I once visited a farm where a forgotten storage tank overflowed for hours, wasting thousands of gallons and creating a muddy mess. That day clearly showed me the simple power a float valve holds.

You should install a float valve in your water tank because it automatically and reliably controls the water level, preventing overflow and ensuring your tank is always adequately filled without any manual work. It is a simple, mechanical, and cost-effective device that saves water, prevents property damage, and gives you complete peace of mind.

Let’s look at the specific ways this small device solves big problems in water management.

How Does a Float Valve Prevent Costly and Damaging Water Overflow Incidents?

An overflowing tank is more than just wasted water; it’s a source of damage and stress. I’ve seen the aftermath firsthand.

A float valve prevents overflow through a simple mechanical shut-off. As the water level rises, it lifts a float ball connected to a lever. This lever slowly closes an inlet port. When the water reaches the pre-set maximum level, the port seals completely, stopping all incoming water flow and preventing any overflow from the tank.

The Core Principle: How It Works

The beauty of a float valve lies in its simplicity. It has no complex electronics or timers. It works purely on buoyancy and mechanical force, much like the valve in a toilet cistern, but built for larger, tougher jobs.

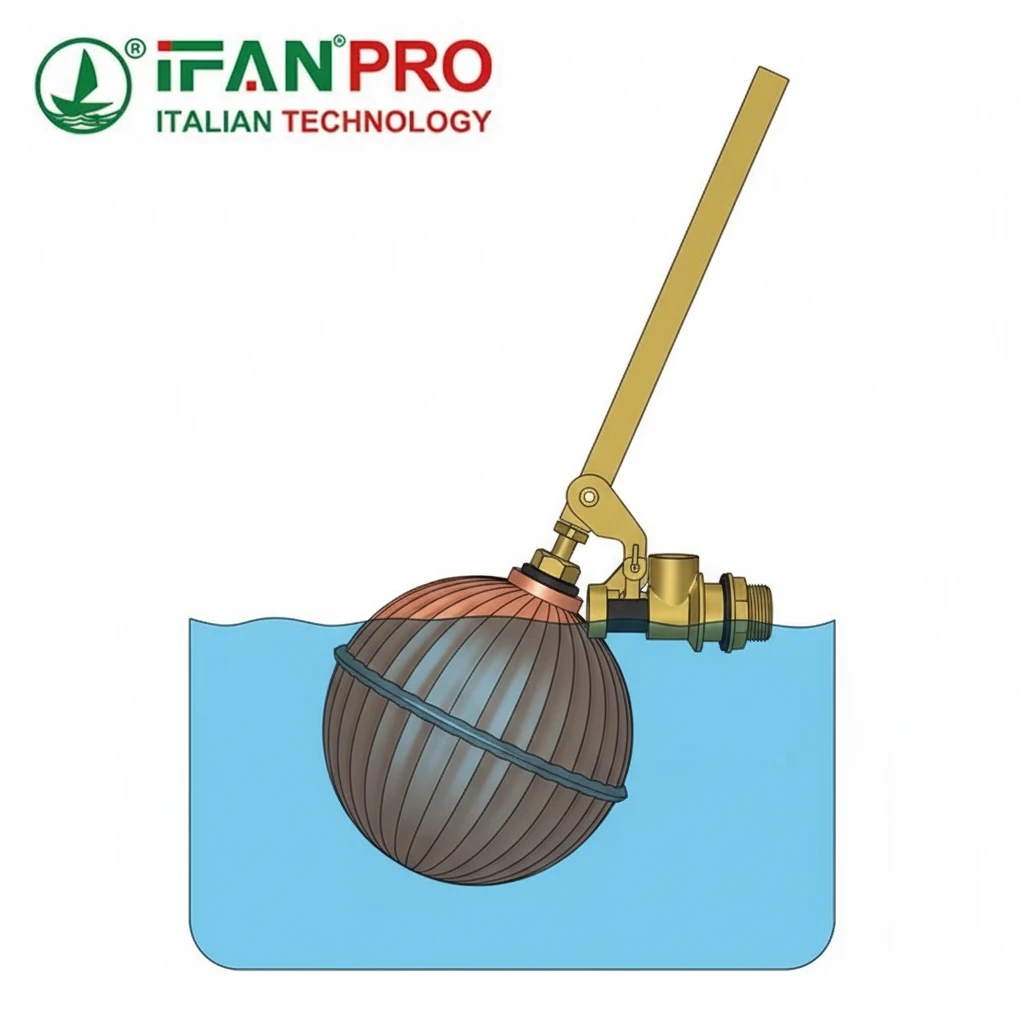

The main parts are the float ball (often a hollow plastic or copper sphere), a lever arm, and a valve seat with a sealing washer. The float ball is attached to one end of the lever. The other end of the lever is connected to the valve’s plunger or piston.

