I once saw a technician spend hours dismantling an entire manifold to fix one small leak. That moment perfectly illustrated why the right fitting is not just a part, but a critical tool for efficient installation and future maintenance.

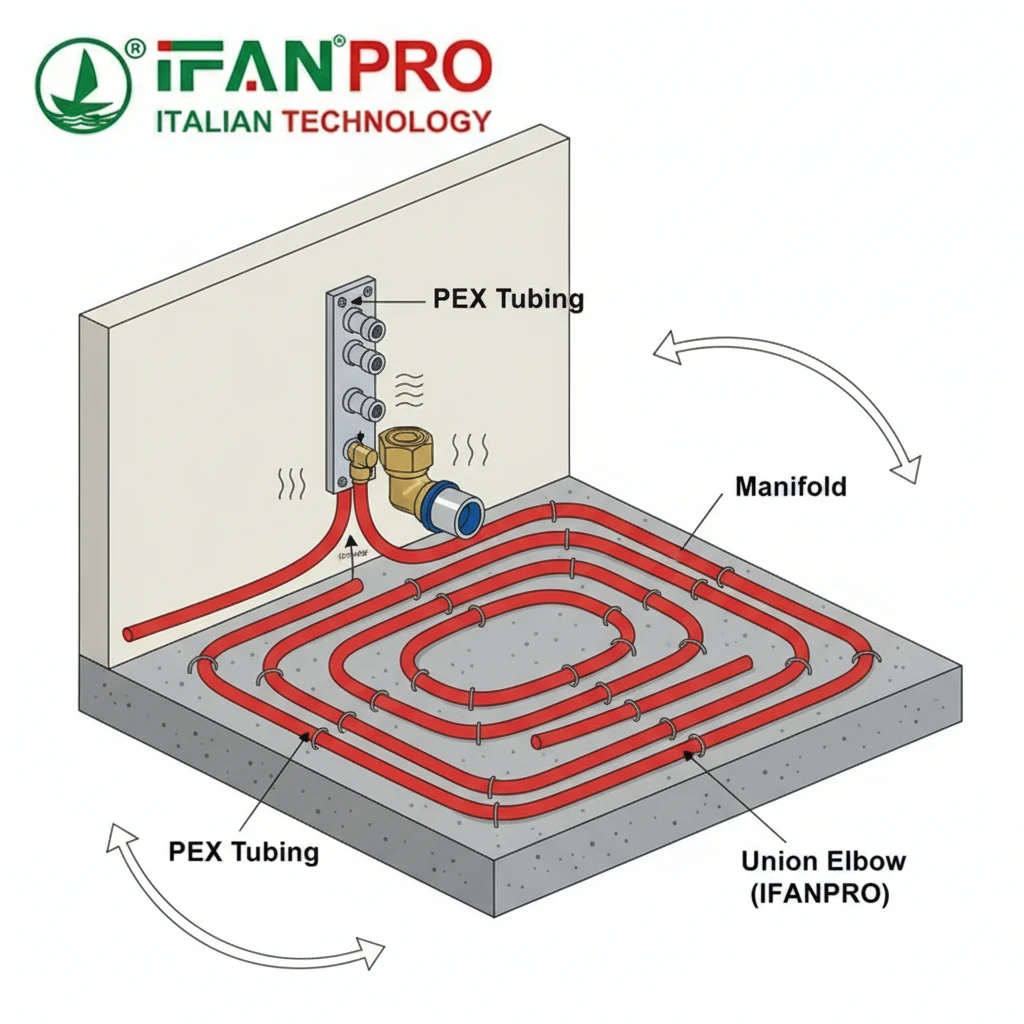

Union elbows are used in PEX radiant heating systems because they provide a removable, sealed connection point. This design allows installers to easily connect or disconnect PEX piping loops at the manifold and offers crucial service access for maintenance, repairs, or future system modifications without requiring a complete system drain or pipe cutting.

While the system works once buried, you must plan for the day you need to access it again. Let’s explore how union elbows solve the key challenges in radiant heating installations.

