Looking back on my plumbing career, I have witnessed firsthand how choosing the right PEX pipe can be critical to the success or failure of a project. Each type of PEX pipe has unique advantages that cater to different installation challenges and performance requirements. Therefore, understanding these differences is essential for the success of any plumbing or heating project.

The plumbing industry primarily relies on three core types of PEX pipe: PEX-A (manufactured via the Engel peroxide method), PEX-B (produced using the silane moisture-cure process), and PEX-C (created through electron beam radiation cross-linking). Additionally, these PEX varieties are available in two categories—”oxygen-barrier” and “non-barrier”—each engineered for specific scenarios, ranging from potable water systems to radiant heating installations.

Selecting the optimal PEX pipe requires evaluating factors such as flexibility, freeze resistance, and application type. Next, we will delve into the unique characteristics and ideal uses of each PEX variety.

How Do PEX-A, PEX-B, and PEX-C Manufacturing Methods Differ?

The manufacturing process of a PEX pipe determines its molecular structure, which in turn directly impacts its real-world performance and application suitability.

PEX-A undergoes peroxide cross-linking during extrusion, resulting in exceptional flexibility and “shape memory”; in contrast, PEX-B achieves cross-linking via silane after extrusion, striking a balance between cost and durability; meanwhile, PEX-C relies on electron beam radiation for cross-linking, forming uniform molecular bonds with unique performance advantages.

PEX-A: Peroxide Cross-Linking (Engel Method)

PEX-A is manufactured using the Engel method. During extrusion, peroxide additives decompose under high temperature and pressure, generating free radicals that form strong covalent bonds between polyethylene molecular chains. This process yields several notable advantages:

- Uniform cross-linking: The cross-linked structure permeates the entire material, with no localized weak points;

- High molecular density: Cross-link density typically reaches 75–85%, far exceeding that of other types;

- Excellent material homogeneity: A stable molecular structure minimizes performance fluctuations.

Because of this, PEX-A exhibits a strong “shape memory” trait—it can be significantly stretched during connection and then strongly revert to its original dimensions. Consequently, it is particularly well-suited for “expansion connection systems” (i.e., temporarily stretching the pipe to install fittings).

PEX-B: Silane Cross-Linking (Moisture Cure)

PEX-B uses the silane cross-linking method, which occurs in two stages: silane additives are mixed in during extrusion, and cross-linking is activated via moisture exposure after extrusion. This approach offers the following advantages:

- Independent process optimization: Extrusion and cross-linking can be adjusted separately, facilitating improved production efficiency;

- Variable cross-link density: Cross-link density typically ranges from 65–80%, adjustable based on requirements;

- Cost-effectiveness: Streamlined production processes while maintaining reliable durability.

Additionally, this manufacturing efficiency gives PEX-B a cost advantage, while still meeting the pressure rating and durability requirements for standard plumbing applications—making it the preferred choice for many routine projects.

PEX-C: Electron Beam Radiation Cross-Linking

PEX-C is cross-linked using electron beam radiation—radiation displaces electrons and forms reactive molecular sites, which in turn promote bonding between molecular chains. Key characteristics of this process include:

- No chemical additives: Cross-linking is achieved solely through physical radiation, avoiding chemical residues;

- Precise radiation control: Strict regulation of radiation dosage is required to ensure performance, but high equipment costs limit availability in some regions;

- Stable chemical resistance: The uniform cross-linked structure provides strong resistance to chemicals such as chlorine.

However, while PEX-C has a relatively narrow application range, its uniform cross-linking properties make it stand out in scenarios requiring high chemical stability.

| Manufacturing Aspect | PEX-A (Engel) | PEX-B (Silane) | PEX-C (Electron Beam) |

| Cross-Linking Method | Peroxide (during extrusion) | Silane (after extrusion) | Electron beam radiation |

| Cross-Link Density | 75–85% (highest) | 65–80% (variable) | 70–80% (uniform) |

| Process Control | Continuous, immediate | Two-stage process | Precise but complex |

| Material Consistency | Excellent throughout | Good (some variation) | Very uniform |

Which PEX Type Offers the Best Flexibility and Freeze Resistance?

All PEX pipes outperform rigid materials like copper or CPVC in terms of flexibility and freeze resistance. However, PEX-A stands out particularly in these two performance metrics.

Benefiting from its high cross-link density and uniform molecular structure, PEX-A offers far superior flexibility and freeze protection compared to other types: it can expand up to 300% of its original size without bursting and reliably revert to its original shape after freeze-thaw cycles—an ability that other PEX types struggle to match.

