I once saw a client’s system struggle with uneven flow and pressure loss. After we switched to a Double Y Tee, the performance improvement was immediate and clear.

A Double Y Tee is chosen for efficient flow division because its unique branched, gradual design minimizes turbulence and pressure drop when splitting or combining fluid flow. This results in smoother operation, lower energy consumption, and more balanced distribution compared to standard tees, making systems more efficient and reliable.

If you manage piping systems, understanding this fitting’s advantage is key. Let’s break down why it’s a superior choice for flow management.

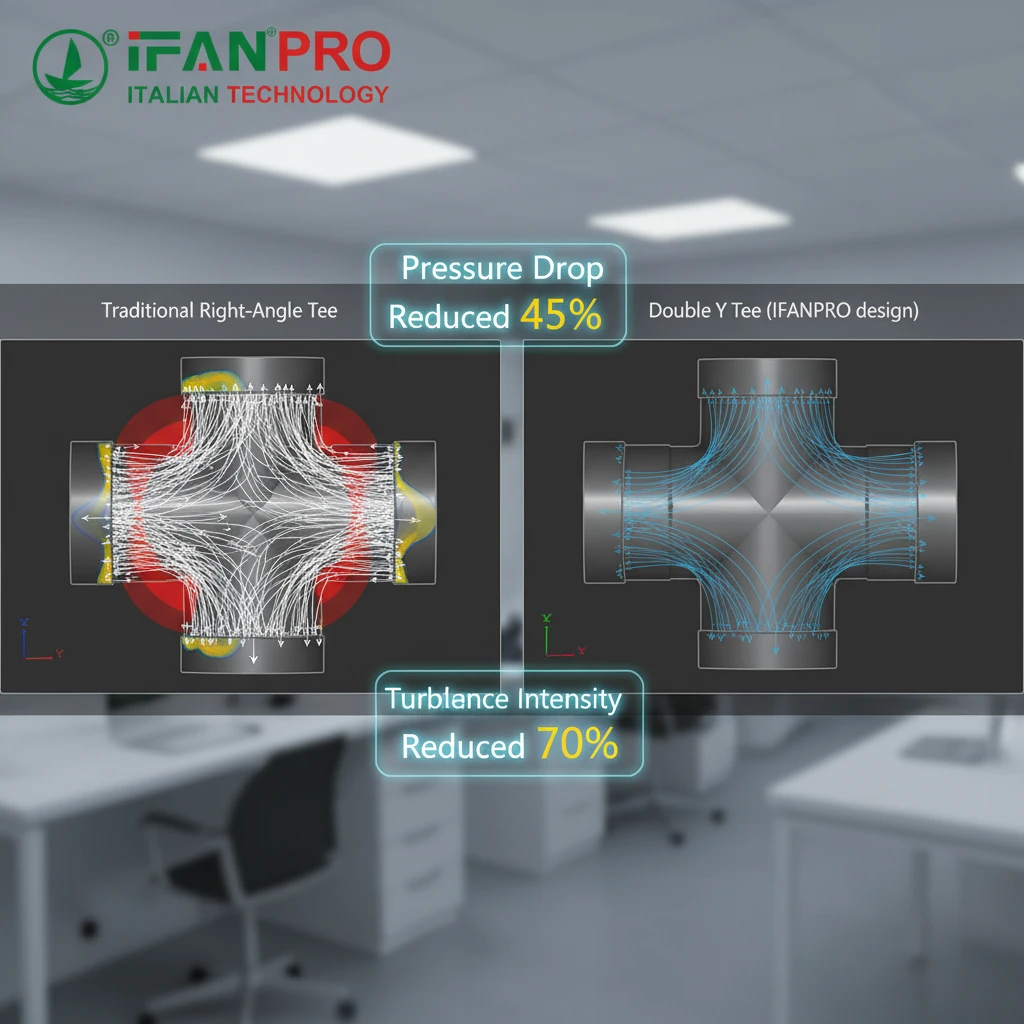

How Does a DOUBLE Y TEE Design Minimize Pressure Drop in Piping Systems?

