I once inspected a failed irrigation system where the pipes held firm, but the glued joints had split. This moment proved that the strength of a PVC system lives or dies by the quality of its glued connections.

Yes, a properly applied PVC glue (or solvent cement) can absolutely withstand significant pressure and create a permanent, leak-proof seal. It works by chemically melting and fusing the PVC pipe and fitting into a single, monolithic piece of plastic at the joint, which is often the strongest part of the entire assembly when done correctly.

However, achieving this perfect seal depends on several critical factors. Let’s break down the science, the steps, and the common pitfalls to understand how PVC glue reliably holds pressure.

What Pressure Ratings and Tests Prove PVC Glue Joint Strength?

Many installers assume the pipe’s rating is the system’s limit. My experience shows that a good solvent-weld joint can actually be stronger than the pipe itself.

Independent pressure tests and industry standards prove that a correctly made solvent-cemented PVC joint can withstand pressures equal to or exceeding the pressure rating of the pipe itself. Tests like the sustained pressure test and the burst pressure test validate that the fused joint is not a weak point but a reinforced section of the pipeline.

Understanding Pressure Ratings

First, it’s crucial to understand that PVC pipes have standardized pressure ratings, such as Schedule 40 or Schedule 80. These ratings indicate the maximum continuous pressure the pipe material can handle. The key question is whether the glued joint can match this strength. Industry standards and rigorous testing confirm that it can.