Flexibility & Shape Memory

PEX-A’s manufacturing process endows it with strong “elastic memory”: it can gradually return to its original form after being bent, a trait that is particularly useful during installation. Furthermore, this memory effect also supports “expansion connections”—temporarily stretching the pipe before inserting a fitting, and the pipe forms a tight sealed connection as it contracts.

In contrast, PEX-B and PEX-C have weaker memory effects: they are more likely to retain their bent shape and perform poorly in expansion connection systems. Although still flexible compared to rigid pipes, they lack the “self-correcting” rebound capability of PEX-A.

Freeze Damage Resistance

All PEX pipes offer better freeze resistance than metal pipes, but PEX-A still stands out as top-tier: when water inside freezes, its molecular structure can accommodate significant expansion (pipe diameter can increase by up to 30–50%) without damage, and it can largely revert to its original size after thawing.

By comparison, PEX-B and PEX-C have limited expansion capabilities—while they can typically withstand freeze-thaw cycles that would crack copper or CPVC, expansion beyond 200% often leads to permanent bulges or stress points, which may affect integrity over the long term.

Therefore, in cold climates or unheated spaces, PEX-A’s freeze-resistant toughness is undoubtedly a major advantage.

| Performance Factor | PEX-A | PEX-B | PEX-C |

| Bending Radius | 5× pipe diameter | 6× pipe diameter | 6× pipe diameter |

| Kink Resistance | Excellent (recovers easily) | Good (may hold kinks) | Moderate (can crack) |

| Freeze Expansion | Up to 300% recovery | Up to 200% recovery | Up to 200% recovery |

| Shape Memory | Strong (returns to shape) | Moderate (some memory) | Limited (holds bends) |

Installation Implications

These differences in flexibility directly impact daily installation workflows:

- PEX-A: Can easily navigate through complex spaces and requires fewer support points;

- PEX-B: Typically needs additional supports to maintain the intended route;

- PEX-C: Requires careful handling to avoid material stress from overly tight bends.

For renovation projects that require running pipes through existing walls, PEX-A’s flexibility often saves significant installation time, making its higher cost justifiable.

Key Applications: Oxygen-Barrier vs. Non-Barrier PEX

In addition to PEX-A, PEX-B, and PEX-C (classified by cross-linking method), PEX pipes can also be divided into “oxygen-barrier” and “non-barrier” categories based on whether they have oxygen-blocking functionality—the former is critical for closed-loop heating systems, while the latter is better suited for potable water scenarios, with distinctly different uses.

