In my years of managing plumbing supply, I’ve seen countless customers try to save a few dollars by reusing old fittings, sometimes with messy results. The question of reusability is more nuanced than a simple yes or no.

Brass conversion fittings can be reusable, but it depends entirely on the connection type, the fitting’s condition, and how it was initially installed. While threaded and some compression fittings are designed for disassembly, soldered or crimped joints are typically permanent and reusing those fittings is not recommended due to high risk of failure.

Understanding the specifics is crucial to making safe and cost-effective decisions for your plumbing projects.

Can You Disassemble and Reuse a Compression-Style Brass Fitting?

A client once called me in a panic after a reused compression fitting sprayed water all over a newly renovated wall. This common mistake highlights the need for clear guidelines.

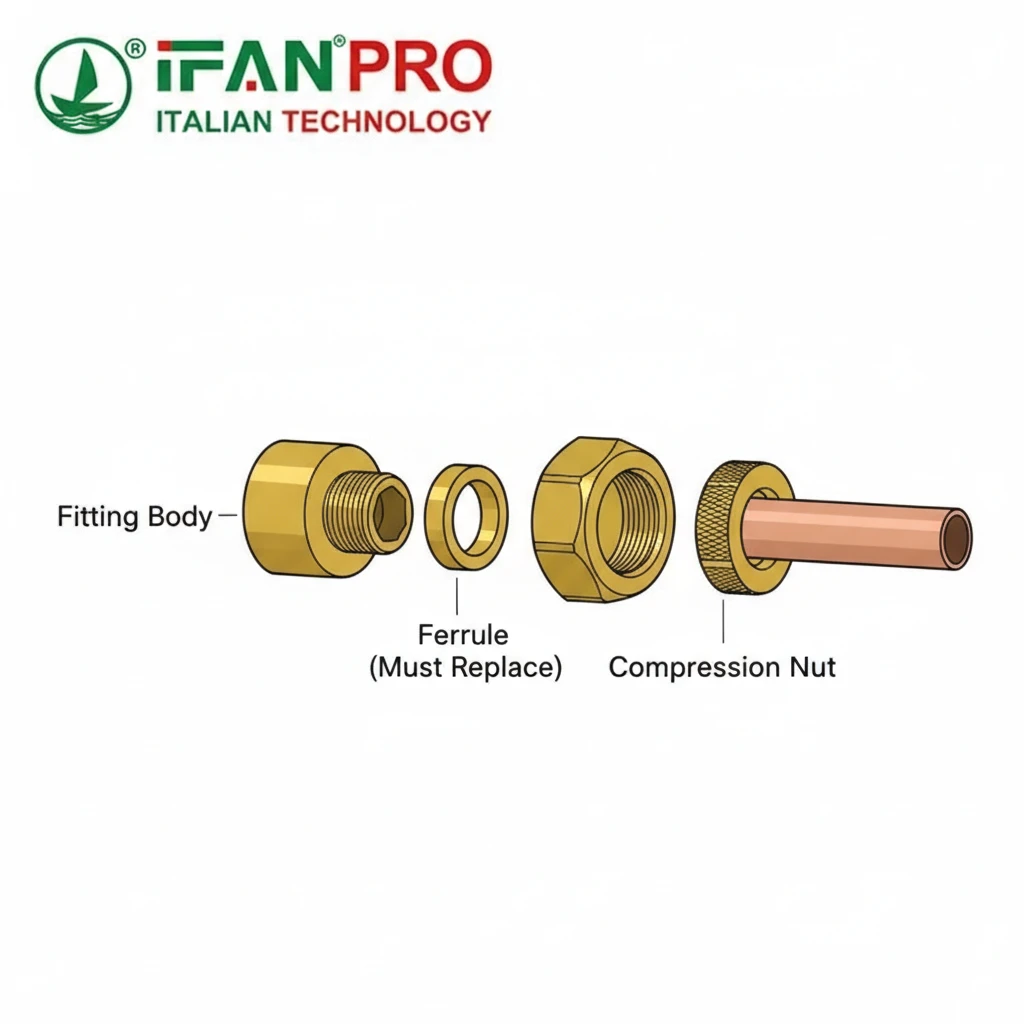

You can often disassemble and reuse a compression-style brass fitting body itself, but you must always replace the soft ferrule or compression ring. This crucial component deforms permanently during the first installation to create a seal, and reusing it will almost certainly lead to leaks.

