I once watched an installer struggle for an hour to align pipes with a standard tee. When we switched to a sweep tee on the next job, the process was smooth and took half the time. That hands-on difference is real.

Yes, sweep tees are generally easier to install than standard tees. Their curved, flowing design allows for more flexible pipe alignment, forgives minor measurement errors, and often requires less force to fit pipes together. This leads to faster, less labor-intensive installations and reduces the risk of stress on the fittings.

If you manage plumbing projects, you know that installation speed and reliability directly impact your budget and timeline. Let’s break down exactly why sweep tees can make your next job simpler and more efficient.

Do Sweep Tees Require Less Time and Labor During Installation Than Standard Tees?

Every minute of labor costs money. I’ve seen crews finish runs faster with sweep tees, and the reason is in their design.

Yes, sweep tees require less time and labor because their curved elbows provide a wider angle for pipe entry, making alignment easier and faster. This design forgives small measurement offsets, reducing time spent on precise cuts and adjustments that are critical with sharp-angled standard tees.

The Alignment Advantage

The main time-saving benefit comes from easier alignment. A standard tee has sharp, 90-degree branch connections. To connect a pipe into this branch, you must align it perfectly perpendicular to the run. If your cut is off by a few degrees, the pipe won’t seat correctly. You then have to re-cut or use excessive force, which can damage the fitting.

A sweep tee, however, has a gently curved branch. Think of it like a gradual ramp versus a steep staircase. This curve gives you a “funnel” effect. The pipe can enter at a slightly wider range of angles and still guide itself into the correct position as you push it in. This flexibility cuts down on frustrating trial-and-error adjustments on site.

Reduced Force and Physical Effort

Because the path is curved, you don’t need to fight against a sharp corner. Pushing a pipe into a sweep tee’s branch requires less physical force than forcing it into a standard tee’s right-angle entry. This is easier on the installer’s body and reduces the risk of accidentally bending or stressing other parts of the assembled pipework. In short, the work is less strenuous and moves quicker.

Step-by-Step Time Comparison

Let’s compare a typical installation step for a branch line:

| Installation Step | With a Standard Tee | With a Sweep Tee |

|---|---|---|

| 1. Measuring & Cutting | Requires high precision. Must be exactly perpendicular. | More forgiving. A slight angle on the cut is often acceptable. |

| 2. Dry Fitting (Checking Alignment) | Often requires multiple checks and re-cuts. | Usually fits correctly on the first or second try. |

| 3. Applying Solvent & Joining | May require awkward pressure to align while joining. | Smoother, more direct pressure as the pipe slides along the curve. |

| Overall Labor Time | Higher due to precision demands and rework. | Lower due to forgiving design and smoother assembly. |

Furthermore, for solvent-weld systems, the easier alignment means you have more time to make the joint before the cement sets. This decreases the chance of a failed, leaky joint that you would later have to cut out and replace—a major time and cost overrun.

How Do Sweep Tees Improve Water Flow Compared to Standard Tee Fittings?

Water pressure is king in a plumbing system. Clients complain about weak shower pressure, often unaware that fitting choice is a key culprit.

Sweep tees dramatically improve water flow by providing a smooth, curved path that reduces turbulence and resistance. In contrast, the sharp, 90-degree turn in a standard tee creates a “water hammer” effect, disrupting flow, increasing pressure drop, and potentially leading to noise and vibration in the pipes.

The Physics of Flow: Turbulence vs. Laminar Flow

To understand the benefit, picture water as cars on a highway. A standard tee is like an immediate 90-degree turn—cars must slow down almost to a stop, causing a traffic jam (turbulence) and losing momentum. A sweep tee is like a gentle, banked highway off-ramp—cars can maintain speed, traffic flows smoothly (laminar flow), and momentum is preserved.

This smooth, laminar flow in a sweep tee has several practical benefits:

- Higher Effective Pressure: Less turbulence means less energy is lost. The water coming out of the downstream fixture (like a showerhead) will have stronger pressure because the fitting itself creates less resistance.

- Reduced Noise: The violent crashing of water against the sharp corner of a standard tee causes noise and vibration. You might hear a “whooshing” or knocking sound in your walls. Sweep tees are significantly quieter.

- Minimized Erosion: Over many years, turbulent, high-velocity water can slowly erode the inner wall of a fitting at the impact point. The smooth flow in a sweep tee eliminates this focal point of wear, contributing to longer system life.

Impact on System Performance

This isn’t just a minor issue. In systems with multiple tee fittings—like a typical residential bathroom group—the pressure drop from several standard tees can add up. The result is poor performance at the furthest fixture. Sweep tees help maintain consistent pressure throughout the entire system.

