I once managed a project where metal pipe supports rusted and failed, causing delays and extra costs. This frustrating experience taught me the true value of choosing the right component from the start, like PVC pipe clips.

PVC pipe clips are cost-effective because they combine a very low initial purchase price with easy installation, long-lasting durability, and minimal maintenance needs. This combination reduces total project costs immediately and continues to save money over the entire lifespan of the piping system.

Let’s break down exactly how these simple components deliver such significant savings for any project.

How Does Low Material Cost Make PVC Pipe Clips Cost-Effective for Projects?

Every project manager watches the budget. I’ve seen how the cost of small items like clips can add up quickly when using metal alternatives.

The low material cost of PVC pipe clips makes projects cost-effective by significantly reducing the initial expenditure for pipe support hardware. This allows project managers to allocate more budget to other critical areas or simply lower the overall project cost without sacrificing quality or reliability.

The Direct Impact on Your Budget

When we plan a project, we list every item we need to buy. Pipe clips, or supports, are essential for every meter of pipe we install. While each clip seems inexpensive, we need hundreds or even thousands of them for a large project. Therefore, the price per unit has a huge impact on the total material cost.

PVC is a widely produced, thermoplastic polymer. Manufacturers make it from common materials, and the production process for simple shapes like clips is very efficient. This keeps the raw material and manufacturing costs low. On the other hand, metal clips, whether made from stainless steel, galvanized steel, or aluminum, require more expensive raw materials and often more complex manufacturing steps like stamping, bending, or welding.

Cost Comparison: Initial Purchase

Let’s look at a direct comparison. The table below shows estimated costs for a standard-sized pipe clip.

| Clip Material | Estimated Cost per Unit (Standard Size) | Key Cost Drivers |

|---|---|---|

| PVC | $0.50 – $1.50 | Low-cost raw material, efficient injection molding process. |

| Galvanized Steel | $1.50 – $3.50 | Cost of steel, anti-corrosion galvanizing process. |

| Stainless Steel | $3.00 – $7.00+ | High cost of stainless steel alloy, more complex fabrication. |

As you can see, choosing PVC clips can cut your initial cost for this line item by 50% or more compared to galvanized steel, and by up to 80% compared to stainless steel. For a project requiring 5,000 clips, this difference translates to thousands of dollars saved immediately. This saving is direct and visible on your purchase order.

Freeing Up Capital for Other Needs

This initial cost saving is important. It does not mean you are choosing a cheaper, lower-quality product. In fact, for most standard applications, PVC performs excellently. The money you save can be used to upgrade another part of the system, handle unexpected expenses, or simply make your bid more competitive. In short, the low material cost of PVC clips gives you immediate financial flexibility and a stronger bottom line from the very beginning of your project.

Why Does Easy Installation of PVC Pipe Clips Save Labor and Project Costs?

Time is money on a job site. I’ve watched crews struggle with heavy, sharp metal clips that slow down the entire installation process.

The easy installation of PVC pipe clips saves labor and project costs because they are lightweight, easy to handle, and can be quickly secured with standard screws or adhesives. This allows installers to work faster, reduces physical fatigue, and minimizes the need for specialized tools, directly cutting down on expensive labor hours.

How Installation Speed Affects Cost

Labor is often the single biggest cost in a construction project. Any factor that speeds up installation directly reduces this major expense. PVC clips are designed for speed and simplicity.

First, they are very light. An installer can carry a large box of PVC clips easily, while the same number of metal clips would be heavy and cumbersome. This means less time spent moving materials around the site.

Simple and Safe Handling

Second, the installation process itself is straightforward. PVC clips are typically secured using ordinary screws into a wall or frame. Some types use strong adhesive pads for even faster mounting on smooth surfaces. Unlike metal clips, PVC clips do not have sharp edges that can cut workers’ hands, so no special gloves are needed. Also, they do not require pre-drilling in most cases, as the screw can often thread directly into the PVC or through a pre-made hole.

Comparing Installation Workflow

Let’s compare the steps for installing a typical metal clip versus a PVC clip.

| Installation Step | Metal Clip (e.g., Galvanized Steel) | PVC Clip |

|---|---|---|

| 1. Handling | Heavy, sharp edges require care. | Lightweight and safe to handle. |

| 2. Positioning | May require two hands or temporary holding. | Easy to position with one hand. |

| 3. Securing | Often requires pre-drilling a pilot hole to prevent screw wandering. | Usually, a screw can be driven directly; some use instant adhesive. |

| 4. Final Adjustment | Hard to bend or adjust if misplaced. | Can be easily removed and re-secured if needed. |

This simpler process means an installer can complete more clips per hour. Over hundreds of clips, this time saving adds up to significant labor cost reduction. Furthermore, easier work leads to less worker fatigue and higher job satisfaction, which can improve overall productivity and safety on site. The project finishes faster, saving not just labor costs but also overhead costs associated with a longer project timeline.

