I once saw a project fail because a cheap adapter leaked, flooding a utility room. This experience taught me that the right fitting is not just a part; it’s the critical seal between two different worlds of plumbing.

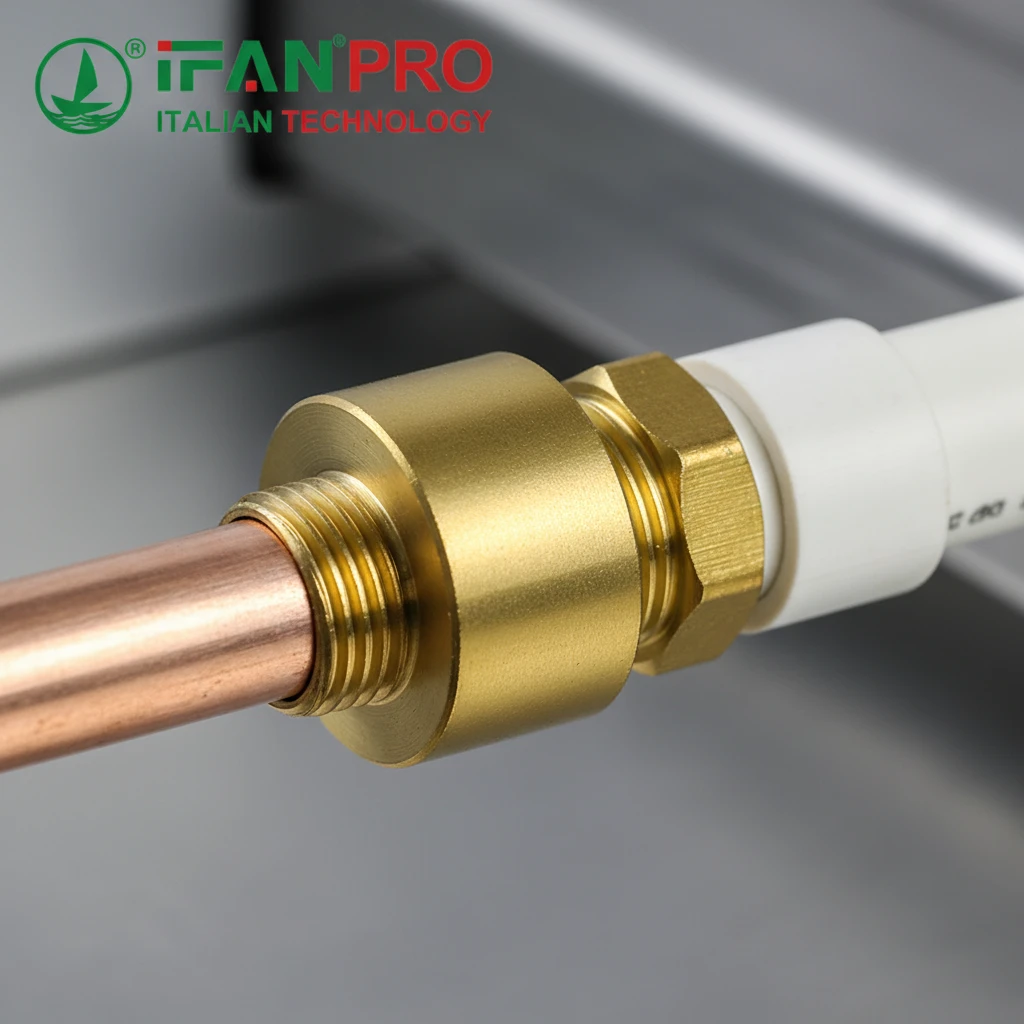

Yes, a high-quality brass fitting can ensure a leak-proof seal, but its success depends on three key elements: its dual-sealing design, correct installation, and material compatibility. It must use different mechanisms to seal against the hard, smooth surface of metal and the softer, flexible surface of plastic simultaneously, forming a reliable bridge between the two pipe systems.

