In my work with mining clients, I’ve seen traditional metal valves fail quickly under harsh conditions. This constant problem led me to closely examine the performance of HDPE valves as a modern solution.

Yes, HDPE female valves are highly suitable for mining pipelines. They offer exceptional resistance to the abrasive wear and chemical corrosion common in mining slurry transport. Their fused connections create leak-proof systems, and their lightweight design allows for faster, safer installation in remote and challenging mine sites, reducing overall project downtime and maintenance costs.

Now, let’s break down the specific reasons why HDPE valves are becoming the preferred choice in the demanding mining industry.

What Properties Make HDPE Valves Durable in Abrasive Mining Environments?

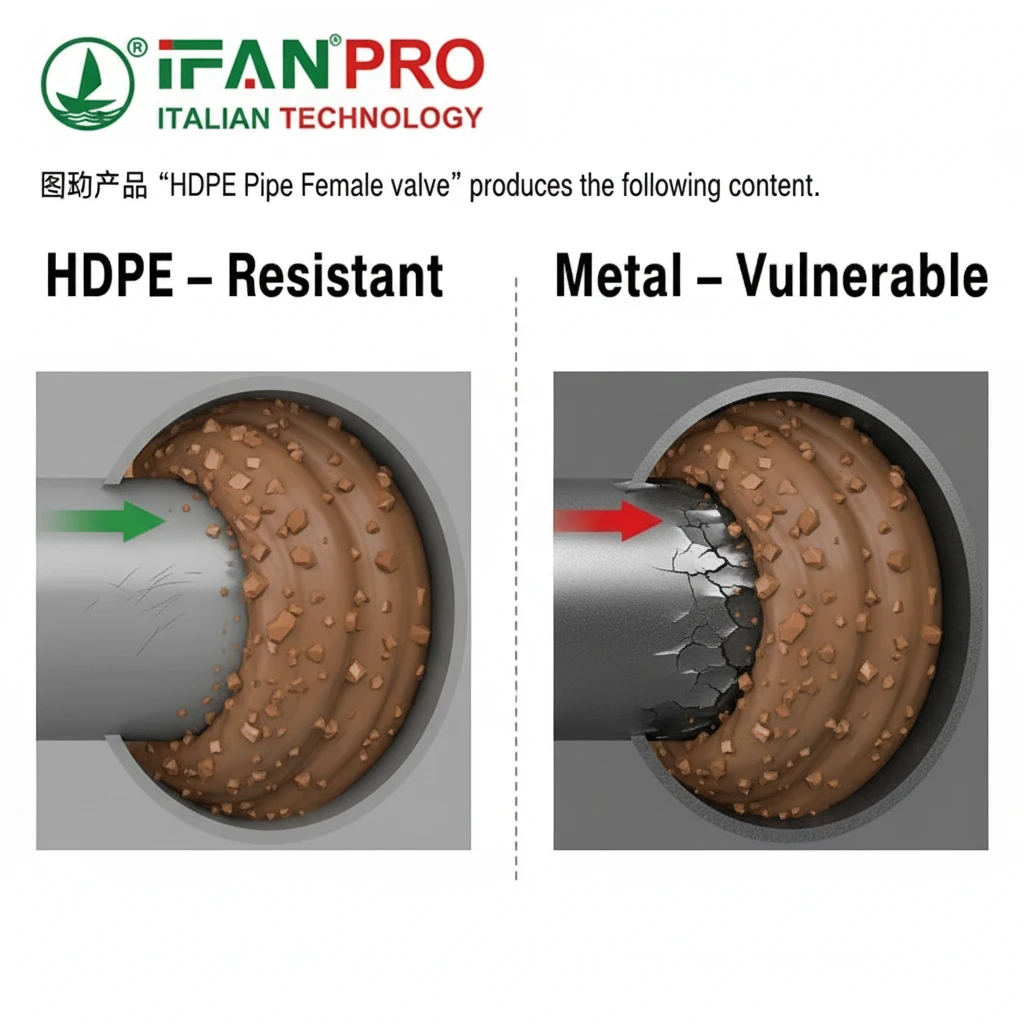

Mining slurry, a mix of water, crushed ore, and rocks, is extremely abrasive. I’ve witnessed metal valves erode thin within months, but HDPE presents a different story.