When your tank is empty, the float ball hangs down. This pulls the lever, which keeps the inlet port wide open. Water flows freely into the tank. As the tank fills, the water lifts the float ball. The rising ball pivots the lever, which gradually pushes the plunger to close the valve. Finally, at the full level, the buoyant force of the float is strong enough to press the plunger tightly into the valve seat, creating a watertight seal and stopping the flow.

Consequences of Overflow

Understanding the risks shows why this automatic shut-off is so valuable. Without a float valve, someone must remember to turn off the pump or inlet valve. People forget, get distracted, or misjudge the fill time. The results are costly:

- Water Waste: A continuous overflow can waste a massive amount of a precious resource, leading to high utility bills.

- Property Damage: Overflowing water can flood basements, damage building foundations, erode soil, and create sinkholes or unstable ground around the tank.

- Structural Damage to the Tank: Constant overflow can lead to rust, corrosion, or algae growth around the top and exterior of the tank, weakening it over time.

Comparing Tank Systems

The table below summarizes the key differences:

| Tank System | Overflow Risk | Required Action |

|---|---|---|

| Tank WITHOUT Float Valve | Very High | Constant manual monitoring and timely valve operation. |

| Tank WITH Float Valve | Extremely Low | None. The system is fully automatic. |

Reliability in Harsh Conditions

Because it is mechanical, a float valve is very reliable. A high-quality valve, like those from IFAN, uses durable materials like brass for the body and EPDM for seals. This means it can work for years in various water conditions without needing electricity or complex maintenance. It’s a “set it and forget it” solution that continuously guards against one of the most common and wasteful tank problems.

What Are the Benefits of Achieving Fully Automatic Tank Refilling Cycles?

Relying on manual refills is unpredictable. I’ve helped clients switch to automatic systems and watched their operations become smoother.

The benefit of a fully automatic refill cycle is consistent, reliable water supply without any human effort. Once the water level drops, the valve opens by itself to refill the tank to the exact level you need. This ensures water is always available for critical uses like irrigation, livestock, or household needs, 24 hours a day.