If any of these elements is weak, the connection will fail. Let’s break down exactly how a good brass fitting works to create a lasting, leak-proof connection.

How Does the Fitting Seal Against Both Rigid Metal and Flexible Plastic?

Connecting different materials is a common challenge. I’ve found that the best fittings are designed to handle the unique properties of each material.

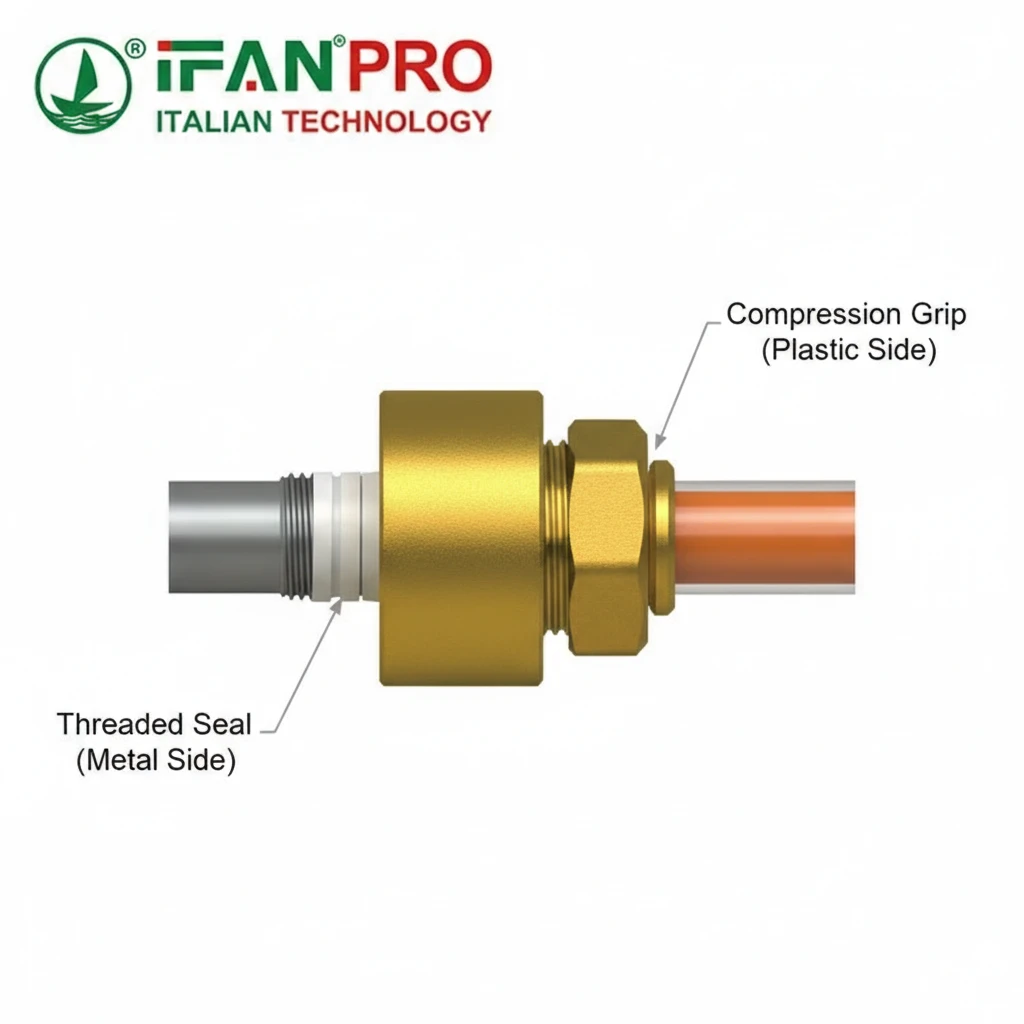

The fitting seals against both materials by using a dedicated mechanism optimized for each pipe type. On the metal side, it typically uses a compressed seal against a smooth, machined surface. On the plastic side, it uses a gripping and compressing seal that accommodates slight flexibility without over-stressing the pipe.

