I recently saw a project fail because a standard valve crushed an aluminum composite pipe. This moment taught me that not every fitting works with these advanced pipes.

Yes, a properly designed valve can and must connect with both the aluminum and PEX layers of a composite pipe. It uses a connection mechanism, like a press sleeve or a special clamping system, that grips the entire pipe structure uniformly. This ensures a strong mechanical hold on the aluminum for stability and a reliable seal on the inner PEX layer for leak-proof performance.

However, this requires specific engineering. Let’s examine how a good valve interacts with each layer of the pipe to create a perfect, lasting connection.

How Does the Connection Mechanism Engage with the Pipe’s Composite Structure?

A composite pipe is not a simple tube. Using the wrong connection is the top mistake we see in the field.

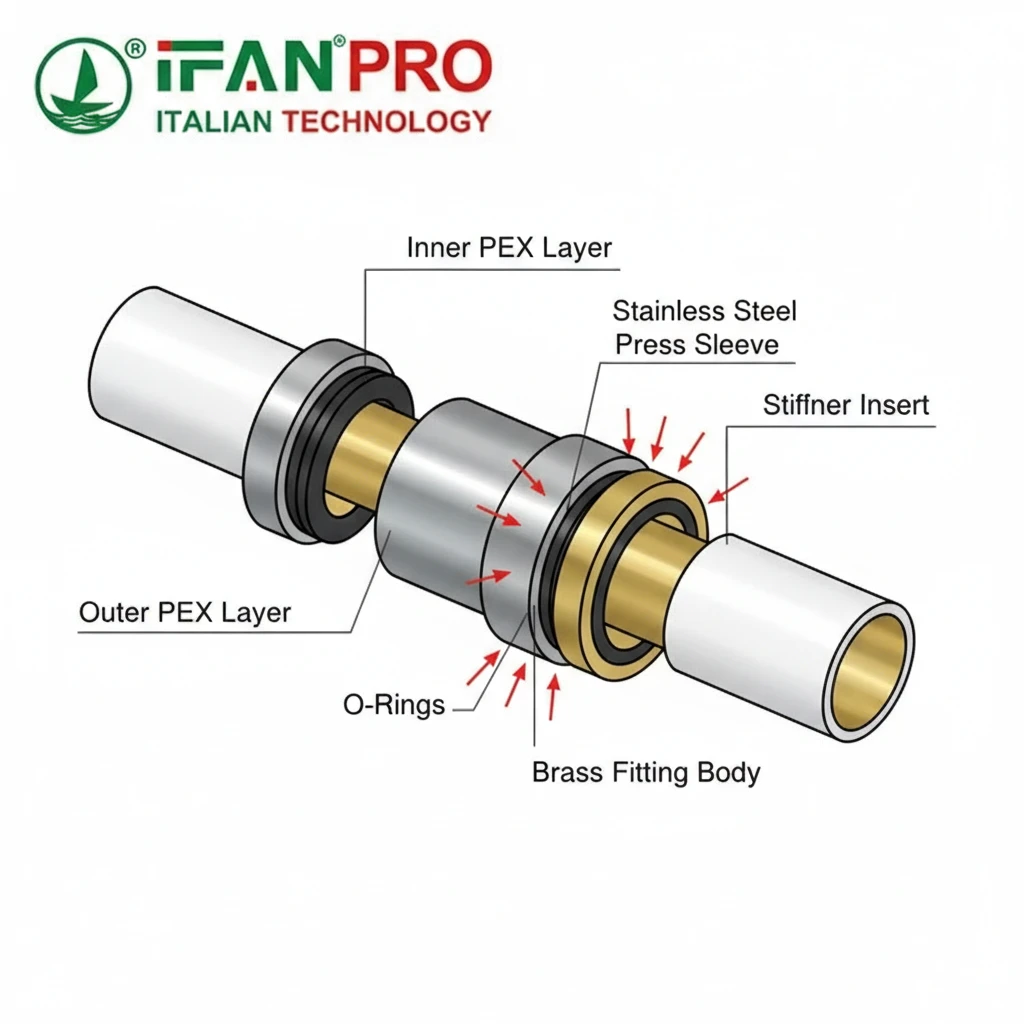

The connection mechanism engages with the composite structure by applying uniform, radial force around the entire pipe circumference. A press-fitting tool compresses a metal sleeve (or a clamp tightens) onto the pipe. This action simultaneously crimps the outer aluminum layer for grip and presses an internal sealing ring against the smooth PEX liner to create the watertight seal.