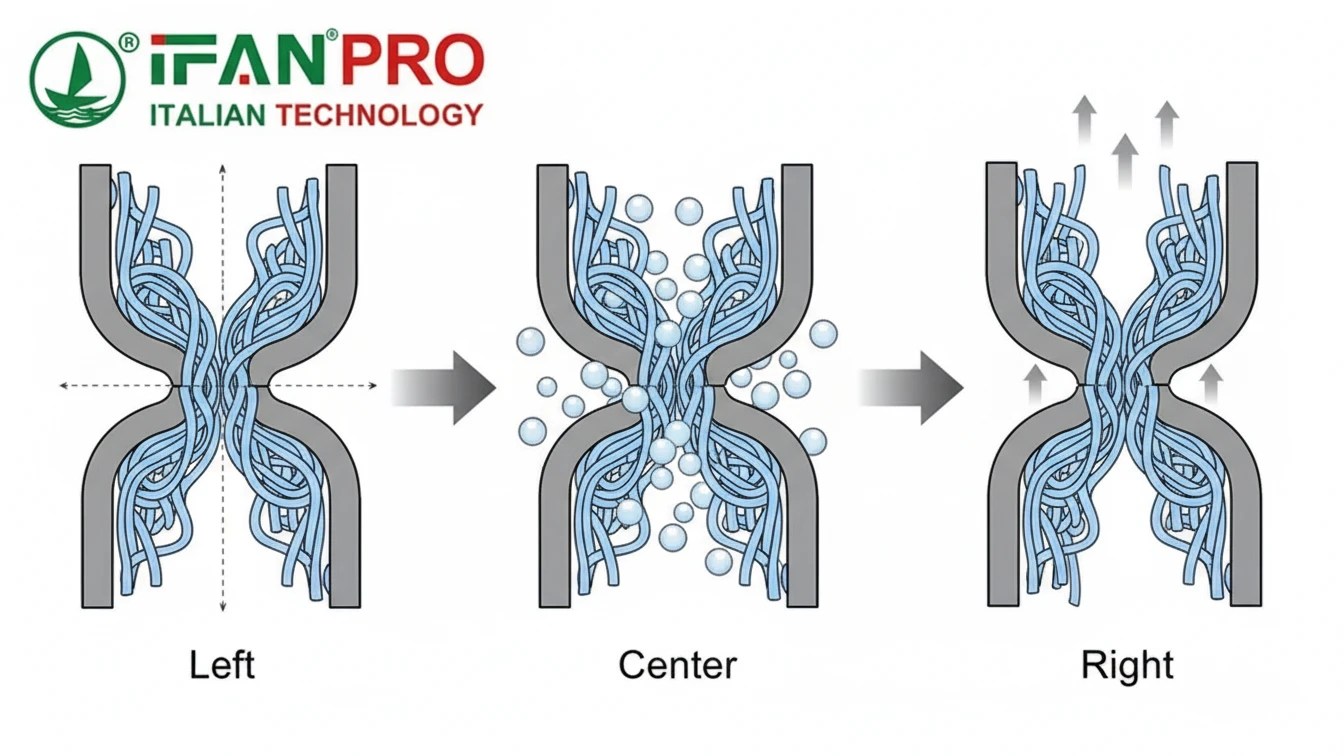

The joint’s strength comes from the chemical welding process. The solvent cement temporarily dissolves the surface layers of both the pipe and the fitting. When pushed together, these softened materials mix and intertwine. As the solvents evaporate, the PVC re-hardens into a new, homogeneous piece of plastic. This fusion creates a bond that is fundamentally different from a mechanical or adhesive connection.

Standardized Validation Tests

Manufacturers and standards organizations use specific tests to certify solvent cements and joint integrity:

- Sustained Pressure Test: This test subjects assembled joints to a constant, high pressure (often 1.5 to 2 times the pipe’s rated pressure) for an extended period, like 1,000 hours. The joint must not leak or fail.

- Burst Pressure Test: This test rapidly increases pressure on the joint until it fails. A quality solvent-welded joint should burst in the pipe wall, not at the joint, proving the joint is stronger than the pipe.

- Tensile Strength Test: This measures the force required to pull a joint apart. A proper chemical weld will transfer the stress to the pipe material.

Typical Pressure Performance Data

The following table illustrates how solvent-welded joints perform under pressure compared to the base pipe material.

| Pipe Schedule & Size | Pipe Pressure Rating (psi) | Expected Minimum Burst Pressure of Solvent-Welded Joint (psi) | Common Test Standard |

|---|---|---|---|

| Schedule 40, 2-inch | 280 psi | 1,200 psi | ASTM D2564 / ISO 20492 |

| Schedule 80, 1-inch | 450 psi | 1,800 psi | ASTM D2564 / ISO 20492 |

| Class 200, 4-inch | 200 psi | 800 psi | ASTM F493 |

As the data shows, the welded joint assembly is designed to far exceed the normal operating pressure of the pipe. This significant safety margin is why PVC solvent welding is trusted for critical applications from residential drain-waste-vent (DWV) systems to pressurized potable water lines and industrial process piping. When you follow the correct procedures, the joint is not your concern; the pipe’s own rating is the system’s limiting factor.

How Does PVC Glue Create a Permanent, Leak-Proof Chemical Weld?

Calling it “glue” is misleading. I tell my team to think of it as a “chemical welder,” because that’s exactly what it does—it merges two pieces into one.

PVC glue creates a permanent seal by using potent solvents to temporarily dissolve the surface layers of the PVC pipe and fitting. This creates a slurry of softened PVC. When assembled, these layers mix completely. As the solvents evaporate, the PVC re-hardens into a single, solid piece of plastic, eliminating any seam where a leak could occur.

The Chemical Reaction Process

To understand why this seal is so reliable, let’s look at the three main components in a typical PVC solvent cement and their roles:

- Solvents: These are the primary active ingredients (like tetrahydrofuran or cyclohexanone). They attack and dissolve the PVC polymer chains on the surface, making them soft and mobile.

- PVC Resin: Fine particles of PVC are suspended in the cement. This adds extra body to the mixture and provides more PVC material to fill the joint gap as it fuses.

- Fillers & Stabilizers: These modify the cement’s viscosity, drying time, and gap-filling properties.

The process is not sticking things together; it’s a controlled chemical reaction. The solvent breaks down the polymer structure, allowing the chains from the pipe and the fitting to intermingle freely. Upon evaporation of the solvent, these polymer chains re-encrystallize together. The result is a fusion zone where it is impossible to tell where the pipe ends and the fitting begins. This is why a properly made joint is often described as “leak-proof” rather than just “leak-resistant.”

