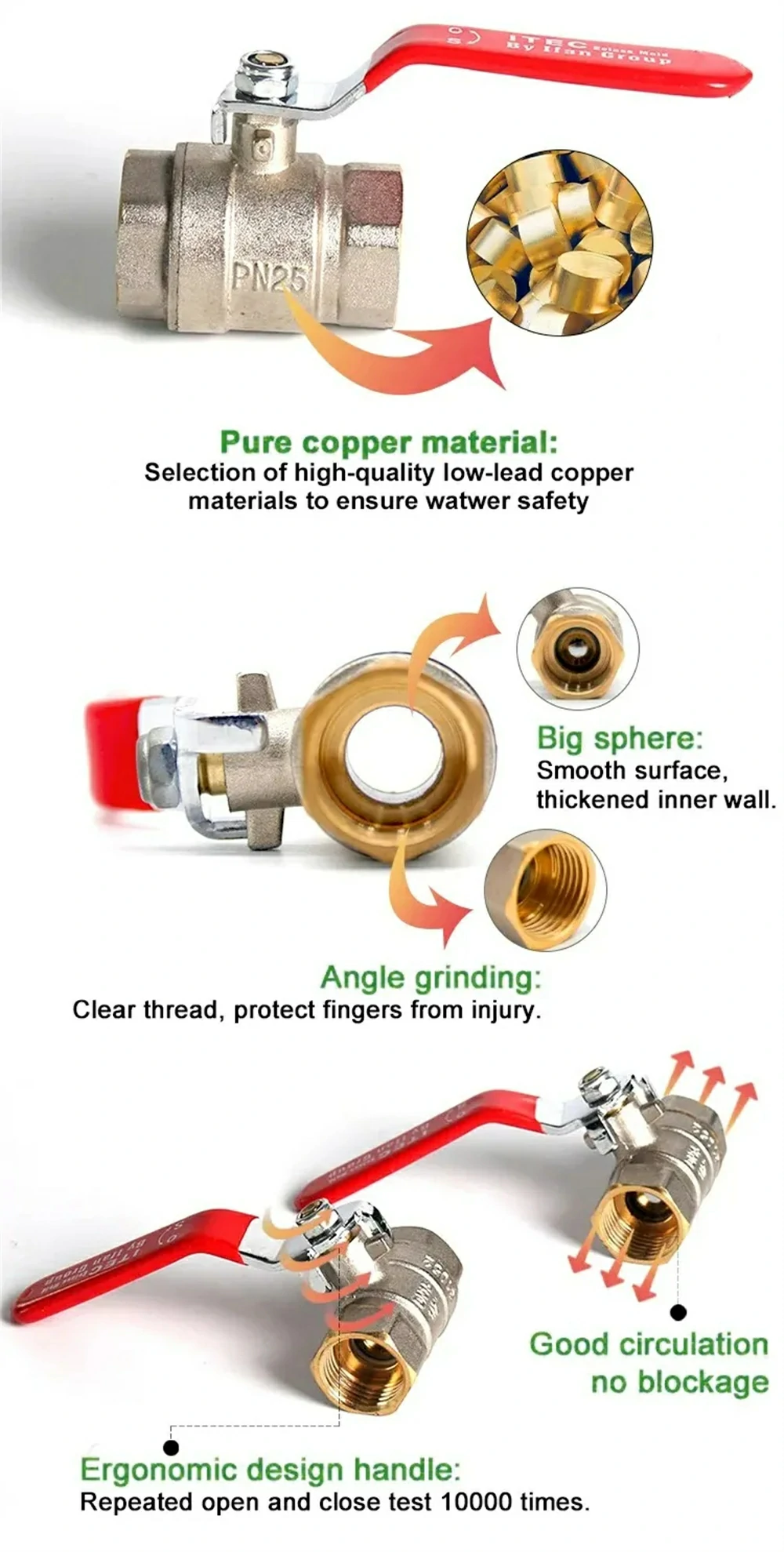

Nombre del producto:Accesorios HDPE

Size:20-110mm

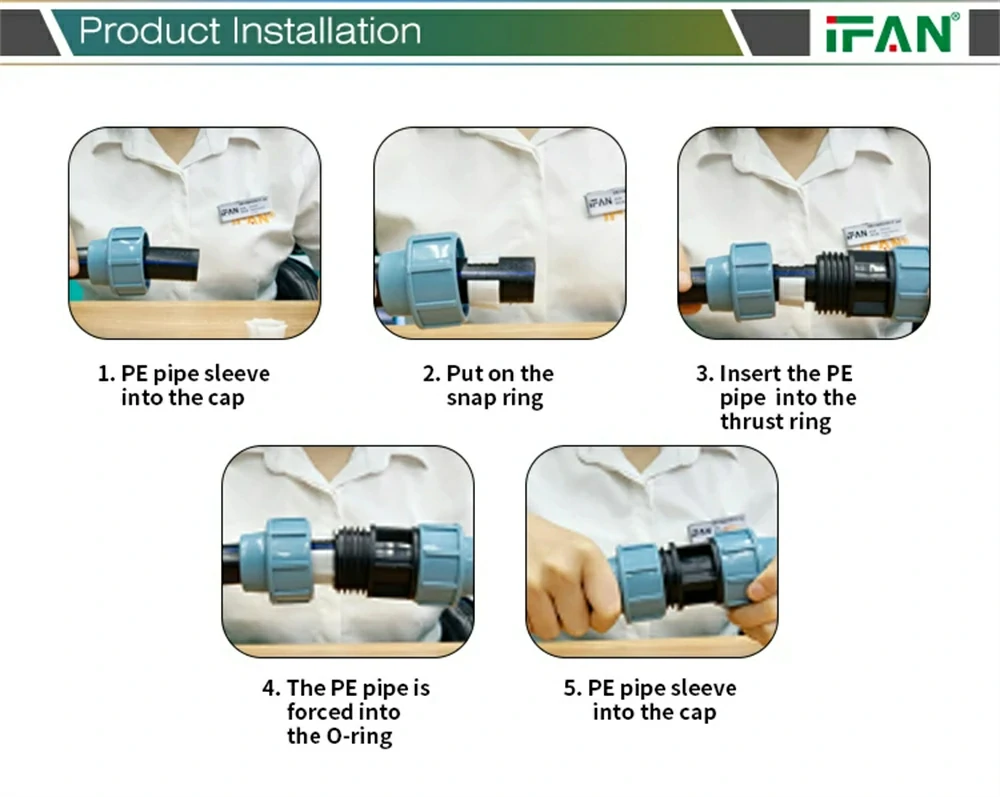

Standard:Quick connection, easy connection

Pressure:PN16

Feature:Quick connection, easy connection

OEM:Available

Packing:IFAN woven bag

Sample:Free (Contact us for a free sample)