The Challenge of a Dual-Layer Pipe

An aluminum-PEX pipe has two main jobs. The inner PEX layer carries water and provides chemical resistance. The outer aluminum layer gives the pipe strength, prevents oxygen from entering, and helps it hold its shape. A valve must work with both layers without harming either.

A standard compression fitting designed for plain PEX will often fail. It might only squeeze the soft PEX, leaving the aluminum layer unsupported. This can cause the connection to become loose over time. Alternatively, a fitting meant for rigid metal pipe could cut or crack the aluminum layer.

The Solution: Uniform Radial Compression

The correct solution applies force evenly all around the pipe. Imagine gently squeezing a soda can from all sides at once—it resists the pressure evenly. This is the principle behind a press-fitting system for composite pipes.

Here is how it works step-by-step:

- You slide the valve onto the prepared pipe end.

- Inside the valve, a specially shaped stainless steel sleeve surrounds the pipe.

- A rubber O-ring or a flat gasket sits inside, positioned to contact the PEX layer.

- Using a powered or manual press tool, you crimp the metal sleeve at precise points.

- This crimping action does two things at once: First, it deforms the sleeve to bite gently into the aluminum layer, locking the pipe in place. Second, it compresses the internal O-ring firmly against the smooth PEX liner, creating the seal.

This method ensures the aluminum layer handles the mechanical stress of holding the connection together, while the PEX layer independently handles the job of sealing against water under pressure. The system uses the strengths of each material perfectly.

Does It Require a Special Insert to Support the Aluminum Layer from Inside?

This is a critical detail many installers miss. An unsupported aluminum layer can collapse.

For most press-connection systems, yes, a special internal stiffener insert is absolutely required. You must place this rigid plastic or metal sleeve inside the pipe end before making the connection. Its job is to prevent the aluminum layer from buckling or deforming inward when the external press sleeve is crimped, ensuring the seal forms correctly and the pipe’s internal diameter stays open.

Why Can’t the Aluminum Layer Support Itself?

The aluminum layer in these pipes is very thin—often just a fraction of a millimeter thick. It is strong against bending but weak against point pressure or crushing. When you apply the tremendous force of a press tool to the outside, without internal support, the aluminum can easily crumple like a soda can.

A crumpled aluminum layer causes two major failures:

- Blocked Flow: The pipe’s inner diameter gets smaller, restricting water flow and causing pressure loss.

- Failed Seal: The internal O-ring needs a perfectly round, firm surface to seal against. A collapsed pipe creates an uneven surface, leading to immediate or eventual leaks.

The Role of the Stiffener

The stiffener, sometimes called a “liner” or “support sleeve,” solves this problem. It is a short tube made of hard plastic (like POM) or sometimes brass. You insert it into the prepared pipe end so it sits right under the area where the press sleeve will crimp.

During the pressing operation, the stiffener acts like an anvil. The press force pushes the aluminum layer against this unyielding internal support. This allows the aluminum to be gripped firmly without collapsing. The table below shows the consequences of skipping this part.

| Scenario | With Proper Stiffener Insert | Without Stiffener Insert |

|---|---|---|

| Aluminum Layer Integrity | Remains round and intact; provides strong mechanical grip. | Can buckle or collapse inward; grip is weak. |

| Water Flow | Unrestricted, full internal diameter maintained. | Often restricted, causing reduced pressure. |

| Seal Reliability | High. O-ring seals against a firm, round PEX surface. | Low. O-ring seals against a deformed, uneven surface. |

| Long-Term Result | A reliable, permanent connection. | High risk of leaks or flow issues over time. |

Pro Tip from IFAN: Always use the exact stiffener insert recommended by the valve manufacturer. Its outer diameter must match your pipe’s inner diameter perfectly. A loose insert is useless, and a too-tight insert can damage the PEX layer during insertion.

What Ensures the Seal Is Made on the PEX Layer, Not Just the Aluminum?

Sealing on the aluminum is a recipe for leaks. The design must force the seal to happen on the correct material.

The valve’s internal geometry ensures the seal is on the PEX layer. A dedicated sealing ring (O-ring or flat gasket) is positioned inside the valve body so that when the pipe is fully inserted, the ring contacts only the exposed inner PEX tube. The crimping action of the external sleeve then compresses this ring directly against the PEX, bypassing the aluminum layer entirely.

Why You Cannot Seal Reliably on Aluminum

Aluminum is a great structural material but a poor sealing surface for water connections. First, it can corrode over time, especially with certain water chemistries. A corroded surface will leak. Second, the seam where the aluminum layer is welded or overlapped creates a tiny ridge or unevenness. An O-ring cannot make a perfect seal over this ridge.

