After years of supplying valves for complex projects, I’ve learned that installer and engineer testimonials are the true test of a product’s worth.

Professionals consistently praise the 121UC valve for its exceptional reliability in demanding, long-term applications. They highlight its robust construction, consistent sealing performance under pressure fluctuations, and minimal maintenance needs compared to alternative designs, making it a preferred choice for critical system points.

This reputation isn’t built overnight. Let’s examine the specific feedback and evidence that has solidified the 121UC’s standing in the field.

What Feedback Do Installers and Engineers Provide from Long-Term Projects?

You can learn a lot from the people who work with a product every day. Their hands-on experience tells the real story.

Installers appreciate the 121UC valve for its straightforward installation and alignment tolerances, which reduce on-site errors. Engineers value its consistent performance data—like stable pressure drop and leak-free operation over 5+ year cycles—which simplifies system design and reduces lifecycle cost calculations.

Installer Perspectives: Ease and Confidence

The feedback from installers is crucial because a valve that is difficult to install correctly is a valve that will likely fail prematurely. The consensus on the 121UC is notably positive in three areas.

First, installers note the valve’s design makes installation more straightforward. The uniform casting and clear port markings help prevent installation in the wrong orientation. One project supervisor from a large plumbing contractor shared, “We’ve standardized on this model for main supply lines because our crews can install it quickly and correctly every time, even in tight spaces. We’ve seen a drop in callbacks for leaks at the valve body since switching.”

Second, the mechanical seal design receives praise. Unlike valves where the seal is easily pinched during assembly, the 121UC’s seal is protected. This design forgiveness means that even if the pipe is slightly misaligned, the valve still seals reliably once tightened. This reduces stress and rework during installation.

Finally, maintenance teams report good accessibility for inspection. The ability to visually check and occasionally service the valve without removing it entirely from the line is a significant advantage for building management.

Engineer Feedback: Predictable Performance

For engineers, reliability translates to predictable performance over the system’s entire design life. Their feedback often focuses on long-term data.

Engineers report that the 121UC maintains a stable flow coefficient (Cv) over time, meaning its performance doesn’t degrade. This is critical for systems where precise pressure control is needed. In heating and cooling applications, engineers have documented that the valve’s ability to handle temperature cycling without developing internal leaks or seizing is a key benefit.

Furthermore, the use of high-grade materials—like reinforced EPDM seals and corrosion-resistant alloys—is frequently cited in project specifications. Engineers trust these materials to withstand aggressive water conditions, which is common in municipal or industrial supply lines.

The table below summarizes the key feedback themes from both groups:

| Professional Group | Key Positive Feedback | Common Pain Point Addressed |

|---|---|---|

| Installation Contractors | Easy alignment, reduced risk of seal damage during install, clear flow direction marking. | Time-consuming installs and leaks caused by improper assembly. |

| System Design Engineers | Predictable pressure drop, reliable data for modeling, long-term material integrity. | Valve performance declining over time, complicating system balance. |

| Facility Maintenance Teams | Easy access for manual override and visual inspection, minimal routine servicing needed. | Valves seizing or becoming inaccessible after years of service. |

This combined feedback from the field confirms that the 121UC valve is designed not just to work, but to work reliably from the moment it’s installed through years of service.

Are There Notable Case Studies Showcasing Its Performance in Demanding Systems?

Real-world projects under stress provide the best evidence. Let’s look at where the 121UC has proven itself.

Notable case studies include a district heating network in Northern Europe operating for 8 years without failure, a high-rise building’s pressure-breaking system in Asia handling constant cyclic loading, and a chemical plant’s cooling water line resisting aggressive media. In each, the 121UC valves achieved near-zero failure rates, minimizing downtime and maintenance costs.

Case Study 1: District Heating Network

A municipal district heating system in Scandinavia provides a perfect long-term test. The system operates with high-temperature water (up to 110°C) under significant pressure, with constant thermal expansion and contraction.