How Do They Simplify Manifold and Loop Connections During Installation?

Installing a radiant system is complex. I’ve watched crews struggle with tight spaces where traditional fixed fittings would make the job nearly impossible.

Union elbows simplify manifold and loop connections by acting as a pre-assembled, angled bridge between the manifold outlet and the PEX tube. Their swivel design allows for easier alignment in cramped spaces, and their removable nut means you can attach the PEX tube first and then connect the entire assembly to the manifold neatly and securely.

Solving the Manifold Connection Puzzle

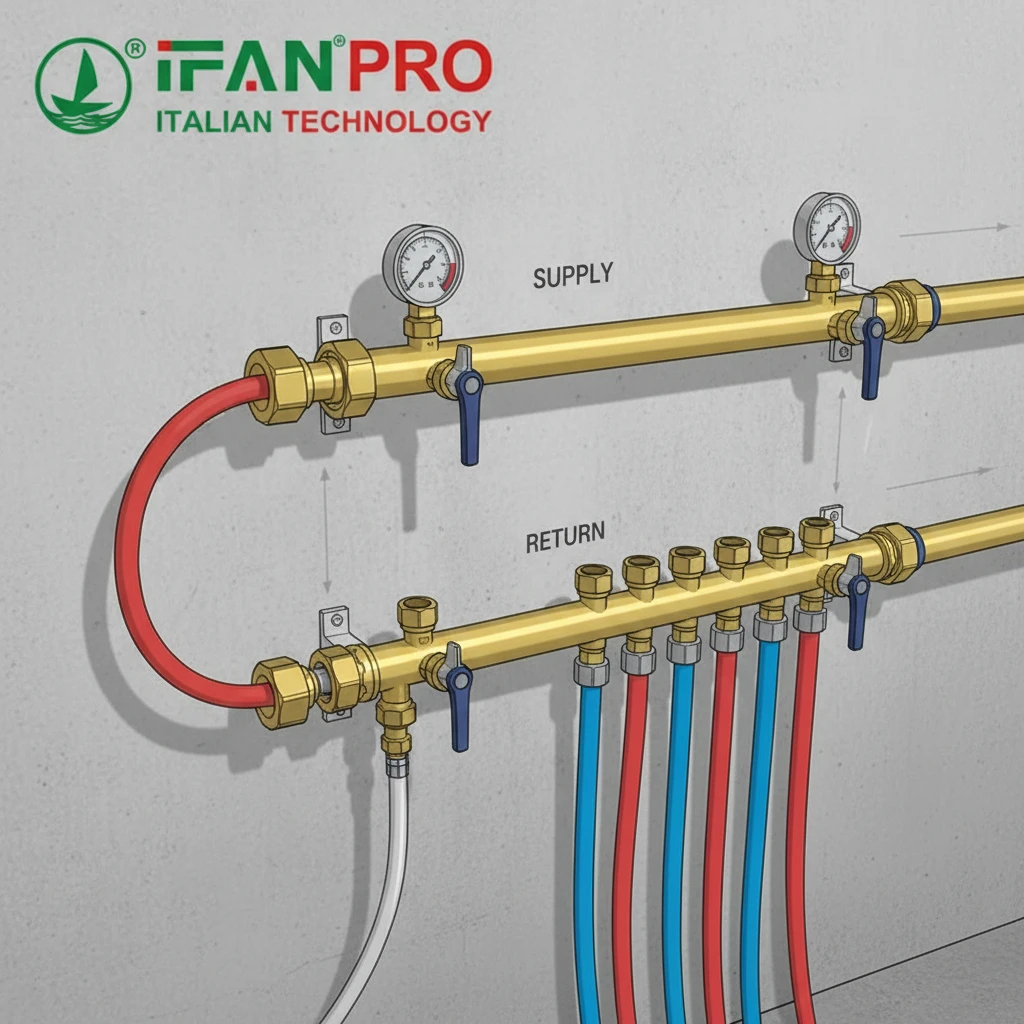

The manifold is the heart of a radiant heating system, but connecting multiple loops to it in a clean, reliable way is a common headache. Pipes come from different directions, and space behind the manifold is often limited. A fixed 90-degree elbow soldered or glued to the manifold port offers no flexibility. If the PEX tube isn’t perfectly aligned, you create stress on the connection from the start.