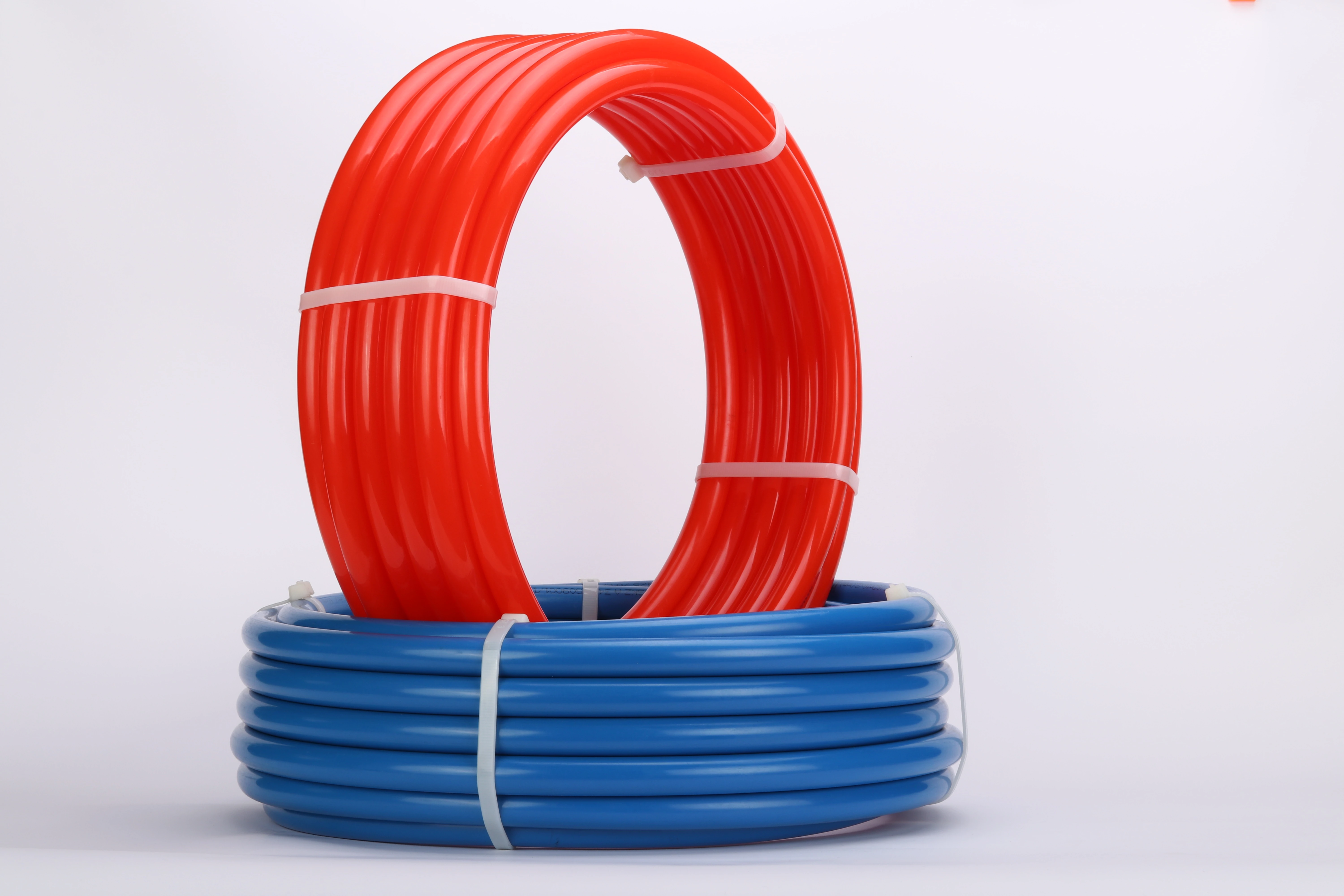

Oxygen-barrier PEX (usually red or blue, with an additional barrier layer) prevents oxygen from seeping into closed-loop heating systems, thereby protecting metal components from corrosion; in contrast, non-barrier PEX (mostly white) is specifically designed for potable water plumbing, where oxygen permeability is not a concern. It is particularly important to note that using the wrong type can cause serious system damage, especially in heating applications.

Oxygen-Barrier PEX: For Closed-Loop Systems

Oxygen-barrier PEX (often labeled as PEX-AL-PEX or EVOH PEX) contains an additional barrier layer (usually ethylene-vinyl alcohol copolymer) that blocks oxygen molecules from penetrating the pipe wall. It is essential in the following scenarios:

- Radiant floor heating systems;

- Snow melt systems;

- Hydronic heating distribution pipes;

- Solar thermal systems;

- All closed-loop systems with metal components (e.g., boilers, pumps, valves).

This is because oxygen infiltration in these systems causes rapid corrosion of metal components, which can ultimately damage expensive equipment and render the system inoperable due to clogging from impurities.

Non-Barrier PEX: For Potable Water

Standard non-barrier PEX is suitable for the following open scenarios:

- Potable water supply pipes;

- Fixture connection pipes;

- Main water supply pipes;

- Municipal water distribution networks.

In these open systems, water is regularly refreshed, so oxygen permeability is not an issue—water naturally contains dissolved oxygen, and no additional barrier is needed.

| Application | Recommended Type | Key Consideration | Consequences of Wrong Choice |

| Radiant Heating | Oxygen-barrier only | Protects metal components | Corrosion and system failure |

| Potable Water | Non-barrier preferred | Cost-effectiveness | None (no harm, just unnecessary cost) |

| Snow Melt Systems | Oxygen-barrier required | Closed-loop operation | Equipment damage |

| Main Water Supply | Non-barrier preferred | No oxygen concerns | Unnecessary expense |

Identification Tips

To avoid misuse, the two types of PEX can be distinguished by the following characteristics:

- Oxygen-barrier PEX: Mostly red or blue, labeled “Oxygen Barrier,” slightly stiffer due to the barrier layer, and more expensive;

- Non-barrier PEX: Usually white, red, or blue, no special labeling, more flexible, and lower in cost.

Therefore, non-barrier PEX must never be used in heating systems—always verify that the specifications match the application scenario before installation.

