I once saw a project get delayed for a week because of mismatched threads. This simple mistake caused leaks, wasted parts, and frustration for everyone involved.

Brass conversion fittings are designed to bridge different systems, so they commonly support major international thread standards including NPT (American), BSPP (British parallel), and BSPT (British tapered). The specific standards a fitting supports are always marked on its body, and identifying them correctly is the most critical step for a leak-free connection.

Confusion over threads is a common problem in global trade. Let’s clarify these standards so you can choose and use fittings with complete confidence.

Do Brass Adapters Commonly Use NPT, BSPP, or BSPT Threads?

A client from the US was baffled when his NPT fitting wouldn’t seal on equipment from Europe. The problem wasn’t the fitting quality, but the standard.

Yes, brass adapters most commonly use NPT, BSPP, and BSPT threads because these are the dominant standards in global plumbing and hydraulic systems. NPT is prevalent in North America. BSPP and BSPT are the standards throughout Europe, Asia, Australia, and most other regions.

Understanding the Big Three Standards

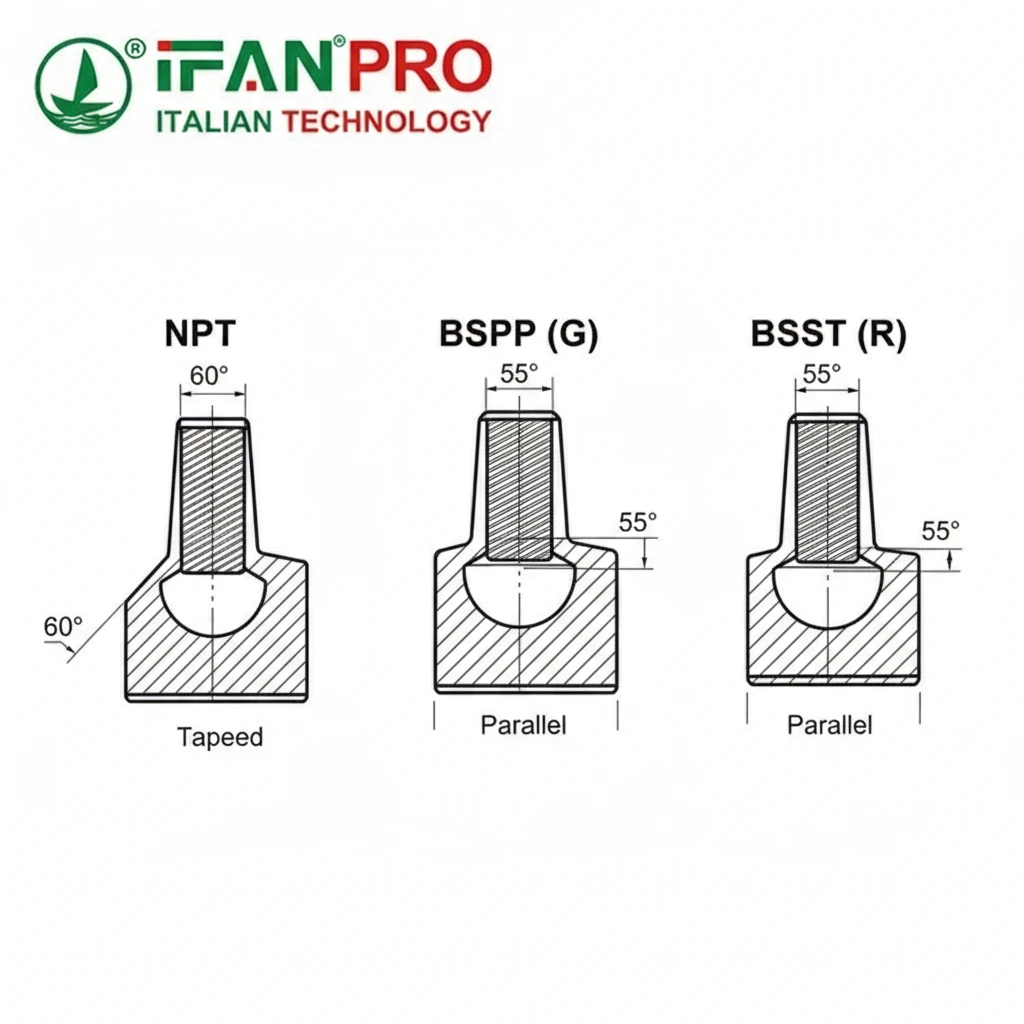

To work with brass adapters, you need to understand the three main families of threads. Each one has a specific design and sealing method.