Pressure drop means wasted energy. Many systems lose efficiency at simple branch points, but the Double Y Tee addresses this directly.

A Double Y Tee minimizes pressure drop by using a gradual, wye-shaped branch with a smoother curve, often around 45 degrees, instead of a sharp 90-degree turn. This gentle transition guides the fluid, reducing sudden changes in direction and velocity that cause turbulence, friction, and significant energy loss in the system.

The Problem with Sudden Direction Changes

First, you need to know what causes pressure drop. In piping, when fluid hits a sharp corner or a sudden obstruction, it has to change direction quickly. This rapid change creates swirling, chaotic motion called turbulence. Turbulence makes the fluid molecules rub violently against each other and the pipe walls. This friction steals energy from the flow, which shows up as a loss of pressure downstream.

A standard tee fitting creates this exact scenario. Fluid moving straight through might be okay, but any flow that has to turn into the branch or from the branch into the main line hits an almost right-angled wall. It’s like running full speed into a corner and trying to turn immediately—you lose a lot of momentum.

How the Double Y Tee Provides a Solution

The Double Y Tee solves this with intelligent geometry. Instead of one sharp corner, it features a branched design that looks like a “Y” within a “Y.” The internal pathway for dividing or merging flow is a long, gradual curve.

Think of it like a highway exit ramp. A standard tee is a sharp, 90-degree turn off the highway—cars must brake hard, causing traffic and risk. A Double Y Tee is a long, curved, banked exit ramp—cars maintain speed and flow smoothly off the main road with minimal disruption.

This smooth curve achieves two things:

- Reduces Turbulence: The fluid changes direction slowly, maintaining a more laminar (smooth, layered) flow. There is less chaotic mixing and friction.

- Maintains Velocity: Because the energy isn’t wasted on creating turbulence, more of the fluid’s kinetic energy is preserved as it moves through the fitting. This maintains both flow rate and pressure.

Impact on System Performance

The result is a system that requires less pumping power to move the same amount of fluid. For a plant manager, this translates directly to lower electricity bills for pumps. It also means the system can achieve the desired flow rates with smaller pumps or at lower settings, reducing capital and operating costs.

| Fitting Type | Approximate Pressure Drop (Relative Index) | Flow Characteristic at Branch |

|---|---|---|

| Standard (Straight) Tee | 100 (Baseline) | High Turbulence, Sharp Turn |

| Double Y Tee | 20 – 40 | Low Turbulence, Smooth, Gradual Turn |

| Long Radius Elbow | 15 – 25 | (For comparison) Smooth Turn |

As the table shows, the Double Y Tee can reduce the pressure loss at a branch connection by 60-80% compared to a standard tee. Over dozens of fittings in a large system, this saving becomes enormous.

Why is a DOUBLE Y TEE More Efficient Than a Standard Pipe Tee?

Efficiency is about getting more output from the same input. When we compare fittings side-by-side, the Double Y Tee’s advantages become very clear.

A Double Y Tee is more efficient than a standard tee because it significantly reduces hydraulic resistance, leading to less pump energy required, minimized erosion and vibration in the pipes, and provides a more balanced and predictable flow split, which improves overall system control and performance.

Direct Comparison of Energy Use

The core of efficiency is energy consumption. As explained in the pressure drop section, the standard tee is a major source of energy waste. A pump must work harder to push fluid through a restrictive, turbulent fitting. This extra work is measured in kilowatt-hours on your electricity meter.

The Double Y Tee’s streamlined path presents much less resistance. Therefore, the pump uses less power to maintain the same system flow and pressure. For a continuously operating industrial system, even a 5% reduction in pump power can save thousands of dollars per year. The Double Y Tee often delivers savings far greater than that at each branch point.

