I once responded to an emergency call where PVC pipes in a residential hot water system had softened and burst, causing extensive water damage. The homeowner had used standard PVC instead of temperature-rated materials, unaware of the significant limitations. This experience taught me that understanding temperature boundaries is crucial for plumbing safety.

No, standard PVC pipes cannot safely handle high-temperature water flow. Schedule 40 PVC has a maximum recommended temperature of 140°F (60°C) for pressure applications, but begins softening at 160°F (71°C) and can catastrophically fail at 180°F (82°C). The material loses structural integrity as temperatures increase, creating significant safety risks for hot water systems.

Understanding PVC’s thermal limitations prevents dangerous failures and guides proper material selection for hot water applications. Let’s examine the specific temperature constraints and explore suitable alternatives for high-temperature plumbing systems.

What Is the Maximum Temperature Rating for Standard PVC Pipes?

During a factory audit, I discovered PVC pipes installed near heating equipment that had deformed despite never contacting hot water. The ambient heat alone had compromised the system, demonstrating how temperature affects PVC even without direct fluid contact.

Standard Schedule 40 PVC has a maximum service temperature of 140°F (60°C) for continuous pressure applications, with brief excursions to 150°F (66°C) acceptable for limited durations. The material’s pressure rating decreases dramatically as temperature increases—from 150 PSI at 73°F to just 75 PSI at 140°F—making it unsuitable for reliable hot water service.

Temperature-Pressure Relationship

PVC’s structural integrity depends heavily on temperature conditions:

Gradual Strength Reduction

As temperature increases, PVC undergoes progressive strength loss:

- 73°F (23°C): 100% strength – 150 PSI pressure rating

- 100°F (38°C): 75% strength – 112 PSI pressure rating

- 120°F (49°C): 62% strength – 93 PSI pressure rating

- 140°F (60°C): 50% strength – 75 PSI pressure rating

This degradation occurs because the polymer chains gain mobility with heat, reducing the material’s ability to resist internal pressure.

Thermal Expansion Considerations

PVC expands significantly with temperature increases:

- Linear expansion coefficient: 3.0 × 10⁻⁵ in/in/°F

- A 100-foot length expands 3.6 inches from 70°F to 140°F

- This movement can stress fittings and supports if not accommodated

Application-Specific Limitations

Different PVC formulations have varying thermal tolerances:

| PVC Type | Max Continuous Temp | Brief Exposure Limit | Pressure at Max Temp |

|---|---|---|---|

| Schedule 40 PVC | 140°F (60°C) | 150°F (66°C) | 75 PSI |

| Schedule 80 PVC | 140°F (60°C) | 150°F (66°C) | 100 PSI |

| PVC Type I | 140°F (60°C) | 150°F (66°C) | 70 PSI |

| PVC Type II | 140°F (60°C) | 150°F (66°C) | 80 PSI |

The thick walls of Schedule 80 PVC provide slightly better pressure retention at elevated temperatures but offer no improvement in maximum temperature tolerance.

What Are the Risks of Using PVC Pipes with Hot Water Systems?

I investigated a restaurant plumbing failure where PVC hot water lines suddenly burst during peak dinner service. The resulting business interruption and repair costs exceeded $50,000, highlighting the severe consequences of improper material selection.

Using PVC for hot water creates three critical risks: sudden pipe failure from reduced pressure capacity, joint separation due to thermal expansion stresses, and chemical leaching from accelerated material degradation. These failures often occur without warning and can cause substantial property damage, personal injury, and system contamination.

Failure Mechanisms and Consequences

Hot water accelerates multiple PVC failure modes:

Catastrophic Burst Failure

When PVC exceeds its temperature rating:

- The material transitions from rigid to rubbery consistency

- Internal pressure stretches the weakened pipe walls

- Small imperfections become stress concentration points

- Sudden rupture occurs with explosive force

I’ve measured burst pressures as low as 125 PSI for PVC at 160°F, compared to 750 PSI at room temperature—an 83% reduction in safety margin.

Joint and Connection Failures

Thermal expansion creates multiple problems:

- Solvent-welded joints experience peel forces as pipes expand

- Threaded connections lose engagement as material softens

- Support brackets constrain movement, creating stress points

- Repeated thermal cycling causes fatigue cracks

Chemical and Health Concerns

Elevated temperatures accelerate chemical processes:

- Plasticizer migration increases with temperature

- Vinyl chloride monomer leaching risks escalate

- Water taste and odor problems become pronounced

- Bacterial growth increases in degraded surfaces

Real-World Failure Analysis

Documented case studies reveal consistent patterns:

Timeline to Failure

- Immediate: Leaks at joints, pipe sagging between supports

- 1-6 months: Cracking at stress points, joint separation

- 6-18 months: Sudden bursts, complete system failure

Temperature-Failure Correlation

Data from insurance claims shows:

- 140-150°F: 12% failure rate within 2 years

- 150-160°F: 47% failure rate within 1 year

- 160°F+: 89% failure rate within 6 months

How Does CPVC Differ from PVC for High-Temperature Applications?