Visualizing the Fusion Zone

A cross-section of a perfect joint shows a continuous, uniform material with no distinct boundary line. This is fundamentally different from a mechanical joint, which relies on compression forces against a gasket, or a traditional adhesive, which bonds to surfaces but leaves a distinct layer of foreign material in between.

Advantages Over Mechanical Connections

This chemical weld method offers key advantages for pressure systems:

- Uniform Stress Distribution: Because it becomes one piece, stress from internal pressure or external bending is distributed evenly across the joint area. There is no single point of high stress like there is at the threads of a threaded connection.

- No Creep or Relaxation: Unlike rubber gaskets that can dry out, compress, or degrade over decades, the fused PVC is as stable as the pipe itself.

- Immunity to Vibration: A fused joint will not loosen from vibration, a common cause of failure in threaded systems.

In essence, the goal of using PVC solvent cement is to make the joint disappear, transforming multiple parts into a continuous, monolithic pipeline. This is the core principle behind its ability to hold pressure permanently.

What Are the Correct Surface Prep and Application Steps for PVC Glue?

Success is 90% preparation. I’ve seen more joints fail from rushed prep than from using the wrong brand of cement.

The correct steps are: clean and dry the pipe and fitting, apply primer (if required), apply an even coat of cement to both surfaces, assemble immediately with a quarter-turn, and hold firmly for 30 seconds. The most critical steps are the initial cleaning and the swift, sure assembly to ensure a proper chemical weld before the cement sets.

Step-by-Step Guide to a Perfect Joint

A flawless chemical weld depends on a meticulous, step-by-step process. Skipping or rushing any step compromises the joint’s integrity. Here is the definitive procedure based on industry codes and manufacturer instructions.

Step 1: Cutting and Deburring

First, cut the pipe squarely using a PVC cutter or a fine-tooth saw. A crooked cut leaves gaps. Then, remove all the internal and external burrs (rough plastic shreds) with a deburring tool or a file. Burrs can create paths for leaks and disrupt the smooth flow of water.

Step 2: Cleaning and Dry-Fitting

This is the most skipped but vital step. Wipe the pipe end and the fitting socket with a clean, dry rag to remove dirt, moisture, or grease. Then, do a dry fit. Mark the pipe depth with a pencil. This ensures the pipe will seat fully during the glued assembly, which is done under pressure and sightless.

Step 3: Applying Primer

For pressure applications and most plumbing codes, primer is mandatory. It is not just a cleaner. Purple primer contains aggressive solvents that deeply soften and prepare the PVC surface, ensuring a deeper, more reliable weld. Apply primer generously to the pipe end and the inside of the fitting. It should be applied until the PVC surface looks slightly softened and glossy.

Step 4: Applying Solvent Cement

Immediately after the primer dries (a few seconds), apply a uniform, moderate coat of the correct solvent cement. Use the applicator brush or a dauber. Apply cement to the pipe end first, then to the inside of the fitting socket. The coat should be even and sufficient to become tacky.

Step 5: Assembly and Holding

This must be done quickly. Within 15-20 seconds of applying the cement:

- Push the pipe into the fitting, twisting it one-quarter turn as you go. This spreads the cement evenly.

- Push until the pipe bottoms out in the fitting socket, reaching your depth mark.

- Hold the joint firmly together for at least 30 seconds to prevent it from pushing back out as the cement sets.

- Wipe away the excess cement bead around the joint with a rag.

Common Cement Types and Their Use

Use the right cement for your job. This table helps you choose.

| Cement Type | Color | Best For | Key Feature |

|---|---|---|---|

| Regular Clear | Clear | Non-pressure DWV systems | Fast set time |

| All-Purpose | Blue/Gray | Schedule 40 & 80 pressure pipe | Medium body, general use |

| Heavy-Duty | Orange | All schedules, including large diameters | Extra thick for gap filling |

| Hot & Cold | Green | Applications in very hot or cold weather | Extended working time |

Step 6: Curing

While the joint sets quickly, it needs time to fully cure and develop its maximum strength before being pressurized. Follow the manufacturer’s instructions, but a general rule is:

- Handling Time: 15 minutes (you can move the pipe).

