Media

Home » Media

30 years of brand history

100+ agents worldwide

German process equipment

Ten series of one-stop procurement

IFANPRO 121UC PEX-AL-PEX Valve: Comprehensive Review and Technical Specs

I once had a client whose entire underfloor heating system failed because of a cheap, poorly manufactured valve. That costly mistake taught me the importance

Upgrading Residential Plumbing: Ensuring a Safe Water Supply with the 121UC Valve

I once visited a home where contaminated water flowed from brand-new pipes. The culprit? A low-quality valve leaching chemicals into the supply. That day, I

The Ideal Flow Control Solution for Light Machinery and Agricultural Irrigation

I once visited a farm where inconsistent water pressure ruined an entire season’s crop yield. That costly lesson taught me why choosing the right flow

A Contractor’s Guide: Best Practices for Installing and Maintaining PEX-AL-PEX Crimp Valves

I once watched a rookie contractor ruin an entire plumbing rough-in because he used the wrong crimping tool. That expensive lesson taught me that proper

Why More Contractors Are Switching to U-Mold PEX-AL-PEX Valves

I remember watching a skilled plumber struggle for twenty minutes just to fit a bulky brass valve into a tight cabinet space. That moment made

Building a Modern Home Water System: Installation and Layout Tips for Cross Tees

I once watched a plumber spend hours trying to fit pipes around a cramped kitchen cabinet. That day, I realized that smart fittings matter more

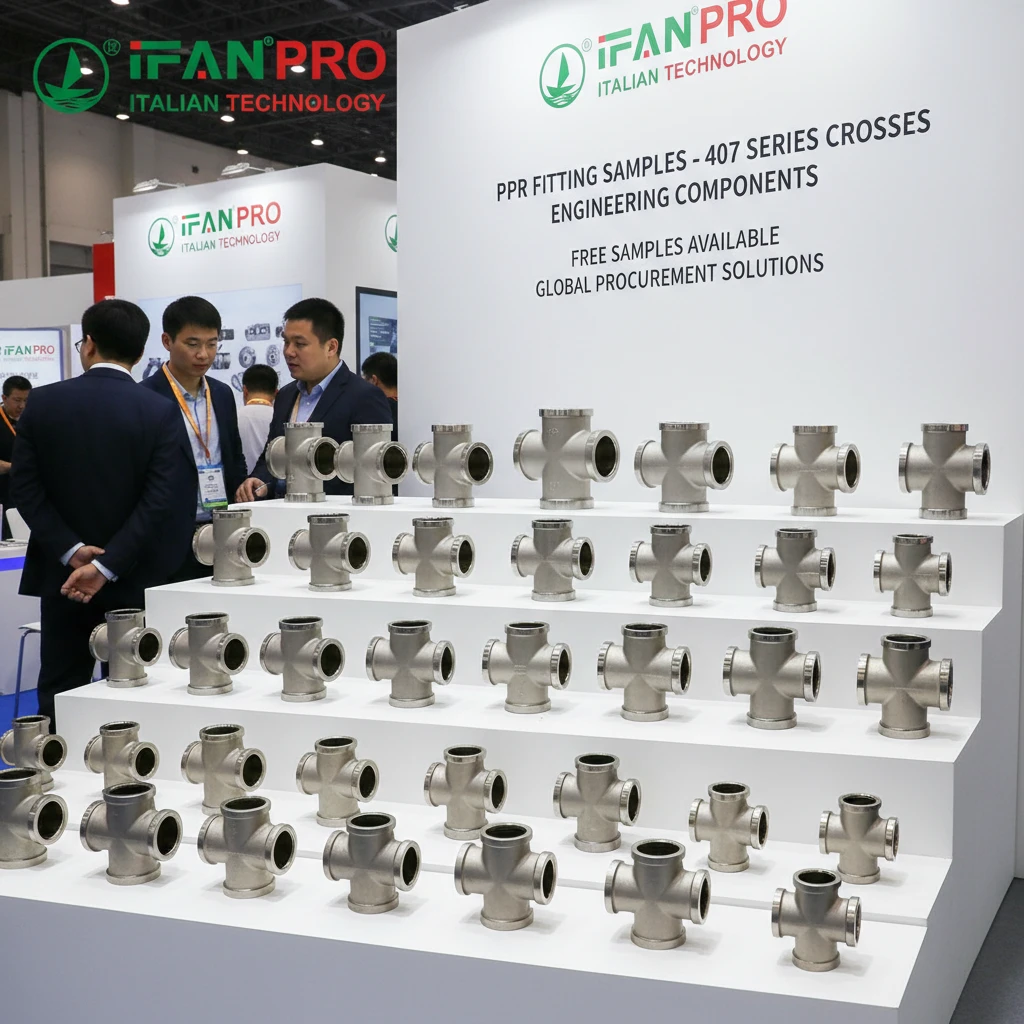

Looking for Reliable Pipe Fitting Suppliers? A B2B Procurement Guide for 4-Way Crosses

I once watched a promising engineering project stall because a supplier’s 4-way crosses arrived with wrong dimensions. That costly mistake taught me why choosing the

How Do 407 Cross Tees Optimize Industrial Fluid Distribution?

I once visited a factory where their entire production line stopped because a single junction point couldn’t handle the flow demand. That day, I learned

High Pressure and Extreme Temperatures: Reviewing the Performance of Stainless Steel Crosses

I once visited a chemical plant where a failed cross fitting caused a complete shutdown. That costly experience taught me the critical importance of choosing

Why Are Stainless Steel 4-Way Fittings the Global Standard for Reliable Plumbing?

I remember a project in the Middle East where ordinary fittings failed within months due to extreme heat. That failure taught me why stainless steel

How to Solder an Elbow Brass Pipe Fitting for Water Lines?

I once watched a newly soldered joint fail under pressure, flooding a client’s wall. That moment taught me that successful soldering relies on precision, not

Why Choose a Brass Elbow for Durable 90-Degree Turns in Plumbing?

I once replaced a plastic fitting that cracked under pressure, flooding a client’s wall. Since then, I’ve trusted brass for critical turns where failure is