As demand for durable, energy-efficient plumbing materials continues to grow, PPR pipe fittings have become widely used in both residential and commercial construction projects. The United States is not only a large consumer of these fittings but also home to a number of manufacturers producing high-quality PPR components.

This article explores the key characteristics of the production process of PPR pipe fittings in the USA, what sets it apart from overseas manufacturing, and how it aligns with industry standards for safety, performance, and sustainability.

🏭 1. Use of High-Quality Raw Materials

One defining feature of U.S.-based PPR production is the strict selection of raw materials. American manufacturers typically use:

- Food-grade polypropylene random copolymer (PP-R Type 3)

- Resins certified by NSF, FDA, or ASTM International

This ensures that fittings are safe for:

- Potable (drinking) water systems

- High-temperature and high-pressure applications

✅ This also aligns with public health codes and EPA guidelines across all 50 states.

🛠️ 2. Advanced Injection Molding Technology

In the USA, PPR fittings are primarily produced using precision injection molding, which involves:

- Melting raw PP-R granules at ~230°C

- Injecting the material into high-pressure steel molds

- Rapid cooling and de-molding for accurate shape and dimensional control

Features of this process:

- High consistency across batches

- Low defect rates

- Smooth surface finish and tight tolerances

✅ American-made fittings are known for their clean finish and structural integrity, ideal for demanding applications.

📐 3. Strict Dimensional Standards (ASTM & DIN)

PPR fittings made in the USA are typically manufactured according to:

- ASTM F2389 – Standard for PP pressure piping systems

- DIN 8077/8078 – German dimensioning and tolerance standards (for export purposes)

Most factories use automated laser measuring systems during quality control to ensure:

- Correct inner and outer diameters

- Wall thickness consistency

- Leak-free socket and thread finishes

✅ These fittings are fully compatible with American and international plumbing systems.

♻️ 4. Emphasis on Sustainability and Waste Reduction

Many U.S. factories are increasingly investing in eco-friendly production practices, including:

- Closed-loop water cooling systems

- Recycling of plastic scrap back into non-critical fittings

- Use of energy-efficient electric molding machines

✅ These methods support LEED-certified construction projects and help reduce the carbon footprint of building materials.

🧪 5. Rigorous Testing and Certification

Quality assurance is a key focus in U.S. PPR fitting production. Common tests include:

- Hydrostatic pressure tests (at various temperatures)

- Thermal aging and impact resistance

- Chemical compatibility and chlorine resistance

Products are usually certified by:

- NSF International

- UPC (Uniform Plumbing Code)

- CSA or ICC-ES for compliance with North American building regulations

🌍 How ifanultra Compares: High-Quality PPR Fittings for the Global Market

While U.S. manufacturers focus on domestic demand, global buyers often seek cost-effective yet compliant alternatives. That’s where ifanultra stands out.

We are a professional PPR pipe and fittings factory based in China, offering:

- DIN and ISO 15874 certified fittings

- Advanced injection molding and quality control

- OEM customization services for global importers

- Competitive wholesale pricing with export-ready logistics

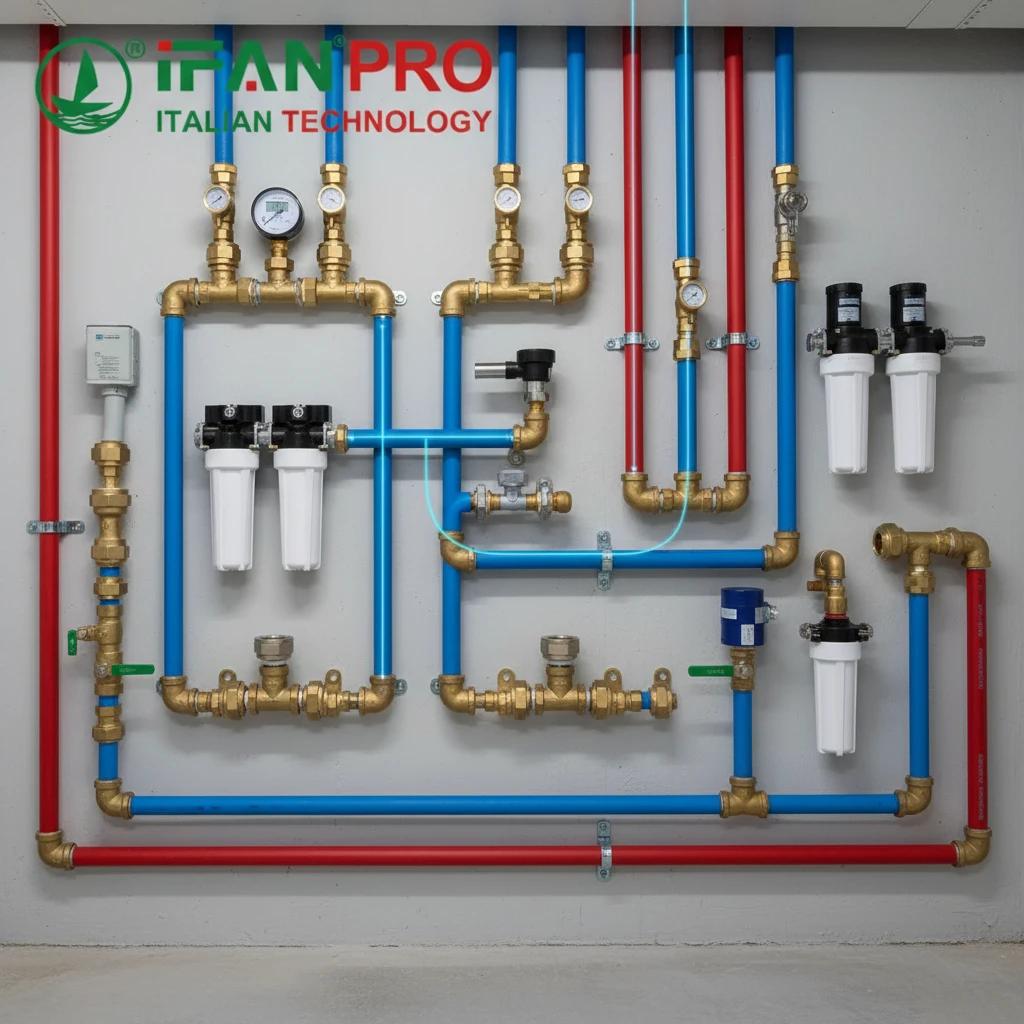

Our products are widely used in:

- Residential water systems

- Heating and HVAC projects

- Industrial water supply lines

✅ ifanultra offers reliable alternatives for buyers looking to match U.S.-level quality at more competitive pricing.

✅ Conclusion

The production process of PPR pipe fittings in the USA is defined by:

- High-quality certified materials

- Advanced molding techniques

- Compliance with ASTM, DIN, and NSF standards

- Sustainability and clean manufacturing

Whether you’re a contractor, distributor, or project manager, understanding these characteristics helps ensure you choose reliable products that meet your technical and regulatory requirements.

For global buyers seeking a balance of quality, compliance, and affordability, ifanultra is your trusted partner for wholesale and custom PPR fitting solutions.

Recent Comments