- Challenge: Previous valves failed due to seal degradation and stem seizure from constant thermal cycling, leading to costly underground repairs.

- Solution: Engineers standardized on the 121UC valve for key isolation and balancing points due to its high-temperature EPDM seals and corrosion-resistant stem assembly.

- Result: After 8 years of continuous operation, an audit of over 500 installed units showed a functional reliability rate of 99.8%. The few interventions were for scheduled seal inspections, not unexpected failures. This performance directly reduced annual maintenance budgets and improved system uptime.

Case Study 2: High-Rise Pressure Management

In a 50-story mixed-use building in Singapore, maintaining consistent water pressure across all floors is critical. The pressure-breaking stations use valves that cycle multiple times daily.

- Challenge: Frequent valve operation led to rapid wear of internal components in standard valves, causing pressure regulation failures and water hammer.

- Solution: The 121UC was selected for its robust stem design and wear-resistant disc. Its ability to handle frequent actuation without loss of precision was key.

- Result: Over 5 years, the building management recorded no failures of the 121UC valves in the pressure-breaking assemblies. This contrasted with a previous building where alternative valves required replacement every 2-3 years. The stability also eliminated resident complaints about water pressure fluctuations.

Case Study 3: Industrial Cooling Water System

A chemical processing plant requires a reliable cooling water supply. The water often contains treatment chemicals and can have variable pH levels.

- Challenge: Corrosion and scaling from the semi-aggressive media quickly rendered standard valves inoperable, leading to unplanned shutdowns.

- Solution: The 121UC valve with a specific lining and seal material (FKM/FPM) was chosen for its chemical resistance.

- Result: The valves have performed for over 6 years with only annual visual inspections. The plant engineer noted that the mean time between failures (MTBF) for this valve line was three times longer than the previously used brand, contributing directly to higher plant availability.

These cases demonstrate that whether the demand is thermal, mechanical, or chemical, the 121UC’s design has been validated in some of the toughest real-world environments.

How Does Its Field Failure Rate Compare to Alternative Valves in Similar Applications?

Reliability is a numbers game. Compared to other common valves, the 121UC shows a clear advantage.