The Automatic Cycle in Action

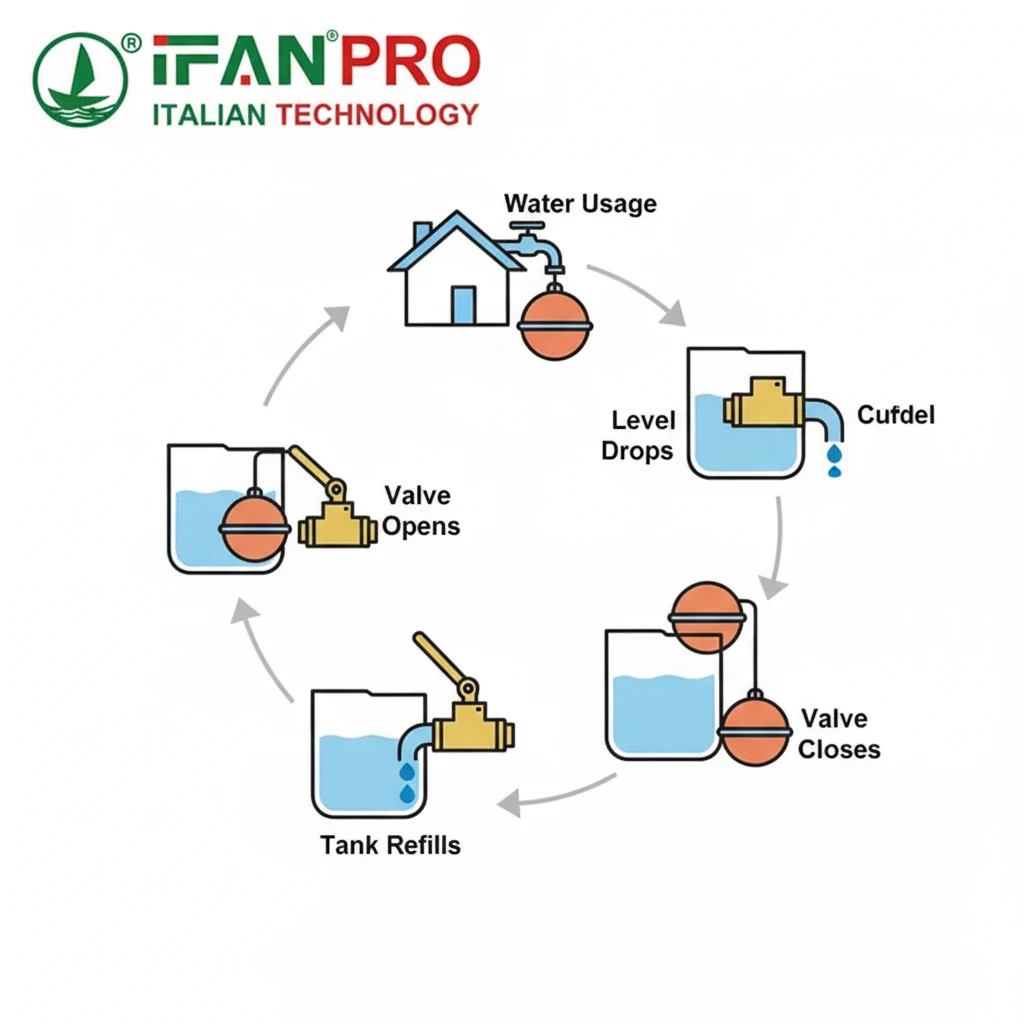

The process is a continuous, self-regulating loop. It starts when water is drawn from the tank for any use—a household faucet, an irrigation system, or animals drinking.

As water leaves, the tank level falls. The float ball, which was floating at the top, begins to sink with the dropping water level. As it sinks, it pulls the lever arm, which retracts the plunger from the valve seat. This opens the inlet port, allowing fresh water to flow into the tank again. The tank refills until the water lifts the float ball back to the “full” position, which shuts the valve. This cycle repeats indefinitely without anyone ever needing to check the tank level.

Key Benefits of Automation

This automation delivers several powerful advantages:

- Uninterrupted Supply: For farms, factories, or large homes, running out of water can halt operations. Automatic refill guarantees that the tank is always replenishing itself, so you never face an empty tank.

- Saves Time and Labor: You eliminate the task of sending someone to check the tank and operate valves. This saves significant labor costs and management time.

- Optimizes Water Usage: It helps maintain a buffer of water. The tank refills during off-peak water usage periods, ensuring high demand can be met instantly. This is more efficient than trying to refill a completely empty tank during peak use.

- Enables Remote Operations: For vacation homes, remote agricultural sites, or unmanned facilities, an automatic float valve is essential. It manages the water supply reliably for weeks or months without any on-site presence.

Comparing Manual vs. Automatic Refill

Let’s look at the practical differences this makes in a real-world scenario, like a livestock farm.

| Task | Manual Tank Management | Automatic Tank with Float Valve |

|---|---|---|

| Monitoring Level | Daily visual checks needed. | No checks needed. |

| Initiating Refill | Worker must go to tank and open valve. | Starts automatically when level drops. |

| Stopping Refill | Worker must return to close valve (risk of forgetfulness). | Stops automatically at set level. |

| Risk of Shortage | High if check is missed. | Very low. |

| Labor Required | Significant and recurring. | One-time installation only. |

The benefit is clear: automation transforms water tank management from a daily chore into a reliable, background utility. You free up human resources for more important tasks while gaining a more dependable water supply.

Why is it a Simple and Cost-Effective Solution for Water Level Management?

In engineering, the simplest solution is often the best. The float valve is a perfect example of this principle I often share with clients.

A float valve is simple and cost-effective because it is a single, self-contained mechanical device with no moving parts. Its installation is straightforward, it requires almost no maintenance, and its upfront cost is very low compared to the value of the water, property, and labor it protects and saves.

Analyzing Simplicity in Design and Installation

The design is brilliantly simple. There are no circuit boards, wires, sensors, or programmable controllers. It’s a handful of robust parts: a metal body, a lever, a float, and a seal. This simplicity means there is very little that can go wrong.

Installation is equally simple. For a standard tank, it involves:

- Drilling or preparing an inlet hole near the top of the tank.

- Screwing the valve body into the hole (often using a standard pipe thread).

- Connecting the incoming water supply pipe to the valve’s inlet.

- Adjusting the float rod or lever to set the desired water level.

A competent plumber or even a skilled DIYer can install it in under an hour. There is no complex wiring or system integration required.

Breaking Down the Cost-Effectiveness

When we talk about cost-effectiveness, we look at the total value over the device’s lifetime.

