I once saw a cramped piping manifold fail because of too many leak points. This made me carefully study when to use a cross fitting versus two tees.

A cross fitting is a single, four-way connector, while two tees are separate three-way connectors joined by a pipe nipple. The main comparison involves connection count, flow efficiency, installation space, and system flexibility. Choosing correctly impacts your system’s cost, reliability, and performance.

Let’s break down this common engineering choice to find the best solution for your project.

How Many Fewer Connections and Seals Does a Single Cross Have Versus Two Tees?

Every connection is a potential leak. In my audits, I find most leaks start at joints, not pipes.

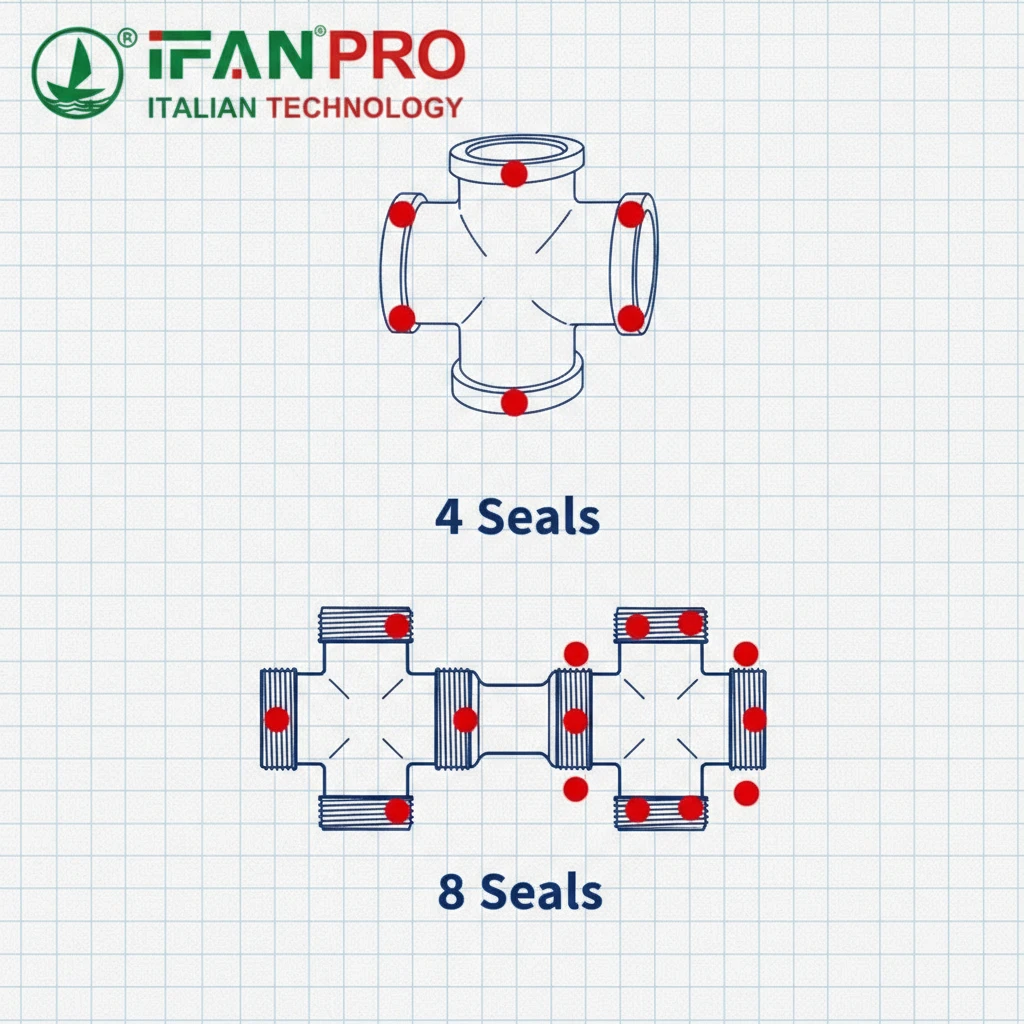

A single cross fitting has 50% fewer primary connections than two tees. One cross creates 4 pipe connections. Two tees, plus the nipple between them, create 8 pipe connections. This means a cross reduces the number of potential leak points by half right away, making the system simpler and more reliable.

