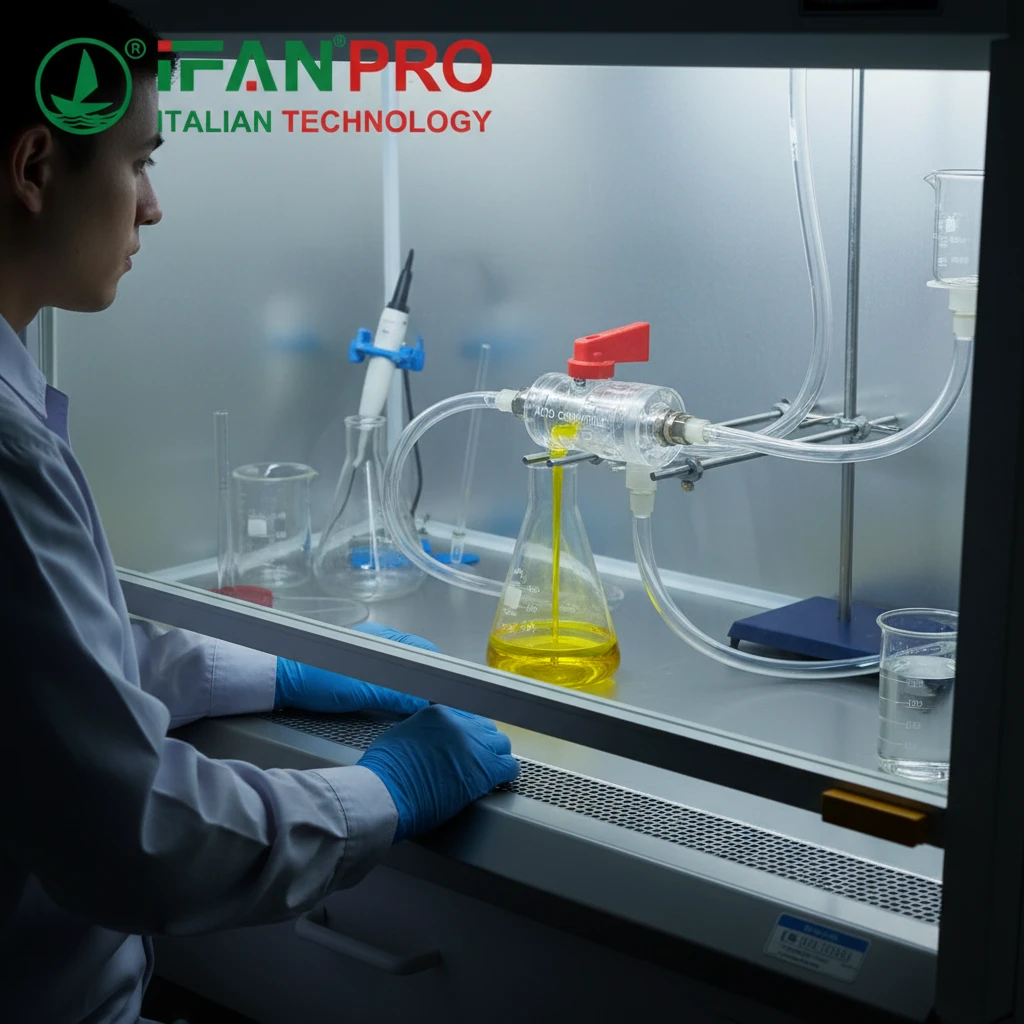

I once saw a critical experiment ruined by an unreliable valve leaking precious reagents. That moment cemented my belief in choosing the right component for the job.

Yes, mini valves are perfectly suitable and often essential for laboratory instruments. Their small size, precise flow control, and compatibility with various pure and aggressive media make them ideal for managing reagents and gases in analytical devices, automated systems, and sensitive research setups.

Now, let’s examine the specific reasons why these compact components are fundamental to modern lab work.

Why Are Mini Valves Ideal for Controlling Reagents and Gases in Labs?

In a lab, every drop and every bubble counts. A standard industrial valve is simply too bulky and imprecise for this environment.

Mini valves are ideal for labs because their compact design allows integration into tight instrument spaces, and they offer exceptionally precise control over tiny fluid or gas volumes. This precision ensures repeatable experiments, prevents waste of expensive chemicals, and enables reliable automation of complex procedures.

