I once audited a system where leaky, inefficient fittings wasted more water than the conservation fixtures saved. That mismatch taught me that true water conservation starts with the connections you can’t see.

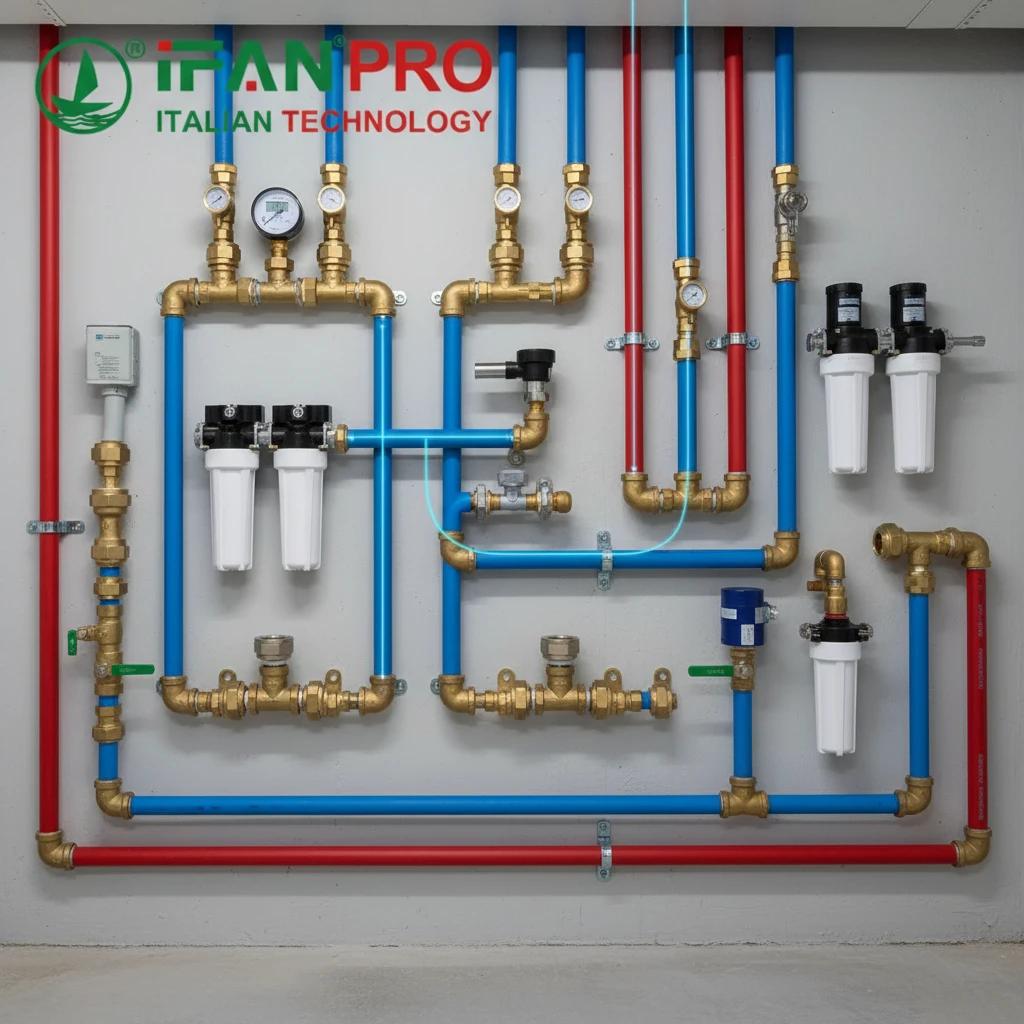

Fittings are the critical, hidden network in water conservation systems. They ensure efficient water delivery by minimizing pressure loss and preventing leaks, they withstand corrosive water in reuse systems for long-term durability, and they directly optimize the performance of every water-saving faucet, toilet, and appliance they connect to.

While everyone focuses on the fixtures, the fittings determine if the system’s promise becomes reality. Let’s explore how these components make or break your water-saving goals.

How Do Precision-Engineered Fittings Minimize Pressure Loss and System Leakage?