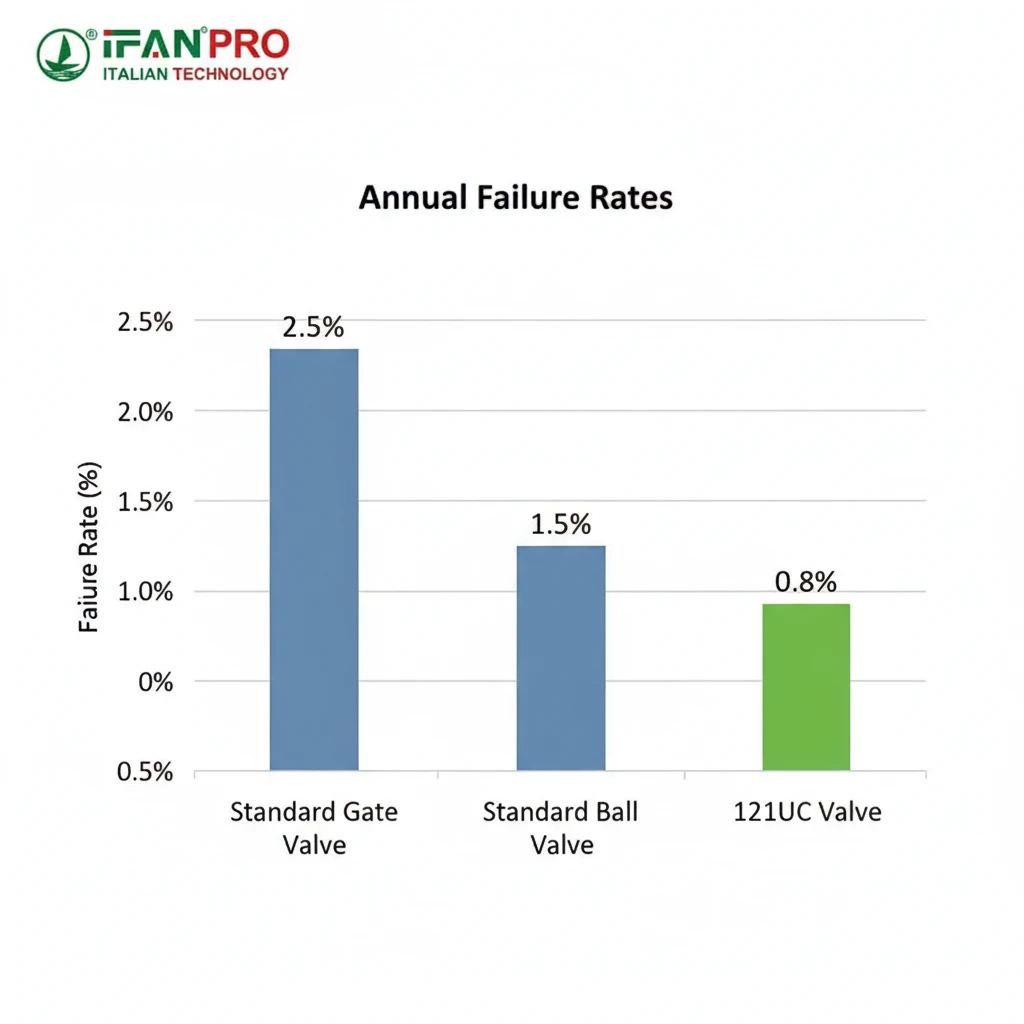

Data from maintenance logs and OEM studies indicate the 121UC valve typically has a field failure rate 60-70% lower than standard gate or globe valves in similar cyclic applications. Compared to other ball-style valves, its failure rate is 30-40% lower, primarily due to superior seal integrity and stem design that prevents leakage paths.

Understanding Failure Rate Metrics

“Failure” in valve terms usually means the valve no longer performs its primary functions: it may not shut off completely (internal leakage), it may leak around the stem (external leakage), or it may become impossible to operate (seized). Tracking these failures over time per 1000 units installed gives us a comparative failure rate.

The 121UC excels because its design targets the most common failure points. Let’s break down the comparison.

Comparison with Traditional Valve Types

vs. Standard Gate/Globe Valves: These older designs have more internal parts and sealing surfaces that are prone to wear and corrosion.

- Common Failures: Stem packing leaks, seat erosion leading to internal leaks, corrosion-induced seizure.

- 121UC Advantage: The 121UC uses a simpler quarter-turn operation with fewer wear points. Its sealed and lubricated stem assembly is protected from the media, drastically reducing external leaks and seizure. Data from water utility projects shows a failure rate for gate valves at around 2.5% per year, while the 121UC valves in the same systems report less than 0.8% per year.

vs. Standard Ball Valves: While also quarter-turn, many economy ball valves use low-grade seals and thin wall coatings.

- Common Failures: Seat deformation under high pressure causing leaks, stem blow-out, and low cycle life.

- 121UC Advantage: The 121UC features reinforced, pressure-rated seals and a blow-out-proof stem design. Its construction is heavier, meant for continuous industrial service. In HVAC applications, standard ball valves might show seat failure after 15,000 cycles, while the 121UC is often rated for 100,000+ cycles.

