Media

Home » Media

30 years of brand history

100+ agents worldwide

German process equipment

Ten series of one-stop procurement

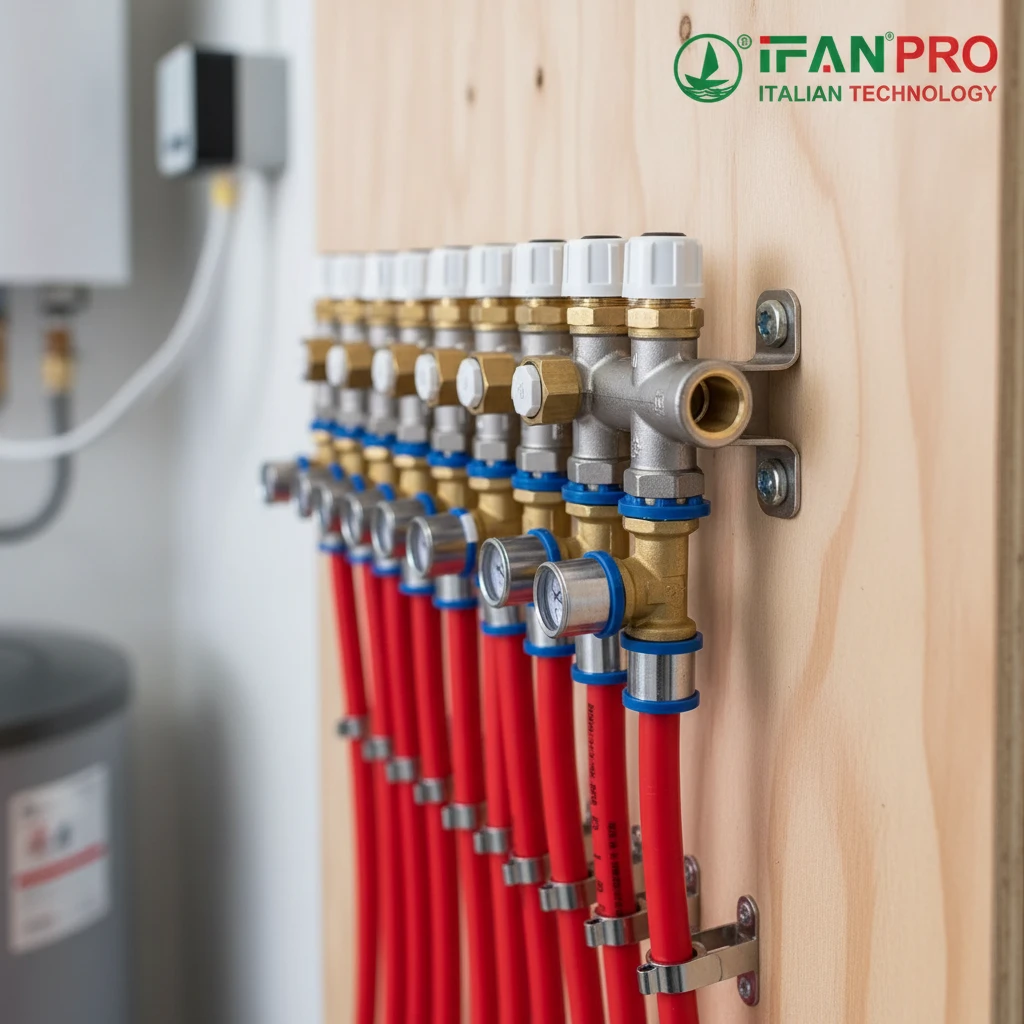

Why Are Union Elbows Used in PEX Radiant Heating Systems?

I once saw a technician spend hours dismantling an entire manifold to fix one small leak. That moment perfectly illustrated why the right fitting is

How Does the Union Mechanism Work with PEX Crimp or Clamp Rings?