The Mechanics of a Compression Joint

To understand reusability, let’s look at how a compression fitting works. The fitting has three main parts: the brass body, a compression nut, and a soft ferrule (usually made of brass or copper). When you tighten the nut, it squeezes the ferrule against the pipe and into the fitting body. This pressure causes the ferrule to deform, or compress, tightly around the pipe, creating a watertight seal.

The key point is that this deformation is permanent. The metal of the ferrule flows and molds itself into the microscopic imperfections of the pipe and fitting. Once you loosen the nut and remove the pipe, that ferrule retains its crushed shape.

Why Reusing the Ferrule Fails

If you try to reuse the old ferrule on the same pipe or a new one, it cannot form a new, proper seal. Its shape is already set. You might get it tight enough to hold for a while, but vibration, temperature changes, or water pressure will eventually cause it to leak. It’s like trying to reuse a crushed soda can as a new one—it’s lost its original structural integrity.

Step-by-Step Guide for Safe Reuse

Here is a practical process for attempting to reuse a compression fitting body:

- Disassemble Carefully: Use two wrenches—one to hold the fitting body and one to loosen the nut—to avoid twisting and damaging the pipes.

- Discard the Old Ferrule: Immediately throw away the used compression ring. Consider it a disposable, one-time-use part.

- Inspect the Fitting Body: Clean the fitting body thoroughly. Check the internal seating area where the ferrule makes contact for any deep scratches, corrosion, or mineral deposits. Damage here can prevent a new ferrule from sealing correctly.

- Inspect the Pipe: The section of pipe that was under the ferrule may have a groove or indent. For the best seal, you should cut the pipe back to a fresh, smooth section.

- Reassemble with New Parts: Always use a brand-new ferrule that matches the fitting and pipe size. Follow proper tightening procedures—usually hand-tight plus a specified number of turns with a wrench—to avoid under- or over-tightening.

Decision Table: To Reuse or Not?

| Condition of the Fitting Body | Recommendation | Reason |

|---|---|---|

| Clean, no scratches or corrosion | Can be reused | A new ferrule can seat properly against a smooth surface. |

| Light surface tarnish | Can be reused after cleaning | Tarnish can be cleaned off with a brass brush without damaging the metal. |

| Deep scratches or gouges | Do not reuse | Scratches provide a path for water to leak, even with a new ferrule. |

| Visible corrosion (pitting) | Do not reuse | Corrosion weakens the brass and creates uneven sealing surfaces. |

| Cracked or warped body | Do not reuse | Structural integrity is compromised, posing a risk of sudden failure. |

In short, the brass body of a compression fitting is potentially reusable, but it is only as reliable as the new ferrule you pair it with and the condition of the body itself. When in doubt, replacing the entire fitting is the safest and most reliable choice.

What Types of Brass Fittings Are Designed for Multiple Uses?

Not all fittings are created equal. Sourcing for clients has taught me that choosing the right type of fitting from the start makes future modifications infinitely easier.

Fittings with threaded connections (like NPT threads) are explicitly designed for multiple uses. Other types, such as push-to-connect fittings with reusable collets and certain flare fittings, are also engineered for disassembly and reassembly, making them ideal for systems that require future adjustments or maintenance.

The Champion of Reusability: Threaded Fittings

Threaded brass fittings are the most common and reliable type meant for reuse. The National Pipe Taper (NPT) thread standard is designed so that tightening the threads pulls the fitting tight and creates a seal. While the threads themselves can be reused many times, the seal is typically created by thread sealant tape or pipe dope.

- How They Work: The taper of the threads means they wedge tighter as you screw them together. The sealant fills any microscopic gaps between the threads.

- Reusability: You can unscrew and rescrew threaded connections many times. However, you must always clean off the old sealant and apply fresh tape or compound every time you reassemble. Reusing old, hardened sealant is a guaranteed path to leaks.

- Common Examples: Couplings, elbows, tees, adapters, and unions with female or male NPT threads.

Other Designed-for-Reuse Fittings

- Unions: This specific fitting is the ultimate tool for reusable connections. A union is a three-piece fitting that uses a threaded nut to join two separate pieces. It allows you to disconnect a line without having to rotate the pipes. The mating surfaces may use a gasket or mating faces that seal; the gasket may need replacement upon reassembly.

- Push-to-Connect Fittings: Many modern push-fit styles are designed to be reusable. They have a release collar that, when pressed, allows you to remove the pipe. You can then reinsert the same pipe or a new one. Always consult the manufacturer’s instructions, as some may recommend replacing internal O-rings or grippers after multiple cycles.