How Does the Durability of PVC Pipe Clips Ensure Long-Term Cost Savings?

A client once had to replace all metal clips in a damp environment after just two years. The long-term cost was shocking, and it’s a mistake we now help others avoid.

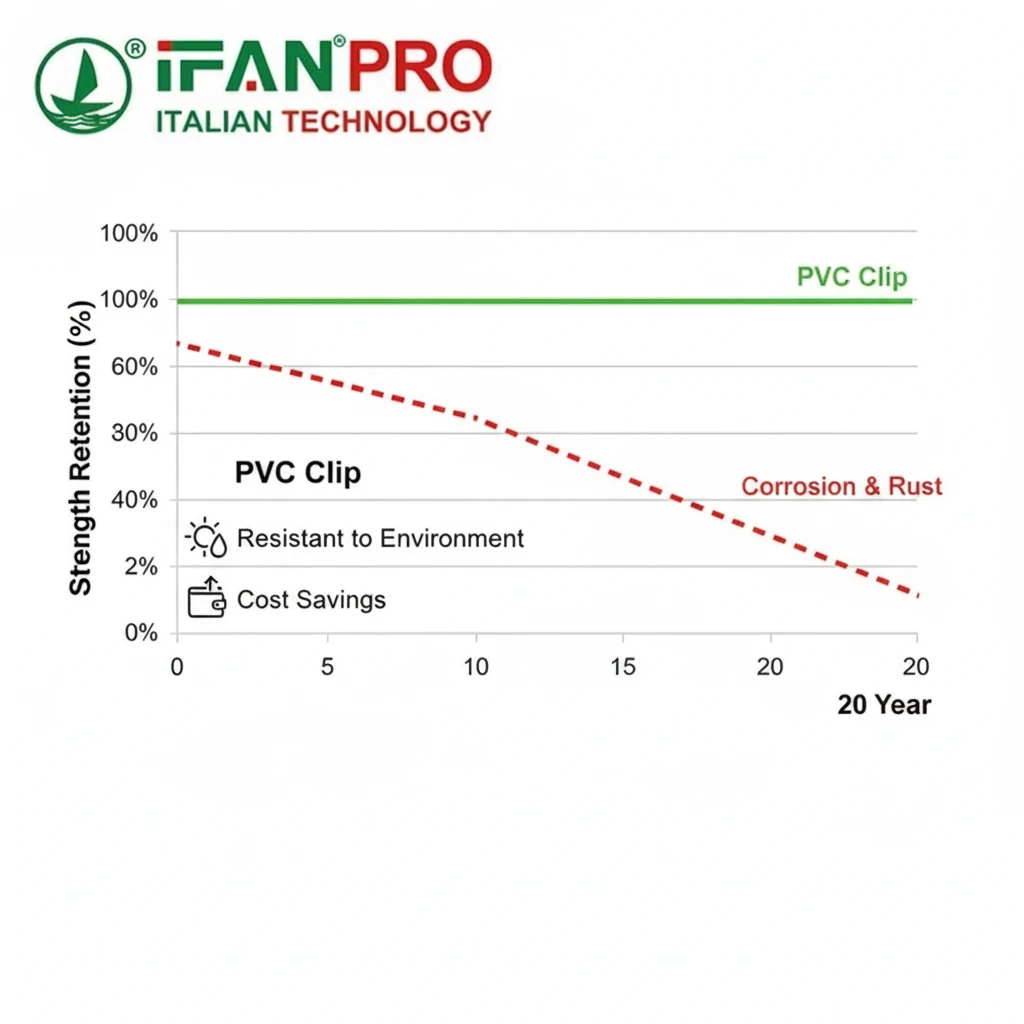

The durability of PVC pipe clips ensures long-term cost savings because PVC is naturally immune to corrosion, rust, and chemical degradation from moisture or common atmospheric elements. This resistance means the clips will not weaken, stain, or fail over time, eliminating the future cost and disruption of premature replacement.

Understanding the True Cost of Failure

Real cost-effectiveness is measured over years, not just at purchase. A component that fails early forces you to pay for it twice: once for the initial purchase and again for the replacement, plus the high cost of the labor to install it. PVC’s inherent properties prevent this cycle.

The biggest threat to pipe supports in many environments is corrosion. Metal clips, even galvanized ones, will eventually rust when exposed to moisture, humidity, or certain chemicals in the air or from the pipe itself. This rust weakens the metal, making it brittle. A rusted clip can snap, causing the pipe to fall and potentially leak. PVC is a plastic, so it cannot rust or corrode. It is completely unaffected by water or humidity.