I recently helped a contractor who was stuck because his pipes didn’t align. A simple swivel union solved his problem, but only because he used

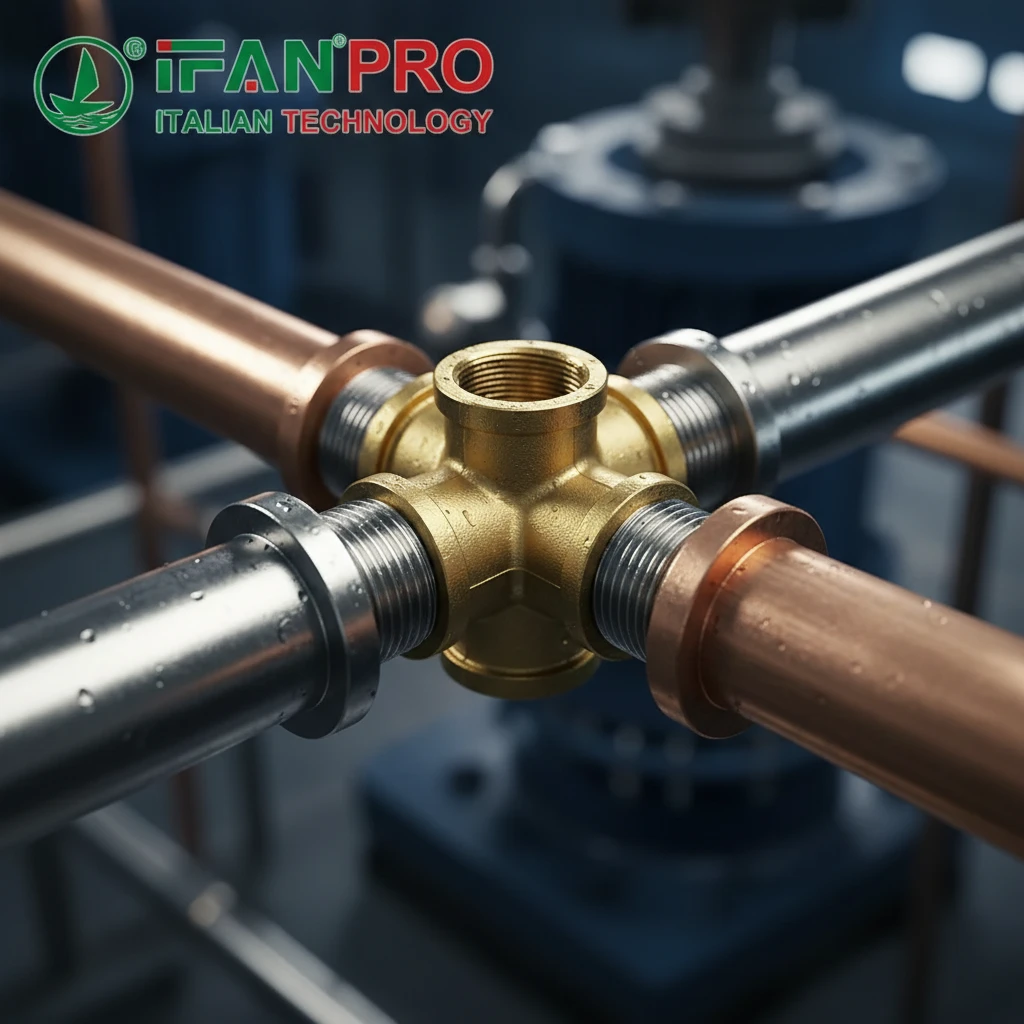

How to Install a Brass Cross Fitting for Four-Way Pipe Connections?

I once saw a plumbing system fail because a cross fitting was installed in the wrong order. The resulting leak and misalignment caused days of

Why Choose a Brass Cross for Distributing Fluid in Complex Systems?

I once faced a tangled mess of pipes and tees that made repairs a nightmare. This experience taught me the true value of a simple,