The Core Challenge of a Hybrid Connection

A brass adapter’s main job is to be a universal translator between two different pipe “languages.” Metal pipes (like copper or steel) are rigid, dimensionally stable, and have very smooth threaded ends. Plastic pipes (like PP-R or PEX) are slightly flexible, can expand and contract with temperature, and have a softer surface.

A one-size-fits-all sealing method does not work here. Because of this, a well-made brass fitting has two distinct “zones” for sealing.

Sealing to the Rigid Metal Pipe

On the metal pipe side, the connection is usually made with threads. The seal here must be airtight and watertight despite the spiral path created by the threads. This is achieved not by the threads themselves, but by what happens between them.

- Thread Sealant: Often, a pipe thread sealant tape (Teflon tape) or a liquid thread compound is applied to the male threads of the metal pipe or the fitting. This paste or tape fills the microscopic gaps and valleys between the threaded spirals, creating a solid barrier.

- Compression against a Seat: In many designs, as you tighten the fitting, the end of the metal pipe is driven tightly against a smooth, flat seat inside the brass fitting. This metal-to-metal contact, aided by the sealant in the threads, creates the primary seal.

Sealing to the Flexible Plastic Pipe

The plastic side requires a gentler but secure method. Overtightening can crack or deform plastic, while under-tightening will cause leaks.

- Compression Fittings: A very common method. The plastic pipe slides into the fitting, and a separate compression nut is tightened. This action pushes a soft, compressible ring (an olive or ferrule) around the plastic pipe. The ring deforms evenly, creating 360-degree pressure that seals against both the pipe’s outer wall and the fitting’s inner wall.

- Grip and Seal: The design ensures the force holds the pipe in place and creates the seal simultaneously. The soft ferrule material (often brass or copper) is harder than the plastic but soft enough to conform perfectly to its surface.

How the Two Systems Work Together

The table below summarizes how one fitting manages two different jobs:

| Pipe Material (Side) | Key Property | Fitting’s Sealing Response | Mechanism |

|---|---|---|---|

| Metal (e.g., Copper) | Rigid, Smooth, Threaded | Fills Gaps, Creates Metal-on-Metal Contact | Thread Sealant + Compression against a machined seat. |

| Plastic (e.g., PP-R) | Slightly Flexible, Softer Surface | Even, Surrounding Compression without Damage | Compression nut squeezes a soft ferrule onto the pipe. |

In short, the brass fitting acts as a smart connector. It provides a hard, threaded interface for the metal and a calibrated, compressive interface for the plastic, managing the forces appropriately for each.

What Sealing Mechanisms Are Used at Each End of the Adapter?

Understanding the specific parts is key to choosing the right fitting. Let’s look inside a typical brass adapter.

At the metal end, the primary sealing mechanisms are tapered threads combined with thread sealant (like Teflon tape or dope) and often a compression seat. At the plastic end, the mechanism is almost always a compression assembly, consisting of a compression nut, a compression ring (ferrule), and a shaped receiving body in the fitting.

A Detailed Look at the Metal-Threaded End

The end that connects to the iron, steel, or copper pipe is mechanically straightforward but precision-dependent.

Tapered Threads (NPT): Most fittings use National Pipe Tapered (NPT) threads. These threads are slightly conical, getting wider at the base. As you screw the pipe into the fitting, the threads wedge tighter and tighter. This taper is the first step in creating a seal.

The Role of Sealants: The threads alone are not enough. The spiral path is a potential leak channel. This is where sealants come in:

- Teflon Tape: Wrapped clockwise around the male threads. It lubricates for easier tightening and fills thread gaps.

- Pipe Dope (Thread Compound): A paste applied to the threads. It often contains particles that help fill gaps and compounds that harden slightly to seal.