HDPE valves are durable in abrasive environments primarily due to the material’s high resistance to wear and its natural flexibility. The smooth interior surface of HDPE reduces friction, while its ability to absorb impact without cracking prevents damage from solid particles, ensuring a much longer service life compared to rigid metal valves.

How HDPE Fights Abrasion

In mining, pipelines carry slurry that acts like sandpaper. Durability here means resisting this constant scouring. HDPE excels because of its unique material properties.

First, HDPE is a very tough plastic. It has a high resistance to wear, meaning it takes a long time for abrasive particles to wear down its surface. While metal might seem harder, once its protective coating is scratched, corrosion accelerates wear. HDPE wears slowly and evenly.

Second, the inner wall of an HDPE valve is very smooth. This smoothness is not just a surface finish; it’s a property of the material itself. This smooth surface creates less friction as the slurry flows past. When slurry flows easily, there is less abrasive force acting on the valve interior. Metal pipes and valves often have rougher interiors, even when new, which increases wear.

The Advantage of Flexibility

Third, and very importantly, HDPE is flexible. This is a key advantage over brittle materials like cast iron or rigid PVC. When a solid rock or a clump of ore hits the inside of a metal valve, it can cause a dent or a crack. When the same impact happens to an HDPE valve, the material can flex and absorb the energy, then return to its original shape. This “live” quality prevents catastrophic failure from impact.

Installation and System Integrity

Finally, the way HDPE valves are installed adds to system durability. They are joined to HDPE pipes using butt fusion or electrofusion. This creates a seamless, monolithic connection that is as strong as the pipe itself. There are no internal grooves, threads, or gaps where abrasive slurry can get trapped and cause localized wear or turbulence. The entire flow path is smooth and continuous, which protects the valve.

Comparing Wear Resistance

| Material | Key Property | Reaction to Abrasive Slurry | Typical Lifespan in Abrasive Service |

|---|---|---|---|

| HDPE | Flexible, Smooth, Wear-Resistant | Wears slowly and evenly; flexes on impact. | 5-10+ years |

| Carbon Steel | Hard but Brittle | Susceptible to scratching; wear leads to thin walls. | 1-3 years |

| Cast Iron | Very Rigid | Can crack on impact; rough surface accelerates wear. | 2-4 years |

| Polyurethane-Lined Steel | Hard Lining | Good resistance, but lining can fail at joints. | 3-7 years |

For a mine operator, choosing HDPE valves means fewer shutdowns for replacements, lower parts inventory, and more predictable maintenance schedules. The durability translates directly into higher uptime and lower costs.

How Do HDPE Valves Resist Corrosion from Slurry and Chemicals in Mining?

Mine water is rarely pure. It often contains acids, alkalis, and salts from the ore itself. I’ve managed replacements for valves eaten away by corrosion, a problem HDPE avoids.

HDPE valves resist corrosion because the plastic material is chemically inert. It does not react with most acids, alkalis, or salts found in mining slurry. Unlike metals, HDPE cannot rust or oxidize, making it immune to electrochemical corrosion, which is a major failure point for metal valves in wet, ionic environments.

Understanding Chemical Inertness

Corrosion is a chemical reaction that destroys a material. In mining, this can come from acidic mine drainage, processing chemicals, or saline water. HDPE’s primary defense is its chemical stability.

The polymer structure of HDPE is non-polar and saturated. In simple terms, it is not chemically “interested” in reacting with the ions and compounds commonly found in mine slurry. This means it won’t dissolve, weaken, or break down when exposed to a wide range of chemicals. Metals, on the other hand, often undergo galvanic or acidic corrosion in the same conditions.