A union elbow solves this with its two-part design. The elbow body threads into the manifold port. The PEX tube is then connected to the other end of the elbow, often via a crimp or clamp ring. The magic happens in the middle: the large union nut connects these two parts. This nut allows the entire elbow-and-PEX assembly to swivel during installation. You can rotate it to find the optimal, most natural path for the tube to leave the manifold, eliminating pipe stress.

Step-by-Step Installation Advantage

Here is a comparison of the connection process, showing how union elbows save time and reduce errors:

| Step | Using Fixed Fittings | Using Union Elbows |

|---|---|---|

| 1. Planning | Must measure exact PEX alignment to manifold port. | Alignment is forgiving; the union allows for adjustment. |

| 2. Assembly | Must connect PEX to fitting, then carefully thread the rigid assembly into the manifold. | Can connect PEX to elbow first, then easily thread the elbow body into the manifold. |

| 3. Final Connection | Any misalignment causes bending stress, risking a leak. | The union nut is tightened last, securing a stress-free alignment. |

| 4. Future Disconnection | Requires cutting the PEX pipe. | Simply loosen the union nut to disconnect. |

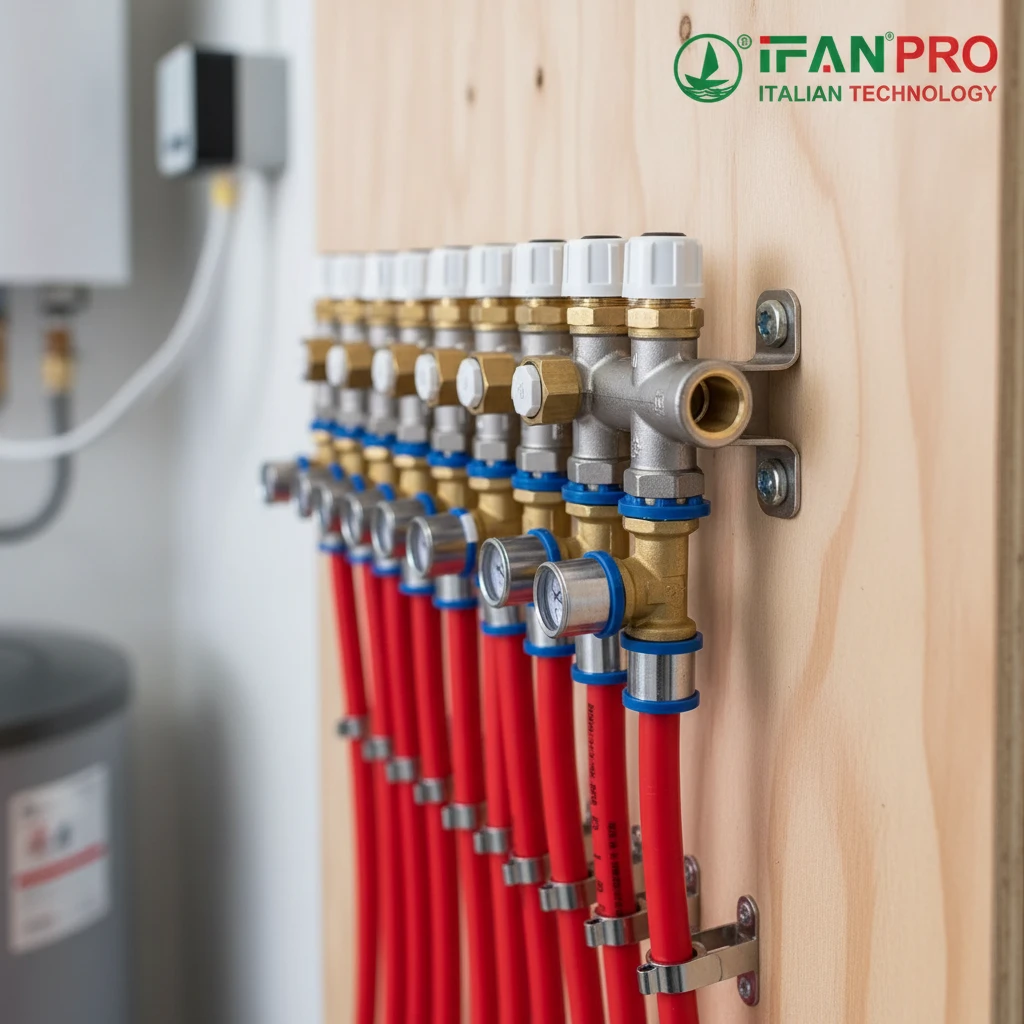

Furthermore, this design allows for a much cleaner and more professional-looking manifold layout. All connections are uniform and robust. For installers, this means faster work, fewer callbacks for leaks, and a happier client looking at a tidy mechanical room.

Why Is Service Access Crucial for Individual Heating Zone Maintenance?

A system failure shouldn’t mean a catastrophe. I recall a project where a single faulty zone valve, buried behind pipes, took a full day to replace, disrupting the whole building.

Service access is crucial because radiant heating systems are designed to last decades, but components like zone valves, flow meters, or air vents will eventually need servicing or replacement. Union elbows provide a clean break point, allowing a technician to remove a single manifold station or loop for repair without disturbing the rest of the functioning system.

The Reality of Long-Term System Ownership

A radiant system is a long-term investment. While the PEX tubing in the floor may last 50 years, the mechanical components connected to it will not. Zone valves, actuators, and flow meters have moving parts and seals that can wear out after 10-15 years. Without planned access points, servicing a single component becomes a major operation.