Resistance to Chemicals and Elements

PVC also offers excellent resistance to a wide range of chemicals, including acids, alkalis, and salts. This makes it perfect for use in challenging environments like chemical plants, wastewater treatment facilities, coastal areas, or indoor swimming pools where chlorine is present. Metal clips in these settings would deteriorate rapidly.

Furthermore, PVC does not conduct electricity. This is a safety feature and also means it will not participate in galvanic corrosion. Galvanic corrosion happens when two different metals touch in the presence of an electrolyte (like water). This can quickly destroy metal clips and the pipes they hold if they are made of different metals. PVC clips eliminate this risk entirely.

Long-Term Performance Comparison

The table below illustrates the long-term outlook for different clip materials in a standard humid environment.

| Clip Material | Expected Service Life (Humid Environment) | Primary Reasons for Failure | Long-Term Cost Implication |

|---|---|---|---|

| PVC | 20+ Years | Virtually no degradation from moisture or corrosion. | One-time purchase. No planned replacement cost. |

| Galvanized Steel | 5-15 Years | The zinc coating wears off, leading to rust and structural failure. | High probability of needing a full replacement cycle. |

| Carbon Steel (Painted) | 3-10 Years | Paint chips, moisture reaches metal, rust begins quickly. | Very high risk of early failure and replacement costs. |

By choosing durable PVC clips, you are essentially making a one-time investment. You install them and forget about them. This reliability provides peace of mind and protects your project from hidden future costs, ensuring that the initial savings you enjoyed are not later wiped out by unexpected repair bills.

How Do PVC Pipe Clips Reduce Overall System Maintenance Costs Effectively?

Unexpected maintenance is a project manager’s nightmare. I advocate for components that are designed to be forgotten, and PVC clips excel at this.

PVC pipe clips reduce overall system maintenance costs effectively because they require zero upkeep, do not damage pipes, and prevent problems that lead to expensive repairs. Their stability and non-corrosive nature mean there is no need for inspections, tightening, cleaning, or replacement under normal conditions.

The Hidden Cost of Maintenance

Maintenance costs are often overlooked during planning but can become a major financial burden. These costs include labor for inspections, materials for replacements, and system downtime. PVC clips minimize or eliminate these expenses in several key ways.

First, as established, they do not corrode. This single fact removes the most common reason for clip failure. You never need to send a maintenance worker to check for rust, paint them, or replace them because they have become weak and brittle. This translates directly to zero scheduled maintenance for the clips themselves.

Protecting the Pipes They Hold

Second, PVC clips actively protect the rest of your system, saving even more money. They are non-abrasive and have a smooth interior surface. When pipes expand, contract, or vibrate slightly within the clip, the PVC will not scratch, wear down, or galvanically corrode the pipe’s exterior. Metal clips, especially if rusted, can grind into the pipe wall over time, creating weak points or even causing leaks. By using PVC, you extend the life of the more expensive piping system.

Preventing System Failures

Third, PVC clips help avoid catastrophic system failures. A failed metal clip can drop a pipe. This can cause:

- Pipe Damage: The falling pipe can crack or break.

- Joint Failure: Stress on the joints can cause leaks.

- Content Spillage: If the pipe carries liquid, a major leak can occur.

- Production Halt: In an industrial setting, this can stop production lines.

The cost of fixing such an event—emergency labor, new materials, and lost production—is enormous. The reliability of PVC clips acts as an insurance policy against these rare but extremely costly disasters.

Maintenance Cost Comparison Table

Consider the typical 10-year maintenance cycle for a commercial plumbing system.

| Maintenance Activity | System with Metal Clips | System with PVC Clips |

|---|---|---|

| Regular Clip Inspection | Required (e.g., annually for rust) | Not Required |

| Clip Replacement | Highly likely, at least partially | Very Unlikely |

| Pipe Damage from Clip | Possible (abrasion, galvanic corrosion) | Very Unlikely |

| Risk of Pipe Drop/Failure | Moderate (if clips rust through) | Very Low |

| Estimated 10-Yr Maintenance Cost | High (Labor + Parts) | Very Low to None |

In summary, PVC pipe clips are a “set-and-forget” component. Their design minimizes interaction with the pipe and the environment, which in turn minimizes the need for any corrective action. This passive reliability is a powerful driver for reducing the total cost of owning and operating any piping system over its full lifespan.

Conclusión

PVC pipe clips deliver cost savings at every stage: initial purchase, installation, long-term durability, and system maintenance. For high-quality, reliable PVC pipe clips that secure your project’s budget, choose IFAN.

Comentarios recientes