- Full Cure Time: 2 hours for small diameters, 24 hours for full pressure testing, especially on larger pipes.

Rushing the cure time is a leading cause of early joint failure during pressure testing.

What Causes PVC Glue Joint Failures and Pressure Leaks Over Time?

A leak years later often traces back to a mistake during the ten-minute installation window. Understanding these failures helps prevent them.

PVC glue joint failures are almost always caused by human error during installation: improper surface cleaning, skipping primer, insufficient cement application, incomplete insertion, or not allowing adequate cure time. Environmental factors like extreme stress, sunlight degradation (UV exposure) on unprotected pipe, or using the wrong type of cement for the application can also lead to long-term leaks.

Analyzing Failure Modes

Even with a product as reliable as solvent cement, failures happen. They typically fall into a few categories, each with a clear root cause.

Category 1: Installation Errors (The Most Common)

This is where most problems start.

- Dirty or Wet Surfaces: Dirt, sand, or water creates a barrier that prevents proper chemical fusion. The cement bonds to the grime, not the PVC.

- No Primer Used: On pressure pipes, skipping primer results in a shallow, surface-level bond that is weak and brittle. It may hold initially but can crack under stress or thermal cycling.

- “Starved” Joint: Applying too little cement means there isn’t enough dissolved PVC to fill the microscopic gaps between the pipe and fitting, leaving voids.

- Improper Assembly: Not pushing the pipe in all the way, failing to twist, or not holding the joint leads to a poor connection that is partially pulled apart by its own spring-back force.

Category 2: Material and Environmental Issues

- Mismatched Materials: Trying to glue PVC to ABS or CPVC without a specific transition cement will not create a proper chemical weld.

- Using Old or Contaminated Cement: Solvent cement has a shelf life. If the can is left open or is very old, the solvents evaporate, leaving a thick, ineffective paste.

- UV Degradation: While PVC pipe is UV-resistant, prolonged direct sunlight makes it brittle. If the pipe surface is chalky and degraded, the cement cannot bond to strong material.

- Excessive Stress or Movement: A solvent-welded joint is strong but rigid. If the pipeline is subjected to ground settlement, freezing, or impact, the stress can crack the pipe right next to the joint or crack a poorly made joint itself.

Troubleshooting Common Joint Problems

Here is a table to diagnose what went wrong with a failed joint.

| Symptom of Failure | Likely Cause | How to Prevent It |

|---|---|---|

| Joint leaks immediately during test | Pipe not fully seated, no primer on pressure pipe, or surfaces were wet. | Dry-fit, mark depth, use primer, ensure surfaces are dry. |

| Joint cracks or leaks after years | “Starved” joint (not enough cement), UV degradation, or excessive physical stress. | Apply a full, even coat of cement, protect pipe from sunlight, install with proper supports. |

| Cement is stringy and doesn’t set well | Cement is old, contaminated, or the wrong type for the conditions (e.g., cold weather). | Always use fresh cement, store lids tightly, choose the right cement for the job. |

| Joint pulls apart easily | No twist during assembly, insufficient hold time, or incorrect cement for the material (e.g., PVC to ABS). | Always use a quarter-turn, hold for 30+ seconds, use correct transition cement for different materials. |

Proactive Prevention Advice

To ensure lifelong integrity:

- Treat the Instructions as Law: The manufacturer’s instructions on the cement can are your guide. Follow them exactly.

- Invest in Quality Materials: Don’t cheap out on a generic, unlabeled cement. Use products from reputable manufacturers like IFAN that ensure consistent formulation and performance.

- Protect the System: Shield outdoor pipes from direct sunlight with paint or insulation. Use proper pipe hangers to avoid stress.

- Inspect Before Pressure: After the full cure time, visually inspect every joint for gaps or signs of poor cement application before conducting the pressure test.

Conclusión

A PVC glue joint, when done right, forms a permanent, pressure-tight seal stronger than the pipe. For guaranteed results, use reliable products like IFAN’s range of PVC primers and solvent cements designed for professional, leak-proof performance.

Comentarios recientes