- Low Initial Cost: A high-quality brass float valve is an inexpensive component, especially when compared to the cost of the tank, pump, and plumbing system it protects.

- Zero Energy Cost: It uses no electricity. It operates on the physical force of water and buoyancy. This means it adds nothing to your energy bill and can work during power outages.

- Minimal Maintenance Cost: A good float valve may need only occasional checking for debris on the seal. Unlike electronic sensors or controllers, it doesn’t require software updates, battery replacements, or technical troubleshooting.

- High Savings Potential: This is the most important point. The valve pays for itself many times over by preventing just one major overflow incident. The savings on wasted water, potential property damage repair, and avoided labor for manual monitoring are substantial.

Cost-Benefit Analysis Table

The following table illustrates the economic logic:

| Cost/Saving Factor | Typical Estimate | Notes |

|---|---|---|

| Cost of a Quality Float Valve | $50 – $150 | One-time purchase. |

| Cost of Installation | 1 hour of labor | Simple, quick job. |

| Annual Maintenance Cost | ~$0 | No recurring costs. |

| Potential Cost of ONE Overflow | $500 – $5000+ | Includes water waste + damage repair. |

| Annual Labor Saving (Monitoring) | 10-50 hours | Eliminates daily checks and manual operation. |

As you can see, the potential loss from a single problem is many times greater than the total cost of buying and installing the valve. It is one of the highest-return investments you can make for a water storage system. Its simplicity is its strength, leading to unmatched reliability and cost savings.

How Does it Eliminate the Need for Manual Monitoring and Valve Operation?

The mental burden of remembering to check a tank is real. My clients are always relieved to remove this task from their lists.

The float valve eliminates manual work by acting as a permanent, automated attendant. Its built-in float sensor constantly monitors the water level and its mechanical actuator immediately operates the valve based on that level. This removes the entire cycle of checking, deciding, and physically turning valves on and off.

The Manual Monitoring Burden

To appreciate the elimination of work, let’s first understand what manual tank management involves. It is a repetitive cycle with several failure points:

- Remembering to Check: Someone must remember to go and check the tank level regularly. This could be daily, twice a day, or more often during high usage.

- Travel and Access: The person must travel to the tank site, which might be on a roof, in a basement, or far away in a field.

- Making a Decision: They must visually judge the water level and decide: “Is it low enough to refill now, or should I wait?”

- Physical Operation: If refill is needed, they must manually open the main inlet valve or start the pump.

- More Monitoring: They must either wait or return later to check when the tank is full.

- Second Operation: They must remember to go back and manually close the valve or stop the pump to prevent overflow.

Every one of these steps is an opportunity for error, forgetfulness, or delay. Step 6 is especially critical—forgetting it causes an overflow.

How the Float Valve Replaces Each Step

The float valve seamlessly replaces this entire flawed human process with a perfect mechanical one.

| Manual Step | How the Float Valve Handles It |

|---|---|

| 1. Remembering to Check | The float is always in the water, checking the level continuously. |

| 2. Travel and Access | No travel needed. The valve is installed directly on the tank. |

| 3. Making a Decision | The pre-set float level is the decision point. It’s a simple rule: “Open if below X, close if at X.” |

| 4. Physical Operation (Open) | The sinking float physically pulls the lever to open the valve. No human hand is needed. |

| 5. More Monitoring | The rising float continuously monitors the fill progress as it happens. |

| 6. Physical Operation (Close) | The rising float physically pushes the lever to close the valve at the exact right moment. |

The Freedom of Automation

The result is total freedom from the task. This elimination of manual work has profound effects:

- Reliability: The machine never gets tired, distracted, or forgetful. It performs the same perfect action every single time.

- Safety: It removes the risk of human error, which is the leading cause of overflows and water shortages in manually operated tanks.

- Scalability: Managing one tank manually is a chore. Managing multiple tanks across a property becomes a huge logistical problem. Float valves make scaling your water infrastructure easy and manageable.

- 24/7 Operation: It works through the night, on weekends, and during holidays. Your water system is no longer dependent on the work schedule or presence of personnel.

By installing this one simple device, you effectively hire a perfectly reliable, unpaid, permanent employee to manage your tank’s water level. It is the ultimate tool for eliminating a repetitive manual task and the risks associated with it.

Conclusion

A float valve is a small investment that delivers huge benefits in protection, convenience, and savings. For reliable automatic water control, choose the durable IFAN float valve for your storage tank system.

Recent Comments