Counting the Potential Leak Points

Every time you join two pieces in a piping system, you create a seal. This seal can be a threaded connection, a fused joint, or a gasket. Over time, factors like vibration, thermal expansion, and pressure surges can challenge these seals.

When you use a standard cross fitting, you have one central body. You connect one pipe to each of its four openings. So, you make 4 connections in total.

Now, let’s look at the two-tee assembly. You need:

- Tee #1: 3 connections.

- A short pipe nipple: 2 connections (one to each tee).

- Tee #2: 3 connections.

Adding these up: 3 (Tee 1) + 2 (Nipple) + 3 (Tee 2) = 8 connections.

Why Fewer Connections Matter for Reliability

The math is clear: the two-tee assembly has twice as many connection points. This directly impacts system reliability in three key ways:

First, it increases the risk of installation error. The installer has to make and seal eight separate joints perfectly. If just one thread isn’t sealed properly or one fusion joint is cold, it will leak. With a cross, there are only four critical joints to perfect.

Second, it affects long-term maintenance. More joints mean more points that can be affected by system stress. For example, if the pipe experiences thermal cycling (heating and cooling), each joint expands and contracts slightly differently. With eight joints in close proximity, the chances of one developing a slow leak over time are higher than with a more rigid, single-piece cross.

Third, it involves more components. You must source and manage three separate items: two tees and one nipple. This increases procurement complexity and the chance of using mismatched or sub-standard parts.

Connection Count and Risk Summary

| Fitting Assembly | Total Components | Primary Pipe Connections | Potential Leak Points (Seals) |

|---|---|---|---|

| Single Cross Fitting | 1 | 4 | 4 |

| Two Tees + Nipple | 3 | 8 | 8 |

Conclusion: For system integrity and simplicity, a one-piece cross fitting is superior. It cuts the number of critical seals in half, reducing initial installation risk and long-term maintenance worries. This is especially crucial in systems carrying expensive, hazardous, or high-purity fluids where any leak is unacceptable.

Which Option Provides Better Flow Characteristics and Lower Pressure Drop?

Turbulence and friction slow fluids down. I’ve measured pressure losses in manifolds where poor fitting choice created a bottleneck.

