I’ve seen too many drainage systems fail because of poor fitting choices. Watching a basement flood due to a clogged, inefficient tee is a costly lesson no one wants to learn.

You should choose a sweep tee for smooth drainage flow because its curved, gradual design guides water and waste around the corner with minimal flow disruption. This reduces turbulence, prevents solids from catching on sharp edges, and significantly lowers the risk of clogs and slow drainage compared to standard, sharp-cornered tees.

Now, let’s look at exactly how a sweep tee solves common drainage problems and why it’s the smarter choice for your system.

How Does a Sweep Tee’s Design Improve Drainage Flow Efficiency?

Clients often complain about slow drains and gurgling sounds. These are classic signs of poor flow efficiency that a simple fitting change can often fix.

A sweep tee’s design improves drainage flow efficiency by using a long-radius, curved interior that gently redirects the flow of water and waste. This smooth bend reduces hydraulic resistance and turbulence, allowing the water to maintain more of its velocity and kinetic energy, which helps carry solids through the fitting without settling.

The Science of Smooth Flow

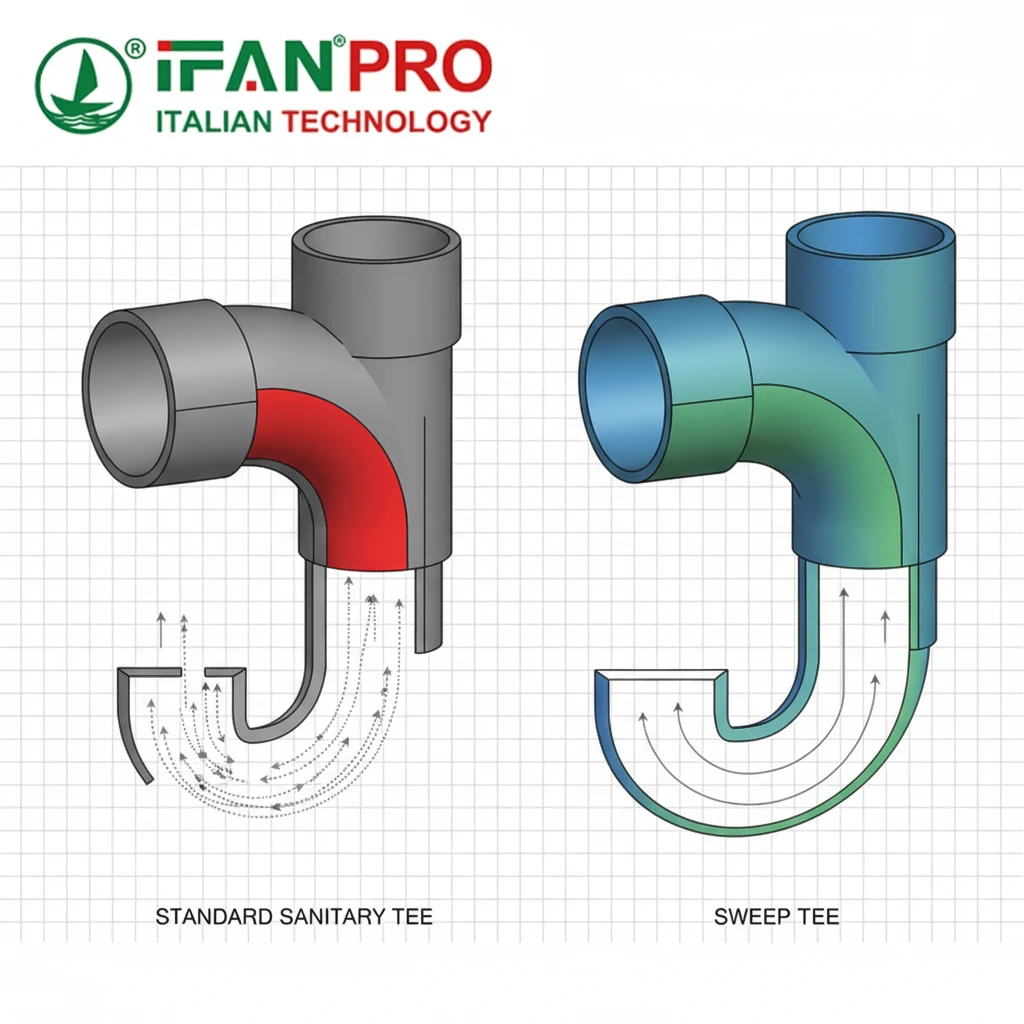

To understand why the sweep tee works so well, we need to think about how water and solids move through a pipe. When flowing water hits a sharp 90-degree corner, like in a standard tee, several bad things happen. First, the water slams into the opposite wall, losing a lot of its speed and energy. This sudden stop creates turbulence—chaotic, swirling water currents. Solids like hair, grease, and food particles get caught in this turbulence. They then fall out of the flow and start to collect in the quiet corners of the fitting.

A sweep tee solves this problem with its curved channel. Imagine driving a car. Taking a sharp turn at high speed is jarring and forces you to slow way down. Taking a gentle, sweeping curve lets you maintain much more of your speed. It’s the same for wastewater. The long-radius curve of a sweep tee guides the flow smoothly, minimizing the impact and keeping the water and waste moving together in a more laminar (smooth) flow.

Key Design Features

Let’s break down the specific design elements that contribute to efficiency:

- Long-Radius Curve: This is the most critical feature. The radius is much larger than that of a standard tee, creating a gradual path.

- Continuous Interior Surface: A well-made sweep tee has a smooth, consistent interior wall without seams or ridges inside the curve where debris can snag.

- Optimized Flow Path: The design aims to create a natural “chute” that directs solids around the bend using centrifugal force, keeping them in the center of the flow.

Flow Characteristic Comparison

| Flow Characteristic | In a Standard Tee | In a Sweep Tee | Result for Drainage |

|---|---|---|---|

| Water Velocity | Drops significantly at the corner. | Maintains a higher, more consistent speed. | Sweep tees prevent slowdowns that cause settling. |

| Turbulence | High, creating chaotic swirls and eddies. | Low, promoting smoother laminar flow. | Less turbulence means fewer spots for debris to collect. |

| Solid Transport | Solids often impact the wall and fall out of the flow. | Solids are guided by the curve and stay suspended. | Better solid transport reduces clog formation. |

| Hydraulic Noise | Can cause loud gurgling and splashing sounds. | Operates much more quietly. | Sweep tees contribute to a quieter plumbing system. |

In practice, this efficient design means water drains faster and more reliably. For building owners and homeowners, this translates to fewer calls about slow drains and a system that handles peak loads—like multiple showers or appliances running—without backing up.

Why Are Sweep Tees More Effective at Preventing Drainage Clogs?

Clogs are the number one headache in drainage. I’ve audited systems where replacing just a few key standard tees with sweep tees solved chronic clogging issues.

Sweep tees are more effective at preventing clogs because their smooth, curved interior offers no sharp angles or flat ledges for debris to catch on. This design allows stringy waste (like hair), fibrous materials, and greasy solids to slide around the bend without snagging, preventing the initial accumulation that starts a clog.

Understanding Clog Formation

A clog doesn’t appear suddenly. It starts small. A single piece of debris catches on a rough edge or sharp corner. Then, more material sticks to that first piece. Grease and soap scum coat the growing mass. Over time, what began as a tiny snag becomes a full blockage that stops water completely. The primary goal of a good drainage fitting is to eliminate those initial catching points.

Standard sanitary tees have a sharp 90-degree corner on the side inlet. This creates a perfect “shelf” or “hook.” When flow comes from the branch line, it shoots straight across the main pipe and slams into the opposite wall. Anything solid in that flow has a high chance of getting stuck right at that corner or on the flat shoulder of the fitting. Once it’s stuck, the clog begins to grow.

The Sweep Tee Advantage

The sweep tee attacks this problem head-on with its flowing geometry.

No Shelves or Hooks: The continuous curve means there is no inside corner for items to lodge against. Think of it like a slide versus a staircase. Objects slide down a smooth slide easily, but they can get caught on the steps of a staircase.

Improved Scouring Action: Because water maintains higher velocity through a sweep tee, it has more power to “scour” or clean the pipe walls. This helps flush away the thin layers of grease and sludge that can build up over time, before they become thick enough to cause problems.

Better Handling of Problematic Waste: Common clog culprits behave better in sweep tees:

- Hair and Threads: These wrap around sharp edges. With no edge to catch, they tend to flow through.

- Grease: Grease cools and solidifies on surfaces. A smooth, fast-flowing surface is less likely to allow grease to stick and build up.

- Food Particles and Solids: They are carried around the bend by momentum rather than being dumped into a quiet corner.

Client Case Study: A Simple Fix

We had a client—a small restaurant—with a floor drain that clogged monthly. The plumber kept snaking it. We suggested a camera inspection. The camera showed a standard tee right under the drain where grease and food bits were consistently building up on the sharp ledge. We replaced that single fitting with a sweep tee. The monthly clogs stopped immediately. The problem wasn’t the pipes; it was the wrong fitting. This is a perfect example of how the right component prevents ongoing maintenance costs and disruptions.

What Are the Key Installation Considerations for Sweep Tees in Drainage Systems?

Even the best fitting can fail if installed wrong. Proper installation is not just about glue; it’s about understanding flow direction and system support.

The key installation considerations for sweep tees are orientation, proper support, and ensuring correct slope. You must install the tee with the curved sweep facing the direction of the flow to guide waste smoothly. Also, you must support the pipes before and after the fitting to prevent stress and misalignment, and maintain a consistent downward slope throughout the run to keep water moving.

Critical Rule: Orientation is Everything

This is the most common and critical mistake. A sweep tee has a right way and a wrong way. The curved sweep must always point in the direction of the downstream flow. If you install it backwards, you create the worst possible scenario: a sharp, recessed ledge that will catch every piece of debris flowing past. It will clog faster than a standard tee.

- How to Remember: The sweep should look like it’s “reaching out” to catch the flow from the branch and guide it gently into the main stream. Always double-check the flow arrows on the fitting or clearly mark the inlet and outlet during planning.

Support and Alignment

Sweep tees are often larger than standard tees. The curved section can make them a bit more vulnerable to stress if the pipes are not properly supported.

- Prevent Stress: You must use pipe hangers or straps on both sides of the fitting. Do not let the weight of the pipes hang on the tee joints. This is especially important in vertical stacks or under heavy concrete slabs.

- Maintain Alignment: Dry-fit the entire assembly first. Make sure all pipes align smoothly without forcing them. Forcing pipes to connect puts stress on the joints and can create minor misalignments inside the pipe that disrupt flow.

Maintaining Proper Slope

Drainage works on gravity. The pipe must slope downward consistently (usually 1/4 inch per foot for most drains). A sweep tee should not disrupt this slope.

- Plan Your Layout: When incorporating a sweep tee, you need to calculate how its larger curve affects the pipe run elevation. You may need to adjust the starting or ending point of your run to maintain a constant fall.

- Check with a Level: After dry-fitting, use a level to ensure the slope is continuous and correct through the fitting. A low spot or flat spot after the tee will cause water to pool and solids to settle.

Installation Checklist Table

Use this simple checklist during installation to avoid errors:

| Step | Task | Why It Matters |

|---|---|---|

| 1. Planning | Identify main flow direction. Determine correct orientation of sweep. | Ensures the fitting will work as designed. Prevents backwards installation. |

| 2. Dry Fit | Assemble pipes and tee without glue. Check alignment and slope with a level. | Catches alignment issues and slope errors before they are permanent. |

| 3. Support | Install hangers or straps within 18 inches of the fitting on both sides. | Prevents joint stress and sagging that can lead to leaks or poor flow. |

| 4. Gluing | Follow manufacturer instructions for primer and solvent cement. Apply evenly and twist into place. | Creates a strong, watertight seal. Avoids excess cement that can create interior obstructions. |

| 5. Final Check | Verify orientation is correct. Ensure no low spots exist in the slope. | Final confirmation for a long-lasting, clog-free installation. |

Taking these extra few minutes during installation ensures your sweep tee performs perfectly for decades, providing the full benefit of its advanced design.

How Does a Sweep Tee Compare to Standard Tees for Drainage Performance?

The choice between fittings is a choice between future problems and long-term flow. Let’s look at the direct comparison.

A sweep tee outperforms a standard sanitary tee in almost every aspect of drainage performance. It offers superior flow efficiency, vastly better clog resistance, quieter operation, and long-term reliability. While a standard tee is acceptable for venting connections, the sweep tee is the definitive choice for any drain line carrying solid waste, especially in critical or high-use applications.

Head-to-Head Performance Breakdown

To make the best decision for a project, you need a clear, side-by-side comparison. Here is how these two common fittings stack up against each other in real-world drainage scenarios.

Performance Comparison Table

| Performance Aspect | Standard Sanitary Tee | Sweep Tee (Long-Radius) | Winner & Explanation |

|---|---|---|---|

| Flow Efficiency | Poor. Causes significant turbulence and velocity loss. | Excellent. Maintains smooth, fast flow with minimal energy loss. | Sweep Tee. Better flow means faster drainage and fewer backups. |

| Clog Resistance | Low. Sharp corners create shelves that catch debris. | High. Smooth curve allows waste to pass without snagging. | Sweep Tee. This is the most important practical advantage. |

| Ideal Application | Vent piping (where no waste flows), or where code specifically allows. | Drain/waste piping, especially for horizontal-to-vertical changes. | Depends. Use each fitting for its intended purpose. |

| Noise Level | Can be noisy (gurgling) due to turbulent flow. | Much quieter due to laminar flow. | Sweep Tee. Provides a quieter building environment. |

| Scouring Action | Weak. Slow water allows grease and sludge to deposit. | Strong. Faster water helps keep the pipe cleaner. | Sweep Tee. Reduces long-term buildup in the pipes. |

| Cost & Space | Generally less expensive and more compact. | Slightly more expensive and requires more space for the radius. | Standard Tee. But the long-term cost of clogs outweighs this. |

Code Considerations and Best Practices

It’s important to know that plumbing codes often reflect this performance difference. Many modern building codes, including the International Plumbing Code (IPC), restrict the use of standard sanitary tees in drainage lines. They are often only permitted for vent connections or specific situations. Sweep tees or combination fittings that provide a directional change are frequently required by code for horizontal drainage lines.

When to Use a Standard Tee:

- Connecting a vertical vent pipe to a horizontal vent line.

- Very specific applications where the fitting will never see waste flow (always check local codes).

When to Use a Sweep Tee:

- Connecting a horizontal drain to a vertical stack (this is crucial).

- Any horizontal-to-horizontal drainage change of direction.

- In kitchen sink drains, shower drains, laundry drains—anywhere stringy or greasy waste is common.

- In any application where reducing maintenance clogs is a priority.

Making the Smart Choice

While the sweep tee might have a slightly higher upfront material cost, the total cost of ownership is lower. Think of the cost of a single emergency plumber visit to clear a clog. That fee alone could cover the upgrade to sweep tees for an entire bathroom. For builders and property managers, specifying sweep tees in drainage lines is a mark of quality. It shows an understanding of hydraulic principles and a commitment to building systems that last, perform well, and minimize future headaches for the owner.

Conclusion

For smooth, reliable, and clog-free drainage, the sweep tee is the superior technical and practical choice. For high-quality, dependable sweep tees that meet international standards, specify IFAN for your next drainage system project.

Recent Comments