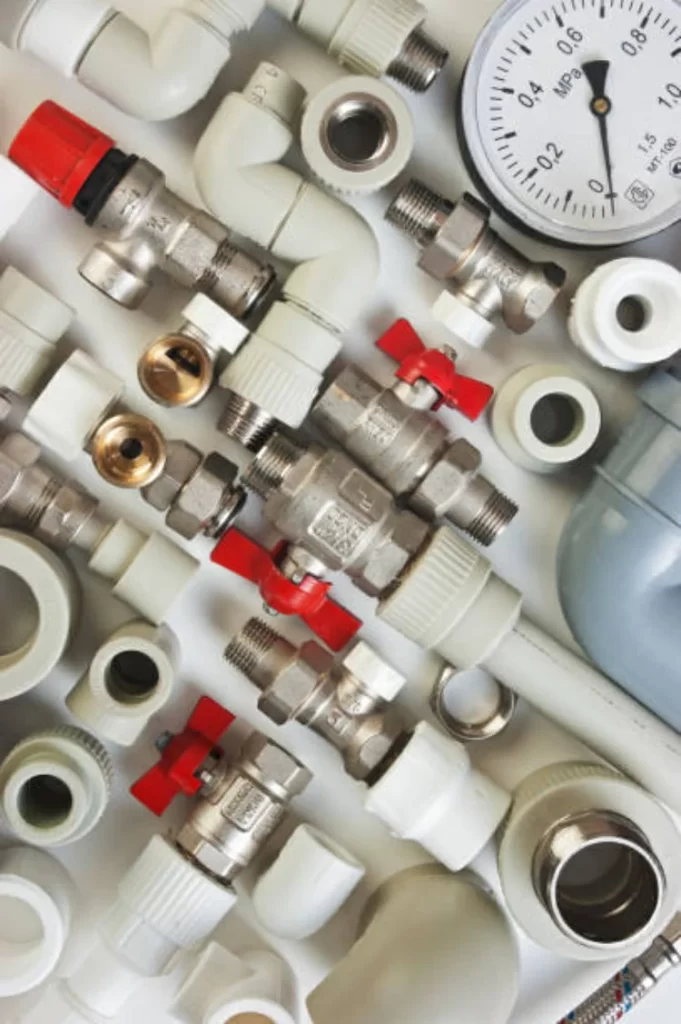

Guidelines for Installing Brass Ball Valves

Proper installation of brass ball valves is crucial to ensure optimal performance, longevity, and safety in fluid control systems. This section outlines the recommended methods and best practices for installing brass ball valves effectively.

Pre-Installation Preparation

Assessing System Requirements

Before installing brass ball valves, assess the specific requirements of the fluid control system, including flow rate, pressure rating, temperature range, and compatibility with the media being conveyed.

Selecting Suitable Valve Size and Type

Choose the appropriate size and type of brass ball valve based on the system specifications and application requirements. Ensure that the valve is compatible with the pipe size and material.

Inspecting Valve Components

Thoroughly inspect the brass ball valve components, including the body, ball, stem, seals, and handle, for any defects, damage, or debris. Clean the valve and remove any contaminants that may affect performance.

Installation Procedures

Positioning the Valve

Identify the desired location for installing the brass ball valve within the pipeline system. Ensure adequate access and clearance around the valve for operation and maintenance purposes.

Preparing the Pipeline

Prepare the pipeline by cutting and deburring the pipe ends to ensure smooth and clean surfaces. Use appropriate tools, such as pipe cutters and reamers, to achieve precise cuts and remove sharp edges.

Applying Thread Sealant

Apply a suitable thread sealant or tape to the male threads of the valve inlet and outlet connections. Ensure proper sealing to prevent leaks and achieve a secure connection between the valve and the pipeline.

Tightening Connections

Carefully thread the brass ball valve onto the pipeline connections, ensuring proper alignment and orientation. Use adjustable wrenches or pipe wrenches to tighten the valve connections firmly without over-torquing, which could damage the valve or fittings.

Checking for Leaks

After installation, thoroughly inspect the valve connections for any signs of leakage. Apply a pressure test, if necessary, to verify the integrity of the installation and ensure leak-free operation.

Safety Precautions

Handling Valves with Care

Handle brass ball valves with care during installation to avoid damaging the valve body, ball, or seals. Avoid dropping or impacting the valve, especially on hard surfaces.

Protecting Valve Components

Protect the valve components from exposure to contaminants, chemicals, or extreme temperatures that could compromise their integrity and performance. Store valves in a clean, dry environment before installation.

Following Manufacturer’s Instructions

Adhere to the manufacturer’s installation guidelines and recommendations provided with the brass ball valves. Follow specific instructions regarding torque values, sealing materials, and operational requirements for optimal performance and safety.

Заключение

Proper installation of brass ball valves is essential for ensuring efficient fluid control, preventing leaks, and prolonging the lifespan of the valve and pipeline system. By following the recommended methods and precautions outlined above, users can confidently install brass ball valves with precision, reliability, and safety in mind, achieving smooth and trouble-free operation in various industrial and commercial applications.

ИФАН является китайским производителем пластиковых труб, фитингов и клапанов с 30-летним опытом работы. Если вы заинтересованы в ИФАН медные фитинги, медные клапаны, пластиковые трубы и фитинги, пожалуйста, свяжитесь с нами. ИФАН предлагает вам разнообразные стандартные трубы для удовлетворения ваших конкретных потребностей. Нажмите ниже, чтобы узнать больше о широком ассортименте доступной и экономичной арматуры и сопутствующих товаров для трубопроводных систем от IFAN.

Мы ответим на ваше письмо или факс в течение 24 часов.

Вы можете позвонить нам в любое время, если у вас возникнут вопросы по нашей продукции.

Для получения дополнительной информации, пожалуйста, посетите наш веб-сайт https://ifanpro.com/

Отправить по почте: [email protected]

Whatsapp: + 86 19857948982

Последние комментарии