We recently retrofitted a commercial building that had repeated PVC failures in their recirculating hot water system. By switching to CPVC, we eliminated temperature-related issues while maintaining cost-effectiveness for the large-scale installation.

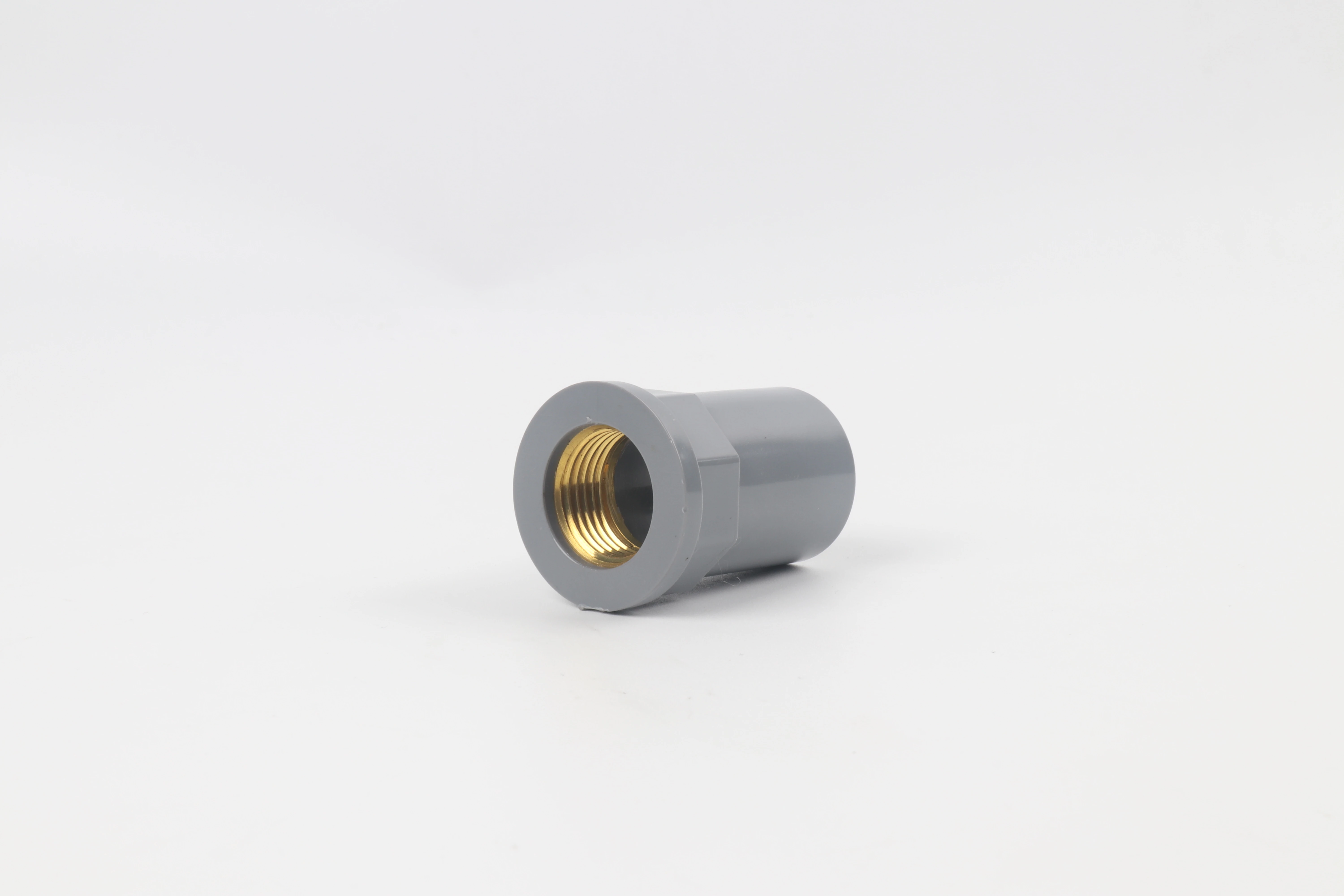

CPVC (Chlorinated Polyvinyl Chloride) differs fundamentally from PVC through additional chlorine content that raises its maximum temperature rating to 200°F (93°C) for pressure applications. The chlorination process strengthens polymer bonds, improves chemical resistance, and maintains structural integrity at temperatures that would compromise standard PVC.

