I once watched a system fail because a cheap valve couldn’t hold its setting. Pressure spiked, and the flow to one zone dropped to zero. This experience taught me the critical difference between any valve and one built for true control.

Yes, the IFAN 121UC thermostatic radiator valve (TRV) is specifically engineered to provide precise, adjustable flow control in manifold setups, not just basic on/off functionality. Its pre-setting mechanism and pressure-independent design allow for accurate flow regulation and stable performance, making it an ideal choice for zoning in systems like underfloor heating.

Many valves claim to control flow, but few perform reliably under real-world conditions. Let’s examine how a professional-grade valve like the 121UC achieves true precision.

Does It Offer Accurate Flow Regulation or Just On/Off Functionality?

A simple on/off valve can cause big problems in a balanced system. I’ve seen rooms overheat while others stay cold because the valve couldn’t provide an intermediate setting.

The 121UC valve offers accurate, pre-settable flow regulation. It is not a simple shut-off valve. By turning the adjustment cap, you select a specific pre-set flow rate (Kvs value), which the valve maintains. This allows fine-tuning of the heat output for each circuit or radiator, which is essential for achieving hydraulic balance and comfort in a multi-zone system.

The Mechanics of Precise Regulation

Understanding flow regulation starts with knowing what a valve needs to do. Its job is to create a specific, repeatable resistance in the pipeline. The 121UC does this with a built-in pre-setting mechanism.

Inside the valve body, an adjustment mechanism changes the size of the opening. When you turn the cap to a numbered setting (e.g., from 0 to 5), you are not just “opening it a bit more.” You are selecting a pre-calibrated orifice size. Each setting corresponds to a specific Kvs value, which is the flow rate in cubic meters per hour that passes through the valve at a set pressure difference. This is a quantifiable, engineering-based method of control.

Contrasting Valve Types

To see why this matters, let’s compare it to common alternatives:

- Simple On/Off Ball Valve: This is like a light switch. It is either fully open (maximum flow) or fully closed (no flow). There is no in-between setting for balancing.

- Manual Wheel Valve: While it can be partially opened, its flow rate is highly sensitive to system pressure changes and is not repeatable. If someone bumps the handle, the setting is lost.

- Pre-Settable TRV (like the 121UC): This provides a locked, numbered setting. Once set, the flow rate is defined and repeatable. The thermostatic head can then automatically adjust around this base setting for temperature control.

The Role of the Kvs Value

The Kvs value is the key to precision. A system designer calculates the required flow for each circuit to deliver the right amount of heat. They then select a valve setting that provides that exact flow. For example:

- Setting 1 might have a Kvs of 0.03 m³/h

- Setting 3 might have a Kvs of 0.15 m³/h

- Setting 5 might have a Kvs of 0.40 m³/h

This table shows how different settings cater to different needs:

| Valve Setting | Typical Kvs Range (m³/h) | Ideal Application |

|---|---|---|

| Low (1-2) | 0.03 – 0.10 | Small radiators or short underfloor heating loops. |

| Medium (3) | 0.15 – 0.25 | Standard radiators or medium-length loops. |

| High (4-5) | 0.30 – 0.40 | Large radiators, long loops, or high heat-demand zones. |

In summary, the 121UC provides metered, adjustable flow regulation. This is the foundation for balancing a system, ensuring that all zones get their designed share of hot water, which a simple on/off valve can never achieve.

How Does It Maintain Stable Flow Settings Despite System Pressure Variations?

System pressure is never perfectly stable. Pumps cycle, other valves open and close, and flow can fluctuate. A good valve must ignore this noise.

The 121UC valve maintains stable flow through its pressure-independent design. Its internal mechanism automatically compensates for upstream and downstream pressure changes within a specified range. This means the selected pre-set flow rate remains constant, whether other zones in the manifold are turning on or off, preventing one zone from stealing flow from another.

