composition

High-grade brass alloy delivers consistent performance. The copper-zinc blend provides optimal strength-to-weight ratio. Quality control ensures uniform material properties throughout.

Applications for Socket 407 Brass Pipes

Industrial facilities use these pipes for critical systems. HVAC installations benefit from their thermal properties. Plumbing systems rely on their corrosion resistance.

Chemical processing plants specify Socket 407 for aggressive media. The brass construction handles acidic and alkaline solutions safely. Marine applications leverage their saltwater resistance.

Direct Factory Benefits

Buying directly from manufacturers eliminates middleman costs. Factory-direct pricing offers significant savings on bulk orders. Quality control starts at the source, not the distributor.

Custom specifications become possible with direct relationships. Manufacturers can modify designs for specific applications. Lead times reduce when dealing directly with production facilities.

Quality Standards and Certifications

Socket 407 brass pipes meet international standards. ISO certifications ensure consistent quality across production runs. Third-party testing validates performance claims.

Material certificates accompany every shipment. Chemical composition reports verify brass alloy specifications. Dimensional inspections confirm socket tolerances.

Installation Advantages

Socket joints simplify installation procedures. No threading or welding required for basic connections. Skilled technicians complete installations faster.

The design accommodates thermal expansion naturally. Stress concentrations reduce compared to threaded alternatives. Maintenance requirements drop significantly over time.

Cost Analysis: Long-term Value

Initial investment in quality pays dividends long-term. Reduced maintenance costs offset higher upfront prices. System reliability prevents costly downtime.

Replacement frequency drops with superior materials. Labor costs decrease due to easier maintenance. Total cost of ownership favors quality products consistently.

Customization Options Available

Factory capabilities include custom socket configurations. Pipe lengths adapt to specific installation requirements. Wall thicknesses modify for pressure specifications.

Special alloy compositions address unique environments. Surface treatments enhance specific properties. End connections customize for existing systems.

Ordering Direct: Process and Benefits

Direct ordering streamlines the procurement process. Factory representatives understand technical requirements better. Engineering support comes standard with direct relationships.

Bulk pricing structures reward larger orders significantly. Shipping arrangements optimize delivery timing and costs. Quality issues resolve faster through direct communication.

Technical Specifications

Socket 407 brass pipes typically feature:

- Copper content: 60-70%

- Zinc content: 30-40%

- Working pressure: Up to 200 PSI

- Temperature range: -20°F to 400°F

- Socket depth: Standard 1.5 inches

- Wall thickness: 0.125 to 0.250 inches

Proceso de garantía de calidad

Manufacturing begins with certified raw materials. In-process inspections catch defects early. Final testing validates performance before shipping.

Dimensional checks ensure socket tolerances. Pressure testing verifies integrity under load. Material testing confirms alloy composition accuracy.

Why Choose Factory Direct?

Eliminating distributors reduces costs substantially. Direct communication improves order accuracy. Technical support comes from actual manufacturers.

Custom requirements receive proper attention. Quality issues resolve through direct channels. Relationship building creates long-term value.

Conclusión

Socket 407 brass pipes deliver unmatched reliability for critical applications. Direct factory purchasing maximizes value while ensuring quality. Professional installers and facility managers trust these proven solutions.

The combination of superior materials, precision manufacturing, and direct sales creates compelling value. Industrial applications demand this level of quality and service. Choose Socket 407 brass pipes for your next project.

Contact our factory directly for technical specifications and pricing. Our engineering team stands ready to support your specific requirements. Experience the difference that direct manufacturing relationships provide.

Comentarios recientes