No Rust, Ever

A huge advantage is that HDPE does not rust. Rust is the oxidation of iron, which requires only water and oxygen. Mining pipelines are full of both. A steel valve will rust from both the inside (from slurry) and the outside (from the environment). This rust weakens the structure and can contaminate the slurry. HDPE valves completely eliminate this problem.

Handling a Wide pH Range

Mining processes can involve both acidic and basic (alkaline) conditions. HDPE performs well across a broad pH range. For example, it is highly resistant to sulfuric acid, which is common in many mining operations. This broad compatibility means one valve material can be used in different parts of a mine without fear of chemical attack.

Common Mining Chemicals vs. HDPE

The table below shows HDPE’s resistance to typical mining substances.

| Chemical Agent | Common Source in Mining | Effect on HDPE Valves |

|---|---|---|

| Sulfuric Acid | Acid Mine Drainage, Ore Processing | Excellent resistance; no degradation. |

| Sodium Hydroxide | Processing, pH adjustment | Excellent resistance. |

| Salt Water / Brine | Groundwater, processing | Excellent resistance; no corrosion. |

| Calcium Chloride | Dust control, processing | Excellent resistance. |

| Oxidizing Agents | Water treatment (e.g., hypochlorite) | Good to moderate resistance; check concentration. |

System-Wide Protection

Because the entire HDPE system (pipes, valves, fittings) is made from the same inert material, you avoid galvanic corrosion. Galvanic corrosion happens when two different metals touch in a wet environment, causing one to corrode faster. With an all-HDPE system, this risk is zero.

For the mining operator, this chemical resistance means no surprise failures from a change in water chemistry. It simplifies material selection and leads to vastly more reliable and predictable pipeline performance.

What Are the Pressure and Safety Standards for Valves in Mining Applications?

Safety is the top priority in mining. A valve failure under pressure can be dangerous and costly. From my audits, I know that understanding and meeting standards is not optional.

Valves for mining must meet strict pressure ratings and safety standards to ensure system integrity. Key standards include ISO 4427 for HDPE piping systems and ASME B16.40 for plastic valves. These define pressure ratings (PN), performance tests, and material requirements to guarantee valves can safely handle the operating pressures and surge events common in mining pipelines.

Understanding Pressure Ratings (PN)

Mining pipelines operate under significant pressure to move slurry over long distances and elevations. Valves must be rated for these pressures with a large safety margin.

The Pressure Nominal (PN) rating, like PN10 or PN16, is a crucial number. It indicates the maximum working pressure in bars that the valve is designed to handle at 20°C. For mining, valves with PN16 or higher are commonly specified. It is critical to select a valve whose PN rating exceeds the maximum operating pressure of your system, including any potential pressure surges (water hammer).

Key International Standards

Adherence to recognized standards is proof of a valve’s quality and safety. For HDPE valves, the most important standards are:

- ISO 4427: This is the global standard for polyethylene (PE) piping systems. It covers the material properties, dimensions, and performance requirements for pipes and fittings. A valve compliant with ISO 4427 is made from certified PE100 or PE100RC resin, ensuring consistent strength.

- ASME B16.40: This American standard specifically governs the design, manufacturing, and testing of thermoplastics valves. It sets the rules for pressure-temperature ratings, markings, and functional testing.

- ISO 9393: This standard specifies the test methods for thermoplastic valves, including pressure tests and seat leakage tests.

Designing for Safety and Surges

Mining safety involves planning for the unexpected. Pressure surges can occur when pumps start or stop suddenly. HDPE systems have an inherent safety advantage due to the material’s flexibility, which can absorb some surge energy. However, valves must still be chosen and installed correctly.

A safe installation involves:

- Selecting the correct PN rating.

- Ensuring the valve is properly fused to the pipe to create a full-strength joint.

- Installing pressure relief valves or surge tanks in the system where needed.

- Following the manufacturer’s installation guidelines precisely.