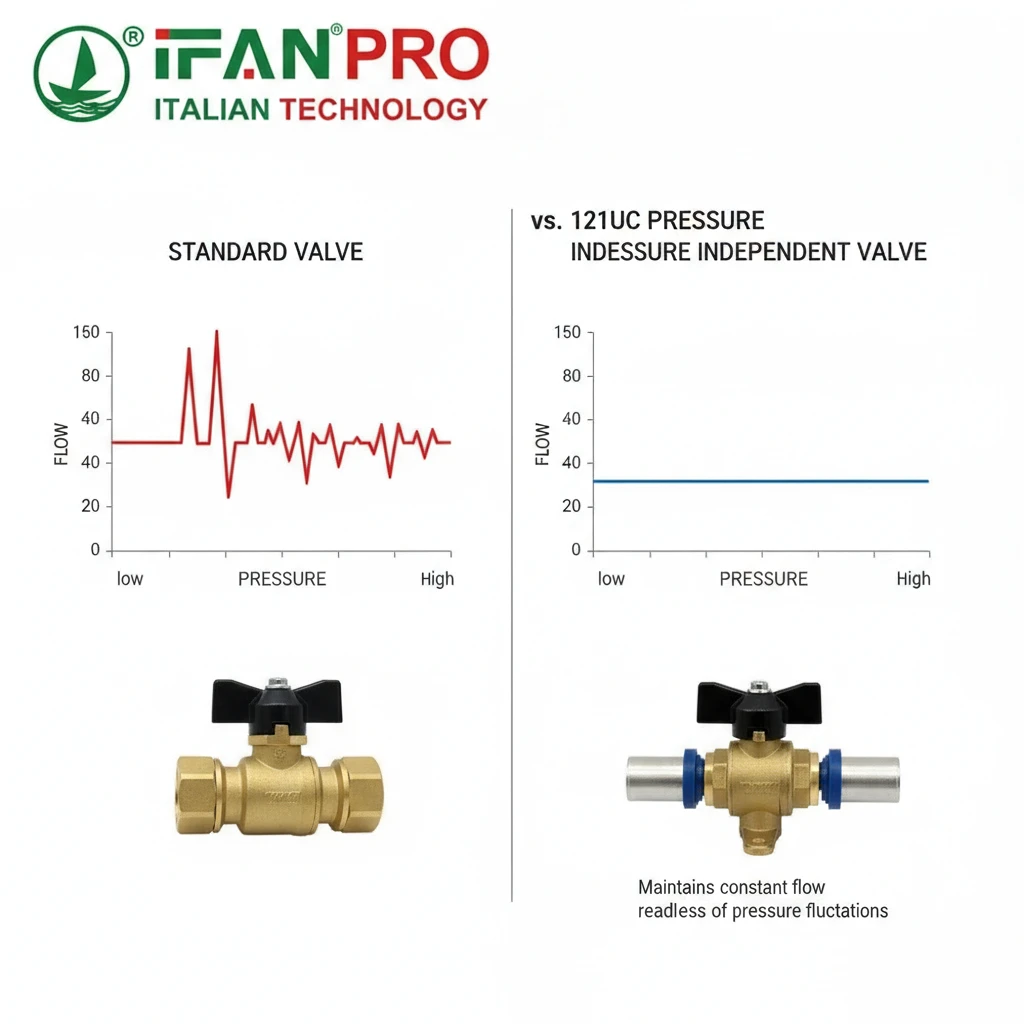

The Problem of Pressure Dependency

In a standard, pressure-dependent valve, the flow rate is a direct result of the pressure difference across it. Think of it like a garden hose. If you open another hose elsewhere, the pressure drops, and your flow decreases. In a heating manifold, when one zone valve opens, it can cause a pressure drop, reducing flow to other circuits. This leads to uneven heating and comfort complaints.

How Pressure Independence Works

The 121UC incorporates a design that decouples flow from pressure fluctuations. Inside, a dynamic regulating cartridge contains a flexible diaphragm or a spring-loaded mechanism. This component senses the pressure difference across the valve.

When system pressure changes, this internal mechanism instantly adjusts the size of the flow opening in the opposite direction. For example:

- If pressure increases, the mechanism slightly restricts the opening to prevent excess flow.

- If pressure decreases, the mechanism allows the opening to widen slightly to maintain the set flow.

The result is a constant, stable flow rate across a wide working range, typically from about 15-150 kPa of differential pressure. This is a critical feature for modern systems with variable speed pumps and multiple zones.

Benefits for System Performance and Comfort

This stability solves major pain points:

- Eliminates Zonal Interference: A shower turning on (activating a hot water circuit) won’t cause a bedroom radiator to cool down because its valve flow stays constant.

- Ensures Design Performance: The system performs as the engineer calculated, delivering the correct BTU/hr to each space.

- Reduces Callbacks: Installers and builders face fewer complaints about “cold rooms” after the system is commissioned.

The alternative—constantly trying to re-balance a system with pressure-dependent valves—is time-consuming and often ineffective. The pressure-independent feature of the 121UC makes the system inherently stable and self-regulating.