Categoría HDPE

Etiquetas Accesorio HDPE, accesorios de tubería de hdpe

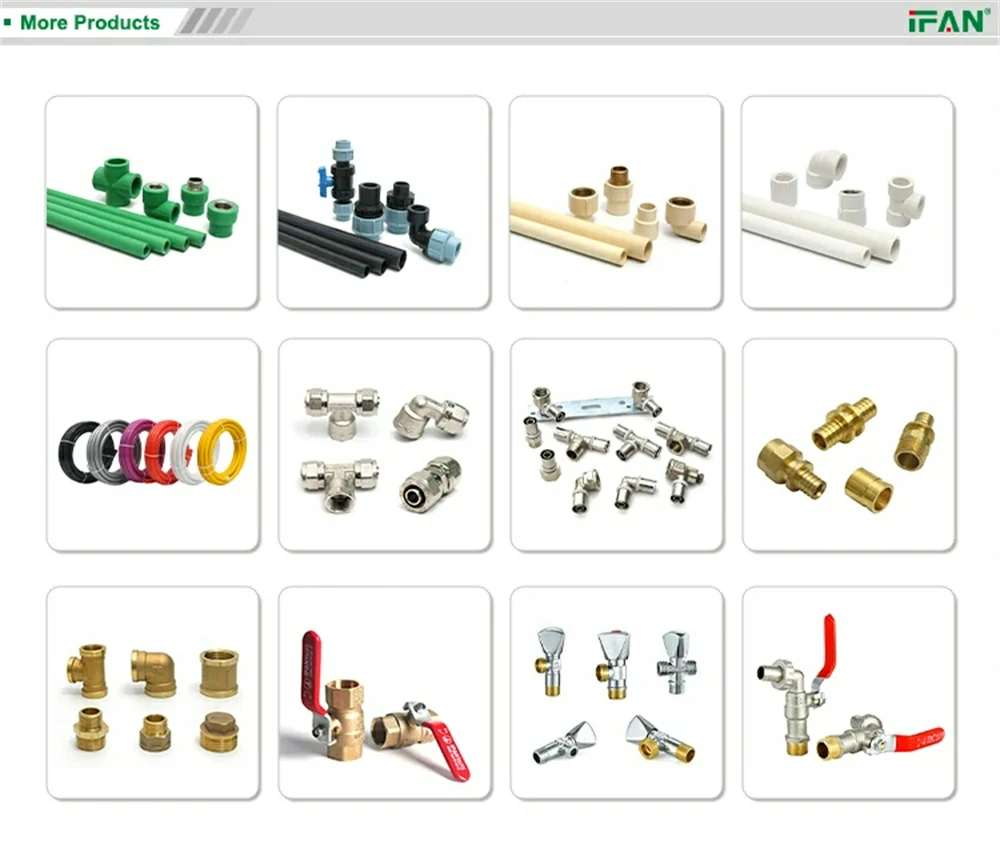

Productos relacionados

Descripción de los productos

Productos Imagen

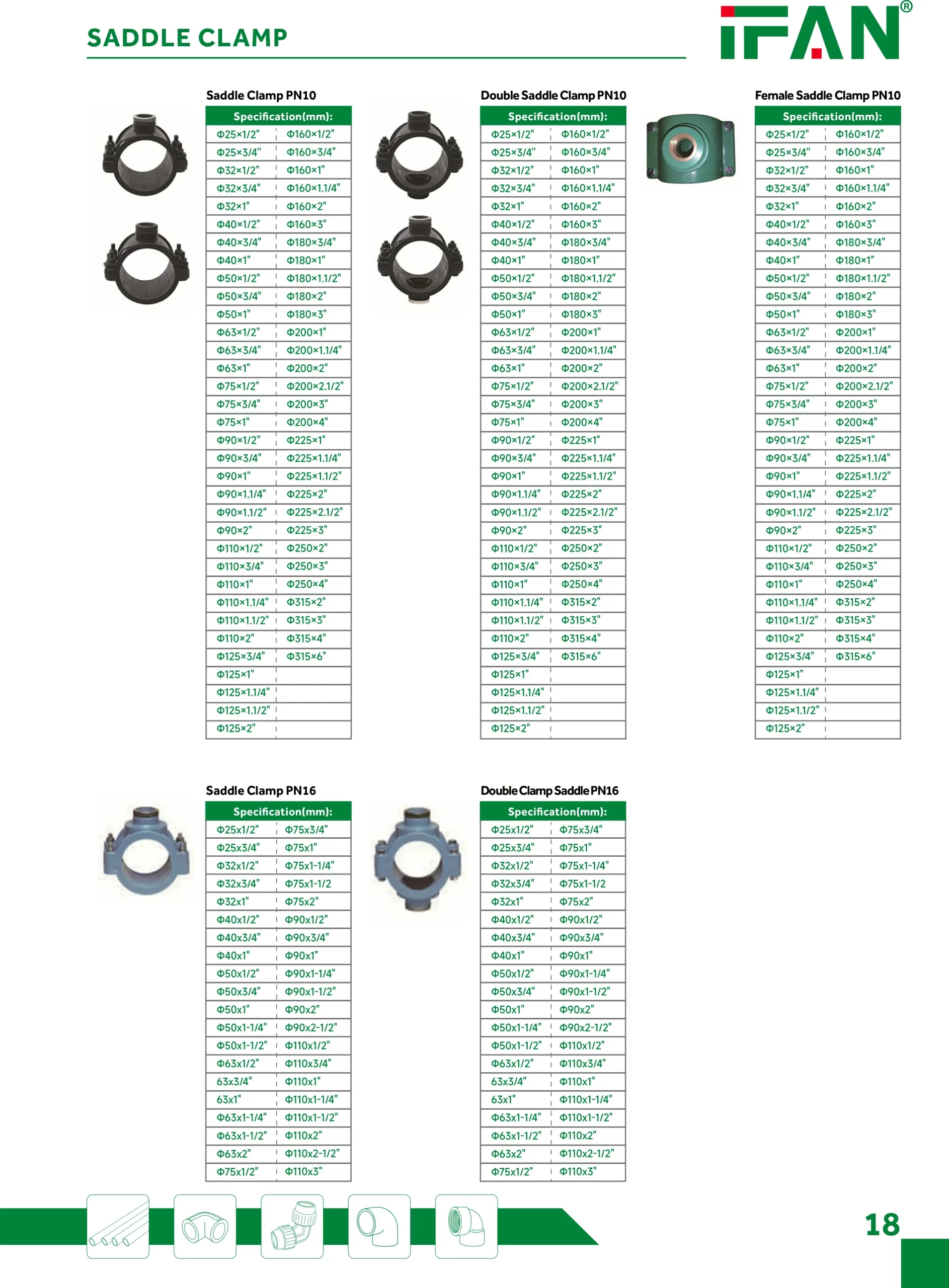

Gráficos de productos

Reseñas

Descripción de los productos

Exploring the Advantages and Applications of HDPE Fittings

The Superior Qualities of HDPE Fittings

Durability and Strength

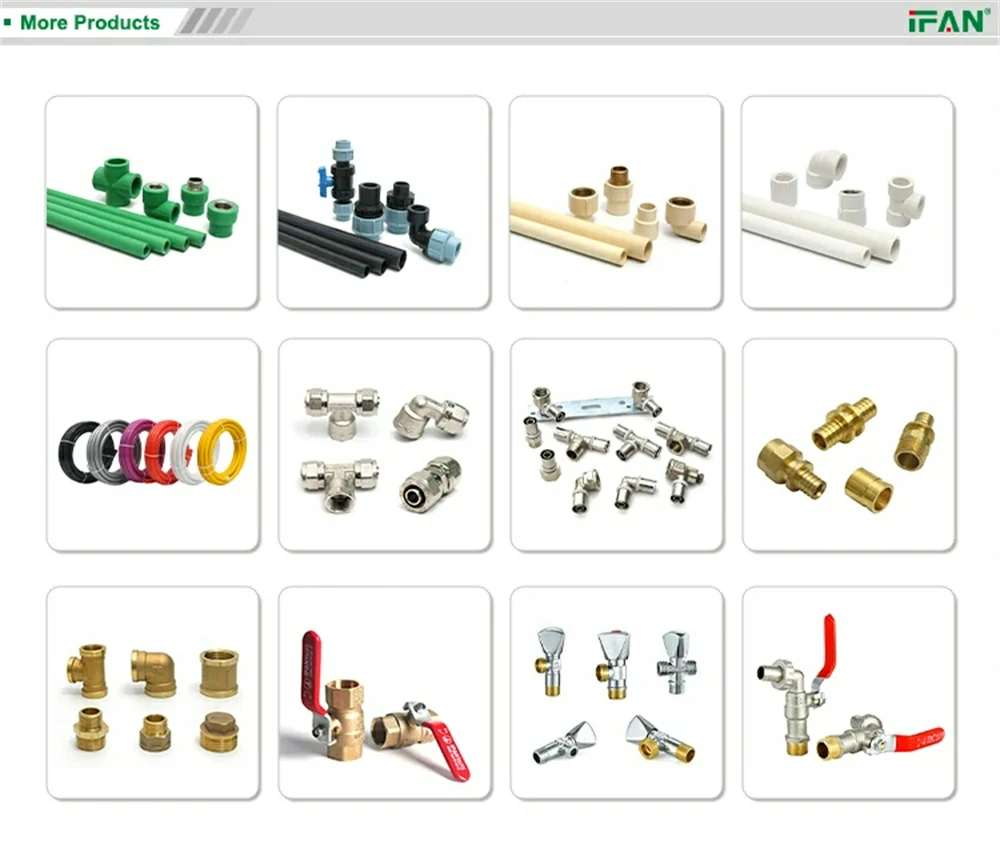

HDPE fittings stand out due to their remarkable durability and strength. Constructed from high-density polyethylene, these fittings resist impacts and stress, making them ideal for tough environments. Unlike metal fittings, HDPE does not corrode or rust, which ensures a longer lifespan. This longevity means fewer replacements and lower maintenance costs, providing a cost-effective solution over time.Flexibility and Versatility