Imagine a flow meter on loop #3 fails. If all connections are permanent, the technician faces a bad choice:

- Try to work in an extremely tight space, often leading to damaged adjacent fittings.

- Cut multiple pipes to remove the faulty part, then install multiple coupling fittings to rebuild it, increasing future leak points.

- Drain the entire, potentially massive, system to safely remove and solder a new fitting.

None of these are efficient or cost-effective. This is where the foresight of using union elbows pays off tremendously.

How Union Elbows Enable Targeted Repairs

With a union elbow at each manifold connection, the repair process becomes simple and localized:

- Close the isolation valves for that specific loop (another good practice).

- Use a wrench to loosen the union nut on the elbow connected to the faulty component.

- The entire component (e.g., valve and flow meter assembly) can now be unthreaded and lifted away from the manifold.

- After repair or replacement, the component is threaded back in, and the union nut is re-tightened.

This process takes minutes instead of hours. It does not require draining the system, cutting any PEX, or heating solder near other plastic components. It minimizes downtime and repair costs. For building managers or homeowners, this design translates directly to lower lifetime ownership costs and less disruption. It turns a potential major repair into a simple, routine maintenance task.

Can They Be Used to Isolate a Single Loop Without Draining the Entire System?

Draining a large radiant system is a huge task. We once avoided a 2-day shutdown for a school gym by using the access points our design included.

Yes, this is one of their primary functions. When paired with individual shut-off valves on the manifold, the union elbow provides the second, physical disconnection point. By closing the loop’s valves and loosening the union nuts at both ends (supply and return), that specific PEX loop can be completely isolated and removed for repair, leaving the rest of the system pressurized and operational.

The Two-Point Isolation Strategy

For true isolation, you need two things: a way to stop the flow, and a way to physically disconnect the pipe. Manifold shut-off valves provide the first. Union elbows provide the second.

Here’s how a loop isolation procedure works in practice:

- Shut Off Flow: Close the balancing valve and shut-off valve on the specific loop’s supply and return ports at the manifold.