First, let’s look at NPT (National Pipe Tapered). This is the American standard. The key word is “tapered.” Both the male and female threads are cut on a cone shape. The seal is created by the metal-to-metal wedging of these tapered threads. For a perfect seal, you must use thread sealant tape or paste on NPT threads. People commonly use it in the USA, Canada, and in systems that follow American design.

Next, we have the two British standards. BSPP (British Standard Pipe Parallel) is also known as “G” threads. The threads are straight, not tapered. The seal is not made by the threads themselves. Instead, the seal happens at the tip of the male thread pressing against a washer or an O-ring inside the female fitting. You will see BSPP used often in Europe for many applications.

The other British standard is BSPT (British Standard Pipe Tapered). As the name suggests, these threads are tapered, similar to NPT. However, the thread angle and pitch are different. Like NPT, it often needs a sealant. BSPT is common in some Asian and European countries.

Key Differences at a Glance

This table helps you see the main differences quickly.

| Thread Standard | Region of Use | Thread Shape | Sealing Method | Common Applications |

|---|---|---|---|---|

| NPT | North America | Tapered | Thread Wedging + Sealant | General plumbing, industrial, HVAC |

| BSPP (G) | Europe, Asia, Australia | Parallel | Washer/O-ring at the end | Hydraulics, fuel lines, water systems |

| BSPT (R) | Europe, Asia | Tapered | Thread Wedging + Sealant | Plumbing, gas, some industrial uses |

Why These Three are Everywhere

These three standards are so common because they cover the needs of the biggest manufacturing and consumer markets in the world. A high-quality brass conversion fitting from a global supplier like IFAN will be clearly marked to show which of these standards it uses. This allows one fitting to connect, for example, an American NPT hose to a European BSPP machine port. Understanding this is the first step to avoiding costly mistakes.

How Can You Identify the Thread Standard on a Fitting?

I received a bag of unmarked fittings once, and identifying them turned into a frustrating puzzle. Now, I always teach my clients the simple identification rules.

You can identify the thread standard by checking three things: the markings on the fitting, the thread shape (tapered or parallel), and by using a thread pitch gauge. Reputable manufacturers always stamp the standard (e.g., “NPT”, “G1/2”, “BSPT”) directly on the fitting’s hex flat for easy visual identification.

Step 1: Look for the Markings

The easiest and most reliable method is to look for the manufacturer’s stamp. This should always be your first step.

- NPT Fittings: These will usually be stamped with the size and “NPT.” For example, “1/2 NPT.”

- BSPP Fittings: These are often marked with the letter “G” followed by the size. For example, “G1/2” or simply “1/2 BSPP.”

- BSPT Fittings: These may be marked with “R” or “BSPT,” like “R1/2” or “1/2 BSPT.”

A good supplier makes this information clear. If the fitting has no markings at all, be very careful. It might be from a low-quality source, and its dimensions could be wrong.

Step 2: Inspect the Thread Shape

If the fitting isn’t clearly marked, you can do a visual and physical check. You need to determine if the thread is parallel or tapered.

- For Tapered Threads (NPT/BSPT): Look at the male thread. The diameter at the end of the thread is noticeably smaller than the diameter at the base (where it meets the fitting body). Run your finger along it; you should feel a slight cone shape.

- For Parallel Threads (BSPP): The male thread will have the same diameter from the tip to the base. The sides look straight and parallel.

Step 3: Measure the Thread Pitch

The final check, especially to tell NPT and BSPT apart, is to measure the thread pitch—the distance between threads. You need a tool called a thread pitch gauge.

This tool has many metal blades, each with teeth that match a specific thread pitch. You match the blade to the threads on your fitting. If it fits perfectly, the blade is labeled with the pitch (e.g., “14 TPI” or “1.814mm”).

Identification Guide Table

Here is a simple guide you can follow.

| Action | What to Look For | Indicates |

|---|---|---|

| 1. Read the Stamp | “NPT”, “G”, “BSPT”, “R” | Direct confirmation of standard. |

| 2. Check the Shape | Thread diameter gets smaller from base to end. | Tapered Thread (NPT or BSPT). |

| Thread diameter is consistent from base to end. | Parallel Thread (BSPP). | |

| 3. Use Pitch Gauge | 14 Threads Per Inch (TPI) for a 1/2″ size. | Likely NPT. |

| 14 TPI for a 1/2″ size. | Likely BSPT (needs sealing method/angle check). | |

| Pitch of ~1.814mm for a 1/2″ size. | Likely BSPP (G). |

When you source fittings from a professional supplier like IFAN, step one is usually all you need. The fittings are clearly and permanently marked, saving you time and preventing errors during installation.

What Should You Do If Thread Standards Do Not Match?