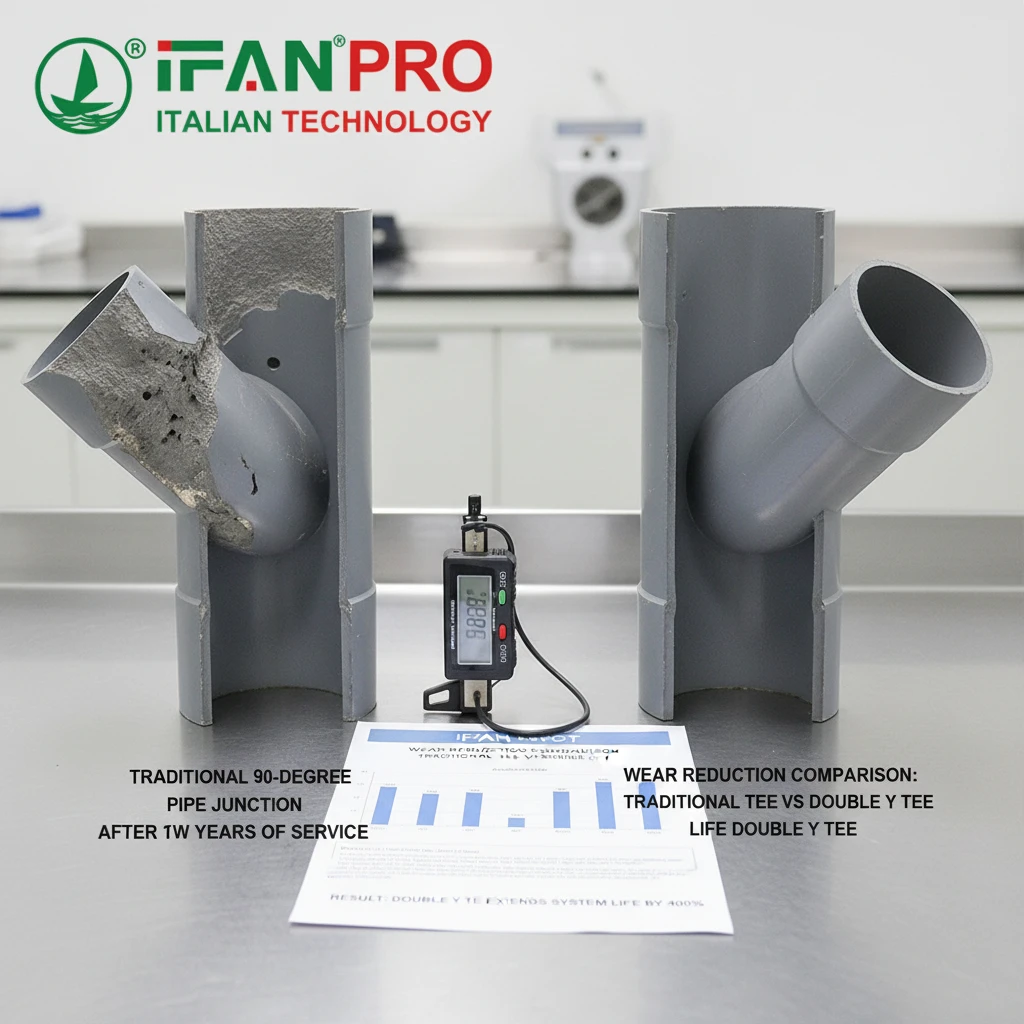

Reducing Long-Term Wear and Tear (System Damage)

Efficiency isn’t just about energy. It’s also about maintenance and system longevity. The turbulent flow inside a standard tee doesn’t just waste energy; it also physically attacks the pipe.

- Erosion: The chaotic, high-velocity fluid particles constantly scour the inner wall of the fitting, especially at the corner. Over time, this thins the metal or plastic, leading to weak spots and potential failure.

- Cavitation: In liquid systems, severe turbulence can cause rapid pressure changes, leading to the formation and implosion of tiny vapor bubbles. These implosions are powerful enough to chip away at the pipe material.

- Vibration: Turbulence causes the pipe to shake and vibrate. This stresses supports, loosens bolts, and can lead to fatigue cracks.