Is It Designed for Easy Integration with Hydraulic Balancing Manifolds?

A valve that’s difficult to install or service can ruin the efficiency of a well-designed manifold. Ease of integration is a feature, not an afterthought.

Yes, the 121UC valve is designed specifically for easy integration with standard hydraulic balancing manifolds. It features a compact, straight-through body with union nut connections for simple, tool-free installation and removal. Its design allows for easy access to the pre-setting cap and thermostatic head even in tight manifold cabinets, streamlining both initial setup and future maintenance.

Physical Design for Manifold Compatibility

The valve’s form factor is crucial. The 121UC typically uses a straight pattern body with female thread connections (like G½” or others) that match the standard ports on distribution manifolds. The union nut connection is key. It allows the installer to hand-tighten the valve onto the manifold station without needing to twist the entire valve body or manifold piping, which prevents stress on the joints.

Furthermore, its compact length and orientation ensure it doesn’t protrude excessively, keeping the manifold cabinet neat and accessible. The pre-setting cap (with clear numerical indicators) and the thermostatic head socket are positioned for easy viewing and adjustment from the front of the manifold.

The Installation and Commissioning Workflow

Easy integration means the valve supports a logical workflow:

- Mounting: Screw the valve body onto the manifold station.

- Piping: Connect the circuit pipe to the other end of the valve.

- Pre-Setting: During hydraulic balancing, the technician uses a special key or tool to turn the adjustment cap to the calculated setting (e.g., “3”). The cap locks in place, preventing accidental changes.

- Head Attachment: Finally, the thermostatic or actuator head is snapped onto the valve body. This can be done later, allowing the system to be pressurized and tested first.

This design separates the hydraulic function (flow setting) from the control function (temperature command), which is best practice. It also means a faulty thermostatic head can be replaced in seconds without draining the system or disturbing the flow setting.

Comparison to Less Integrated Solutions

Some systems use separate valves, fittings, and meters assembled in a custom way. This approach has drawbacks:

- More Leak Points: Every extra connection is a potential leak.

- Bulky Assembly: Takes up more space.

- Difficult Servicing: Isolating one circuit may require special tools.

The 121UC, as a dedicated manifold valve, creates a cleaner, more reliable, and service-friendly package. For builders and technicians, this translates to faster installation, fewer errors, and easier long-term maintenance.

What Features Make It Suitable for Zoning in Underfloor Heating Systems?

Underfloor heating (UFH) has unique demands: low flow rates, many parallel circuits, and a need for silent, stable operation. The wrong valve creates cold floors and high energy bills.

The 121UC valve is highly suitable for UFH zoning due to its low minimum flow setting capability, pressure-independent stability, compact manifold fit, and compatibility with both thermostatic and actuator heads. These features ensure precise balancing of multiple low-flow loops, prevent interaction between zones, and allow for automated room-by-room temperature control.

Meeting the Specific Demands of UFH

Underfloor heating loops are long, narrow pipes with high hydraulic resistance. They require careful balancing to ensure water reaches the end of every loop. The 121UC addresses this perfectly.

1. Precise Low-Flow Control: UFH loops often need very small, precise flow rates. The 121UC’s lower pre-setting positions (like Settings 1 and 2) offer very low Kvs values. This allows technicians to finely tune each loop, ensuring even heat distribution across the floor without any loops being starved of flow.

2. Stability for Consistent Comfort: UFH systems are slow to respond. A flow fluctuation caused by a pressure-dependent valve can take hours to correct, leading to prolonged discomfort. The pressure-independent nature of the 121UC ensures each loop receives its designed flow continuously, maintaining steady floor temperature and comfort.

3. Silent Operation: The internal design of a quality pre-set valve minimizes water turbulence and noise, which is essential for the quiet operation expected from an in-floor system.

