1. Introducción

Floor heating systems are gaining popularity for their energy efficiency and comfort. When choosing materials for these systems, cost-effectiveness is a key consideration. This blog explores whether PPR pipes offer the best balance of affordability and performance for floor heating, especially for clients in construction, HVAC, and engineering sectors.

2. What makes PPR pipes suitable for floor heating?

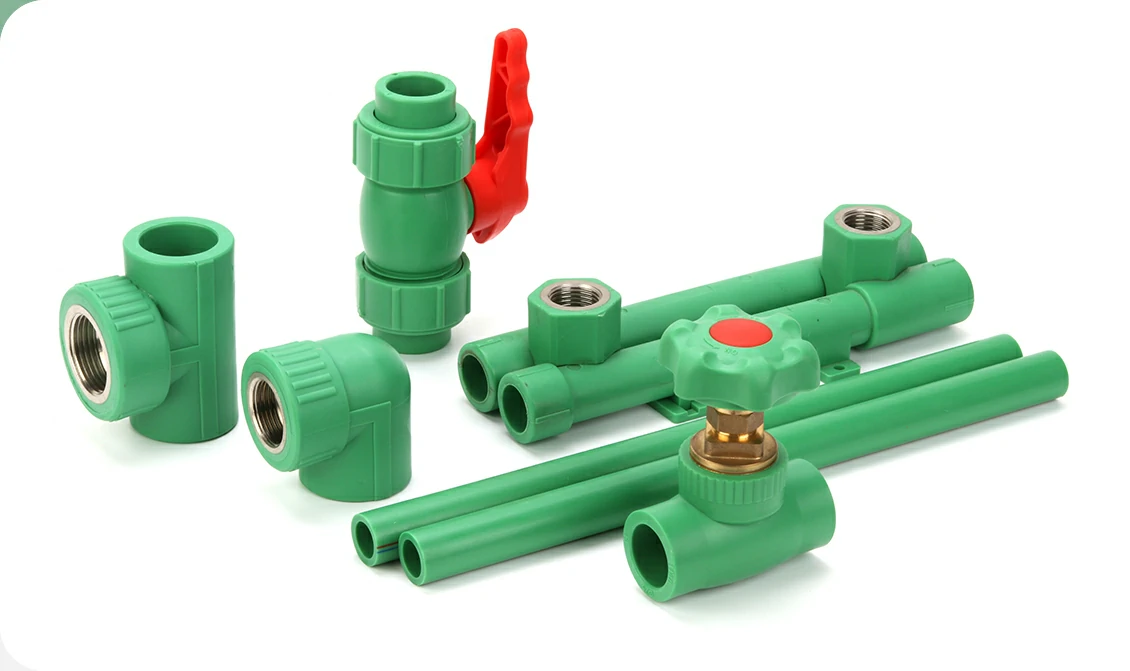

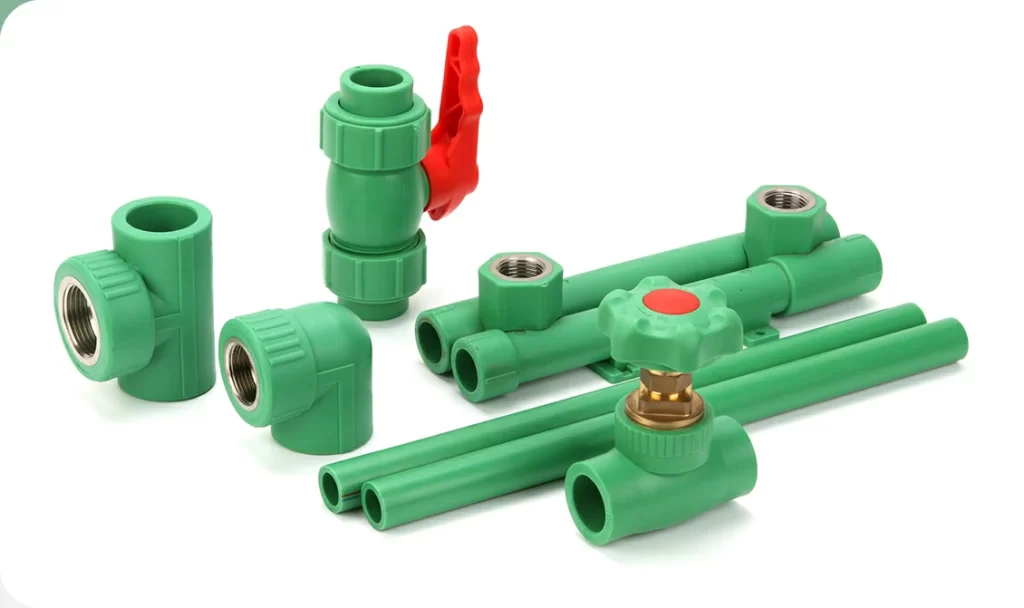

PPR (Polypropylene Random Copolymer) is a thermoplastic polymer with properties ideal for radiant heating:

- Heat resistance: Can handle temperatures up to 95°C

- Flexibilidad: Allows easy installation in complex layouts

- Corrosion resistance: Long lifespan without degradation

- Low thermal conductivity: Maintains heat distribution efficiency

3. Cost breakdown analysis

3.1 Initial material costs

- PPR pipes are 15-30% cheaper than alternatives like PEX or PB

- Standard sizes (DN16-DN32) cost $2.5-$5 per linear meter

- Bulk discounts available for large projects (≥500 meters)

3.2 Installation savings

- Fast jointing with 热熔 welding (50% quicker than compression fittings)

- No need for additional insulation due to PPR’s thermal stability

- Reduced labor hours for complex installations

3.3 Long-term cost benefits

- 50+ year lifespan with minimal maintenance

- Energy savings from efficient heat transfer (up to 12% lower energy bills)

- Resistant to scale buildup reducing cleaning requirements

4. Comparison with other floor heating materials

| Material | Initial Cost | Installation Difficulty | Lifespan | Maintenance Needs |

|---|---|---|---|---|

| PPR | $ | Moderate | 50+ yrs | Low |

| PEX | $$ | Easy | 30-40 yrs | Moderate |

| PB | $$$ | Difficult | 25-30 yrs | High |

| Copper | $$$$ | Skilled labor required | 20-25 yrs | Very high |