- Flare Fittings: Common in gas lines and high-pressure applications, flare fittings use a cone-shaped connection. The pipe end is flared out, and a nut tightens against it onto the fitting body. These can often be reused if the flared end of the pipe is not cracked or deformed. It’s good practice to inspect the flare and use new ferrules if specified.

Fittings Not Designed for Reuse

For contrast, it’s critical to know which fittings are generally one-time-use:

- Soldered/Sweat Fittings: The solder bonds metallurgically. Removing it destroys the seal and leaves residual solder, making a proper new seal nearly impossible.

- Crimp Fittings (PEX): The metal crimp ring is permanently deformed. It must be cut off to disconnect, and the fitting cannot be used again.

- Glued Fittings (for PVC/CPVC): The solvent cement chemically welds the plastic together. It is a permanent bond.

Comparison of Reusable Fitting Types

| Fitting Type | Primary Seal Method | Reusability Factor | Key Consideration for Reuse |

|---|---|---|---|

| Threaded (NPT) | Thread sealant (tape/dope) | High | Must clean threads and apply fresh sealant every time. |

| Union | Gasket or mating faces | Very High | May require gasket replacement; threads are easy to engage. |

| Push-to-Connect | Internal O-ring | Medium-High | Check manufacturer specs; O-rings may wear out. |

| Flare | Metal-to-metal cone | Medium | Requires undamaged flared pipe end; over-tightening can ruin threads. |

| Compression | Deformed ferrule | Low | Only the body may be reusable; ferrule must be replaced. |

Choosing a fitting type designed for multiple uses from the outset saves time, money, and frustration during any future system modifications. For maximum flexibility in applications where changes are anticipated, specify threaded connections or unions.

How Do You Inspect a Used Fitting Before Reinstalling It?

A visual inspection takes two minutes but can prevent a catastrophic failure two months later. This simple step is the difference between a smart save and a costly mistake.

To inspect a used fitting before reinstalling it, you must thoroughly clean it and then check for critical flaws: inspect threads for stripping or cross-threading, examine sealing surfaces for deep scratches or pitting, look for hairline cracks, and ensure there is no internal corrosion or mineral blockages that could restrict flow.

Step 1: Complete Cleaning

You cannot inspect a dirty fitting. Start by removing all old sealant, tape, pipe dope, and any mineral deposits or corrosion.

- For Threads: Use a stiff nylon brush or a dedicated thread cleaning brush. For stubborn debris, a small wire brush can be used carefully to avoid damaging the metal.

- For Interior/Sealing Surfaces: Use a clean cloth and a suitable cleaner (like a mild vinegar solution for scale, followed by water and drying). A toothpick or dental pick can help clear residue from small ports.

Step 2: Detailed Visual and Tactile Inspection

Once clean, examine the fitting systematically under good light, ideally with a magnifying glass for small fittings.

Critical Inspection Zones

1. Threads (for threaded fittings):

- Run your finger over the threads. They should feel sharp and defined, not rounded, flattened, or “stripped.”

- Look for cross-threading damage, which appears as threads that are misaligned or gouged at an angle.

- Check for cracks at the base of the threads, where the fitting is thinnest.

2. Sealing Surfaces:

- This is the smooth area inside a compression fitting or the face of a union. It must be perfectly smooth.

- Use a bright light. Look for scratches, gouges, or pitting (small holes from corrosion). Even a small scratch can channel water past a new ferrule or gasket.

- Feel the surface. It should be smooth to the touch.

3. The Fitting Body:

- Look for hairline cracks, especially in corners, near threads, or in areas that might have been over-tightened.

- Check for warping or distortion. Compare its shape to a new fitting of the same type.

4. Internal Condition:

- Hold it up to the light and look through it. Ensure internal passages are clear of debris or heavy corrosion that reduces the inner diameter (ID).

- Tap it gently on a hard surface. Listen for loose debris inside, which could break free and damage valves or fixtures downstream.

Step 3: Decision-Making Based on Findings

Your inspection should lead to a clear go/no-go decision. The following table outlines common defects and their implications:

| Defect Found | Recommended Action | Risk of Proceeding |

|---|---|---|

| Light tarnish or old sealant | Clean thoroughly and reuse. | None. |

| Minor, shallow surface scratch on sealing face | Do not reuse for pressure applications. May be okay for very low-pressure drain lines, but replacement is safer. | Moderate to High risk of seepage or leak. |

| Deep scratch, gouge, or pitting on sealing surface | Do not reuse. Discard fitting. | Very High risk of immediate or eventual leak. |

| Damaged or stripped threads | Do not reuse. Discard fitting. | Inability to achieve proper tightness; certain leak. |

| Hairline crack | Do not reuse. Discard fitting immediately. | Catastrophic risk of sudden burst flooding. |

| Internal corrosion reducing ID by >15% | Do not reuse. Discard fitting. | Significant flow restriction, increased pressure drop. |

A rigorous inspection is non-negotiable. The small cost of a new brass fitting is insignificant compared to the water damage, wasted time, and potential mold remediation caused by a single fitting failure. When sourcing reliable, high-integrity brass fittings that withstand inspection, IFAN‘s products are manufactured to precise tolerances to ensure performance and longevity.