A Double Y Tee, by promoting smoother flow, dramatically reduces all these damaging effects. This means lower maintenance costs, fewer unplanned shutdowns, and a longer lifespan for your entire piping system.

Achieving Balanced Flow Distribution

For splitting flow, a standard tee is notoriously bad at providing an even division. Due to its abrupt geometry, more fluid tends to continue straight on, while the branch receives a weaker, more turbulent flow. This leads to uneven performance in parallel lines or equipment downstream.

The Double Y Tee, with its symmetrical and gradual design, creates a much more balanced and predictable flow split. This is critical in applications like:

- Feeding two parallel heat exchangers.

- Distributing coolant to multiple machine tools.

- Dividing raw material to twin processing lines.

Balanced flow ensures consistent product quality and uniform equipment loading, which are hallmarks of an efficient, well-managed operation.

In Which Applications Does a DOUBLE Y TEE Optimize Flow Distribution Best?

Knowing where to use a specialized fitting is as important as knowing why. Based on our projects, the Double Y Tee is the star performer in several key scenarios.

A Double Y Tee optimizes flow distribution best in applications requiring low turbulence and balanced splitting or combining of fluids. Key uses include pump suction/ discharge headers, slurry transport systems, HVAC hydronic circuits, and industrial process lines where erosion, vibration, or energy loss from standard tees is a major concern.

Pump Header Assemblies (Critical Application)

This is perhaps the most important application for a Double Y Tee. Pump headers are the main pipes that connect multiple pumps to a common suction source or discharge line.

- Suction Header: Using standard tees here can create uneven flow into each pump, causing one pump to starve for fluid (cavitation) while others run normally. Cavitation destroys pump impellers. The Double Y Tee ensures smooth, balanced flow from the main source to each pump inlet, protecting this expensive equipment.

- Discharge Header: When multiple pumps feed into one main line, standard tees cause backpressure and turbulence, forcing pumps to work against each other. Double Y Tees allow each pump’s discharge to merge smoothly into the main flow, improving efficiency and reducing wear.

Handling Abrasive or Sensitive Fluids

Some fluids are particularly punishing or delicate, making smooth flow essential.

- Slurry Systems: Slurries (mixtures of liquid and solid particles) are highly abrasive. Any turbulence in a standard tee accelerates wear, quickly grinding through the fitting wall. The Double Y Tee’s laminar flow path reduces this abrasive action, extending system life dramatically.

- Sensitive Process Fluids: In food, beverage, or pharmaceutical lines, product integrity is key. Turbulence can shear delicate ingredients, damage suspended cultures, or incorporate unwanted air. The gentle flow in a Double Y Tee preserves product quality.

- High-Viscosity Fluids: Thick fluids like oils, syrups, or polymers require enormous energy to push through restrictions. The low resistance of a Double Y Tee is crucial for keeping these systems economical to operate.

HVAC and Hydronic Heating/Cooling Systems

Modern buildings use water to transport heat and cooling. These systems have dozens of branch points to serve different zones or radiators.

- Balanced Flow: Using Double Y Tees at main branches helps ensure each building zone gets its designed share of hot or cold water. This eliminates “cold zones” and “hot zones,” improving comfort and control.

- Quiet Operation: Turbulence in pipes translates to noise in walls and ceilings. The quiet flow from Double Y Tees contributes to a more peaceful building environment.

- Energy Savings: Circulator pumps in large buildings run constantly. Reducing system pressure drop with better fittings directly reduces pump energy use.

Application Selection Guide

| Application | Problem with Standard Tee | Benefit of Double Y Tee |

|---|---|---|

| Pump Suction Header | Uneven flow, pump cavitation | Balanced flow, prevents pump damage |

| Slurry/Sand Pipeline | Extreme localized erosion | Smooth flow path, longer system life |

| Process Mixing Lines | Uncontrolled turbulence, poor mixing | Predictable, gentle flow merging |

| HVAC Main Branches | Unbalanced zone temperatures, noise | Balanced flow distribution, quiet operation |

| Fire Protection Sprinkler Mains | Unpredictable pressure loss calculations | Lower, more consistent pressure drop |

What are the Key Installation Tips for DOUBLE Y TEE Fitting Performance?