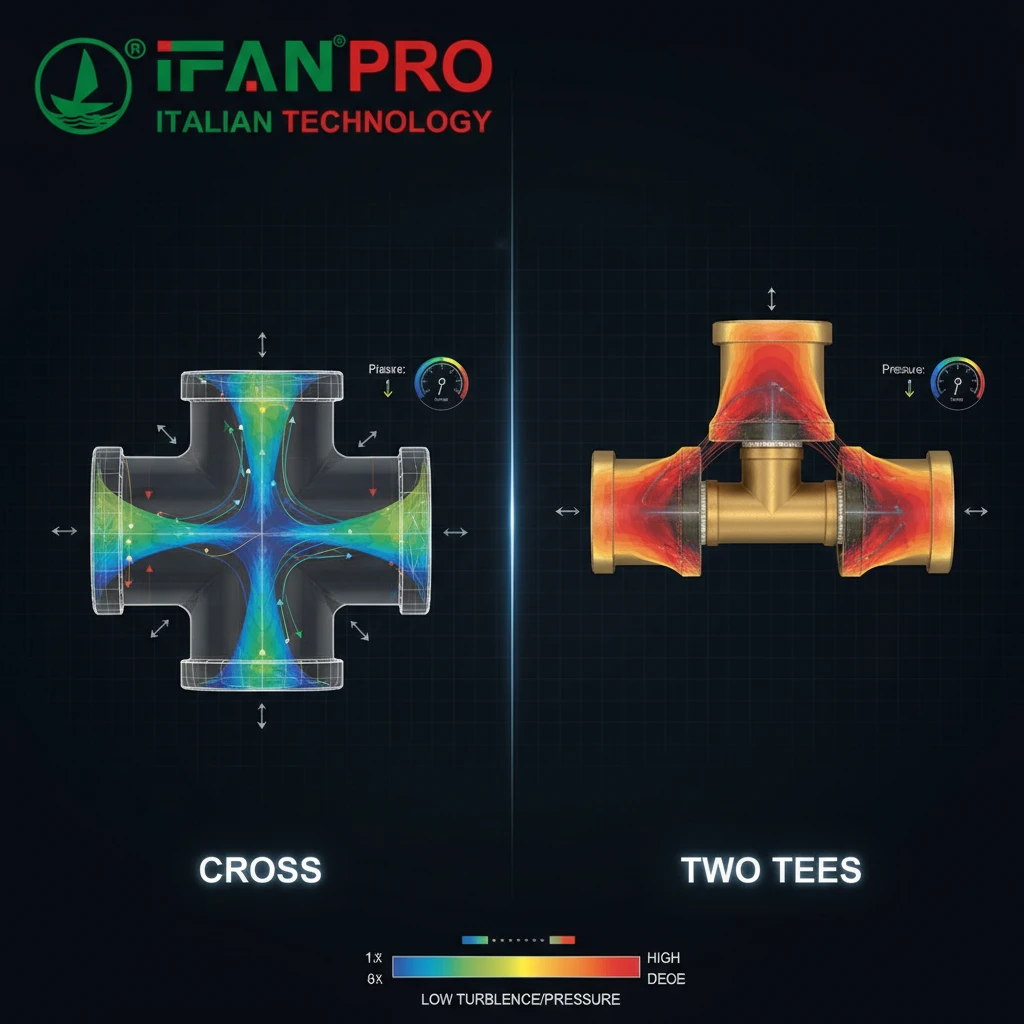

A single cross fitting usually provides better flow and lower pressure drop than two tees. The internal geometry of a cross is designed for multi-directional flow in one cast or molded body, while two tees create a longer, more turbulent path with sharp directional changes that disrupt smooth flow and increase resistance.

Understanding Flow Path and Turbulence

Pressure drop is the loss of fluid pressure as it moves through a system. Fittings are major contributors to this loss because they disrupt the smooth, straight flow of the pipe.

Inside a well-designed cross fitting, the fluid paths intersect in a single, compact chamber. The fluid entering one port and exiting the opposite port experiences a relatively direct, though interrupted, path.

Now, picture the path through two tees. Fluid must:

- Enter the first tee.

- Make a 90-degree turn into the connecting nipple.

- Travel through the short nipple.

- Make another 90-degree turn into the second tee.

- Finally, exit.

This creates a longer, more tortuous path. Each 90-degree turn is a point of high turbulence and friction, which translates directly into pressure loss.

The Impact on System Performance

This pressure drop has real consequences. For a pump pushing fluid through the system, a higher pressure drop means it must work harder to achieve the same flow rate. This leads to higher energy costs. In some cases, it can mean you need a larger, more expensive pump.

The two-tee assembly often has another flow problem: the internal diameter. The connecting nipple’s ID might not perfectly match the internal bore of the tees. Even a small misalignment or a slight recess at the joints can create edges that catch the flow, causing more turbulence and pressure loss. A one-piece cross has a continuous, smoother internal passage.

Comparing Pressure Drop Scenarios

Let’s look at a common scenario: water flowing straight through a 1-inch manifold.

| Scenario | Fitting Configuration | Estimated Relative Pressure Drop | Key Reason |

|---|---|---|---|

| Straight-Through Flow | Single Cross Fitting | Low | Single, compact intersection. |

| Straight-Through Flow | Two Tees + Nipple | Medium to High | Two 90-degree turns and a longer path. |

| Branching Flow | Either Option | Similar | Flow dynamics are complex in both. |

Important Note: For flows that branch off (e.g., from one inlet to two side outlets), the difference might be less dramatic, as both configurations involve splitting the flow. However, the cross’s integrated design often still manages this split more smoothly.

Conclusion: If minimizing pressure drop and maximizing flow efficiency are your goals—common in hydraulic systems, main supply lines, or irrigation systems—the single cross fitting is typically the better engineering choice. It offers a hydraulically superior path.

What Are the Space and Alignment Advantages of a One-Piece Cross Fitting?