A frantic call from a client about a mismatched thread used to mean project stoppage. Now, we see it as a routine problem with clear solutions.

If thread standards do not match, you must use a correct brass conversion fitting designed to bridge the two specific standards. Never force mismatched threads together. The solutions are to use a dedicated adapter, a swivel fitting with seals, or in some cases, re-tap the thread to the correct standard using a proper tap and die set.

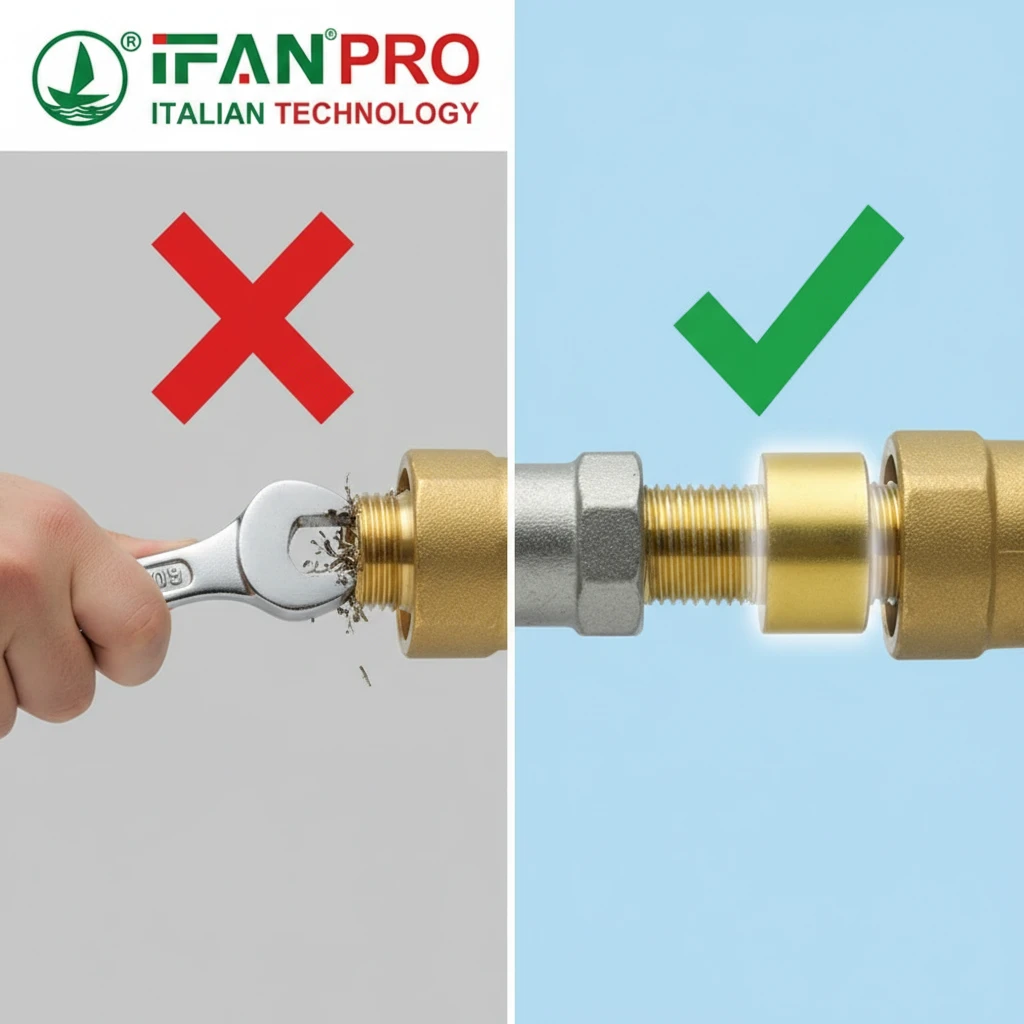

Why Forcing It is a Disaster

First, understand what not to do. Never use a wrench to force a 1/2″ NPT male thread into a 1/2″ BSPP female port. They are not the same, even if the size number looks similar.

- It will not seal: The threads will not engage properly, causing a guaranteed leak.

- It will damage the threads: Forcing it can “cross-thread” or strip the softer brass or aluminum threads, ruining both components. This turns a small problem into an expensive repair.

- It creates a safety risk: In pressurized systems for air, water, or fuel, a failed connection can be dangerous.

The Correct Solution: Use an Adapter

The proper fix is to use a fitting whose sole job is to connect different standards. This is exactly what brass conversion adapters are for.

For example, if you have an NPT hose and a BSPP machine port, you need an “NPT Male to BSPP Female” adapter. The fitting will have NPT threads on one end and BSPP threads on the other. It acts as a perfect bridge. High-quality adapters from IFAN are machined to exact specifications for both standards, ensuring a perfect, leak-free connection on both sides.