The Compression Seat: In many quality fittings, the final turn of the thread drives the perfectly cut end of the metal pipe against a flat, machined surface inside the brass fitting. This creates a secondary, very effective metal-to-metal seal.

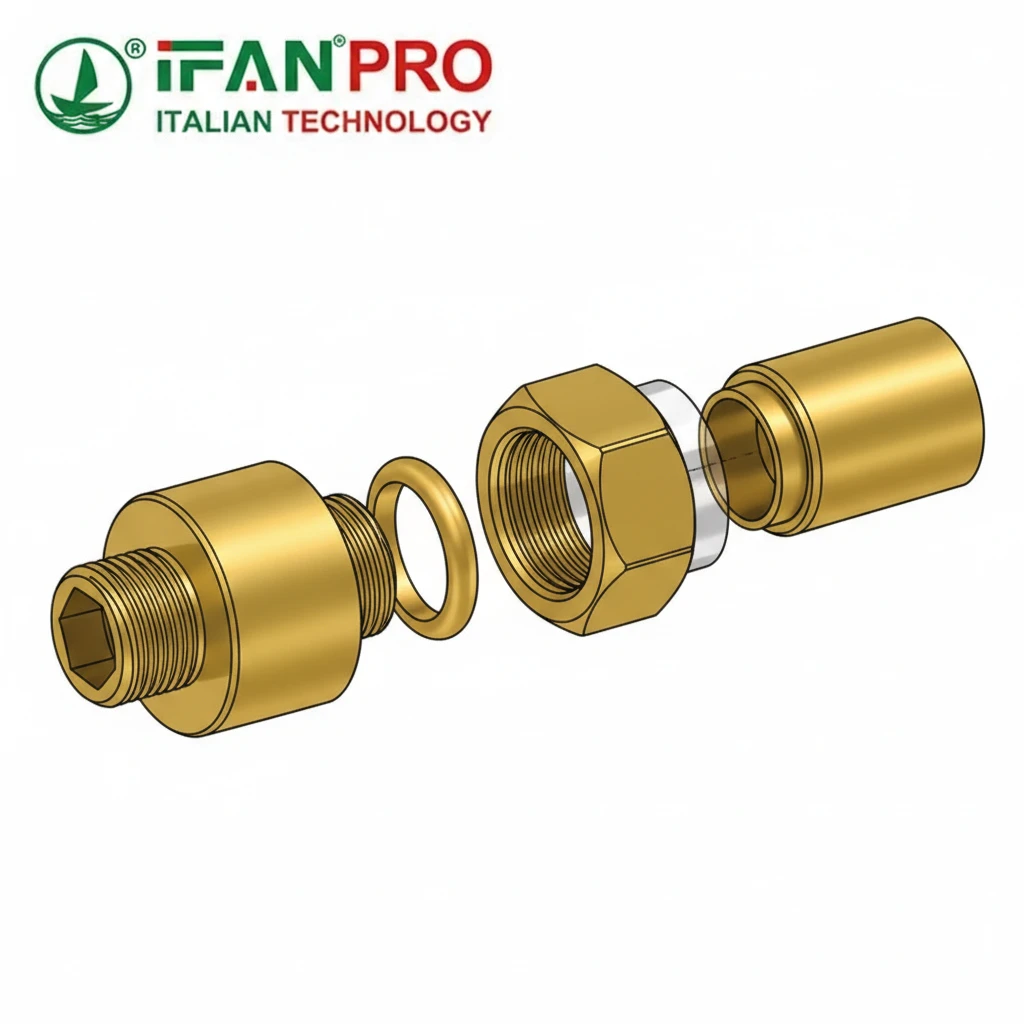

A Detailed Look at the Plastic Compression End

This side is an assembly of parts working together. Each part has a specific role.

