1. Introduction: The Dominance of PPR Fittings in European Plumbing Systems

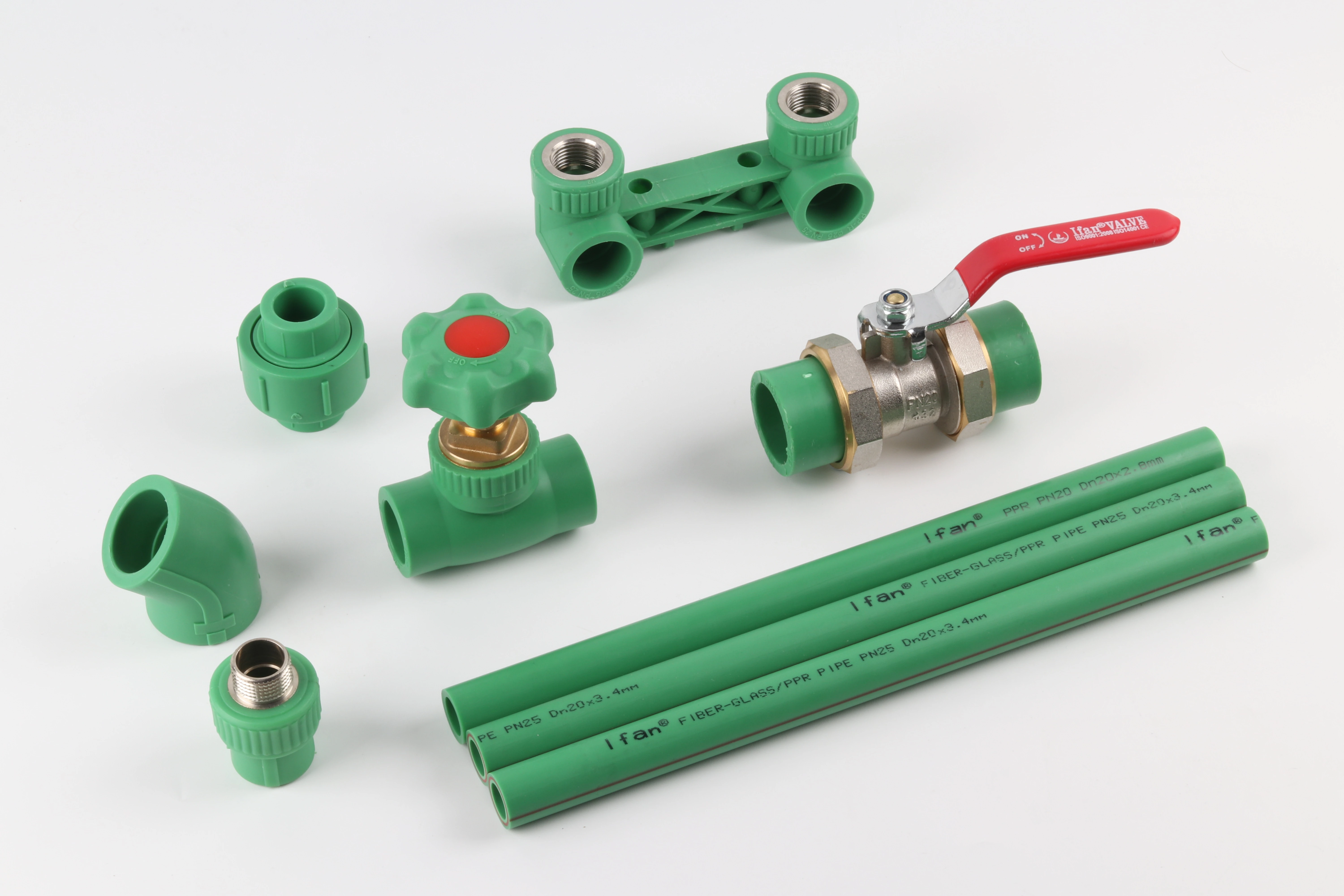

PPR (polypropylene random) fittings have become the gold standard in European plumbing and heating systems, valued for their durability, chemical resistance, and thermal stability. In Europe, strict regulatory standards and a focus on sustainability drive the design of PPR fittings to meet rigorous performance requirements. This article explores the key design features that make European PPR fittings stand out in global markets.

2. Material Standards: High-Grade PPR Raw Materials

European PPR fittings are typically manufactured from premium-grade PPR materials (e.g., PPR CT1, CT2, CT3.1) that comply with standards like DIN 8077/8078 and ISO 15874. Key design considerations include:

- Molecular Structure: Optimized random copolymerization for enhanced heat resistance (up to 95°C for long-term use).

