Understanding the Importance of Maintenance

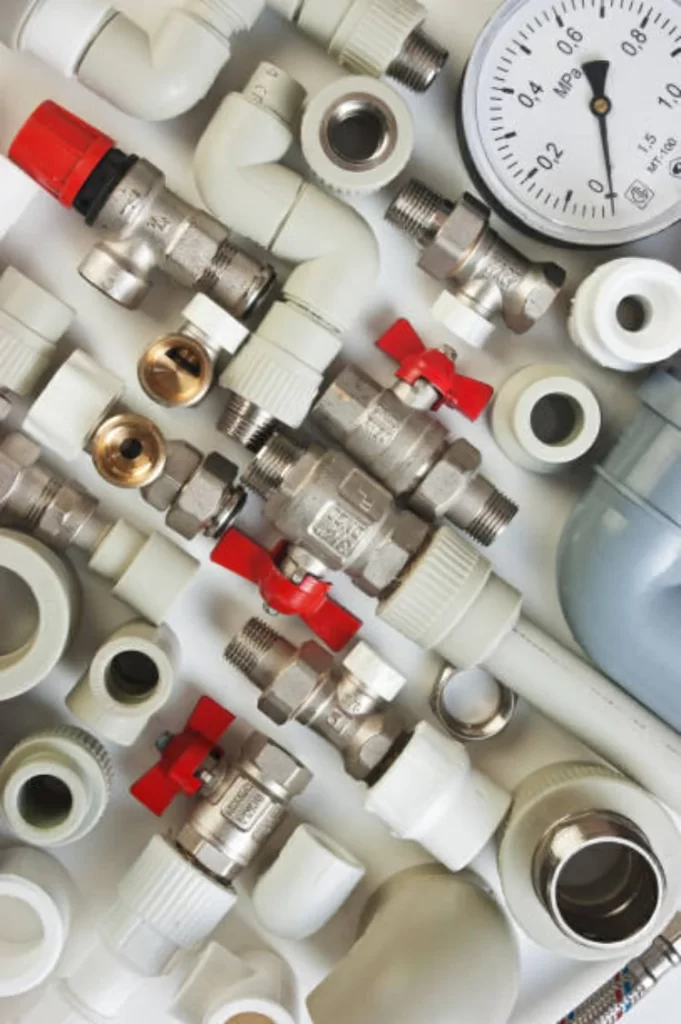

Proper maintenance of brass stop valves is crucial to ensure their longevity, optimal performance, and reliability in plumbing systems. Regular maintenance helps prevent issues such as leaks, corrosion, and malfunctions, thereby extending the lifespan of the valves and minimizing the need for costly repairs or replacements.

Inspection and Cleaning

Regular Inspection

Performing routine inspections of brass stop valves is essential to identify any signs of wear, damage, or deterioration. Inspect the valves for leaks, corrosion, or mineral deposits that may affect their functionality. Check the valve’s handle, stem, packing nut, and body for any visible signs of damage or irregularities. Additionally, ensure that the valve operates smoothly and without any resistance or sticking.

Cleaning Procedures

Cleaning brass stop valves periodically can help remove accumulated dirt, debris, or mineral deposits that may impede their performance. Start by shutting off the water supply to the valve and relieving any pressure in the system. Use a soft cloth or brush and a mild detergent solution to clean the exterior surfaces of the valve, including the handle, stem, and body. Avoid using abrasive cleaners or harsh chemicals that may damage the valve’s finish or components. Rinse the valve thoroughly with clean water and dry it with a soft towel before reassembling and returning it to service.

Preventive Maintenance Measures

Greasing and Lubrication

Applying a small amount of lubricant or silicone grease to the moving parts of brass stop valves can help reduce friction, prevent corrosion, and prolong their lifespan. Lubricate the valve’s stem, threads, and packing nut with a suitable lubricant to ensure smooth operation and prevent seizing or sticking.

Pruebas de presión

Periodically pressure testing brass stop valves can help identify any leaks or defects in the valve’s seals, gaskets, or components. Use a pressure testing kit to pressurize the valve and inspect it for any signs of leakage or pressure loss. Address any issues promptly to prevent further damage or malfunctions.

Conclusión

Proper maintenance of brass stop valves is essential for ensuring their reliability, longevity, and optimal performance in plumbing systems. By conducting regular inspections, cleaning procedures, and preventive maintenance measures, it is possible to prevent issues such as leaks, corrosion, and malfunctions, thereby maximizing the lifespan of brass stop valves and ensuring uninterrupted operation in plumbing systems. Investing time and effort in maintenance can ultimately save money and resources by avoiding costly repairs or replacements in the long run.

IFAN es un fabricante chino de tuberías, accesorios y válvulas de plástico con 30 años de experiencia. Si está interesado en IFAN accesorios de cobre, válvulas de cobre, tuberías y accesorios de plástico, póngase en contacto con nosotros. IFAN le ofrece una variedad de tuberías estándar para satisfacer sus necesidades específicas. Haga clic a continuación para obtener más información sobre la amplia gama de productos de válvulas y productos relacionados con sistemas de tuberías asequibles y rentables de IFAN.

Responderemos a su correo electrónico o fax en 24 horas.

Puede llamarnos en cualquier momento si tiene alguna duda sobre nuestra producción.

Para más información, visite nuestra página web https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Comentarios recientes