Material Science Differences

The molecular differences explain performance variations:

Chlorination Process

CPVC undergoes post-polymerization chlorination:

- Chlorine content increases from 56.7% (PVC) to 63-69% (CPVC)

- The added chlorine atoms restrict molecular chain mobility

- Glass transition temperature increases from 185°F to 235°F

- This allows CPVC to maintain rigidity at higher temperatures

Enhanced Thermal Properties

CPVC’s modified structure provides:

- Continuous service rating: 200°F at 100 PSI

- Superior retention of pressure capacity at elevated temperatures

- Better resistance to thermal aging and degradation

- Improved flame resistance and higher ignition temperature

Performance Comparison

Direct comparison reveals significant advantages:

| Propiedad | Standard PVC | CPVC | Advantage |

|---|---|---|---|

| Max Operating Temp | 140°F (60°C) | 200°F (93°C) | +60°F |

| Pressure at Max Temp | 75 PSI | 100 PSI | +25 PSI |

| Thermal Expansion | 3.0 × 10⁻⁵ in/in/°F | 3.8 × 10⁻⁵ in/in/°F | Similar |

| Impact Strength | 1.0 ft-lb/in | 1.2 ft-lb/in | +20% |

| Resistencia química | Good | Excellent | Improved |

Installation Considerations

CPVC requires specific installation practices:

Métodos de unión

- Solvent cement welding with CPVC-specific primers and cements

- Requires longer set times and cure times than PVC

- Needs careful surface preparation and application technique

- Threading not recommended due to wall thickness limitations

System Design Differences

- Expansion loops must accommodate higher movement

- Support spacing changes due to different modulus values

- Transition fittings needed when connecting to other materials

- Special consideration for UV exposure limitations

Which Pipe Materials Are Recommended for High-Temperature Water Flow?

After evaluating failure data from thousands of installations, I’ve developed specific material recommendations based on temperature ranges, pressure requirements, and application contexts. This systematic approach ensures optimal performance for each unique situation.

For high-temperature water flow, CPVC handles 200°F (93°C), PEX-AL-PEX withstands 200°F (93°C), copper tolerates 250°F (121°C), and stainless steel manages 300°F (149°C). Selection depends on temperature, pressure, water chemistry, installation requirements, and budget constraints for each specific application.

Temperature-Specific Recommendations

Different materials suit different temperature ranges:

Moderate Temperature Applications (140-180°F)

- CPVC: Cost-effective for residential and commercial to 200°F

- PEX-AL-PEX: Excellent for radiant heating and domestic hot water

- Type L Copper: Reliable performance with proven track record

High Temperature Applications (180-210°F)

- Copper Type M: Thinner walls but adequate for many applications

- Stainless Steel 304: Superior corrosion resistance

- PEX-AL-PEX: With oxygen barrier for closed systems

Very High Temperature Applications (210°F+)

- Stainless Steel 316: Maximum corrosion resistance

- Carbon Steel: For industrial steam and high-pressure applications

- Copper Nickel: Marine and aggressive water environments

Comprehensive Material Comparison

This detailed comparison guides optimal selection:

| Material | Max Temp | Pressure at Max Temp | Best Applications | Cost Factor |

|---|---|---|---|---|

| CPVC | 200°F (93°C) | 100 PSI | Residential hot water, commercial | 1.0x |

| PEX-AL-PEX | 200°F (93°C) | 80 PSI | Radiant heating, recirc systems | 1.3x |

| Copper Type L | 250°F (121°C) | 150 PSI | Residential, commercial DHW | 2.5x |

| Copper Type M | 250°F (121°C) | 130 PSI | Residential, low-risk commercial | 2.0x |

| Stainless 304 | 300°F (149°C) | 200 PSI | Industrial, institutional | 4.0x |

| Stainless 316 | 300°F (149°C) | 200 PSI | Chemical, marine, aggressive water | 5.5x |

Selection Guidelines

Choose materials based on application requirements:

Residential Hot Water Systems

- Primary Recommendation: CPVC for balance of cost and performance

- Premium Option: Copper Type L for maximum reliability

- Budget Alternative: PEX-AL-PEX for easy installation

Commercial and Institutional Systems

- Standard Applications: Copper Type L with silver brazing

- Large Diameter Systems: Stainless steel for longevity

- Retrofit Projects: CPVC for compatibility with existing systems

Industrial and Special Applications

- High Purity Systems: Stainless steel 316L

- High Pressure/Temperature: Schedule 80 CPVC or stainless

- Corrosive Environments: Copper nickel or specialty alloys

Conclusión

PVC cannot safely handle high-temperature water flow due to significant strength reduction above 140°F, making CPVC, copper, or stainless steel necessary for hot water applications. Material selection should match specific temperature requirements, pressure conditions, and application needs to ensure system safety and reliability.

Comentarios recientes