5. Real-world project examples

5.1 Residential development in Beijing

- 200-unit complex using PPR pipes saved ¥1.2M in material costs

- 10% faster installation compared to previous PEX projects

- 8% lower energy consumption confirmed by post-installation audits

5.2 Commercial office renovation in Shanghai

- Retrofit project using custom-sized PPR pipes reduced material waste by 18%

- 15-year warranty from Yifan Pipeline provided additional cost security

- Maintenance costs cut by 60% over 5 years

6. Key factors affecting cost-effectiveness

6.1 Project scale

- Small projects (≤100m²): PPR saves 10-15% vs PEX

- Large projects (≥5,000m²): Savings increase to 20-25%

6.2 Customization needs

- Yifan Pipeline offers:

- Custom wall thickness for specific pressure requirements

- Color-coded pipes for easy installation

- Pre-insulated pipe solutions reducing installation steps

6.3 Climate considerations

- Cold climates benefit from PPR’s freeze resistance (-20°C)

- High-temperature regions gain from PPR’s heat stability

7. ifan Pipeline’s cost-effective solutions

As China’s leading PPR pipe manufacturer, we provide:

- Factory-direct pricing: Cut out middlemen for 20-30% savings

- Technical support: Free thermal design calculations

- Certificaciones: Compliance with EN 12201, GB/T 18742, and ISO 9001

- Personalización: Tailored solutions for complex projects

8. Conclusion

PPR pipes offer the best combination of low initial cost, installation efficiency, and long-term savings for floor heating systems. For clients looking to balance budget and performance, ifan Pipeline provides:

- Premium PPR pipes at competitive prices

- Custom solutions for unique project requirements

- Comprehensive support from design to installation

Visite ifanultra.com to explore our floor heating solutions or contact us for a free cost analysis for your next project.

Comentarios recientes