Installation space is often tight. Aligning two separate tees perfectly by hand is frustrating and time-consuming.

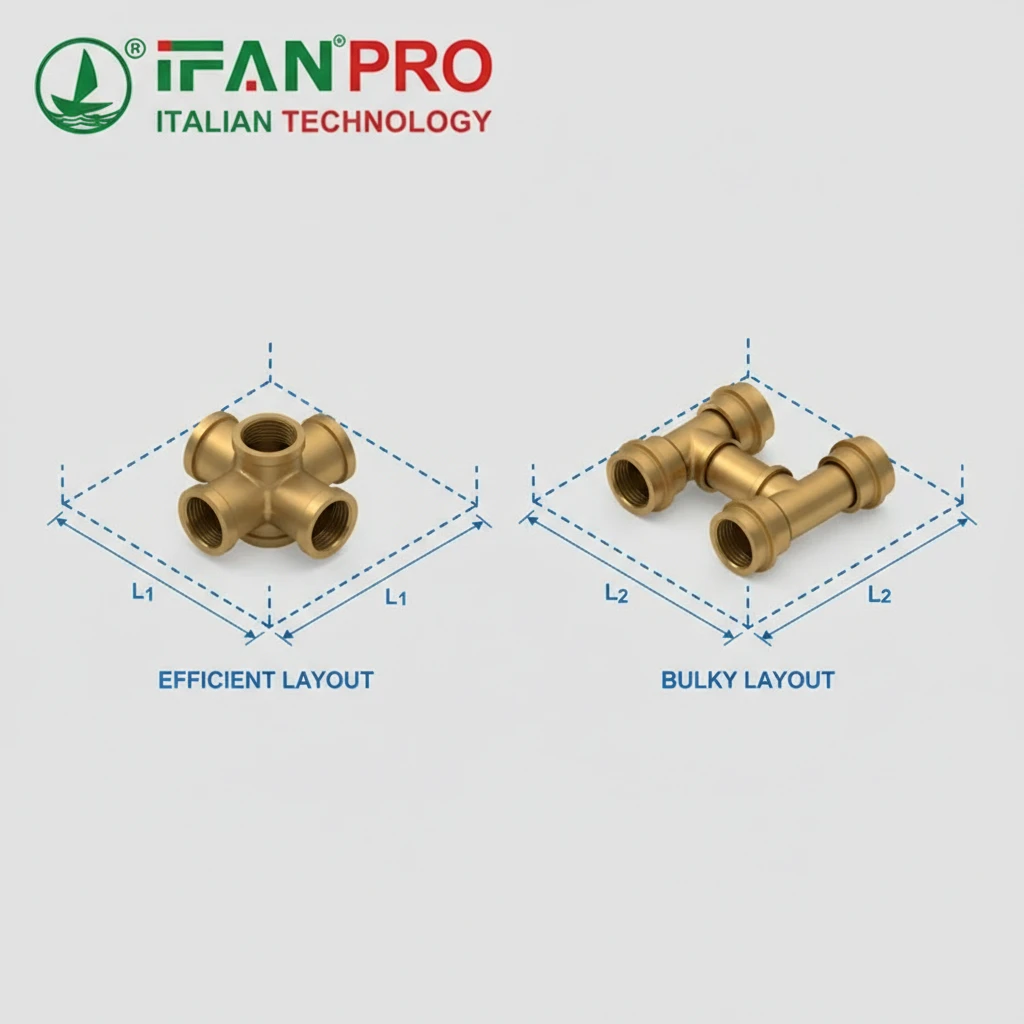

A one-piece cross fitting offers major space and alignment advantages. It is more compact, saving valuable space in dense pipe racks. Most importantly, its ports are factory-perfectly aligned at 90-degree angles, guaranteeing a square and parallel manifold without measuring or forcing pipes, which speeds up installation and prevents stress on the system.

The Critical Advantage of Built-In Alignment

The most significant benefit of a cross fitting is its precision. In a single casting or molding process, all four outlets are fixed at perfect 90-degree angles relative to each other. This is guaranteed.

When you try to build the same configuration with two separate tees and a nipple, you face a alignment challenge. You must:

- Screw or fuse the first tee onto a pipe.