Many assume water simply flows through a pipe. But in conservation systems, every drop and every bit of pressure counts. Poor fittings waste both.

Precision-engineered fittings minimize pressure loss by offering smooth, unrestricted internal waterways that match the pipe diameter, reducing turbulent flow. They prevent system leakage through consistent, high-quality sealing mechanisms—like reliable O-rings or perfectly fused joints—that remain intact under system pressure and thermal cycling, eliminating the most common source of water waste.

The Direct Link Between Fitting Design and Water Waste

Water pressure is the energy that moves water through your system. When pressure drops, fixtures like showerheads and faucets don’t perform correctly, often leading users to bypass or remove water-saving devices. Fittings are a major source of this pressure loss.

Two main problems occur with cheap or poorly designed fittings:

- Internal Turbulence: If the inside of a fitting is rough, has sharp edges, or suddenly narrows (a condition called “necking”), it disrupts smooth water flow. This creates turbulence, which steals energy from the water stream and reduces downstream pressure. It’s like putting a kink in a hose.

- Leakage: Even small, persistent drips from a poorly sealed joint add up to thousands of gallons of wasted water per year. Leaks often occur at threaded connections, under-specified O-rings, or cold joints in glued systems.

How Quality Fittings Solve These Problems

Superior fittings are designed to tackle these issues head-on. Here is how they work:

For Minimizing Pressure Loss:

- Swept Interior Design: High-quality elbows and tees have a smooth, curved interior path. This guides water around corners with minimal disruption, unlike cheap fittings with sharp, 90-degree corners inside.

- Bore Consistency: The internal diameter (bore) of a good fitting matches the internal diameter of the pipe it connects to. This prevents the constriction that causes pressure drops.

- Clean Mold Lines: Precision manufacturing ensures no rough plastic seams or flashing remain inside the fitting to create friction.

For Eliminating Leakage:

- Advanced Sealing: For threaded applications, fittings use thick, durable EPDM O-rings designed for constant pressure. For solvent-weld or heat-fusion systems (like PP-R), the joint becomes monolithic, creating a leak-proof seal that is actually stronger than the pipe itself.

- Robust Construction: They are made from virgin materials that resist cracking under stress, preventing leaks that develop over time.

Comparing Fitting Performance

The table below shows the impact of fitting choice on system efficiency:

| Fitting Type & Quality | Impact on Pressure | Risk of Leakage | Long-Term Water Waste Potential |

|---|---|---|---|

| Low-Quality, Generic Fitting | High pressure drop due to turbulence and constriction. | High. Prone to seal failure and material cracking. | Very High. Wastes water through both inefficiency and drips. |

| Precision-Engineered Fitting (e.g., IFAN) | Minimal pressure drop due to smooth bore and hydraulic design. | Very Low. Uses superior seals and fusion/thread technology. | Very Low. Maintains designed flow and prevents leaks. |

Choosing the right fitting is the first step in building an efficient, leak-free foundation for any water conservation system.

Why Are Material Choices Crucial for Longevity in Water Reuse and Greywater Systems?

Greywater and reclaimed water are much harsher than fresh potable water. Standard potable water fittings can fail quickly in these aggressive environments.

Material choices are crucial because greywater and reuse systems contain soap residues, fats, salts, and microbes that aggressively corrode or degrade unsuitable plastics and metals. Fittings must be made from chemically inert, non-absorbent, and biofilm-resistant materials to ensure the system lasts for decades without failure, protecting the investment in the conservation infrastructure.

The Harsh Reality of Greywater

To understand why materials matter, you must understand what flows through these pipes. Greywater (from showers, sinks, laundry) contains:

- Abrasive Particles: Sand, dirt, and lint.

- Chemicals: Alkaline soaps, shampoos, and cleaning agents.

- Organic Matter: Skin cells, fats, oils, and food particles.

- Microorganisms: Bacteria that thrive in nutrient-rich water.

This combination is far more corrosive and demanding than clean tap water. It attacks systems in three main ways:

The Three Fronts of Material Degradation

1. Chemical Attack and Corrosion:

- Metal Fittings Danger: Metals like standard brass or steel can corrode rapidly when exposed to the salts and pH swings in greywater. This leads to pinhole leaks and metal contamination.