The Core Advantage: Precision and Size

The primary challenge in a laboratory is handling very small quantities with very high accuracy. A mini valve addresses this challenge directly. First, its physical size is a perfect match for benchtop instruments, diagnostic devices, and sensor arrays where space is extremely limited. In fact, using a large valve is often not even an option.

More importantly, mini valves are engineered for precision. They allow an operator or an automated system to start, stop, or modulate flow with great accuracy. This is crucial for tasks like adding an exact 10 µL aliquot of a reagent to a sample, controlling the purge gas flow to a spectrometer, or switching between different solvent lines in a chromatography system. Without this level of control, experimental results become inconsistent and unreliable.

Enabling Automation and Reducing Error

Furthermore, mini valves are key to lab automation. Modern labs use automated workstations to run tests 24/7. These systems rely on arrays of electrically or pneumatically actuated mini valves to perform fluid handling tasks. The valve’s small size and fast response time allow for rapid, sequential operations without cross-contamination.

This automation, enabled by reliable mini valves, directly tackles common lab pain points. For example, it reduces human error since manual pipetting and fluid handling are prone to mistakes, while automated valve systems execute the same movement perfectly every time. Additionally, it increases throughput because scientists can set up a method and let it run overnight, dramatically increasing lab output. Finally, it improves safety by allowing for the safe handling of hazardous or toxic substances within an enclosed flow path.

Application Comparison Table

The table below shows where different mini valve types excel in the lab:

| Valve Type | Best For Lab Use In… | Key Reason |

|---|---|---|

| Solenoid Valves | Automated analyzers, DNA sequencers, HPLC systems. | Fast electrical actuation, perfect for computer control. |

| Manual Pinch Valves | Peristaltic pump tubing lines, controlling flexible sanitary tubing. | Simple, low-cost, isolates fluid from valve mechanism. |

| Mini Ball Valves | Manual isolation of gas lines, reagent bottles, or instrument sections. | Reliable on/off control, easy to operate. |

| Diaphragm Valves | Handling sterile fluids, aggressive chemicals, or slurries. | Seals isolate fluid from internal parts, preventing contamination. |

In short, the combination of small size and high precision makes the mini valve not just suitable, but a critical enabling component for accurate and efficient laboratory science.

How Do They Meet the Cleanliness and Biocompatibility Requirements for Labs?