The inner PEX tube, however, is a perfect sealing surface. It is smooth, continuous, non-corrosive, and slightly flexible. A compressed O-ring can embed itself into the PEX slightly, creating a leak-proof barrier that lasts for decades.

How Valve Design Directs the Seal

A well-designed valve for aluminum-PEX pipe has a specific internal “landing zone.” When you prepare the pipe, you strip back the outer plastic and the aluminum layer to expose a precise length of the inner PEX tube. This exposed PEX is the only part that reaches the sealing ring inside the valve.

Here’s a breakdown of the sealing process:

- Proper Pipe Preparation: You use a special calibration tool to cut the pipe. This tool cleanly removes the outer layers, leaving the PEX core perfectly round and ready.

- Correct Insertion: You push the pipe into the valve until it hits a built-in stop. This guarantees the exposed PEX is exactly aligned with the internal O-ring.

- Precision Compression: When you press the external sleeve, it does not squeeze the sealing ring directly. Instead, it squeezes the pipe from the outside. This force pushes the exposed PEX section firmly inward against the stationary O-ring. The aluminum layer, now supported by the stiffener, simply transfers this force without being part of the seal.

This design is foolproof when executed correctly. The seal physically cannot occur on the aluminum because the sealing element and the aluminum never touch in a way that allows for compression. The valve’s body blocks the aluminum from reaching the O-ring.

Can Improper Installation Damage the Aluminum Barrier Layer?

Unfortunately, yes. The aluminum layer is the most delicate part of the pipe and is easily damaged by haste or using wrong methods.

Improper installation can easily and permanently damage the aluminum barrier layer. Common mistakes include over-pressing the connection, using the wrong press jaws, forgetting the internal stiffener, or using a dull cutting tool. This damage can crush, cut, or crease the aluminum, compromising its oxygen barrier function and weakening the pipe’s structural integrity at the most critical point: the connection.

Types of Installation Damage and Their Effects

The aluminum layer is thin and precise. Damage during installation is often invisible from the outside but has serious long-term consequences.

1. Over-Pressing or Using Wrong Jaws:

Every press-fitting system requires specific jaws matched to the fitting size. Using the wrong jaws or pressing too many times can over-compress the sleeve. This crushes the aluminum layer beyond its ability to spring back. The result is a severely weakened connection point that may crack under thermal stress.

- Effect: Creates a brittle point that may fail with temperature changes or water hammer.

2. Forgetting the Internal Stiffener:

As discussed, this is the most common error. Without the stiffener, the press force causes the aluminum to collapse inward.

- Effect: Restricts flow and creates a poor sealing surface, leading to leaks.

3. Poor Pipe Cutting and Preparation:

Using a generic pipe cutter or a dull tool can leave a ragged, uneven end. It can also deform the aluminum, creating a small “bell” or flare at the pipe end. This deformed end cannot insert properly into the valve.

- Effect: Prevents the pipe from seating fully against the internal stop, leading to a shallow seal and potential pull-out failure.

4. Debris in the Connection:

If metal shavings from cutting or dirt get between the aluminum and the press sleeve, it prevents uniform compression.

- Effect: Creates an uneven grip and a potential leak path.

The Silent Killer: Compromised Oxygen Barrier

A visible crease or cut is bad, but a more subtle problem exists. The aluminum layer’s key job is to act as an oxygen diffusion barrier, preventing air from entering the water system and corroding ferrous metal parts (like radiators or boiler internals). Even a tiny crack or pinhole in the aluminum, caused by a poor cut or press, ruins this barrier.

You won’t see an immediate water leak, but years later, you may face expensive corrosion damage in your heating system. This is why professional, precise installation is non-negotiable.

Best Practices to Prevent Damage

Follow this simple checklist to protect the aluminum layer:

- Use the Right Tools: Invest in the manufacturer-specified pipe cutter, calibration tool, and press jaws.

- Always Use a Stiffener: Never, ever skip this step. Check it’s fully inserted.

- Clean the Pipe End: Wipe away any aluminum chips or dust after cutting and calibrating.

- Press Once, Correctly: Align the press tool perfectly and complete the crimp in one smooth action. Do not re-press.

Conclusión

A valve must be specifically designed to connect safely with both layers of an aluminum-PEX pipe. For reliable performance, choose engineered solutions like IFAN’s press-fitting valves, designed with the correct internal geometry and paired with the necessary support inserts.

Comentarios recientes