- Plastic Solution: Chemically inert plastics like Polypropylene (PP-R) are ideal. They do not react with soaps, salts, or mild acids, ensuring the fitting’s wall strength does not degrade over time.

2. Biological Fouling and Biofilm:

- The organic matter in greywater promotes rapid bacterial growth, forming a slimy “biofilm” on pipe and fitting walls.

- Smooth, Non-Porous Surfaces are Key: Materials must have an ultra-smooth interior that offers no pores or roughness for biofilm to anchor to. PP-R excels here. Absorbent or rough materials will become clogged with biological growth, reducing flow and creating odors.

3. Physical Wear from Abrasives:

- Sand and grit can scour the interior of pipes and fittings over years, thinning walls.

- Material Hardness Matters: The fitting material must have inherent abrasion resistance to maintain its integrity over a 20-50 year lifespan.

Material Selection Guide for Reuse Systems

Choosing the wrong material guarantees premature system failure. Here is a clear guide:

| Material | Suitability for Greywater/Reuse Systems | Key Reason |

|---|---|---|

| PP-R (Polypropylene Random) | Excellent | Chemically inert, highly resistant to biofilm, smooth bore, and durable. The top choice. |

| Schedule 40 PVC | Good | Resistant to chemicals, but some plasticizers can degrade. Joints (glued) are reliable if made properly. |

| CPVC | Fair to Good | Handles heat well but can become brittle. Slightly less chemically robust than PP-R. |

| Silicon-Brass | Good (for specific points) | A special brass alloy resistant to dezincification. Use only where metal is unavoidable (e.g., valve connections). |

| Standard Brass/Copper | Not Recommended | Prone to corrosion and dezincification from chemicals and salts in greywater. |

For a system that lasts, specify fittings made from virgin PP-R compound. They offer the best combination of chemical resistance, longevity, and hydraulic efficiency for the challenging environment of water reuse.

How Can the Right Fittings Optimize the Efficiency of Fixtures and Appliances?

A low-flow fixture is only as efficient as the plumbing that feeds it. Bottlenecks at the fitting level can ruin the performance of the best appliances.

The right fittings optimize efficiency by delivering the designed water volume and pressure directly to the fixture without restriction or turbulence. They ensure the appliance receives stable, predictable flow, allowing its internal water-saving mechanisms—like aerators, pressure-compensating valves, and efficient spray patterns—to function exactly as intended.

Fittings as Performance Enablers

Think of your plumbing system as a highway and water as cars. Fixtures are the off-ramps. If the highway has narrow lanes (constricted pipes) and bad intersections (turbulent fittings), traffic (water) backs up, and no one gets off the ramp efficiently.

Here’s how common fitting problems sabotage fixture performance:

The Problem of Inlet Restriction: Many appliances, like washing machines and dishwashers, have inlet valves that require a minimum pressure to open and fill properly. If the elbow or valve feeding the appliance hose has a narrow bore, it restricts flow and pressure. This can lead to longer fill times, incomplete cycles, and even machine errors.

The Problem of Unstable Flow: Pressure-compensating (PC) showerheads and faucets are engineered to provide a consistent spray force regardless of changes in incoming water pressure. However, if an upstream fitting creates significant local turbulence or pressure drop, it can destabilize the flow before it even reaches the fixture, making the PC technology less effective.

Selecting Fittings for Peak Appliance Performance

To be a true performance enabler, a fitting must be:

- Full-Port: This means the internal opening of the fitting (like a valve or an elbow) is as large as the internal diameter of the pipe itself. There is no reduction in size to cause a bottleneck.

- Hydraulically Smooth: The interior should guide water smoothly, not create swirls or eddies that waste pressure energy.

- Correctly Sized: Using a ½-inch fitting on a ¾-inch supply line to a fixture will instantly cripple its potential flow.

Practical Fitting Upgrades for Common Fixtures

Consider these specific upgrades to unlock savings:

- For Toilets: Use a smooth-bore, full-port angle stop valve for the toilet supply. A cheap, restrictive multi-turn valve can slow the tank refill, potentially causing incomplete flushes and double-flushing—which wastes more water than it saves.