- Measure and cut the nipple to exact length.

- Attach the nipple to the first tee.

- Then, attach the second tee to the other end of the nipple while trying to keep it perfectly parallel to the first tee.

If the nipple is even a fraction of an inch too long or short, or if you overtighten one joint, the second tee will be out of alignment. This forces you to bend the connecting pipes to make them fit, putting unwanted stress on the entire assembly. This stress can lead to early joint failure.

Saving Space in Compact Designs

A cross fitting is inherently more compact. The distance between the two opposite ports (the “legs” of the cross) is determined by the fitting’s own body length.

In a two-tee assembly, that distance is the length of the nipple plus the bodies of the two tees. This always makes the assembly longer. In a crowded mechanical room, control panel, or equipment skid, saving a few inches of linear space can be crucial for accessibility and maintenance.

Installation Speed and Ease

A one-piece cross simplifies the installer’s job dramatically. It becomes a single component to position and secure. This is faster and requires less skill than fabricating a precise two-tee assembly on-site. It reduces the tools and steps needed, cutting labor time and cost.

Practical Installation Comparison

| Consideration | One-Piece Cross Fitting | Two Tees + Nipple Assembly |

|---|---|---|

| Alignment Guarantee | Perfect, factory-set 90° angles. | Must be achieved manually on-site. |

| Overall Length | Shorter, more compact. | Longer, due to nipple + two fitting bodies. |

| Installation Steps | Position once, make 4 connections. | Position and align 3 parts, make 8 connections. |

| Risk of Assembly Stress | Very Low. | High, if pipes must be forced to align. |

Conclusion: For clean, professional, and reliable installations—especially in tight spaces or on prefabricated modules—the one-piece cross is the superior choice. It eliminates alignment headaches, saves space, and reduces installation labor. This advantage is clear in industrial control panels, hydraulic power units, and complex plumbing manifolds.

When Might Using Two Tees Be More Practical Than a Single Cross?

Even the best tool isn’t right for every job. I’ve advised clients to use tees when flexibility or availability is key.

Using two tees is more practical than a single cross in three main cases: when you need to adjust the spacing between branches, when a specific cross size or material is not available, or when you must insert a valve, gauge, or other device between the two branch points. This setup offers valuable flexibility for repairs and modifications.

The Need for Adjustable Spacing

Sometimes, the exact distance between the two branch outlets is critical, and standard cross fittings don’t match that measurement. With two tees, you can simply cut the connecting nipple to any custom length you need. This is common in retrofit projects or when connecting to existing equipment with fixed port locations.

For example, if you need to connect two pieces of equipment that are 14 inches apart, and crosses only come in 10-inch or 18-inch center-to-center distances, two tees with a 14-inch nipple are the only practical solution.

Dealing with Availability and Inventory

Cross fittings, especially in less common sizes, materials (like special alloys), or pressure ratings, might not be readily available. Every plumbing supplier stocks a wide range of tees and nipples. In an urgent repair or a remote project location, you are much more likely to find the parts to make two tees work than to find a specific cross fitting.

This makes the two-tee assembly a valuable fallback option. It simplifies your spare parts inventory, as you can use common tees for multiple purposes instead of stocking specialized crosses for every possible configuration.

The Ability to Add Components In-Line

This is the biggest functional advantage. The space between the two tees—occupied by the nipple—is a perfect place to install other components.

Common components added between tees include:

- A Valve: To isolate one branch independently.

- A Pressure Gauge: To monitor the line.

- A Strainer or Filter: To protect downstream equipment on one branch.

- A Thermal Expansion Tank: In plumbing systems.

- A Check Valve: To prevent backflow.

You cannot insert anything into a standard cross fitting. It is a single, solid block. If you need this kind of functionality, the two-tee design is not just practical; it’s necessary.

