Product Name:HDPE Fittings

Size:20-110mm

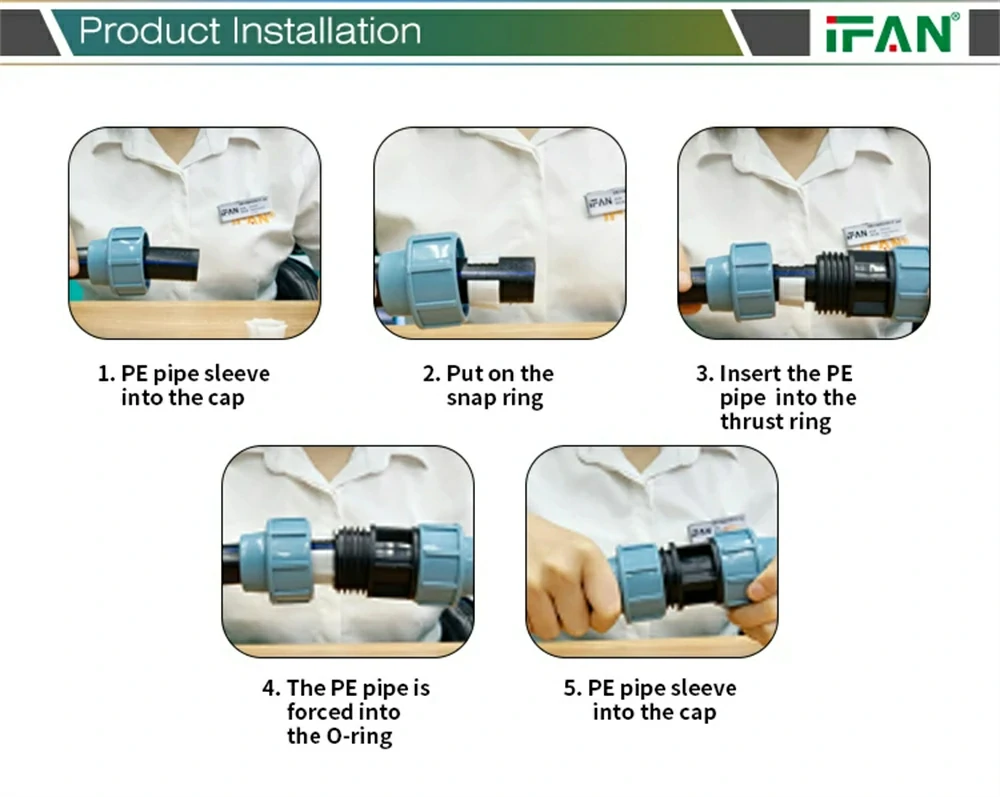

Standard:Quick connection, easy connection

Pressure:PN16

Feature:Quick connection, easy connection

OEM:Available

Packing:IFAN woven bag

Sample:Free (Contact us for a free sample)