- For Washing Machines: Install full-port, quarter-turn ball valves on the hot and cold supply lines. These allow maximum, unrestricted flow for faster filling.

- For Showerheads: Ensure all elbows and tees in the shower supply line are quality, swept-design fittings. This preserves pressure so your low-flow showerhead delivers a strong, satisfying spray.

- For Kitchen Faucets: A high-efficiency aerator is useless if the supply lines under the sink are kinked or connected with fittings that have tiny internal passages. Use braided supply lines with wide, reinforced internal hoses.

By ensuring every connection in the chain is optimized, you allow the fixture’s own water-saving technology to work at 100% of its designed capability.

What Should You Look for in Fittings to Maximize a System’s Water-Saving Potential?

Selecting fittings shouldn’t be an afterthought. To maximize savings, you need to be a discerning buyer and look for specific, verifiable features.

To maximize water-saving potential, look for fittings with: 1) Certified smooth-bore, full-port design to maintain pressure, 2) Material certifications (like NSF 61 and NSF 14) for durability in potable or reuse water, 3) Leak-proof joint technology (like heat fusion or quality O-rings), and 4) Compatibility with system design pressure and temperature ratings. Always prioritize system compatibility and third-party certification over the lowest price.

A Buyer’s Checklist for Conservation-Focused Fittings

Don’t just pick a fitting from a catalog. Use this actionable checklist based on common installation failures:

1. Demand Hydraulic Efficiency Data.

Ask for it. A serious manufacturer can provide flow coefficient (Cv) values or pressure drop charts for their fittings. Compare them. A lower pressure drop per fitting means higher system-wide efficiency. Look for marketing terms like “swept tee,” “low-loss elbow,” or “full-port design” as starting points.

2. Verify Material and Safety Certifications.

Certifications are your independent proof of performance. They are not optional for a conservation system.

- NSF/ANSI 61: For potable water safety (prevents leaching).

- NSF/ANSI 14: For plastic piping system component performance (covers dimensions, pressure ratings, burst strength).

- Additional Certifications: For greywater, look for material resistance certifications specific to wastewater or chemical exposure.

3. Choose the Most Reliable Joining Method for the Application.

The joint is the weakest point. Select the strongest option suitable for your system:

- For PP-R Systems: Heat fusion is king. It creates a permanent, monolithic, leak-proof joint.

- For Retrofit or Connections to Fixtures: Quality compression fittings with EPDM O-rings are excellent. Ensure the O-ring is a visible, replaceable grade of rubber, not a thin, integrated gasket.

4. Ensure Complete System Compatibility.

A fitting is part of an ecosystem. Mismatches cause leaks and inefficiency.

- Pressure/Temperature Rating: The fitting’s rating (e.g., PN20 at 20°C) must meet or exceed the system’s maximum operating conditions.

- Chemical Compatibility: For reuse systems, confirm the material is rated for constant exposure to soaps and mild effluents.

- Size Consistency: Ensure the fitting’s outer and inner diameters match your pipe specifications to avoid installation stress.

The True Cost of Cheap Fittings

It’s tempting to save money on fittings. But consider this comparison of lifecycle costs:

| Cost Factor | Cheap, Generic Fittings | Quality, Engineered Fittings |

|---|---|---|

| Initial Purchase Price | Low | Higher |

| Risk of Early Leakage | High | Very Low |

| Impact on Fixture Efficiency | Reduces efficiency | Maximizes efficiency |

| Long-Term Maintenance Cost | High (repairs, leaks, wasted water) | Very Low |

| System Lifespan | Shortened | Maximized (50+ years) |

The math is clear: the higher upfront cost of quality fittings pays for itself many times over through water savings, avoided repairs, and long-term reliability.

Conclusión

The right fittings are the backbone of an effective water conservation system, ensuring every saved drop reaches its destination. For fittings that guarantee efficiency, durability, and leak-free performance, build your system with IFAN’s full range of precision-engineered PP-R fittings and valves.

Comentarios recientes