Minimum Required Standards Checklist

Use this table as a guide when specifying HDPE valves for mining.

| Standard | What It Covers | Why It Matters for Mining |

|---|---|---|

| ISO 4427 | Material quality, dimensions, and system performance. | Ensures the valve material is high-grade PE100, capable of long-term pressure holding. |

| ASME B16.40 / ISO 9393 | Valve design, manufacturing, and pressure testing procedures. | Confirms the valve has been individually tested to hold and seal under pressure without leaking. |

| Manufacturer’s PN Rating | Certified working pressure. | Provides the clear, guaranteed pressure limit for safe operation. |

Always request certified test reports from your supplier. A professional supplier like IFAN can provide these documents, giving you confidence that the valves meet the rigorous demands of your mining operation and keep your people and processes safe.

Why Is the Lightweight Nature of HDPE Valves Beneficial for Mining Installations?

Mines are often in remote, rugged locations. I’ve coordinated logistics for heavy metal valves, and the contrast with handling HDPE components is staggering.

The lightweight nature of HDPE valves is a major benefit for mining because it makes transportation to remote sites easier and cheaper, allows for manual handling without heavy machinery, and enables faster, safer installation. This reduces labor costs, minimizes the need for large equipment in tight spaces, and significantly speeds up project timelines and repair work.

Easing Transportation and Logistics

Moving equipment to a mine site is a major cost factor. Heavy metal valves require robust packing, special lifting equipment, and more fuel for transport.

An HDPE valve of the same size can weigh up to 90% less than its cast iron or steel counterpart. This dramatic weight reduction means more valves can be shipped on a single truck, reducing freight costs. For remote sites accessible only by helicopter or difficult roads, the ability to transport essential parts easily is a game-changer. Lightweight HDPE valves turn complex logistics into a simple task.

Simplifying On-Site Handling and Installation

Once on site, the advantages grow. Installing a heavy metal valve often requires a crane, forklift, or a team of workers just to move it into position. This is slow, expensive, and can be hazardous in confined spaces like a pump house or a tunnel.

HDPE valves can typically be carried and positioned by one or two workers. This eliminates the need for lifting machinery for most valve installations. The result is faster installation, lower equipment rental costs, and reduced risk of injury from handling heavy loads.

Impact on Installation Speed and Safety

Speed is money in mining projects. Faster pipeline installation means the system becomes operational sooner. The combination of lightweight components and simple fusion joining dramatically accelerates installation times compared to welding or bolting flanged metal valves.

Furthermore, safety improves. Workers are not struggling under heavy weights. There are no hot works like welding or grinding near potentially flammable materials. The fusion process for HDPE is clean and electrical, which is much safer in various mine environments.

Total Cost of Installation Comparison

| Installation Factor | HDPE Valve System | Traditional Metal Valve System |

|---|---|---|

| Valve Weight (e.g., 8″) | ~5 kg | ~50 kg |

| Lifting Equipment Needed | Usually none (manual). | Crane or forklift often required. |

| Jointing Method | Fast, portable electrofusion or butt fusion. | Slow, requires bolting/flanging or welding. |

| Team Size for Installation | 1-2 people. | 3-4 people (including equipment operators). |

| Relative Installation Speed | Fast | Slow |

Facilitating Maintenance and Modifications

Mining operations change. Pipelines need to be extended, rerouted, or repaired. The lightweight and fusion-based nature of HDPE makes these modifications much easier. A section can be cut out and a new valve fused in quickly, with minimal downtime. This operational flexibility is a huge advantage over welded metal systems.

In summary, the lightweight benefit of HDPE valves is not just about the material itself. It creates a ripple effect that lowers costs, increases safety, and improves operational agility throughout the entire lifecycle of the mining pipeline.

Conclusión

HDPE female valves are an excellent, durable, and safe choice for mining pipelines, offering superior abrasion and corrosion resistance. For reliable, standards-compliant HDPE valves and expert mining pipeline support, contact IFAN to discuss your project needs.

Comentarios recientes