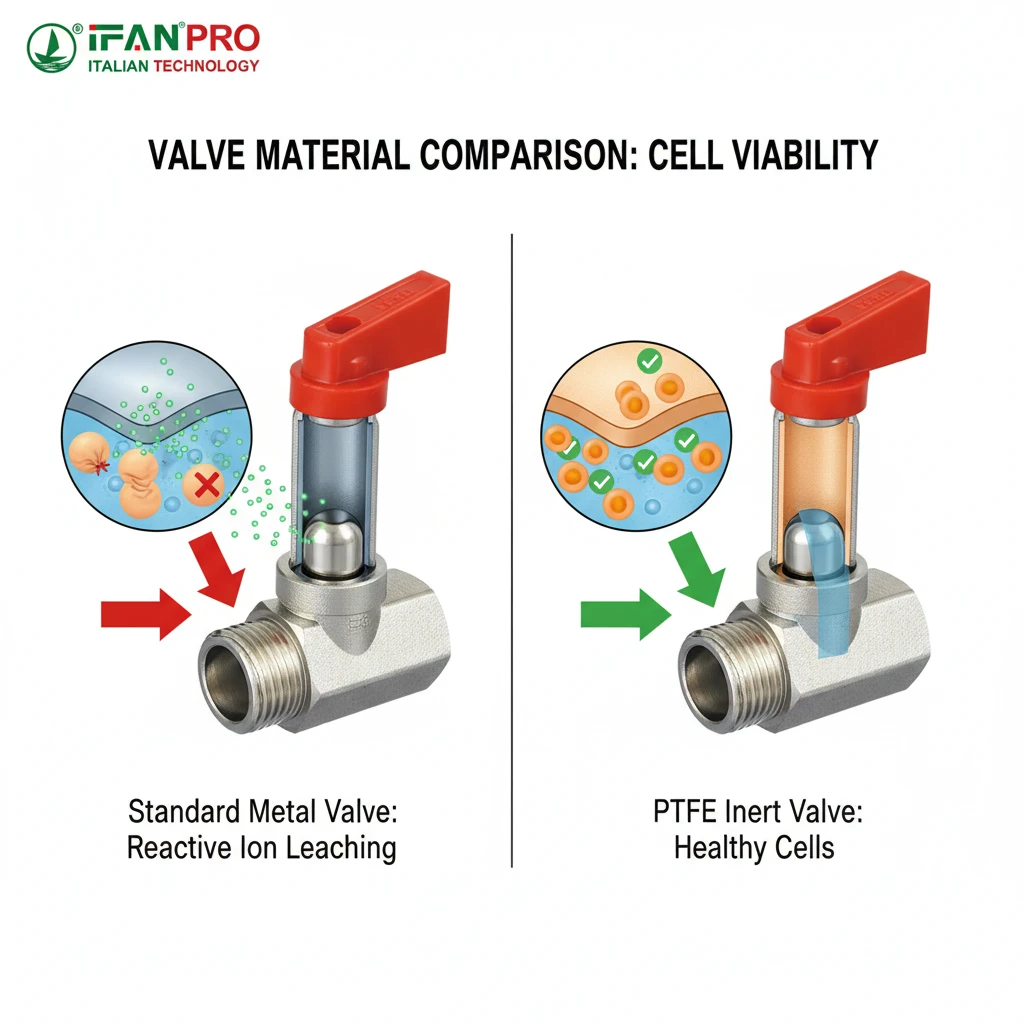

A single contaminant or a toxic leachate can invalidate months of research. Therefore, material choice in valves is not an afterthought; it is a primary requirement.

Mini valves meet lab cleanliness and biocompatibility needs by being constructed from inert, non-contaminating materials like PTFE (Teflon), PFA, USP Class VI compliant silicones, and high-purity ceramics. These materials do not react with sensitive media, resist absorption, and can withstand repeated sterilization cycles without degrading.

Understanding Material Inertness

Laboratory work often involves ultra-pure water, sensitive biological samples (like proteins or cells), or precise chemical reactions. Consequently, the valve materials that come into contact with these fluids must be completely inert. This means they should not leach (release plasticizers, metal ions, or polymer fragments into the fluid), absorb (soak up reagents or analytes from the fluid, which can cause carryover contamination), or react chemically with acids, bases, solvents, or biological compounds.

Materials like PTFE and PFA are gold standards here. They are “non-stick” and have extremely low reactivity. This ensures that the fluid passing through the valve remains exactly as pure as when it entered.

Meeting Specific Standards

For specific fields, formal certifications are mandatory. For instance, biocompatibility (USP Class VI, ISO 10993) is critical for medical device testing, pharmaceutical research, and any work involving living cells. Compliant materials have passed rigorous tests for toxicity. Valves made with USP Class VI silicones or PTFE are common in these settings.

Similarly, for cleanliness in analytical chemistry, techniques like HPLC or ICP-MS can detect parts-per-billion levels. Therefore, valves must be free of leachable metals (like zinc or iron) that could create background noise in the analysis. As a result, valves with wetted parts made entirely of PTFE, PEEK, or ceramic are used here.

Sterilization and Cleaning

Labs also require valves that they can clean or sterilize. For example, a valve used in fermentation or cell culture must endure autoclaving (high-pressure steam) or chemical sanitizers without corroding or losing its sealing properties. Materials like 316L stainless steel (for the body) and PTFE (for seals) excel for this purpose. This cleanability prevents biofilm formation and ensures long-term, reliable operation.

Material Selection Guide for Lab Valves

Choosing the right material is the most important step. This table provides a clear guide:

| Fluid Type | Recommended Valve Body / Wetted Parts | Key Property |

|---|---|---|

| General Chemicals, Solvents | PTFE, PFA, PP | Excellent chemical resistance across a broad range. |

| Ultra-Pure Water & Analytics | High-Purity PTFE, PEEK | Extremely low leachables and particulates. |

| Biological Buffers & Cell Media | USP Class VI Silicone, PTFE, 316L SS | Biocompatible, non-cytotoxic. |

| Abrasive Slurries | Ceramic, Alumina | Extreme hardness and wear resistance. |

| Sterile Processes | Autoclavable 316L SS with PTFE seals | Withstands repeated steam sterilization. |

By selecting a mini valve with the correct material pedigree, labs protect the integrity of their work and ensure their instruments perform as designed.

What Makes Them Suitable for Integration into Analytical Instrument Flow Paths?

Modern analytical instruments are marvels of compact engineering. Every millimeter inside the casing is carefully planned.