Flow Efficiency Comparison

| Flow Characteristic | Standard Tee | Sweep Tee |

|---|---|---|

| Type of Flow at Branch | Highly Turbulent | Smooth, Laminar |

| Pressure Drop | High | Low |

| Noise Generation | High (Can cause water hammer) | Low |

| Long-Term Wear | Higher risk of erosion at corner | Even, minimal wear |

| Best For | Non-critical drain lines or low-flow vents | Pressurized supply lines where flow rate matters |

For applications like home water supply, hydronic heating, or any system where flow efficiency is critical, specifying sweep tees is a simple design choice that yields measurable performance improvements.

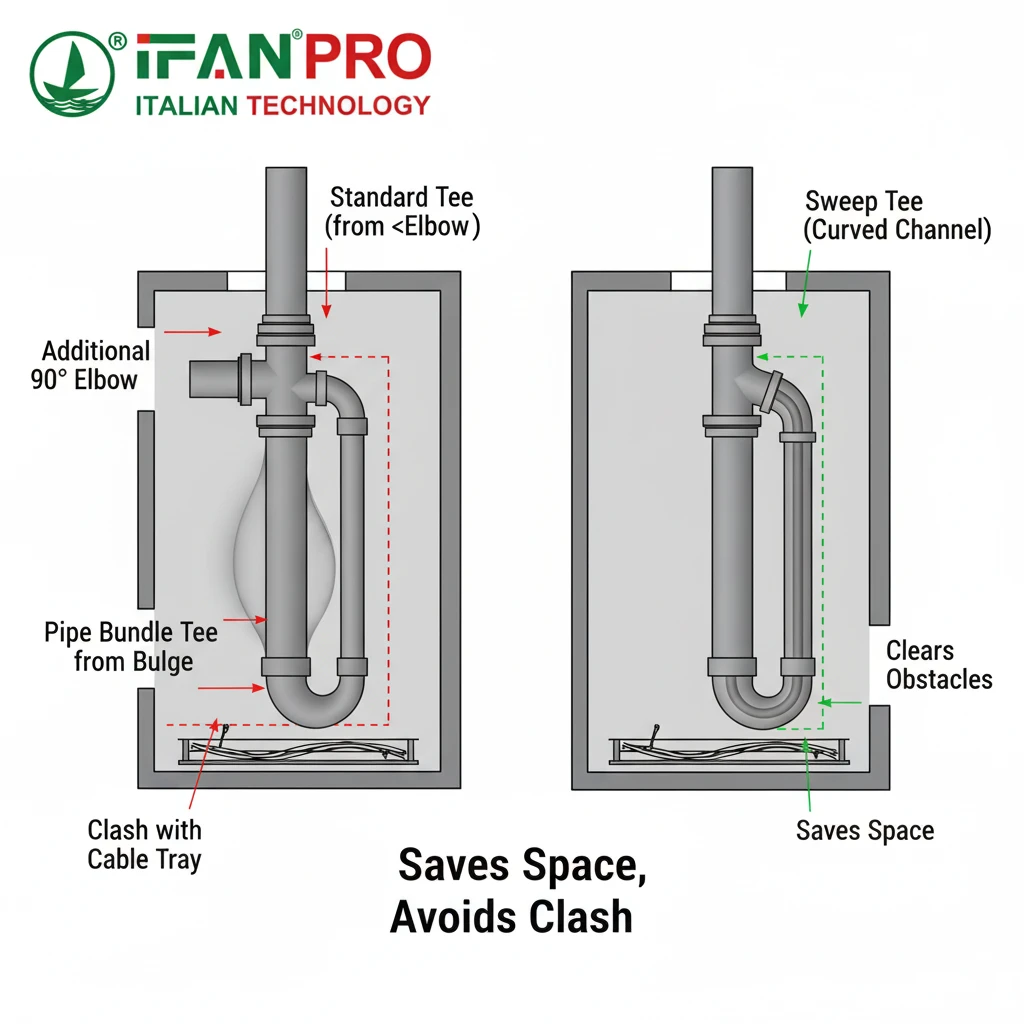

What Are the Space and Alignment Advantages of Using Sweep Tees Over Standard Tees?

Tight spaces behind walls or in mechanical rooms are a constant challenge. Sweep tees offer a clever geometric solution.

The primary space advantage of sweep tees is their ability to create a branch connection with a wider, more gradual bend. This often allows for installation in tighter vertical or horizontal spaces where the longer radius of the curve can be accommodated more easily than the rigid geometry of a standard tee, which requires more clearance for straight pipe entry.

Solving Alignment Problems in Constrained Spaces

Imagine you need to run a pipe through a wall stud and then immediately tee off to a fixture. With a standard tee, the branch points straight out. You need enough space on the other side of the stud for the entire fitting plus a straight segment of pipe. This can be impossible in tight framing.