- Disconnect: Loosen the union nuts on the elbows connected to those manifold ports. The loop is now mechanically disconnected from the main system.

- Depressurize the Loop (Only): A small drain valve can be opened on the isolated loop itself to drain just that circuit, or repairs can be made if the loop is already empty.

- Repair/Replace: The faulty section within that isolated loop can now be worked on.

- Reconnect: After repair, reconnect the loop by tightening the union nuts and re-opening the manifold valves.

The Critical Benefit: System Integrity and Time Savings

The alternative—draining the entire system—is often a massive undertaking. A large residential or commercial system can hold hundreds of gallons of treated water. Draining it is wasteful and time-consuming. But the bigger problem is re-filling and purging the system of air. Air pockets in radiant floors cause noise and reduce heating efficiency, and bleeding a large system can take days or even weeks to achieve proper performance.

By allowing single-loop isolation, union elbows preserve the integrity and stability of the entire system. The other 95% of the system remains undisturbed, full of water, and under pressure. This capability is not just a convenience; for hospitals, data centers, or any facility requiring continuous operation, it is an essential design feature. It transforms system maintenance from a major logistical event into a manageable, localized task.

How Do They Accommodate Floor Movement or Settling in Slab Systems?

Concrete moves and settles. We design for this reality, because fittings that don’t accommodate movement become the weakest link.

Union elbows accommodate minor floor movement at the critical point where the rigid manifold meets the flexible PEX tubing entering the slab. The slight rotational play in the union connection, combined with the natural flexibility of the PEX loop, absorbs stress from slab settlement or thermal expansion, preventing those forces from transferring to and potentially cracking the manifold or its connections.

Understanding Forces in a Slab System

A poured concrete slab is not a completely static structure. It cures, shrinks, and can settle unevenly over time. It also expands and contracts with temperature changes. The PEX tubing embedded within it moves with the concrete. However, the manifold is mounted on a wall or in a cabinet, fixed to the building’s structure. This creates a potential conflict: a moving floor connected to a fixed manifold.

If the connection is completely rigid—like a fixed elbow—the forces from slab movement transmit directly to the manifold’s threaded ports. Over time, this constant stress can lead to:

- Leaks at the manifold threads: The fitting can loosen or crack.

- Strain on the PEX: The pipe can be pinched or pulled at a sharp angle.

- Manifold damage: In extreme cases, the manifold itself can crack.

The Role of the Union Elbow as a Stress-Relief Point

The union elbow introduces a controlled, flexible link. While the union nut is tight, it does not create a totally immovable “weld.” There is a very slight amount of permissible angular flex at the joint (similar to the concept discussed in the previous article, but for a different purpose). This flexibility is key.

When the slab settles or moves, the PEX loop pulls or pushes on the elbow. Instead of that force traveling straight into the manifold, the union connection allows for a tiny bit of give. The PEX itself, which is very flexible near the manifold, can also bend slightly to accommodate the movement. Together, they act as a shock absorber.

Design Practices for Stress Absorption

Proper installation maximizes this benefit. Installers should create a “service loop” of extra PEX tubing near the manifold before the pipe enters the slab. This loop gives the pipe material extra length to flex. The union elbow is the articulated joint at the start of this flexible section.

The table below contrasts a rigid connection strategy with one designed for movement:

| Connection Design | How it Handles Slab Movement | Risk Outcome |

|---|---|---|

| Rigid Connection | Forces transfer directly to the manifold. | High risk of leaks or cracks over 5-10 years. |

| Union Elbow + Service Loop | Movement is absorbed by PEX flex and union play. | Forces are dissipated; system remains intact long-term. |

Therefore, using union elbows isn’t just about serviceability; it’s a proactive measure for long-term system durability. It ensures that the mechanical connections are protected from the dynamic environment of the building structure itself.

Conclusión

Union elbows are essential for installable, serviceable, and durable PEX radiant systems. For reliable performance, choose IFAN’s brass or polymer union elbows designed specifically for heating manifolds.

Comentarios recientes