Category HDPE

Tags HDPE fitting, hdpe pipe fitting, hdpe plumbing fitting

Prodcuts Description

Products Image

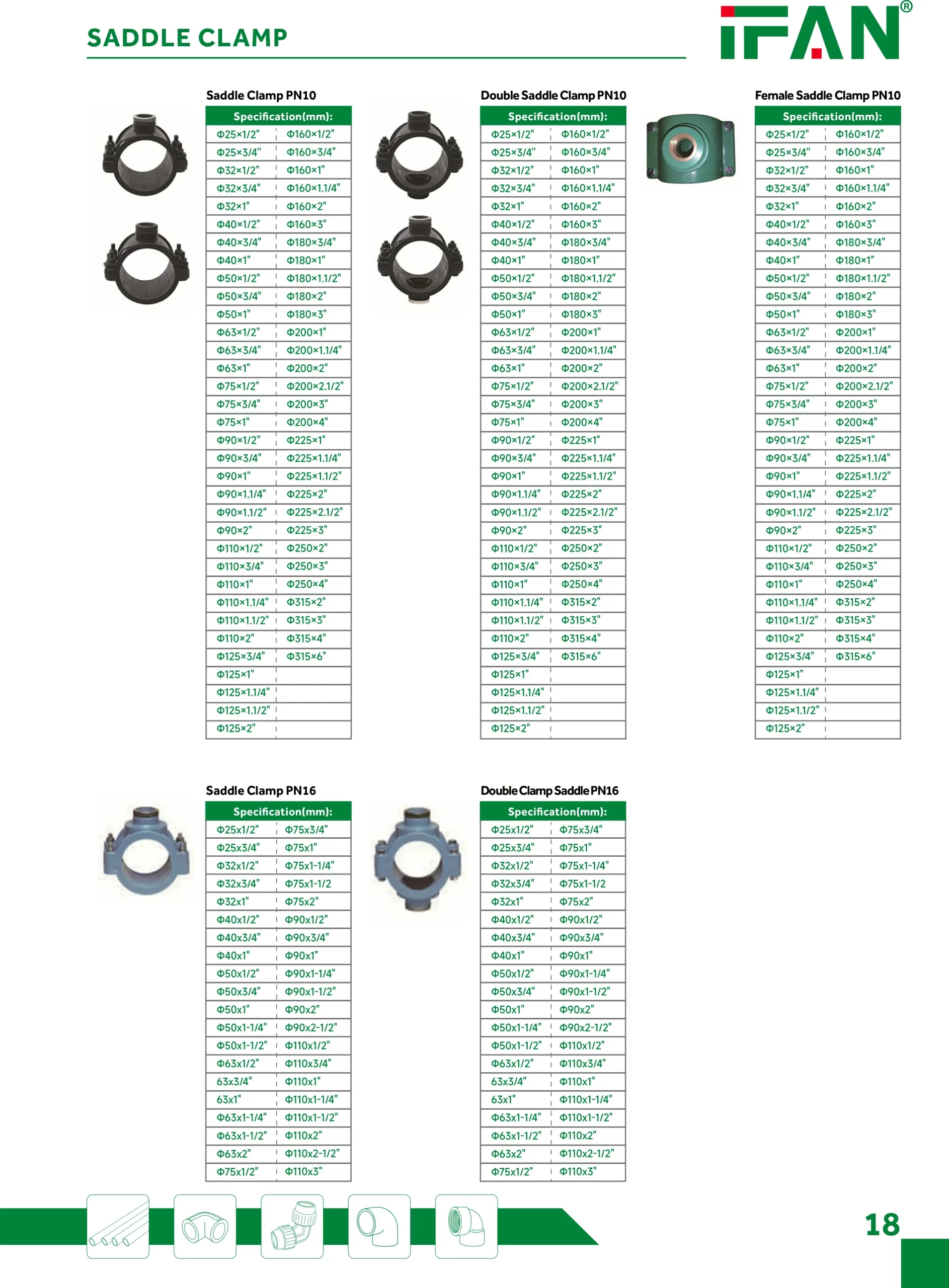

Products Charts

Reviews

Prodcuts Description

The Advantages and Applications of HDPE Fittings

Introduction to HDPE Fittings

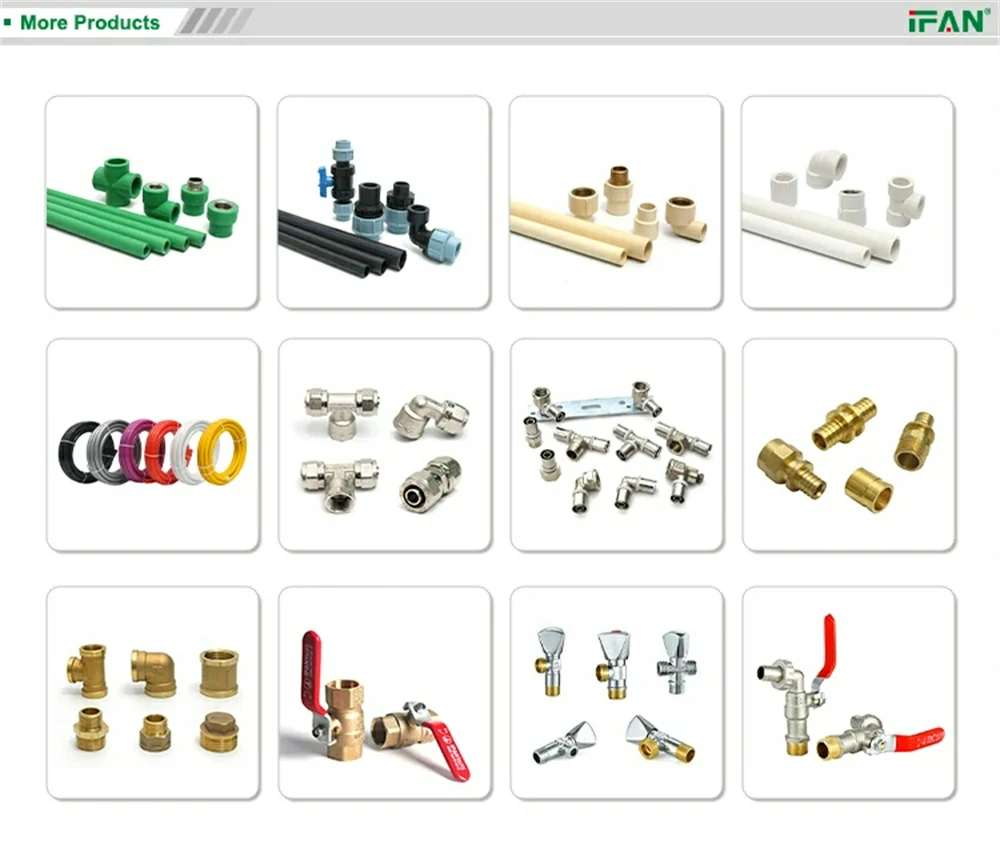

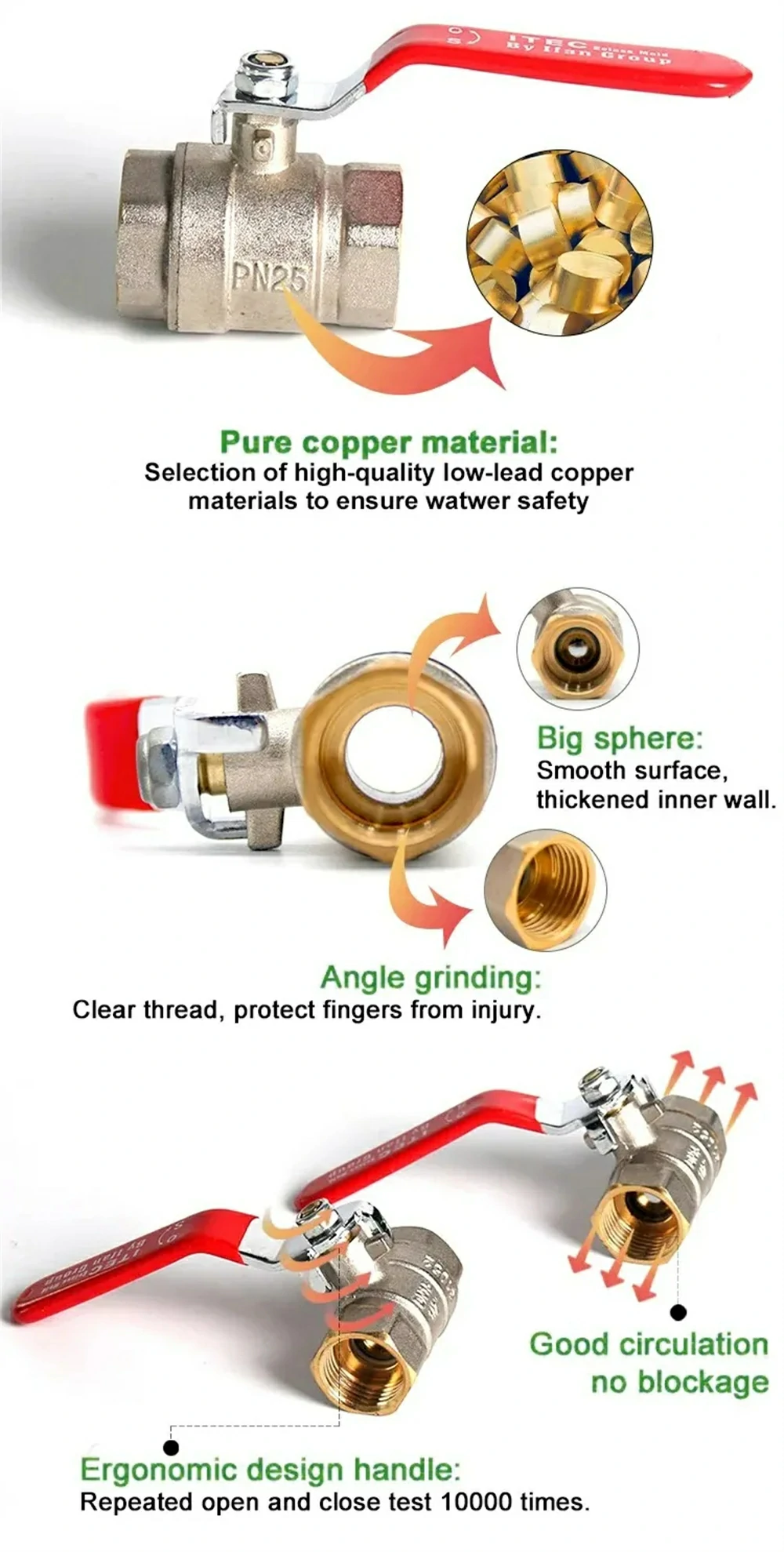

HDPE (High-Density Polyethylene) fittings are integral components in various industries due to their exceptional properties and versatility. Manufacturers produce these fittings from HDPE pipes, renowned for their high strength, durability, and resistance to corrosion. This article explores the advantages and diverse applications of HDPE fitting in modern engineering projects.Advantages of HDPE Fittings

Superior Durability and Strength

HDPE fitting are renowned for their exceptional durability and strength, making them ideal for demanding applications. Unlike traditional materials such as metal, HDPE does not corrode or degrade over time when exposed to chemicals or harsh environmental conditions. This longevity ensures that HDPE fittings have a prolonged service life, reducing maintenance costs and downtime significantly.Flexibility and Ease of Installation