Another key advantage of HDPE fitting is their flexibility. This characteristic allows them to absorb shock and adapt to ground movements without cracking. Their versatility makes them suitable for a variety of applications, including those with significant temperature fluctuations. Additionally, HDPE fittings perform well in both underground and above-ground installations, adapting seamlessly to different project requirements.Chemical and Corrosion Resistance

HDPE fittings offer excellent resistance to chemicals and corrosion, a crucial factor for many industries. They can handle exposure to acids, bases, and various chemicals without deteriorating. This resistance is particularly beneficial in chemical plants and wastewater treatment facilities where the presence of corrosive substances is common. Thus, HDPE fittings ensure a safe and reliable piping system in aggressive environments.Ease of Installation

The ease of installation is another notable benefit of HDPE fittings. These fittings are lightweight, simplifying the handling and installation process. They can be joined using methods like heat fusion, which creates a secure and leak-free connection. This ease of installation reduces labor costs and speeds up project timelines, making HDPE a preferred choice for many contractors and engineers.Common Applications of HDPE Fittings

Water Supply Systems

HDPE fittings are widely used in water supply systems. Their durability and safety make them ideal for delivering potable water. They do not leach harmful substances into the water, ensuring a clean and safe supply. Moreover, their resistance to biofilm formation helps maintain water quality. Whether used in residential, commercial, or municipal systems, HDPE fitting provide a reliable solution for water distribution.Wastewater and Sewage Systems

In wastewater and sewage systems, HDPE fittings excel due to their chemical resistance and durability. They can handle the harsh conditions associated with wastewater and sewage without degrading. Their smooth interior surfaces reduce friction and prevent clogs, ensuring efficient flow. Additionally, HDPE’s resistance to root intrusion and ground movement makes them suitable for underground installations, providing long-term reliability.Gas Distribution Networks

HDPE fittings play a crucial role in gas distribution networks. Their flexibility and impact resistance are essential for handling the pressures and stresses of gas transport. HDPE’s impermeability to gas and resistance to chemical reactions ensure safe and efficient distribution. These characteristics make HDPE fitting a top choice for natural gas and other gas applications, ensuring the integrity of the distribution network.Industrial Piping Systems

Industries such as chemical processing, mining, and oil and gas rely on HDPE fitting for their piping systems. HDPE’s resistance to corrosive chemicals and durability under harsh conditions make it ideal for these demanding applications. Whether transporting chemicals, slurries, or other industrial fluids, HDPE fittings provide a reliable and efficient solution. Their ability to withstand high pressures and temperatures adds to their suitability for industrial use.Future Trends and Considerations

Innovations in HDPE Technology

The future of HDPE fittings looks promising with ongoing innovations in material science. Advances in HDPE technology are enhancing its properties, making it even more versatile and durable. These improvements are likely to expand the range of applications for HDPE fitting, from advanced water treatment solutions to more efficient gas distribution systems.Environmental Impact

HDPE fitting contribute to environmental sustainability in several ways. Their long lifespan and low maintenance requirements reduce waste. Furthermore, HDPE is recyclable, supporting the principles of the circular economy. As industries and municipalities increasingly focus on sustainability, the demand for HDPE fittings is expected to grow, driven by their eco-friendly benefits.Expanding Applications

The versatility of HDPE fittings continues to reveal new applications. From renewable energy projects to advanced agricultural irrigation systems, HDPE fitting are proving to be a reliable and efficient solution. As more sectors recognize their benefits, the adoption of HDPE fitting is likely to increase, solidifying their role in modern infrastructure and industrial systems.Póngase en contacto con