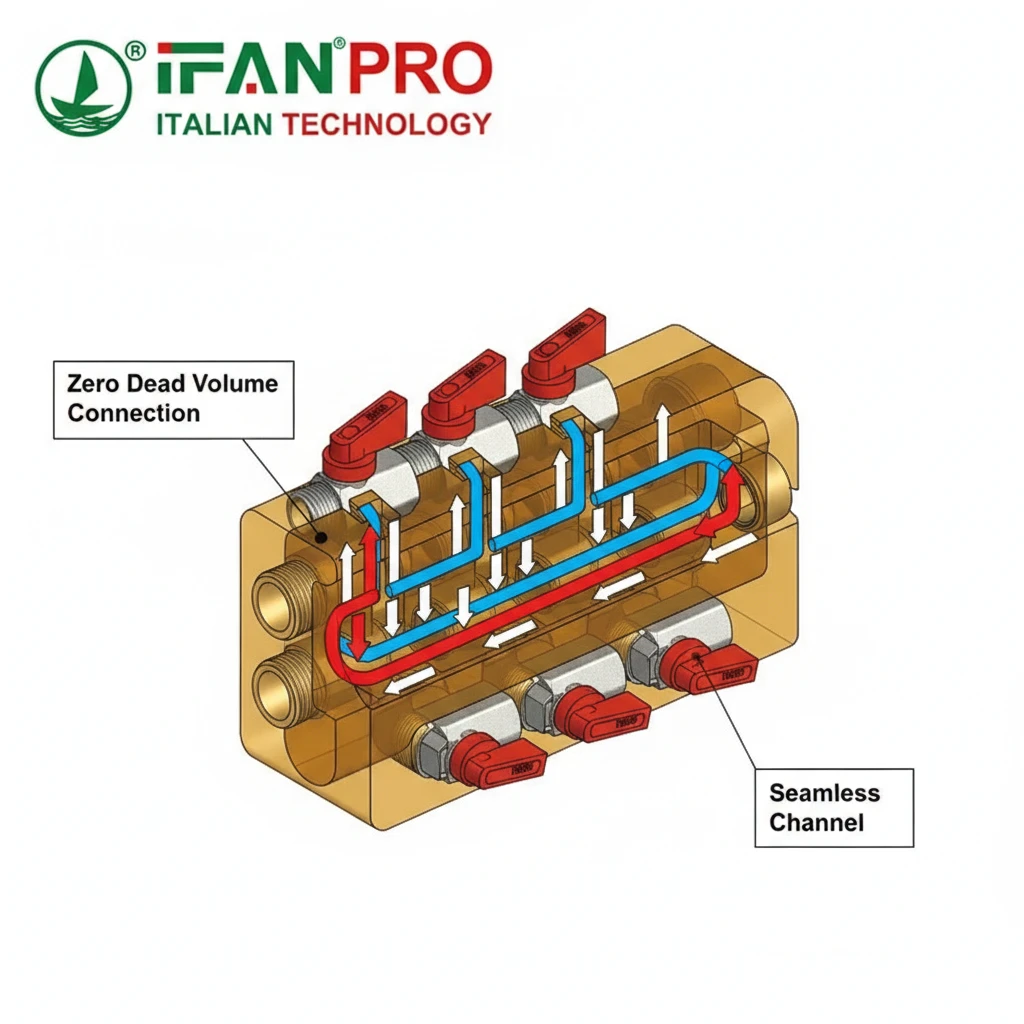

Mini valves are suitable for integration because their compact, modular designs allow them to be mounted directly onto manifolds or fluidic circuit boards, minimizing dead volume that can cause sample mixing and carryover. Their reliable actuation ensures the timing and sequence of the instrument’s automated methods are executed flawlessly.

The Problem of Dead Volume

When a sample travels through an instrument’s flow path, any small, stagnant cavity it passes is called “dead volume.” In a poorly designed system, a sample can leave a tiny portion behind in this cavity. Then, when the next sample or reagent flows through, it can pick up that leftover residue, leading to carryover contamination. This produces inaccurate, blurred results.

A key design feature of mini valves for instrumentation is their low internal volume and flow-through design. The best ones have a direct, streamlined flow path with no unnecessary cavities. When engineers integrate them directly into a custom manifold—often a block of PTFE or PEEK with drilled channels—they create a seamless, continuous conduit. This design minimizes dead volume to the absolute minimum, which is critical for techniques like chromatography (where sharp, well-defined sample peaks are needed), flow injection analysis (where precise sample boluses are injected), and clinical analyzers (where cross-contamination between patient samples must be avoided).