What Are the Limitations on Reusing Soldered Brass Fittings?

The permanence of soldered joints is both their strength and their primary limitation for reuse. I advise clients to consider soldered systems as final.

The primary limitation on reusing soldered brass fittings is that the soldering process permanently alloys the fitting to the pipe. Attempting to desolder and reuse the fitting is highly impractical; it often damages the fitting, leaves contaminated solder surfaces, and almost never results in a reliable, leak-free seal upon reassembly.

The Science of a Soldered Joint

To understand why reuse is so problematic, we need to see what happens during soldering. A soldered (“sweat”) joint uses capillary action to draw molten solder into the tiny gap between the pipe and the fitting’s inner cup. The solder is not just glue; it forms a metallic bond with both the copper pipe and the brass fitting.

When you heat the fitting and pipe, you melt the solder, which flows and then solidifies into a new, continuous metal structure that includes both the pipe and fitting. They become, in effect, one single piece of metal at that joint.

Why Attempts to Reuse Fail

Attempting to take this joint apart is a destructive process with several negative outcomes:

- Heat Damage: Applying enough heat to melt the existing solder (a process called “sweating” or “desoldering”) often means applying extreme, localized heat for a prolonged period. This can overheat the brass fitting, causing it to lose its temper (anneal), become softer, and more prone to future failure under stress. It can also burn off the protective plating or cause unsightly and corrosive oxidation.

- Residual Solder: It is nearly impossible to remove all the old solder. The interior “cup” of the fitting will have a thin, uneven layer of hardened solder remaining. This contaminated surface prevents a new, clean solder joint from forming correctly. Fresh solder will not flow evenly or bond properly to the old, contaminated solder, leading to a weak, porous, and leak-prone joint.

- Pipe Damage: The process usually ruins the end of the pipe as well. To remove it from the fitting, you often have to cut it or damage it so that it is no longer the correct length or has a deformed end, making it unusable.

- Integrity Loss: Even if you manage to clean it out seemingly well, the structural integrity of the fitting is compromised. The repeated heating cycles and physical stress of removal make it unreliable for holding pressure.

Practical Scenarios and Advice

- Modifying a Soldered System: If you need to change a soldered plumbing line, the correct method is to cut out the section containing the old fitting. You then use new couplings and a fresh section of pipe to rebuild the line. The old fitting is discarded.

- Salvaging from Old Plumbing: Some may try to salvage fittings from a demolition. This is generally a false economy. You have no history of the fitting—how many times was it heated? Was it exposed to corrosive chemicals? The risk of a hidden flaw is high.

- The Only Exception: In rare cases, a skilled technician with a professional-grade soldering torch and solder-sucking tools might salvage a very large, expensive specialty fitting. However, the labor cost and risk involved almost always exceed the cost of a new fitting. For standard elbows, tees, and couplings, it is never worth the attempt.

Comparison: Reusability of Connection Methods

| Método de conexión | Ease of Disassembly | Potential for Fitting Reuse | Outcome of Attempted Reuse |

|---|---|---|---|

| Roscado | Easy | Excellent | Reliable with fresh sealant. |

| Compression | Moderate | Fair (Body Only) | Reliable only with new ferrule and if body is undamaged. |

| Push-to-Connect | Easy | Good | Reliable per manufacturer’s cycle limits, may need O-ring. |

| Soldered | Very Difficult/Destructive | Very Poor | Unreliable, weak joint; fitting is often damaged. |

| Crimped (PEX) | Impossible (must cut) | None | Fitting is destroyed during removal. |

The clear advice is to consider soldered brass fittings as permanent, one-time-use components. For systems where future modification is a possibility, design using threaded connections, unions, or other serviceable fitting types from the start.

Conclusión

Reusing brass fittings requires knowing the joint type, inspecting meticulously, and understanding the risks. For reliable, high-quality brass fittings you can trust for new installations or select reuse, explore the durable range from IFAN.

Comentarios recientes