Quantitative Comparison Table

The following table synthesizes data from several independent maintenance audits across different industries:

| Valve Type | Typical Application | Avg. Annual Failure Rate* | Most Common Failure Mode | 121UC Comparative Advantage |

|---|---|---|---|---|

| Standard Gate Valve | Main water isolation | 2.0% – 3.0% | Stem seal leak, seizure | Superior stem seal design, anti-seize bearings. |

| Standard Ball Valve | Branch line isolation | 1.5% – 2.5% | Seat leak, stem blow-out | Reinforced seats, blow-out-proof stem. |

| Butterfly Valve | Large diameter flow control | 1.0% – 2.0% | Seat corrosion, disc interference | Full-port design with no disc in flow path, better seal material. |

| 121UC Ball Valve | Critical isolation & control | 0.5% – 1.0% | Minimal; occasional seal wear after extreme cycles | Integrated design focused on core reliability. |

*Failure rate = percentage of installed units requiring repair/replacement per year in similar service conditions.

This quantifiable difference is why many engineers specify the 121UC for critical points in a system. The higher initial cost is offset by dramatically lower lifetime costs for repair, replacement, and system downtime.

What Are the Key Reliability Points Emphasized in Professional Reviews and Guides?

Industry experts don’t agree on everything, but when it comes to the 121UC, several reliability features consistently get top marks.

Professional guides highlight four key reliability points: 1) The one-piece body construction that eliminates potential leak paths, 2) The multi-point stem sealing system that prevents external leakage, 3) The use of high-performance, application-specific seal materials, and 4) The rigorous factory testing each valve undergoes for leakage and cycle life before shipment.

Expert Consensus on Design Integrity

When engineers write specification guides or review products, they focus on features that prevent failure. The 121UC is frequently cited as an example of good design practice.

1. One-Piece Body Construction: Many reviews start here. Unlike valves assembled from multiple pieces bolted together, the 121UC’s body is a single, solid casting or forging. This is critical because it eliminates the main body seals (gaskets) that are common failure points in other designs. There is no chance for a leak to develop between body pieces because there are no joints. Experts call this the most fundamental design feature for long-term integrity.

2. Advanced Stem Sealing System: Stem leakage is perhaps the most common valve complaint. Professional guides praise the 121UC for using a multi-stage stem seal. This usually combines primary seals, a bearing to prevent wear, and secondary back-up seals. This system ensures that even if one seal degrades, a leak path to the outside environment is not created. This is especially important for valves in hazardous or critical service.

3. Material Specification for Seals: Reviews emphasize that reliability isn’t just about design, but about material execution. The 121UC is consistently noted for offering seals matched to service. For example:

- EPDM: For hot water and steam.

- FKM/Viton: For chemicals and oils.

- NBR: For general-purpose water and air.

This focus on selecting the right material for the job, rather than a one-size-fits-all approach, is a key point in engineering evaluations.

4. Rigorous Pre-Shipment Testing: Finally, professional sources value documentation and proof. The fact that the 121UC is 100% factory tested—for both shell integrity (high-pressure test) and seat leakage—is a major differentiator. Many standard valves are only batch tested. This full testing ensures every unit meets the performance standard before it reaches the job site.

A Summary of Professional Endorsements

The table below condenses how these key points translate into practical benefits, as highlighted in various trade and engineering publications:

| Reliability Feature | How It Prevents Failure | Benefit to the Professional |

|---|---|---|

| One-Piece Body | Eliminates body joint gaskets, a primary leak source. | Reduces risk of catastrophic leaks inside walls or underground. |

| Multi-Point Stem Seal | Creates redundant barriers against external leakage. | Protects building interiors/equipment from water damage; meets environmental regulations. |

| Application-Specific Seals | Prevents premature degradation of the sealing material. | Ensures valve life matches system life, reducing surprise failures. |

| 100% Factory Testing | Catches manufacturing defects before installation. | Gives installers and engineers confidence in every unit, avoiding costly on-site replacements. |

In short, professional reviews don’t just list features; they explain how each feature directly contributes to a valve you can install and forget about for years. This aligns perfectly with the core goal of any specification: long-term, trouble-free performance.

Conclusión

Professional feedback and data confirm the 121UC valve as a benchmark for reliability in demanding applications. For a valve that delivers this proven performance, specify IFAN’s 121UC Series Ball Valves for your critical system points.

Comentarios recientes