Introduction to Brass Stop Valves

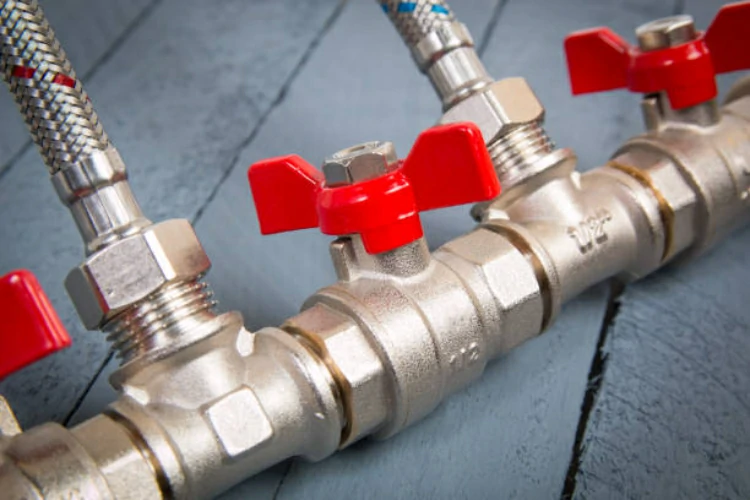

Brass stop valves are essential components in plumbing systems, providing a means to control the flow of water in pipes. They are commonly used in residential, commercial, and industrial settings to regulate water supply to specific fixtures or areas. Proper installation of brass stop valves is crucial to ensure optimal performance and longevity of the plumbing system.

Installation Steps for Brass Stop Valves

Pre-Installation Preparation

Before installing brass stop valves, it is essential to gather all the necessary tools and materials, including a wrench, pipe cutter, thread seal tape, and, of course, the brass stop valves themselves. Ensure that the water supply to the area where you will be working is shut off to prevent any accidents or water damage.

Cutting the Pipe

Using a pipe cutter, carefully cut the section of the pipe where you intend to install the brass stop valve. Make sure to measure and mark the precise location for the cut to ensure a proper fit. After cutting, use a deburring tool to remove any rough edges or burrs from the pipe to prevent damage to the valve or fittings.

Applying Thread Seal Tape

Wrap thread seal tape around the male threads of the pipe in a clockwise direction. This will help create a tight seal and prevent leaks once the brass stop valve is installed. Be sure to wrap the tape around the threads two to three times for optimal sealing.

Installing the Valve

Carefully thread the brass stop valve onto the pipe until it is snugly in place. Use a wrench to tighten the valve further, but be careful not to over-tighten, as this can damage the valve or fittings. Ensure that the valve is oriented correctly to allow for easy operation once installed.

Testing for Leaks

After installing the brass stop valve, restore the water supply and inspect the valve and fittings for any leaks. If you detect any leaks, proceed to carefully tighten the fittings further or apply additional thread seal tape as necessary until you resolve the leaks.

Safety Considerations and Tips

Always wear appropriate safety gear, such as gloves and eye protection, when working with plumbing tools and materials. *Be cautious when cutting pipes to avoid injury and ensure accurate cuts. *Double-check the orientation of the brass stop valve before tightening to prevent installation errors. *Test the valve thoroughly for leaks before completing the installation to avoid water damage and costly repairs.

Conclusión

Proper installation of brass stop valves is essential to ensure the reliable and efficient operation of plumbing systems. By following the steps outlined above and adhering to safety considerations, you can install brass stop valves with confidence, knowing that they will provide years of dependable service in your plumbing system.

IFAN es un fabricante chino de tuberías, accesorios y válvulas de plástico con 30 años de experiencia. Si está interesado en IFAN accesorios de cobre, válvulas de cobre, tuberías y accesorios de plástico, póngase en contacto con nosotros. IFAN le ofrece una variedad de tuberías estándar para satisfacer sus necesidades específicas. Haga clic a continuación para obtener más información sobre la amplia gama de productos de válvulas y productos relacionados con sistemas de tuberías asequibles y rentables de IFAN.

Responderemos a su correo electrónico o fax en 24 horas.

Puede llamarnos en cualquier momento si tiene alguna duda sobre nuestra producción.

Para más información, visite nuestra página web https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Comentarios recientes