One of the standout features of HDPE fitting is their flexibility, both literally and figuratively. HDPE fittings can be easily molded to suit various configurations, allowing for seamless integration into complex piping systems. This flexibility not only simplifies installation but also minimizes the need for additional connectors or fittings, thereby reducing potential leak points and enhancing system reliability.Chemical Resistance

HDPE fittings exhibit excellent resistance to a wide range of chemicals, including acids, bases, and other corrosive substances. This property makes them suitable for applications where resistance to chemical attack is crucial, such as in industrial plants, wastewater treatment facilities, and chemical processing industries. The inert nature of HDPE ensures that there is no risk of contamination to the conveyed fluid or surrounding environment.Environmental Sustainability

In today’s environmentally conscious world, HDPE fitting are preferred for their eco-friendly attributes. HDPE is a recyclable material, and its production requires less energy compared to other plastics and metals. Moreover, HDPE fittings can contribute to sustainable construction practices by promoting water conservation and reducing carbon footprint throughout their lifecycle.Applications of HDPE Fittings

Water Supply and Distribution

HDPE fittings are extensively used in water supply and distribution systems due to their resistance to corrosion. Their smooth internal surface ensures optimal flow characteristics. Municipalities and utility companies rely on HDPE fitting for potable water transmission, irrigation, and wastewater management. In these applications, reliability and longevity are paramount.

Mining and Industrial Applications

In mining operations and industrial environments, HDPE fitting are selected for their durability and capacity to endure abrasive materials and challenging conditions. These fittings are utilized in slurry lines, facilities for chemical processing, and systems for mine dewatering. They provide efficient and reliable performance under challenging conditions.