Integration with UFH Control Systems

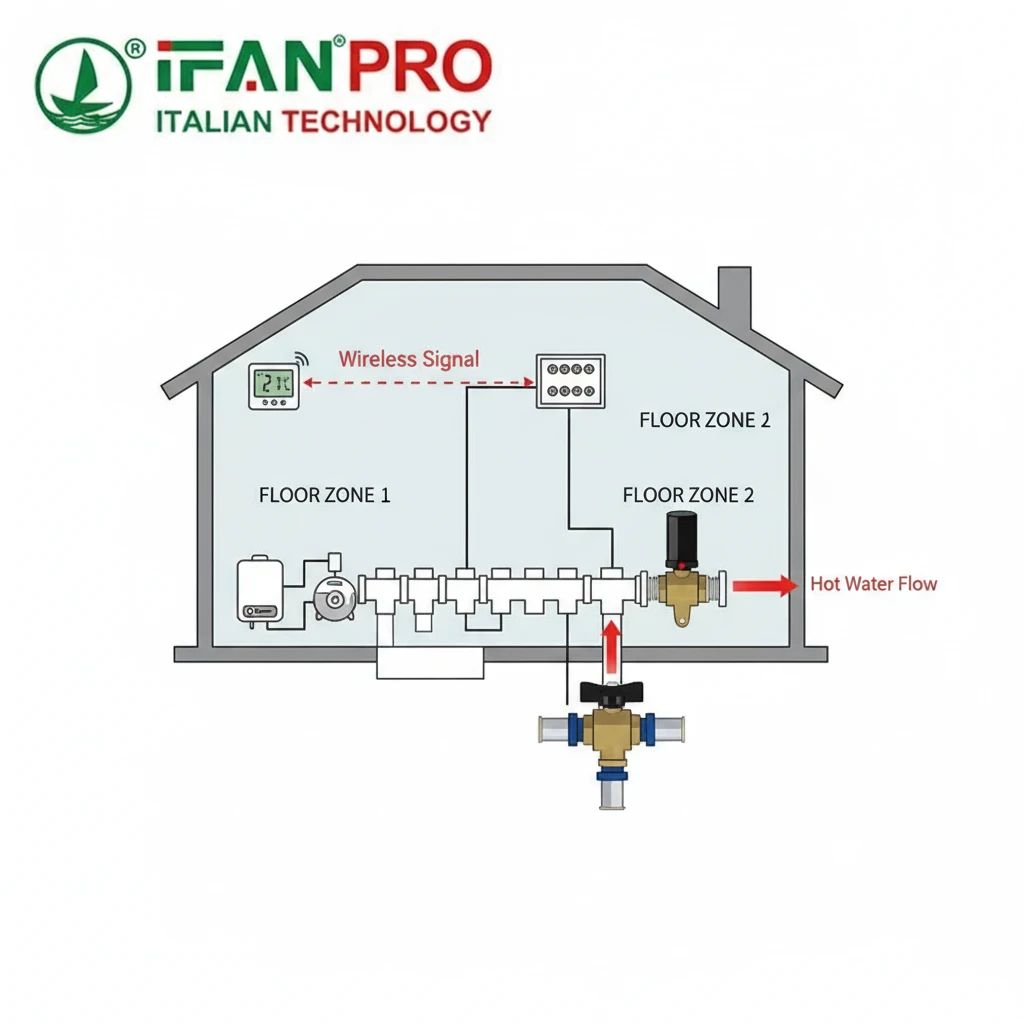

Modern UFH systems rarely use manual thermostatic heads on the manifold. They typically use electric actuators connected to a central programmer or room thermostats.

The 121UC is designed for this. Its valve stem is compatible with a wide range of standard (usually M30x1.5) thermal and electric actuators. An electric actuator can be mounted on each valve on the manifold. This actuator is then wired to a control system that can open or close the valve based on a room thermostat’s call for heat.

This creates a fully zoned system:

- Each room or zone has its own thermostat.

- Each manifold circuit valve has an actuator.

- The control system only opens valves for zones that need heat, saving energy.

- The pre-set function of the 121UC ensures that when a valve is open, it delivers the correct amount of flow.

Feature Summary for UFH Applications

| Feature | Benefit for Underfloor Heating |

|---|---|

| Low Kvs Settings | Enables precise balancing of low-flow, high-resistance heating loops. |

| Pressure Independence | Prevents zone interaction and maintains stable loop flow for even heating. |

| Compact Union Connection | Allows dense, tidy arrangement on a multi-circuit UFH distribution manifold. |

| Actuator Compatibility | Enables integration with automated zoning controls for room-by-room scheduling. |

| Lockable Pre-Setting | Protects the hydraulic balance from being accidentally altered after commissioning. |

In essence, the 121UC provides the precise hydraulic foundation that allows the comfort benefits of a zoned underfloor heating system to be fully realized.

Conclusión

For precise, stable, and integratable flow control in manifold systems, the pressure-independent IFAN 121UC valve is an excellent solution, especially for zoned applications like underfloor heating.

Comentarios recientes