Enabling Complex Fluidic Routing

Sophisticated instruments often need to perform complex fluid handling sequences. For example, a method might require: “Switch to Buffer A for 30 seconds, then inject Sample from Loop 1, then flush with Solvent B.” Designers achieve this by using a network of mini valves—often in a configuration called a “selection valve” or “multi-port valve.”

These valves act as the traffic directors of the instrument’s fluidics. Their suitability comes from three main features. First, they have a fast response time, so they can switch positions in milliseconds to keep up with high-speed methods. Second, they provide reliable sealing; they must seal perfectly every time, for thousands or millions of cycles, without leaking. Third, they offer compact stackability, meaning multiple valves can be grouped together in a small area to save space.

Integration and Control Interface

Finally, mini valves designed for integration have user-friendly mounting features (like threaded ports or flange mounts) and standardized electrical connectors (for solenoid valves). This allows instrument designers to install them easily and connect them to the central control board. As a result, the valve becomes a seamless, reliable component of a larger automated system, executing its programmed role without needing manual intervention.

Can They Handle the Corrosive or High-Purity Media Common in Laboratories?

Labs deal with everything from ultrapure water to concentrated acids. Clearly, a valve that can’t handle the medium is a point of failure waiting to happen.

Yes, specialized mini valves are explicitly designed to handle corrosive and high-purity media. By utilizing advanced body materials like PVDF, PTFE, or PEEK, and seals made from FFKM (Kalrez®) or EPDM, they resist chemical attack. For ultra-pure applications, valves are designed with smooth, crevice-free wetted surfaces to prevent particle trapping or bacterial growth.

The Challenge of Corrosive Media

Laboratories routinely use strong acids (e.g., hydrochloric, nitric), bases (e.g., sodium hydroxide), and oxidizing agents (e.g., bleach, hydrogen peroxide). These chemicals will rapidly degrade standard materials. For instance, a valve with incompatible seals will swell, crack, and leak. Similarly, metal bodies may corrode, contaminating the fluid and seizing the mechanism.

The solution is material science. Valve manufacturers match the valve’s wetted materials—every part the fluid touches—to the chemical’s properties. For example, PVDF (Polyvinylidene Fluoride) is excellent for strong acids and halogens. PTFE (Polytetrafluoroethylene) is universally resistant to almost all chemicals. PEEK (Polyether Ether Ketone) is a high-strength plastic resistant to many solvents. Finally, specialty elastomers like FFKM are used for seals, offering broad chemical resistance where flexibility is needed.

The Challenge of High-Purity Media

On the other end of the spectrum, ultra-pure water (UPW) or sensitive pharmaceuticals demand absolute cleanliness. Here, the threat isn’t the fluid destroying the valve, but the valve contaminating the fluid. Contamination can come from leachables (molecules slowly released from components), particulates (microscopic debris from wear), or biological growth (bacteria adhering to rough surfaces).

Therefore, valves for these applications use the highest purity grades of PTFE or PEEK. Manufacturers polish their internal surfaces to a mirror finish. Moreover, the design eliminates small gaps and crevices where fluid can stagnate and allow microbes to multiply. All these features ensure the valve maintains, rather than degrades, the purity of the fluid.

Media and Material Compatibility Guide

Selecting the wrong material can lead to rapid valve failure. This table helps match the medium to the valve:

| Laboratory Medium | Recommended Valve Body Material | Recommended Seal Material | Critical Consideration |

|---|---|---|---|

| Concentrated Acids & Bases | PVDF, PTFE | PTFE, FFKM | Full chemical resistance chart review is essential. |

| Organic Solvents | PTFE, 316L SS | FFKM, PTFE | Check for swelling of elastomers. |

| Ultra-Pure Water | High-Purity PEEK, PTFE | PTFE (compressed) | Extremely low leachable and particulate standards. |

| Pharmaceutical Buffers | 316L SS (Electropolished), PEEK | USP Class VI EPDM, Silicone | Biocompatibility and cleanability are key. |

| Oxidizing Agents (e.g., Bleach) | PVDF, PTFE | PTFE, FFKM | Standard elastomers like NBR will degrade quickly. |

Always consult a detailed chemical compatibility chart before final selection. A reputable supplier like IFAN can provide this critical engineering support to ensure the valve will perform reliably in your specific application.

Conclusión

Mini valves are indispensable for labs, offering precise control, material compatibility, and easy integration. For reliable performance in your sensitive applications, specify IFAN’s range of chemically inert and precision mini valves.

Comentarios recientes