Gas Distribution

The natural gas industry favors HDPE fitting for gas distribution pipelines due to their leak-free joints and resistance to slow crack growth. These fittings ensure the safe and efficient transport of natural gas from production sites to residential and commercial consumers. Additionally, HDPE fittings adhere to stringent safety standards and regulations.

Landfill and Geothermal Applications

HDPE fittings are crucial in landfill liners and caps, providing impermeable barriers to prevent leachate contamination and methane emissions. They also play a role in geothermal heating and cooling systems, efficiently exchanging thermal energy between the ground and buildings. This enhances energy efficiency and promotes sustainability.

Conclusion

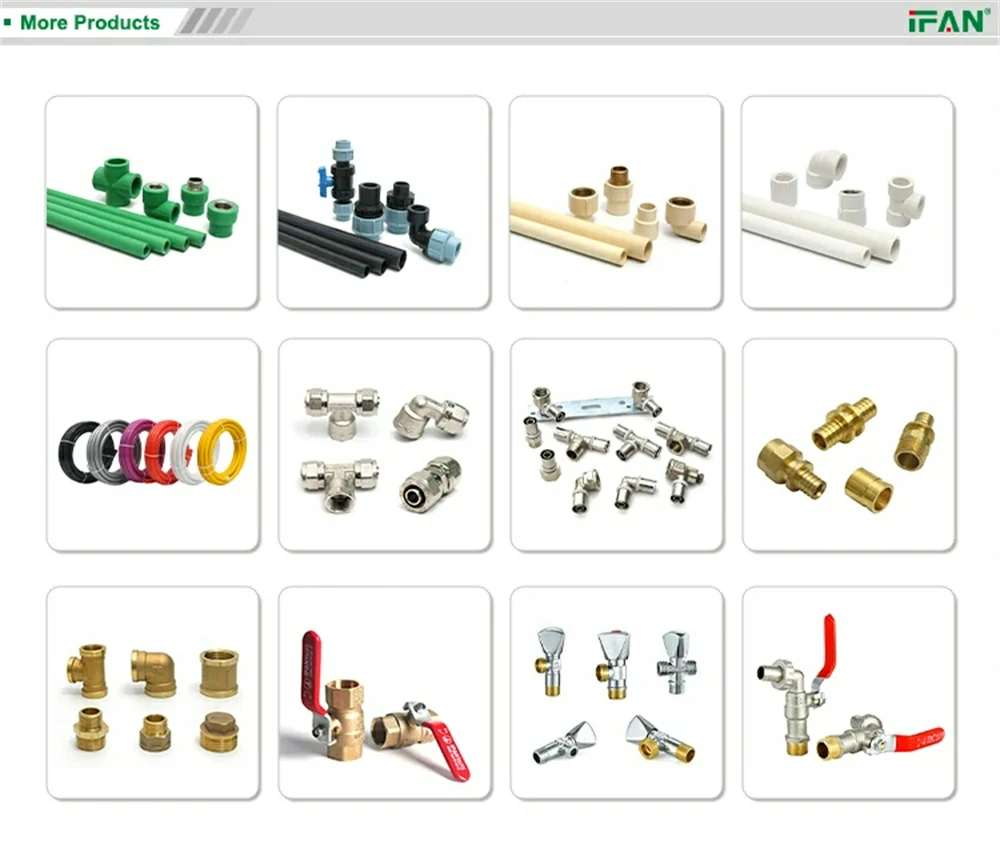

HDPE fittings stand out as reliable, durable, and versatile components essential for a wide array of applications across various industries. Their superior characteristics, including strength, chemical resistance, and environmental sustainability, make them the preferred choice for modern engineering projects. Whether in water supply networks, industrial applications, or environmental projects, HDPE fitting continue to demonstrate their value in enhancing efficiency, reducing costs, and ensuring long-term performance.Contact

