High-Density Polyethylene (HDPE) pipes are widely used in various applications due to their versatility, durability, and cost-effectiveness. In this article, we will compare HDPE pipes with other pipe materials such as PVC and PEX, highlighting their differences and advantages in different scenarios.

Strength and Durability

HDPE Pipes

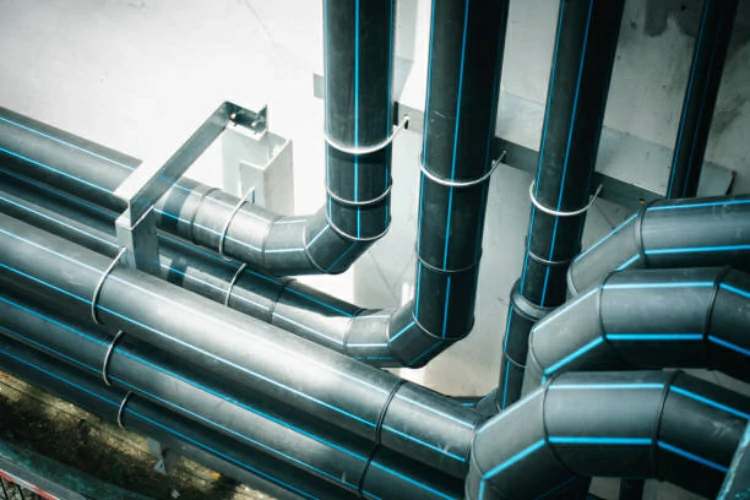

HDPE pipes are known for their exceptional strength and durability. These pipes can withstand high pressures and temperature variations without deforming or cracking, making them suitable for both above-ground and underground applications. HDPE pipe are resistant to corrosion, abrasion, and chemical damage, ensuring long-term performance and reliability.

PVC Pipes

PVC pipes, while lightweight and affordable, may not offer the same level of strength and durability as HDPE pipes. This pipes are susceptible to cracking and damage under high pressure or extreme temperatures. Additionally, PVC pipes may degrade over time when exposed to sunlight or certain chemicals, limiting their lifespan in some applications.

PEX Pipes

PEX pipes are known for their flexibility and ease of installation. While PEX pipes are suitable for certain applications such as residential plumbing, they may not be as durable as HDPE pipes in high-pressure or abrasive environments. PEX pipes may also be vulnerable to damage from UV exposure and certain chemicals, impacting their longevity and performance.

Flexibility and Versatility

HDPE Pipes

HDPE pipes are highly flexible and versatile, allowing for easy installation in various settings. These pipes can be bent and curved to accommodate changes in terrain or layout, reducing the need for additional fittings and joints. HDPE pipe are commonly used in applications such as water supply, drainage, and gas distribution, where flexibility and versatility are essential.

PVC Pipes

PVC pipes are also flexible and versatile, making them suitable for a wide range of applications. However, PVC pipes may become brittle over time, especially in cold climates or when exposed to certain chemicals. This limitation may restrict the use of PVC pipes in environments where flexibility and durability are critical.

PEX Pipes

PEX pipes offer excellent flexibility and ease of installation, particularly in residential plumbing systems. However, PEX pipes may not be as versatile as HDPE pipes in larger-scale applications such as municipal water distribution or industrial piping. Additionally, PEX pipes may require special tools and fittings for installation, increasing the overall cost and complexity of the system.

Environmental Impact and Sustainability

HDPE Pipes

HDPE pipes are considered environmentally friendly and sustainable due to their recyclability and long lifespan. These pipes are often made from recycled materials and can be recycled after use, reducing waste and conserving resources. HDPE pipes also have a low carbon footprint compared to other pipe materials, making them a preferred choice for eco-conscious projects.

PVC Pipes

While PVC pipes are widely used in various applications, they may raise environmental concerns due to their manufacturing process and potential for chemical leaching. PVC production involves the use of chlorine and other chemicals that can release harmful byproducts into the environment. Additionally, PVC pipes may release toxic compounds when burned, posing risks to human health and the environment.

PEX Pipes

PEX pipes are generally considered safe and environmentally friendly. However, concerns have been raised about the potential for chemical leaching from PEX pipes, particularly in hot water applications. While PEX pipes are regulated for safety, some users may prefer alternative materials such as HDPE for peace of mind regarding environmental impact.

Conclusion

HDPE pipes offer numerous advantages over other pipe materials such as PVC and PEX. With their exceptional strength, durability, flexibility, and environmental sustainability, HDPE pipes are a versatile and cost-effective solution for various applications. By understanding the differences between HDPE pipes and other pipe materials, users can make informed decisions when selecting pipes for their projects, ensuring efficient and reliable performance for years to come.

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interested in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments