Brass Plumbing Fitting Leakage Repair Guide

Introducción

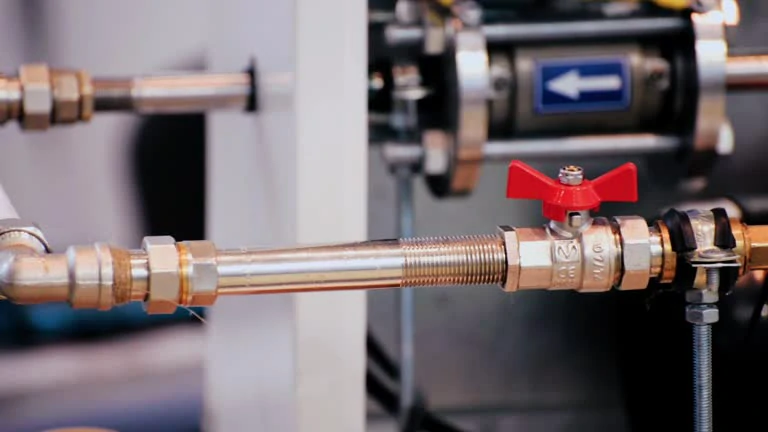

Brass plumbing fitting are known for their durability and resistance to corrosion. However, even the most reliable fitting can develop leaks over time. Addressing leaks promptly ensures the longevity of your plumbing system and prevents further damage. This guide outlines the steps for identifying and repairing leaks in brass plumbing fittings.

Identifying the Source of the Leak

Visual Inspection

Start with a thorough visual inspection. Look for signs of water around the fitting, such as water droplets, puddles, or discoloration. Check all connections, joints, and fittings.

Feel for Moisture

Run your fingers along the fitting and surrounding pipes. Feel for any moisture that may indicate a leak. This can help pinpoint the exact location of the problem.

Listen for Drips

Listen for dripping sounds, which can help identify a slow leak. Sometimes, leaks can be hard to see but easy to hear.

Preparing for Repair

Turn Off the Water Supply

Before starting any repair work, turn off the water supply to the affected area. This prevents further water damage and allows you to work safely.

Drain the Pipes

Open the faucets connected to the affected pipes to drain any remaining water. This step ensures a dry working area and reduces the risk of further leaks during the repair process.

Gather Necessary Tools and Materials

Prepare the necessary tools and materials, such as pipe wrenches, Teflon tape, pipe joint compound, replacement fittings, and plumber’s tape. Having everything ready ensures a smoother repair process.

Repairing Threaded Brass Fittings

Tighten Loose Fittings

If a leak occurs at a threaded joint, try tightening the fitting with a pipe wrench. Be careful not to over-tighten, as this can cause damage to the fitting or pipe.

Apply Teflon Tape

If tightening doesn’t stop the leak, disassemble the fitting. Wrap Teflon tape around the threads of the male fitting. Ensure the tape covers the threads completely to create a watertight seal.

Reassemble the Joint

Reassemble the joint by screwing the fittings back together. Tighten securely, but avoid over-tightening. Turn the water supply back on and check for leaks.

Repairing Soldered Brass Fittings

Cut Out the Damaged Section

Use a pipe cutter to remove the damaged section of the pipe if the leak is in a soldered joint. Cut slightly beyond the damaged area to ensure all corrosion or damage is removed.

Clean the Pipe Ends

Clean the pipe ends using sandpaper or a pipe cleaning tool. Remove any oxidation or debris to ensure a proper solder connection.

Apply Flux and Connect Fittings

Apply flux to the pipe ends and the inside of the replacement fitting. This helps the solder flow and create a strong bond. Insert the fitting into the pipe ends.

Heat and Solder the Joint

Use a propane torch to heat the joint evenly. Apply solder to the joint, ensuring it melts and flows around the entire connection. Allow the joint to cool naturally.

Repairing Compression Brass Fittings

Tighten the Compression Nut

If a leak occurs at a compression fitting, try tightening the compression nut with a wrench. Be careful not to over-tighten, as this can damage the fitting.

Replace the Compression Ring

If tightening doesn’t stop the leak, disassemble the fitting. Replace the compression ring and reassemble the joint. Ensure the ring sits properly on the pipe and fits snugly.

Reassemble and Test

Reassemble the fitting and tighten the compression nut securely. Turn the water supply back on and check for leaks.

Preventing Future Leaks

Regular Maintenance

Perform regular maintenance on your plumbing system to prevent future leaks. Inspect for signs of corrosion, check fittings and joints, and ensure all connections are secure.

Use High-Quality Materials

Use high-quality fittings and materials to ensure the longevity of your plumbing system. Cheaper materials may save money initially but can lead to leaks and repairs down the line.

Apply Proper Techniques

Ensure all fittings are installed using proper techniques. Incorrect installation can lead to leaks and damage. Follow manufacturer guidelines for best results.

Check Water Pressure

High water pressure can cause leaks in brass fittings. Install a pressure regulator if necessary to keep the pressure within safe limits.

Conclusión

Repairing leaks in brass plumbing fittings requires attention to detail and proper techniques. By identifying leaks early, preparing adequately, and following the correct repair procedures, you can extend the life of your plumbing system and maintain its efficiency. Regular maintenance and preventive measures will help avoid future leaks and ensure a reliable water supply for your home.

Conectar

IFAN es un fabricante chino de tuberías, accesorios y válvulas de plástico con 30 años de experiencia. Si está interesado en IFAN accesorios de cobre, válvulas de cobre, tuberías y accesorios de plástico, póngase en contacto con nosotros. IFAN le ofrece una variedad de tuberías estándar para satisfacer sus necesidades específicas. Haga clic a continuación para obtener más información sobre la amplia gama de productos de válvulas y productos relacionados con sistemas de tuberías asequibles y rentables de IFAN.

Responderemos a su correo electrónico o fax en 24 horas.

Puede llamarnos en cualquier momento si tiene alguna duda sobre nuestra producción.

Para más información, visite nuestra página web https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Comentarios recientes