How to Select the Right PEX Type for Your Project

After understanding the different types of PEX pipes and their characteristics, the next step is to select the most suitable type based on specific project requirements. The core of selection lies in comprehensively evaluating project requirements, installation conditions, budget constraints, and long-term performance expectations.

Specifically, if a project requires extreme flexibility, superior freeze resistance, or uses expansion connections, PEX-A should be selected; if it is a cost-sensitive, standard plumbing project using crimp connections, PEX-B is the ideal choice; if the application scenario demands high chemical stability, PEX-C can be considered; additionally, regardless of the type selected, oxygen-barrier PEX must be used for closed-loop heating systems.

Since there is no “one-size-fits-all PEX” suitable for all plumbing scenarios, analysis must be conducted on a project-by-project basis:

Project Type & Installation Conditions

- New Construction (Open Walls):

At this stage, pipe routing is relatively straightforward, and PEX-B usually offers the best cost-effectiveness—straight paths minimize reliance on flexibility, and crimp connections are highly efficient in open spaces.

- Proyectos de renovación y modernización:

Unlike new construction, these projects require running pipes through existing structures, and PEX-A’s flexibility simplifies the pipe-running process; meanwhile, expansion connections perform better in tight spaces—although its cost is higher, the time saved in installation often offsets this expense.

- Extreme Climate Applications:

In frigid regions, PEX-A’s freeze resistance is a worthwhile investment; if environmental conditions are more severe, PEX-AL-PEX (aluminum-plastic composite PEX) can also be considered to enhance durability.

Connection Method Compatibility

The connection system you choose will also significantly impact the selection of PEX type:

- Expansion Systems:

These require pipes to have strong rebound capabilities, so they are best matched with PEX-A; although dedicated tools are required, they provide extremely high connection reliability.

- Crimp Systems:

These have the broadest compatibility and are suitable for all PEX types; they are the lowest-cost option for small construction teams, and accessories are easily accessible.

- Clamp Systems:

These are also suitable for all PEX types and allow visual inspection to confirm connection quality, with costs similar to crimp systems.

| Project Scenario | Recommended PEX Type | Método de conexión | Consideraciones clave |

| Production Homebuilding | PEX-B | Crimp | Cost efficiency, reliability |

| Custom Luxury Homes | PEX-A | Expansion | Performance, flexibility |

| DIY Plumbing Repairs | PEX-B | Crimp/Clamp | Ease of use, tool cost |

| Radiant Heating | PEX-A/PEX-B (oxygen-barrier) | Any compatible | Must have oxygen barrier |

| Retrofit Plumbing | PEX-A | Expansion | Flexibility for existing walls |

Budget & Long-Term Value

While initial cost is an important consideration, greater emphasis should be placed on the total lifecycle value of the project:

- PEX-A:

It is 20–40% more expensive than PEX-B, but its long-term value is reflected in: reduced installation time, fewer connection failures, stronger freeze protection, and easier subsequent modifications—these advantages often yield higher returns.

- PEX-B:

It offers outstanding cost-effectiveness in scenarios where: budgets are limited, installation conditions are favorable (e.g., open spaces), and freeze damage risk is low, meeting standard requirements at a lower cost.

- PEX-C:

Its price varies by region and manufacturer, typically falling between PEX-A and PEX-B; its uniform cross-linking structure gives it unique value in scenarios requiring stable chemical resistance, and whether it is worth investing in can be evaluated based on specific needs.

Conclusión

Based on the comprehensive analysis of PEX pipe types above, PEX-A, PEX-B, and PEX-C each have distinct advantages and are suitable for different scenarios: PEX-A performs best in terms of flexibility, freeze resistance, and compatibility with expansion connections, making it ideal for complex installations and frigid environments; PEX-B strikes a balance between cost and performance, serving as a cost-effective choice for standard plumbing projects; PEX-C excels in uniform cross-linking structure, making it suitable for scenarios with special chemical stability requirements.

Additionally, the distinction between oxygen-barrier and non-barrier types is equally critical: barrier-type PEX must be used for heating systems, while non-barrier-type PEX is preferred for potable water systems. Therefore, only by matching the PEX type to the specific needs of the project can the optimal balance be achieved between performance, reliability, and value.

For detailed step-by-step guidance on PEX installation, refer to our guide: PEX Pipe Installation Best Practices; to compare the pros and cons of PEX with traditional materials, read: PEX vs Copper Piping: Pros & Cons.

Comentarios recientes