Decision Guide: Cross vs. Two Tees

| Situation | Recommended Choice | Primary Reason |

|---|---|---|

| Maximize reliability, minimize leaks | Single Cross | Fewer connections, simpler system. |

| Optimize flow, reduce pressure drop | Single Cross | Smoother internal passage. |

| Tight space, need perfect alignment | Single Cross | Compact, factory-aligned. |

| Need custom spacing between outlets | Two Tees | Nipple length can be customized. |

| Need to install a valve/gauge between branches | Two Tees | Allows for in-line components. |

| Urgent repair, limited parts availability | Two Tees | Tees and nipples are more commonly stocked. |

Conclusion: While the cross fitting wins on performance and reliability, two tees offer crucial flexibility. They are the go-to choice for custom spacing, adding inline components, or when you face supply chain limitations. Always match the fitting choice to the project’s specific needs.

Conclusión

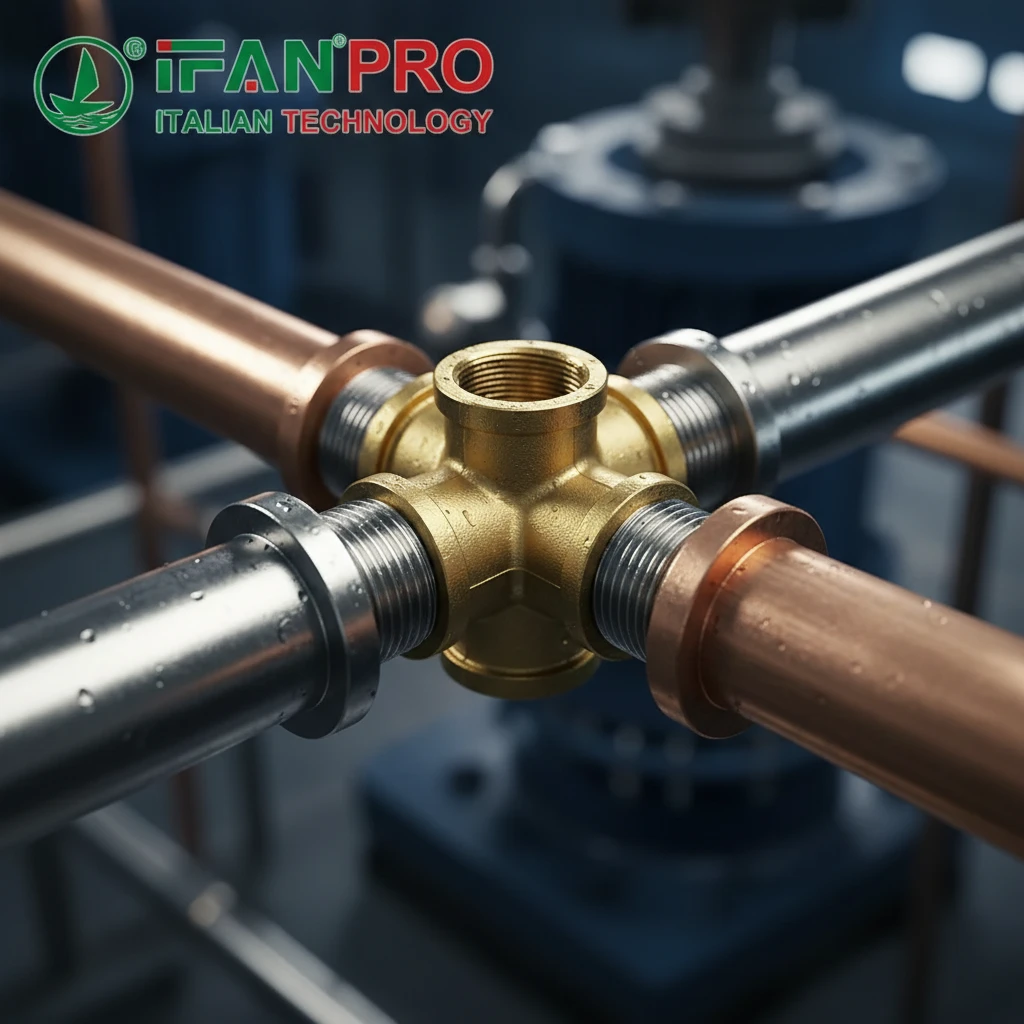

Choose a cross for reliability and efficiency, but use two tees for flexibility. For high-quality, reliable cross fittings and tees, trust IFAN to supply the right components for your system’s needs.

Comentarios recientes