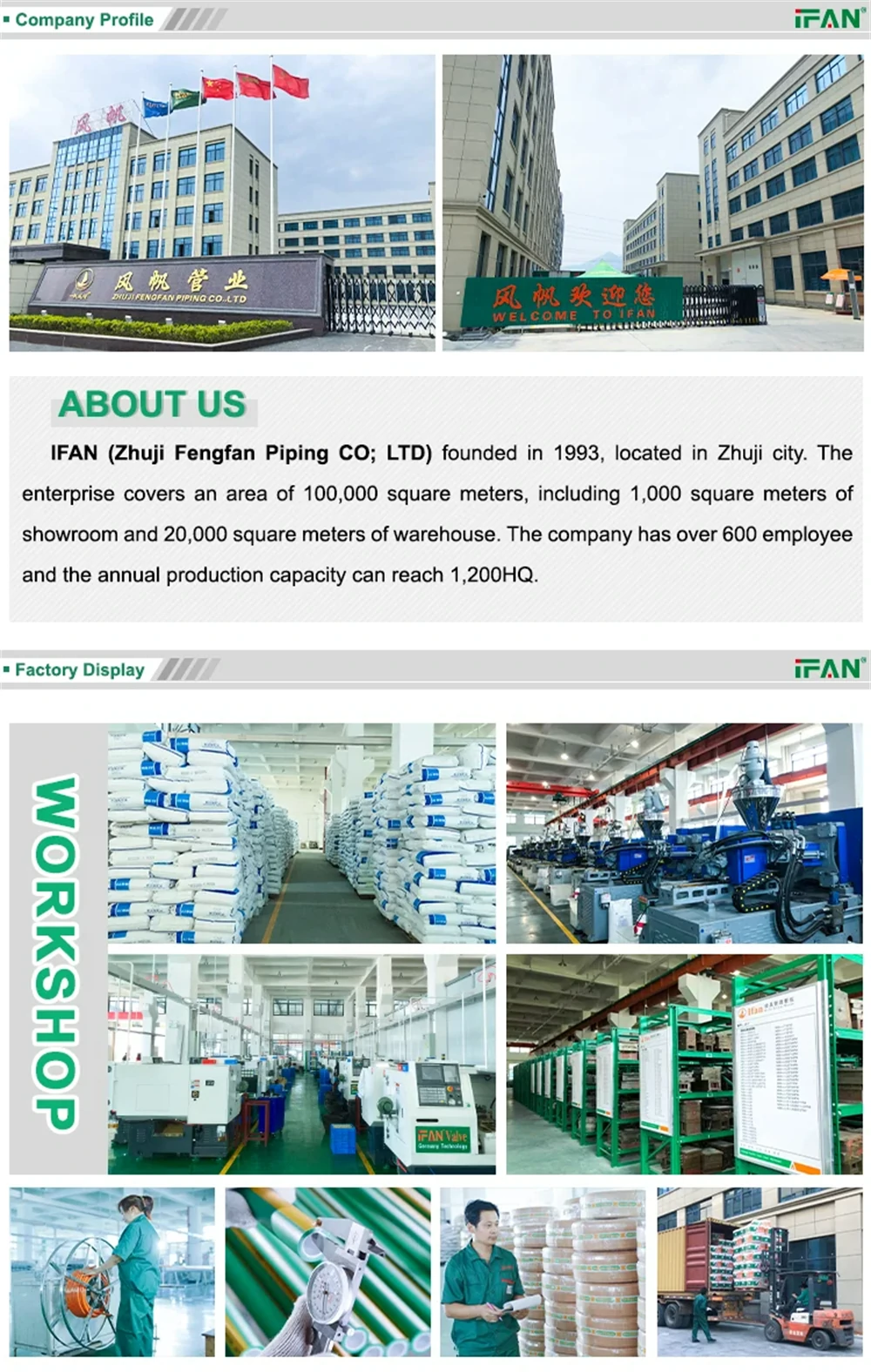

With 30 years of experience, IFAN is a specialist manufacturer specializing in the production of high quality plastic fittings, fittings and valves. Our products cover copper valves, PPR valves and various fitting and fittingxs to meet different customer needs. No matter what your needs are for plumbing or valves, IFAN offers a wide range of cost-effective products to support your project. Below is our contact information, this is our Whatsapp: + 86 19857948982,Email:[email protected]

Products Image

Products Charts

Reviews

0