- The Fitting Body: This is the main part of the brass adapter. It has a smooth, deep socket for the plastic pipe to insert into. At the base of this socket, there is often a small ridge or stop to ensure the pipe is inserted to the correct depth.

- The Compression Ring (Ferrule or Olive): This is a small, critical ring, usually made of soft copper or brass. It slides onto the plastic pipe before assembly. When compressed, it deforms.

- The Compression Nut: This nut threads onto the body of the fitting. As you tighten it, it pushes the compression ring forward into a tapered section inside the fitting body.

The Sealing Action Sequence

Here is how these parts work together during installation:

- Step 1: The plastic pipe is cut square and deburred. The compression nut and then the compression ring are slid onto the pipe.

- Step 2: The pipe is pushed fully into the fitting body until it hits the internal stop.

- Step 3: The compression nut is hand-tightened, then tightened with a wrench. The nut forces the compression ring into the tapered seat in the fitting body.

- Step 4: The ring is squeezed. It deforms inward, gripping the plastic pipe tightly. It also deforms outward, sealing against the tapered wall of the fitting body. The resulting seal is on the outside of the plastic pipe, which is much stronger than trying to seal on the inside.

This design is reliable because it creates uniform pressure and does not require heating or special tools, making it ideal for field repairs and connections.

Why is a Proper Installation Crucial for Achieving a Leak-Proof Seal?

You can have the best fitting in the world, but install it wrong and it will leak. I’ve fixed many leaks that were purely due to installation errors.

Proper installation is crucial because it activates the fitting’s designed sealing mechanisms correctly. Mistakes like under-tightening, over-tightening, incorrect sealant use, or poor pipe preparation prevent these mechanisms from working, leaving gaps for water to escape. A perfect seal is a result of both good design and precise execution.

The Consequences of Poor Installation

Think of the fitting as a lock and the installation process as the key. The wrong key, or using it clumsily, will not open the lock. In plumbing, a failed installation leads to drips, leaks, water damage, and costly call-backs.

The goal of installation is to create continuous, uniform pressure at the precise sealing points. Any deviation breaks this pressure seal.

Common Installation Mistakes and Their Effects

Let’s look at what happens when steps are skipped or done incorrectly:

1. Poor Pipe Preparation:

- Problem: Cutting plastic pipe with a saw that leaves a ragged, angled, or burred end.

- Result: The pipe won’t insert fully to the internal stop. The compression ring will seal against a uneven surface, creating a path for leaks. Burrs can also cut the ring.

- Solution: Always use a proper pipe cutter for a clean, square cut. Deburr the outside and inside edge.

2. Incorrect Use of Thread Sealant on the Metal Side:

- Problem: Using no sealant, using too little Teflon tape, or wrapping it in the wrong direction (counter-clockwise).

- Result: Water easily winds its way through the spiral thread path and leaks out.

- Solution: Apply 2-3 layers of high-quality Teflon tape clockwise (looking at the end of the pipe). For pipe dope, apply a consistent layer over all threads.

3. Incorrect Tightening (The Biggest Issue):

- Problem A – Under-tightening: The compression ring does not deform enough to grip and seal.

- Problem B – Over-tightening: On the plastic side, this can crush the pipe, crack it, or deform the brass threads. On the metal side, it can crack the fitting.

- Solution: Hand-tighten first, then use wrenches. Follow the “two-wrench” rule: one wrench to hold the fitting body, one to turn the nut. Tighten until snug, then typically a further quarter to half turn. You should feel firm resistance.