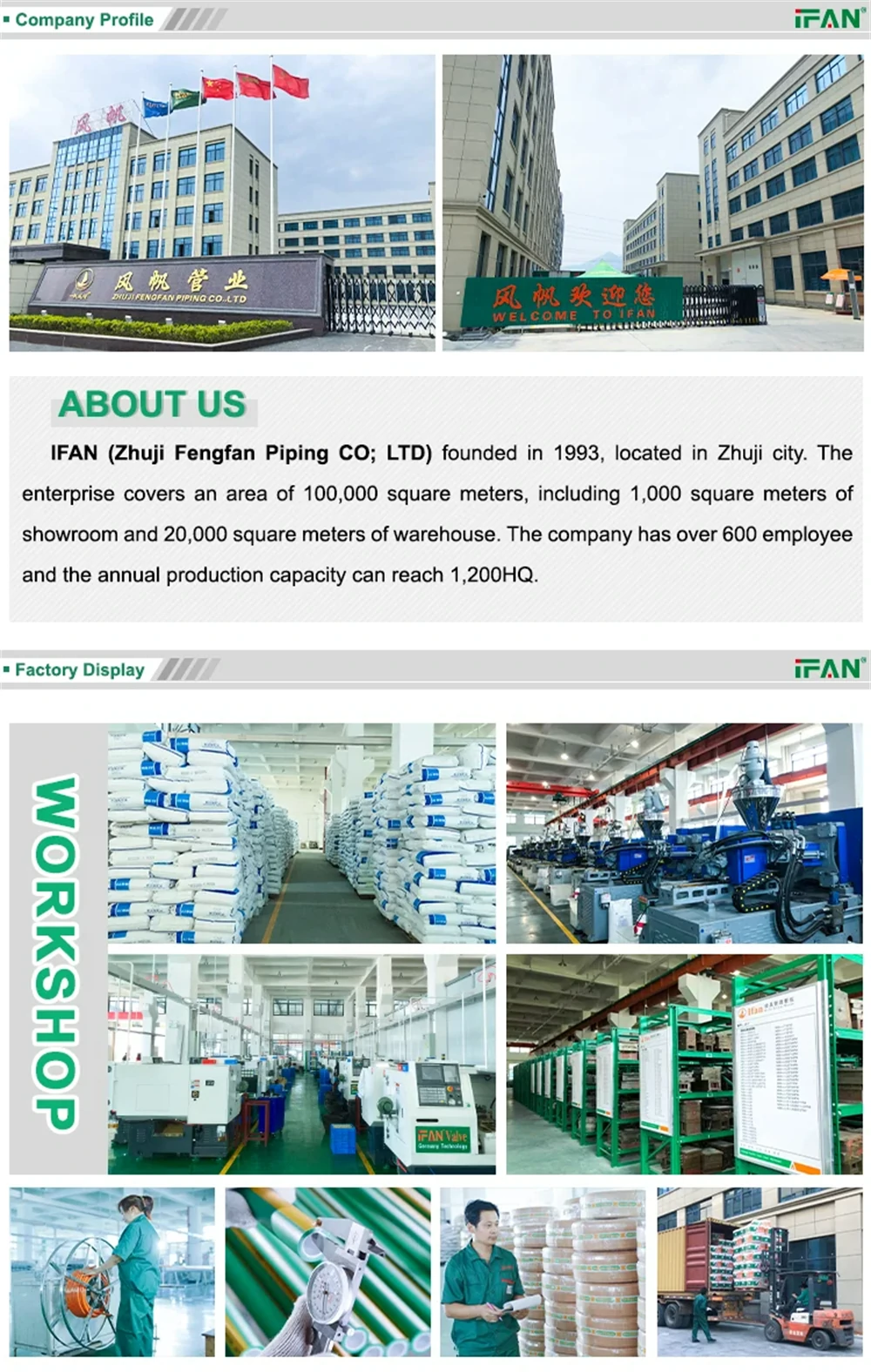

Con 30 años de experiencia, IFAN es un fabricante especializado en la producción de accesorios, racores y válvulas de plástico de alta calidad. Nuestros productos abarcan válvulas de cobre, válvulas de PPR y diversos racores y fittingxs para satisfacer las distintas necesidades de los clientes. No importa cuáles sean sus necesidades de fontanería o válvulas, IFAN ofrece una amplia gama de productos rentables para apoyar su proyecto. A continuación encontrará nuestra información de contacto Whatsapp: + 86 19857948982,Email:[email protected]

Productos Imagen

Gráficos de productos

Reseñas

0