Even the best fitting can fail if installed incorrectly. From our field audits, here are the most critical practices to ensure your Double Y Tee performs as designed.

The key installation tips are: ensure the fitting is oriented correctly with the flow direction, provide adequate straight pipe runs before and after the tee to stabilize flow, use proper support to avoid stress on the branches, and during welding or bonding, prevent internal bead formation or glue blockage that can ruin its smooth bore.

Tip 1: Correct Orientation is Non-Negotiable

A Double Y Tee has a specific inlet and outlet. It is not symmetrical like a standard tee. Installing it backwards will create more turbulence and pressure drop than a standard tee, defeating its entire purpose.

- For Flow Division: The single, straight inlet should be on the main flow source. The two branched outlets should point in the direction of the divided flows.

- For Flow Combining: The two branched inlets should receive the incoming flows, merging them into the single, straight outlet.

Always check the manufacturer’s arrow or marking on the fitting. If none exists, remember the rule: the long, gradual curves are for the splitting/combining flows; the relatively straighter path is the main run.

Tip 2: Respect Straight-Run Requirements

Fluid needs distance to become stable and uniform before entering a fitting and to settle down after leaving it. Installing a Double Y Tee too close to a pump, valve, or elbow will disrupt the flow pattern and reduce its efficiency.

As a general rule of thumb:

- Upstream: Provide a straight pipe length of at least 5 to 10 pipe diameters before the inlet of the Double Y Tee.

- Downstream: Provide a straight pipe length of at least 10 pipe diameters after the outlets before introducing another fitting.

This allows for fully developed flow to enter and minimizes the disturbance downstream, letting the smooth flow characteristic re-establish.

Tip 3: Proper Support Prevents Stress and Misalignment

The branched shape of a Double Y Tee can make it mechanically weaker than a straight pipe section, especially in metal systems. Improper support can lead to sagging, which stresses the welds or threads and can misalign the pipes, creating new points of turbulence.

- Support the pipe on both sides of the fitting, close to it.

- Avoid using the tee itself as a anchor point for the pipe run.

- For heavy systems, consider using a dedicated support clamp that cradles the fitting body without restricting thermal expansion.

Tip 4: Protect the Internal Bore During Joining

The smooth, polished inside surface is what makes the fitting work. You must protect it during installation.

- For Welded Systems (Butt-Weld): Use proper welding technique to avoid excessive “weld bead” protruding into the pipe bore. In critical applications, specify “back purging” with inert gas to prevent internal oxidation (sugaring) which creates a rough surface.

- For Socket-Weld or Threaded Systems: Ensure no welding spatter or thread sealant (like Teflon tape) enters the bore. Keep threads clean.

- For Solvent-Cement (Plastic): Apply glue sparingly. Excess glue can drip inside and harden into an obstruction, creating a turbulence point right in the critical flow path. Always follow the manufacturer’s cementing instructions.

Installation Checklist Table

| Step | Key Action | Reason / Consequence if Ignored |

|---|---|---|

| 1. Orientation | Verify flow direction matches marked arrow. | Backwards installation causes severe turbulence. |

| 2. Upstream Pipe | Ensure min. 5-10D straight pipe before inlet. | Unstable inlet flow reduces fitting efficiency. |

| 3. Downstream Pipe | Ensure min. 10D straight pipe after outlets. | Allows smooth flow to re-establish fully. |

| 4. Supports | Install adequate supports near, not on, the tee. | Prevents stress, sagging, and weld failure. |

| 5. Joining Quality | Prevent internal beads, spatter, or glue blockage. | Internal obstructions ruin the smooth bore advantage. |

Conclusion

For efficient, reliable, and balanced flow division, the Double Y Tee is the superior engineering choice. For top-quality Double Y Tees that deliver on these promises, partner with IFAN. Our fittings are designed for optimal performance.

Recent Comments