Alternative Solution: Swivel Fittings

Another excellent option for hose connections is a swivel fitting with a built-in sealing face. In these fittings, the thread is only used to hold the fitting in place. The actual seal is made by a flat face with an O-ring or a washer. This means you can connect, for instance, a BSPP-threaded swivel to an NPT port, and as long as it’s tightened, the O-ring will create the seal independently of the thread type. This provides more flexibility.

Last Resort: Re-Tapping the Thread

Sometimes, you may need to change the thread on a component itself. This should be done carefully.

- You need the correct tap (for female threads) or die (for male threads) for the new standard you want.

- You must ensure there is enough material to cut the new threads without weakening the part.

- This process requires skill. It is often better to replace the component or use an adapter.

Solution Comparison Table

| Problem Scenario | Best Solution | How It Works | Note |

|---|---|---|---|

| NPT Hose to BSPP Port | Use an NPT Male to BSPP Female adapter. | The adapter screws into the BSPP port, and the hose screws onto the NPT end. | Simple, reliable, and cost-effective. |

| Connecting Two Hoses with Different Threads | Use two adapters, or use swivel fittings with universal seals. | Swivel fittings seal via face O-rings, making the thread type less critical for sealing. | Excellent for reducing stress on hoses. |

| Wrong Thread on a Machine Part | Re-tap the part (if feasible). | Use a tap to cut new, correct threads into the existing hole. | Requires tools and skill. Risk of damaging part. |

The key takeaway is to plan for thread compatibility. Always specify the thread standard you need when ordering. A good supplier’s catalog will have hundreds of adapter combinations for precisely this reason.

Why Is Thread Compatibility Critical for International Projects?

Managing a project that sources from China, assembles in Poland, and installs in the UAE taught me that thread standards are a universal language you must speak fluently.

Thread compatibility is critical for international projects because equipment and components are sourced from different countries, each with its preferred standard. Mismatches cause leaks, project delays, safety failures, and increased costs for replacement parts and labor, jeopardizing the entire project’s timeline and budget.

The Reality of Global Sourcing

Modern projects rarely use parts from just one country. You might buy a pump from Germany (BSPP), valves from the USA (NPT), and pipes from China (which could be BSPP or BSPT). If you don’t specify and control the thread standards, you will receive a truckload of incompatible parts. The assembly phase then becomes a nightmare of finding adapters, waiting for shipping, and making emergency purchases at high cost.

Consequences of Getting It Wrong

Let’s break down what actually happens when threads are incompatible on a large project.

- Major Delays: This is the biggest impact. Work stops. The installation team cannot proceed. You must now source the correct adapter or part, which can take days or even weeks if it’s a special item. This delay can have a ripple effect, holding up other trades and pushing back the project completion date.

- Cost Overruns: Emergency air freight for a small fitting, overtime labor for rework, and the cost of the wrong parts that are now scrap—all these eat into your budget.

- Safety and Reliability Risks: A temporary “fix” or forced connection in a pressurized system is a liability. It could fail after the installation is complete, leading to water damage, equipment failure, or even a dangerous burst.

- Reputational Damage: For a project manager or a business, consistently having these basic compatibility issues makes you look unprofessional and unreliable in the eyes of your clients and partners.

How to Ensure Compatibility: A Practical Guide

You can avoid these problems with careful planning. Here is what we advise our clients at IFAN to do.

- Establish a Project Standard: At the very beginning, decide on the primary thread standard for the entire project. For example, “All hydraulic connections on this project will use BSPP (G) threads.” Document this and share it with every supplier.

- Specify Clearly in Every Order: Never just order a “1/2 inch brass fitting.” Always specify “1/2 inch NPT male to 3/4 inch BSPP female brass adapter.” Put the full description in writing on your purchase order.

- Audit Your Supplier: Work with suppliers who understand global standards. They should ask you about thread types if you forget to specify. Their product pages and catalogs should list the standards clearly.

- Use a Qualified Sourcing Partner: For complex international procurement, a partner like IFAN can manage this for you. We confirm thread standards with every factory, perform quality checks to verify markings and dimensions, and ensure all the components we source for you will work together seamlessly.

Managing thread compatibility is not just a technical detail; it’s a fundamental part of project management for any international supply chain. Getting it right from the start is the mark of a professional.

Conclusión

Understanding and specifying thread standards prevents costly errors and ensures reliable, leak-free systems. For guaranteed compatible brass conversion fittings in NPT, BSPP, and BSPT, source your project components from IFAN.

Comentarios recientes