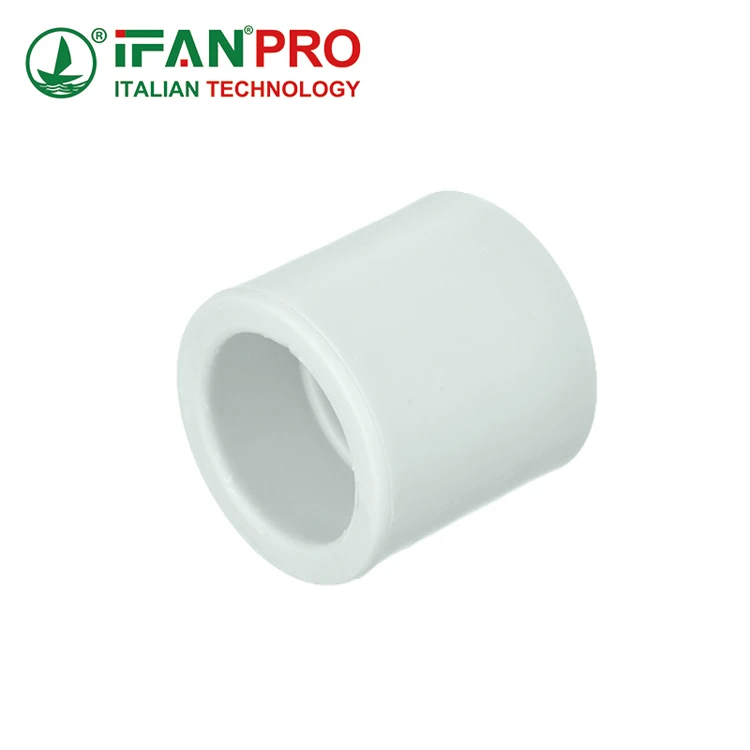

Why Choose Factory Direct PPR Fitting Sockets?

Factory direct purchasing eliminates middleman costs. You get premium PPR fitting sockets at wholesale prices. Our manufacturing facility produces over 50,000 units monthly. Quality control happens at every production stage.

Understanding PPR Fitting Socket Quality Standards

High-quality PPR sockets use virgin polypropylene raw materials. The fusion welding creates permanent, leak-proof connections. Our sockets withstand temperatures up to 95°C continuously. Pressure ratings reach 25 bar for residential applications.

Material Composition Matters

Virgin PPR material ensures longevity. Recycled plastics compromise structural integrity. Our factory sources premium-grade polypropylene exclusively. Each batch undergoes rigorous testing before production.

Manufacturing Process Excellence

Precision Injection Molding

State-of-the-art machinery shapes each socket. Temperature control maintains consistent wall thickness. Cooling systems prevent internal stress formation. Quality inspectors check dimensional accuracy.

Surface Finish Standards

Smooth interior surfaces reduce friction loss. Uniform wall thickness prevents weak points. Professional-grade tools create precise threading. Each socket meets international ISO standards.

Product Range and Specifications

Our PPR fitting socket collection includes:

Standard Sizes Available:

- 20mm to 110mm diameter range

- Male and female threading options

- Reducer sockets for size transitions

- Elbow sockets for directional changes

Technical Specifications:

- Working pressure: 16-25 bar

- Temperature range: 0°C to 95°C

- Fusion welding compatibility

- Corrosion-resistant properties

Installation Benefits

PPR sockets install faster than traditional fittings. Heat fusion creates seamless joints. No additional sealing materials required. Professional plumbers prefer our quick-connect design.

Welding Process Simplified

Heat the pipe and socket simultaneously. Insert when both surfaces become molten. Hold steady for cooling period. The bond becomes stronger than original pipe.

Cost Advantages of Factory Direct Purchasing

Wholesale pricing starts at bulk orders. No distributor markups inflate costs. Direct shipping reduces delivery time. Custom specifications available without premium charges.

Volume Discounts Available

Orders over 1,000 pieces qualify for tier pricing. Bulk packaging reduces unit costs further. Long-term contracts secure better rates. Express manufacturing for urgent projects.

Quality Assurance Guarantee

Every socket undergoes pressure testing. Dimensional accuracy verified with precision tools. Material composition certified by third-party labs. ISO 9001 certification ensures consistent quality.

Testing Protocols

Hydrostatic pressure testing at 150% working pressure. Thermal cycling tests simulate real-world conditions. Impact resistance testing prevents field failures. Chemical compatibility verified for various fluids.

Custom Manufacturing Services

Standard sizes don’t fit every application. Our engineering team designs custom solutions. Prototype development takes 7-10 days. Production scaling happens rapidly after approval.

Design Capabilities

CAD modeling for complex geometries. 3D printing for prototype validation. Material selection guidance provided. Engineering support throughout development process.

Global Shipping and Support

Worldwide delivery from our Chinese facility. Sea freight for large orders reduces costs. Air express for urgent requirements. Local technical support in major markets.

Packaging Standards

Protective foam prevents shipping damage. Individual wrapping for premium products. Bulk packaging for construction projects. Custom labeling available upon request.

Why Choose Our Factory

30 Years Manufacturing Experience: Continuous improvement drives innovation. Experienced engineers solve complex challenges. Modern equipment ensures consistent quality.

Competitive Pricing Structure: Factory direct eliminates extra costs. Bulk production reduces per-unit pricing. Long-term partnerships create mutual benefits.

Technical Support Team: Engineering assistance for specifications. Installation guidance provided freely. After-sales support ensures satisfaction.

Environmental Commitment

PPR materials are 100% recyclable. Our factory follows environmental protocols. Energy-efficient production reduces carbon footprint. Waste reduction programs minimize environmental impact.

Contact Information for Orders

Ready to order high-quality PPR fitting sockets? Contact our sales team directly. Technical specifications available upon request. Sample orders ship within 48 hours.

Factory Direct Benefits:

- Wholesale pricing guaranteed

- Custom manufacturing available

- Quality assurance included

- Global shipping supported

Transform your plumbing projects with premium PPR fitting sockets. Factory direct purchasing ensures optimal value and performance.

Comentarios recientes