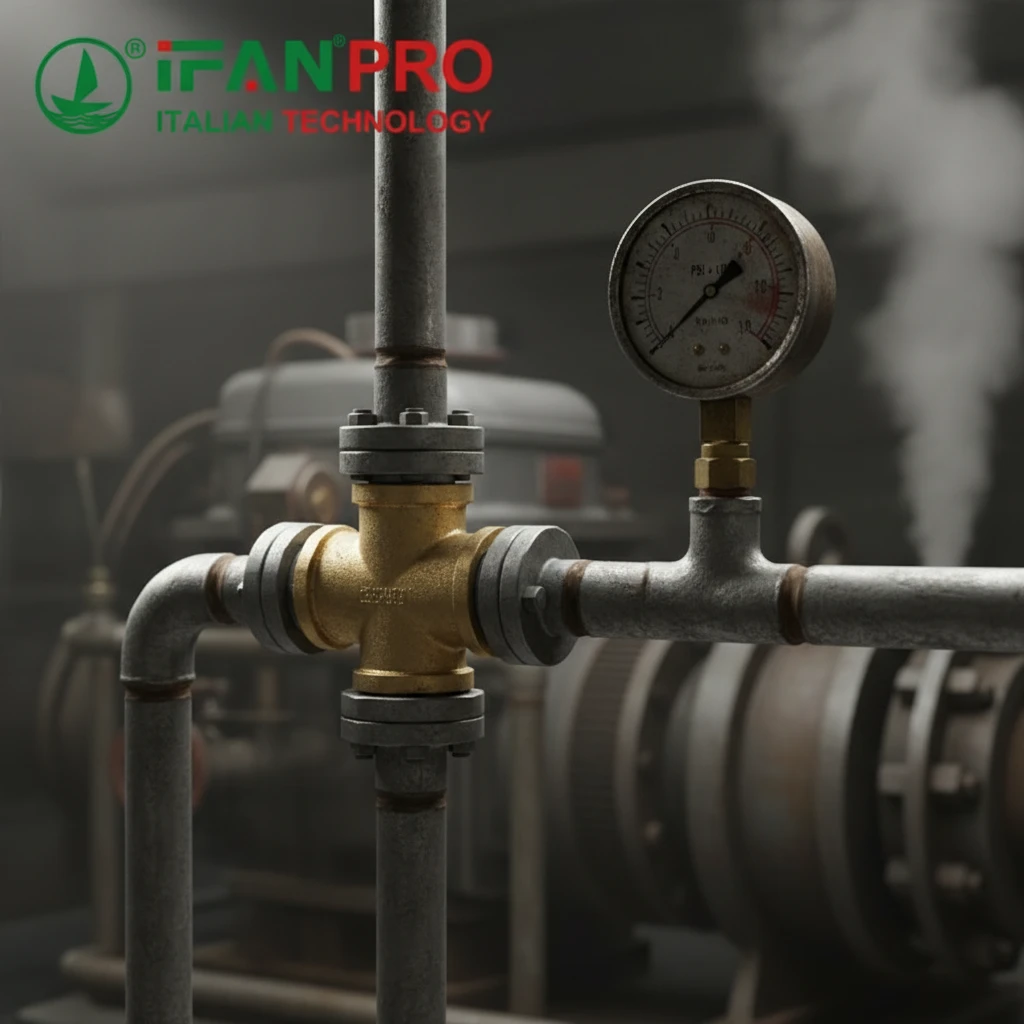

Can a Brass Cross Fitting Handle High Pressure from All Four Ports?

I once saw a project delayed because a cross fitting failed under unexpected pressure surge. This moment made me deeply analyze what it truly takes

Are Brass Cross Fittings Suitable for Heating and Cooling Manifolds?

I recently visited a site where a poorly chosen manifold fitting failed, causing a costly system shutdown. This moment cemented my belief in selecting the

How Does a Cross Fitting Compare to Two Tees in a System?

I once saw a cramped piping manifold fail because of too many leak points. This made me carefully study when to use a cross fitting

What Are the Common Applications for Industrial Brass Cross Fittings?

I once watched a maintenance team spend hours shutting down a production line just to replace a single, failed plastic fitting in a compressed air

Does the Cross Design Allow for Balanced Flow Distribution?

I once inspected a heating system where one room was always cold. The problem wasn’t the boiler; it was an unbalanced flow from a poorly

How to Ensure Leak-Proof Sealing on All Four Connections?

I once watched a newly installed pressure system fail because a single port on a brass cross leaked. That moment taught me that true reliability

Are These Fittings Available in Different Threading Standards?

In my years at IFAN, I’ve seen too many projects stall because of one small detail: mismatched threads. A fitting that seemed perfect would arrive,

Why is Brass the Preferred Material for Durable Cross Fittings?

I once visited a chemical plant where stainless steel fittings had failed, but the brass ones in the same line were flawless. This firsthand experience