A sweep tee’s curve changes the geometry. The branch line begins to turn immediately as it leaves the main run. This means the pipe starts changing direction within the footprint of the fitting itself. You can often route the branch line along a different path (like angling up or down) without needing extra space for a separate elbow fitting right after the tee. This integrated direction change is a major space-saver.

Flexibility for Off-Axis Connections

Sometimes, pipes are not perfectly parallel or perpendicular due to building constraints. The rigid 90-degree requirement of a standard tee forces you to use additional fittings (like two 45-degree elbows) to make the connection, which adds cost, potential leak points, and labor.

A sweep tee provides inherent flexibility. Its curved leg can absorb small misalignments between the main pipe and the branch pipe. This can sometimes allow you to connect pipes that are slightly off-angle without needing extra correction fittings. This simplifies the bill of materials and the installation process.

Application Examples: Where Space Matters Most

| Scenario | Challenge with Standard Tee | Solution with Sweep Tee |

|---|---|---|

| Tight Wall Cavity | Requires large open space for the perpendicular branch. | Curved branch can turn within the cavity, fitting between studs. |

| Under a Shallow Sink | Limited vertical space for the trap arm connection. | The sweep can start the horizontal drain run lower, saving height. |

| Complex Manifold Setup | Requires multiple fittings spaced far apart for clearance. | Sweep tees can be packed closer together due to their flow-directed design. |

| Retrofit/Repair Work | Existing pipes are not perfectly aligned. | Can accommodate minor existing misalignments without re-piping. |

In essence, the sweep tee is a more adaptable component. It gives the installer and designer more options to solve spatial puzzles, often leading to a cleaner, less cluttered, and more efficient pipe layout.

Can Sweep Tees Reduce Long-Term Maintenance Costs Compared to Standard Tees?

My clients prioritize upfront cost, but smart ones ask about long-term upkeep. Sweep tees are an investment in reliability.

Yes, sweep tees can reduce long-term maintenance costs. Their smooth flow minimizes turbulence-related erosion and vibration, leading to less wear on the fitting and connected pipes. Crucially, they greatly reduce the risk of debris buildup and clogs at the branch connection, which is a common failure point in standard tees, avoiding costly emergency cleanouts or repairs.

Preventing Clogs and Blockages

This is the most significant maintenance advantage, especially for drainage systems. In a standard tee, the wastewater hits a sharp corner and loses velocity. Solids like hair, grease, or debris can easily settle and catch on that internal corner. Over time, this creates a “catch point” for clogs to form.

A sweep tee has no such sharp corner. The smooth, curved transition keeps solids moving in suspension, carrying them around the bend and down the drain. This design is fundamentally more self-cleaning. For building managers or homeowners, this means fewer calls to clear slow drains and a lower chance of major blockages that can cause backups and water damage.

Reducing System Stress and Fatigue

As discussed earlier, the turbulent flow in a standard tee causes vibration and water hammer. This constant, low-grade hammering stresses not just the tee itself, but also the pipes connected to it and the straps holding them to the wall. Over decades, this can contribute to fatigue, loose fittings, and small leaks.

Sweep tees promote smooth, quiet flow. This puts far less mechanical stress on the entire piping assembly. A less stressed system is a more reliable system that requires fewer interventions over its 50-year lifespan.

Comparative Maintenance Risk Analysis

| Potential Maintenance Issue | Risk with Standard Tee | Risk with Sweep Tee | Long-Term Cost Implication |

|---|---|---|---|

| Clog Formation at Branch | High (Sharp corner traps debris) | Low (Swept design carries debris through) | High: Plumber call-out, cleanout fees, potential damage. |

| Erosion/Thinning of Fitting Wall | Moderate (Turbulence focused on one point) | Very Low (Smooth, even flow) | Moderate: Potential for pinhole leaks after many years. |

| Vibration & Noise Complaints | High (Water hammer effect) | Low | Variable: Tenant complaints, investigation time, added damping. |

| Joint Stress from Flow Forces | High (Abrupt direction change) | Low (Gradual direction change) | Low but present: Contributes to overall system longevity. |

While the initial purchase price of a sweep tee may be slightly higher than a standard tee, this cost difference is almost always offset by avoiding just one emergency plumbing service call. When you factor in the improved flow performance and longer system life, the total cost of ownership is clearly lower.

Conclusión

Sweep tees offer clear advantages in easier installation, better flow, space flexibility, and lower maintenance. For reliable, high-performance sweep tees and other premium pipe fittings, choose IFAN to ensure your project’s quality and efficiency from start to finish.

Comentarios recientes