Step-by-Step Installation Checklist

Follow this simple guide for a reliable connection:

| Step | For the METAL End | For the PLASTIC (Compression) End |

|---|---|---|

| 1. Prepare Pipe | Ensure threads are clean, undamaged. | Cut pipe square, deburr inside and out. |

| 2. Apply Sealant | Wrap Teflon tape clockwise (2-3 layers) or apply pipe dope. | (Not applicable) |

| 3. Assemble Parts | Screw metal pipe into fitting. | Slide nut, then compression ring onto pipe. Insert pipe fully into fitting body. |

| 4. Tighten | Tighten firmly with wrenches. Avoid extreme force. | Hand-tighten nut, then use wrenches for a final quarter to half turn. |

| 5. Check | Look for sealant squeeze-out. Do a pressure test. | Ensure pipe cannot be pulled out. Do a pressure test. |

Proper installation is not hard, but it requires attention to detail. Rushing this process almost always guarantees a future problem.

How Does the Material Compatibility Prevent Leaks Over Time?

A fitting might seal perfectly on day one but fail in a year. Long-term material compatibility is what separates a good fitting from a great one.

Material compatibility prevents leaks by ensuring all connected parts expand, contract, and wear at similar rates when exposed to water, temperature changes, and pressure. Incompatible materials can lead to galvanic corrosion, stress cracking, or seal degradation, which slowly breaks the seal from the inside out.

The Hidden Enemy: Galvanic Corrosion

This is the most critical factor when connecting metal and plastic. Brass is chosen as the adapter material for a very good reason.

- The Problem: When two different metals are in contact in the presence of an electrolyte (like water), an electrochemical reaction occurs. One metal (the less noble, like steel) will corrode and sacrifice itself to protect the other. This is galvanic corrosion.

- The Brass Solution: Brass is an alloy of copper and zinc. It is much closer to copper on the galvanic series than steel is. When a brass fitting connects to a copper pipe, the galvanic activity is minimal and very slow. Using a brass fitting between, say, a steel pipe and a plastic pipe isolates the steel and prevents rapid corrosion at the connection point.

Thermal Expansion and Long-Term Stress

Plastic and metal expand at different rates when heated by hot water.

- PP-R Expansion: PP-R expands significantly more than metal when hot. A rigid connection could create huge stress.

- How the Design Helps: The compression fitting on the plastic side has a small amount of built-in flexibility. The gripping action holds the pipe, but the soft ferrule and the pipe itself can absorb tiny movements without breaking the seal. The pipe is also free to expand into the fitting socket slightly.

- Material Fatigue: High-quality brass is chosen for its durability and resistance to fatigue from constant pressure and temperature cycling. Cheap, porous brass alloys can develop micro-cracks over time.

Degradation of Sealing Components

The seals themselves must be made of compatible, long-lasting materials.

- Compression Ring Material: The ferrule is often soft copper or a specific brass alloy. It must be softer than the fitting body but harder than the plastic pipe. It must also resist water corrosion and not become brittle.

- Thread Sealant Longevity: Quality Teflon tape or pipe dope is chemically inert and designed not to dry out, shrink, or decompose inside the joint over decades.

Choosing the Right Fitting for the Job

Compatibility means matching the fitting to your specific pipes. Using the wrong type invites failure.

| Your Pipe System | Recommended Fitting Type | Key Compatibility Reason |

|---|---|---|

| Copper to PP-R | Brass adapter with copper compression end for PP-R. | Brass is galvanically compatible with copper. Compression suits PP-R. |

| Galvanized Steel to PEX | Brass adapter with female threads for steel, and a PEX crimp or clamp end. | Brass acts as a barrier, preventing steel corrosion from migrating. |

| Stainless Steel to PVC | Caution needed. Use a brass fitting with a plastic (e.g., nylon) sleeve or gasket if possible. | Stainless and brass can still have galvanic issues; a non-metallic isolator is best. |

In summary, a fitting that is materially compatible ensures the seal you create today remains intact years from now, despite the constant changes in temperature, pressure, and chemical environment inside your pipes.

Conclusión

A leak-proof seal between plastic and metal is achievable with a well-designed brass fitting, precise installation, and attention to material compatibility. For reliable, long-lasting connections, specify IFAN’s precision brass fittings and adapters for your next hybrid plumbing project.

Comentarios recientes