- Virgin Material Purity: Minimal recycled content to ensure consistency in pressure resistance and lifespan.

- UV Stabilization: Added additives in outdoor-rated fittings to prevent degradation from sunlight exposure (e.g., for solar heating systems).

3. Pressure and Temperature Resistance: Engineered for Stringent European Climates

European PPR fittings are designed to withstand diverse climatic conditions, with features such as:

- Pressure Classifications: Standardized as PN10, PN16, and PN20 to match high-pressure municipal water systems and heating networks.

- Thermal Expansion Management: Contoured designs that minimize stress from temperature fluctuations (common in radiant floor heating applications).

- Hydrostatic Testing: Compliance with EN 12201, ensuring fittings maintain integrity under prolonged pressure cycles.

4. Connection Systems: Precision Engineering for Leak-Proof Installations

European PPR fitting designs prioritize ease of installation and reliability:

- Heat Fusion Compatibility: Universally compatible with socket fusion, electrofusion, and butt fusion techniques, adhering to EN 15875.

- Integral Sealing Rings: In press-fit fittings (e.g., compression-type connections), O-rings are designed for zero-leakage under pressure.

- Threaded Inserts: Brass or stainless steel inserts for metal pipe connections, treated with anti-corrosive coatings (e.g., nickel plating) to prevent galvanic corrosion.

5. Dimension and Compatibility Standards: Harmonized with European Pipe Systems

To ensure interoperability, European PPR fittings follow strict dimensional norms:

- Nominal Diameters (DN): Standardized from DN15 to DN110, matching EN 10220 for pipe 外径 (OD) and wall thickness.

- Metric Threading: Compliance with ISO 7-1 (tapered threads) and ISO 228-1 (parallel threads) for seamless integration with valves and fixtures.

- Compression Fitting Tolerances: Tight manufacturing tolerances to prevent play or misalignment during installation.

6. Anti-UV and Anti-Oxidation Design: Extended Outdoor Performance

For outdoor applications (e.g., irrigation or solar systems), European fittings feature:

- Carbon Black Additives: 2.5% minimum concentration in PPR pipes and fittings to block UV radiation (EN 13476-2).

- Oxidation Inhibitors: Long-life stabilizers that protect against thermal degradation in high-temperature systems.

7. Environmental and Safety Certifications: Meeting EU Green Standards

Sustainability is central to European design, with features like:

- Reciclabilidad: Monomaterial construction to facilitate easy recycling at end-of-life.

- Lead-Free Compliance: Conformity with EU Directive 2014/28/EU for potable water systems, ensuring no hazardous leaching.

- CE Marking: Mandatory certification under EN 12201, verifying compliance with health, safety, and environmental requirements.

8. Ergonomic and Installation-Friendly Design

European PPR fittings prioritize installer efficiency:

- Anti-Slip Textures: Molded grips on fittings for easier hand tightening during temporary installations.

- Visual Alignment Marks: Indicator lines on socket fittings to ensure proper insertion depth during fusion.

- Compact Geometry: Reduced overall size for space-constrained installations (common in European residential buildings).

9. Resistance to Chemicals and Scale Build-Up

Design features to combat water quality issues:

- Smooth Internal Surface: Ra ≤ 0.8μm finish to minimize sediment accumulation and bacterial growth.

- pH Neutrality: Inert PPR material that does not react with acidic or alkaline water, adhering to EN 1452-2.

10. Innovations in European PPR Fitting Design

Cutting-edge trends include:

- Smart Fittings: Integral RFID tags for inventory management and installation tracking.

- Multi-Layer Composite Designs: PPR-AL-PPR structures for enhanced oxygen barrier properties in heating systems (EN 15875).

- Quick-Connect Systems: Push-fit fittings with audible clicks for rapid installations in renovation projects.

11. How European Design Features Benefit Global Applications

The rigorous standards of European PPR fittings make them ideal for:

- High-Rise Buildings: Pressure-resistant designs for vertical plumbing systems.

- Renewable Energy Projects: Compatibility with solar thermal and geothermal heating networks.

- Potable Water Distribution: Compliance with strict health standards for safe drinking water systems.

Conclusion: Why European PPR Fitting Design Sets the Benchmark

European PPR fittings combine technical excellence, regulatory compliance, and sustainability to meet the most demanding plumbing needs. For manufacturers and buyers seeking reliable, high-performance solutions, understanding these design features is crucial. At ifanpro.com, our PPR fittings are engineered with European standards in mind, offering custom solutions that align with global market requirements. Contact us to explore fittings that blend innovation, durability, and regulatory compliance.

Comentarios recientes