I once saw a project delayed for weeks because standard 90-degree elbows just wouldn’t fit the tight, irregular space. The solution was a simple custom angle.

You should choose a custom elbow for complex layouts because it is precisely engineered to fit unique spatial and performance requirements. It eliminates multiple connection points, reduces potential leak sources, optimizes flow, and solves installation challenges that standard, off-the-shelf fittings simply cannot address, leading to a more reliable and efficient system.

This approach transforms a problematic layout into a streamlined one. Let’s break down exactly how and why this works.

How Do Custom Elbows Eliminate the Need for Multiple Fittings and Extra Joints?

In complex pipe runs, installers often connect several standard elbows and straight pipes to navigate obstacles. I’ve seen this create a “spaghetti junction” of connections.

A single custom elbow eliminates the need for multiple fittings and extra joints by consolidating a series of direction changes into one precisely bent piece. This replaces several standard elbows, couplings, and short pipe segments, directly reducing the total number of welded or threaded connections in the system.

The Problem with Multiple Standard Fittings

When a pipeline needs to change direction around a beam, column, or piece of equipment, the default solution is often to use standard fittings. For example, to navigate a 30-degree offset, a plumber might use two 45-degree elbows and a short nipple. To go around a corner with a specific offset, they might use a combination of a 90-degree elbow, a straight pipe, and another 90-degree elbow.

Each of these connections—where an elbow meets a pipe or another fitting—is a potential failure point. Every joint requires welding, threading, or gasketing. Each one is a place where leaks can start, either immediately from a poor installation or over time due to stress and wear. Furthermore, each joint adds to the material cost and, more importantly, the labor time for assembly and inspection.

The Custom Solution: Consolidation

A custom elbow is designed to make that exact same directional change in one continuous piece. Instead of welding three separate components together, you have one component. This has an immediate and powerful effect.

First, it drastically reduces the part count. You are purchasing and handling one item instead of three or four. Second, and most critically, it minimizes the number of joints. The potential leak points are reduced from, say, four (at each connection of the multi-fitting assembly) to just two (where the single custom elbow connects to the main pipeline).

Comparison: Navigating a Specific Offset

The table below shows a clear comparison for creating a 24-inch lateral offset.

| Method | Components Required | Total Joints/Connections | Key Risk |

|---|---|---|---|

| Standard Fittings | Two 45° Elbows, One Nipple, Two Couplings | 6 | High: 6 potential leak points; requires precise measurement of nipple. |

| Custom Elbow | One 45°-45° Offset Elbow (Bent to Spec) | 2 | Low: Only 2 potential leak points at the ends. |

From a project management and quality control perspective, this simplification is a major advantage. Fewer parts mean less inventory to manage. Fewer welds mean less inspection time and a significantly lower statistical probability of a leak. For the installer, it means a faster, cleaner, and more straightforward installation process, directly translating to lower labor costs and higher reliability.

Why Does a Single Custom Fitting Improve System Reliability in Complex Layouts?

Every joint is a weak link. In a critical system, reducing weak links is the most direct path to reliability. A client’s chemical transfer line failure taught me this lesson painfully well.

A single custom fitting improves reliability because it removes the internal stresses and turbulence caused by misaligned, multiple standard fittings. It creates a smooth, continuous path for fluid, reduces vibration and fatigue at connection points, and eliminates the risk of assembly errors that can occur when joining several small pieces in a confined space.

Understanding Joint Stress and Fatigue

System reliability in piping isn’t just about preventing leaks today; it’s about preventing failures over years of operation under pressure, temperature cycles, and vibration. Multiple standard fittings joined together create several inherent reliability risks.

First, there is alignment stress. Even with skilled installers, it is challenging to perfectly align the axes of two separate elbows and a pipe nipple. Microscopic misalignment creates internal stress in the fittings and at the weld points. Over time, this stress can lead to fatigue cracks, especially in systems with thermal cycling or vibration (like in HVAC or industrial plants).

Second, turbulence at joints can cause erosion. When fluid flows through a series of closely spaced elbows, it doesn’t get a chance to stabilize. This creates chaotic, turbulent flow between the fittings, which can erode the pipe wall from the inside over many years, a process called erosion-corrosion. A single, smooth-bent custom elbow guides the fluid more gently, minimizing this damaging turbulence.

The Human Factor: Assembly Error

Complex layouts in tight spaces are difficult to work on. When an installer has to weld or thread several small components together in an awkward position, the chance of error increases. A weld might not have full penetration, or a threaded connection might be over-tightened and crack. These assembly defects are hidden until they cause a failure.

A custom elbow, made to the exact required dimensions, simplifies the task. The installer has only two welds to make, and they are typically in more accessible positions. This reduces the complexity of the task and, therefore, the probability of an installation mistake. It turns a complicated assembly puzzle into a simple “connect point A to point B” operation.

Reliability Factors Compared

| Reliability Factor | Multi-Standard-Fitting Assembly | Single Custom Elbow |

|---|---|---|

| Number of Potential Leak Points | High (4-6) | Low (2) |

| Internal Alignment Stress | Likely due to assembly | None (manufactured as one piece) |

| Flow Turbulence & Erosion Risk | High at each turn | Lower, smoother transition |

| Risk of Installation Error | Higher due to complexity | Lower due to simplicity |

| Long-Term Fatigue Resistance | Lower (stress points at joints) | Higher (continuous material) |

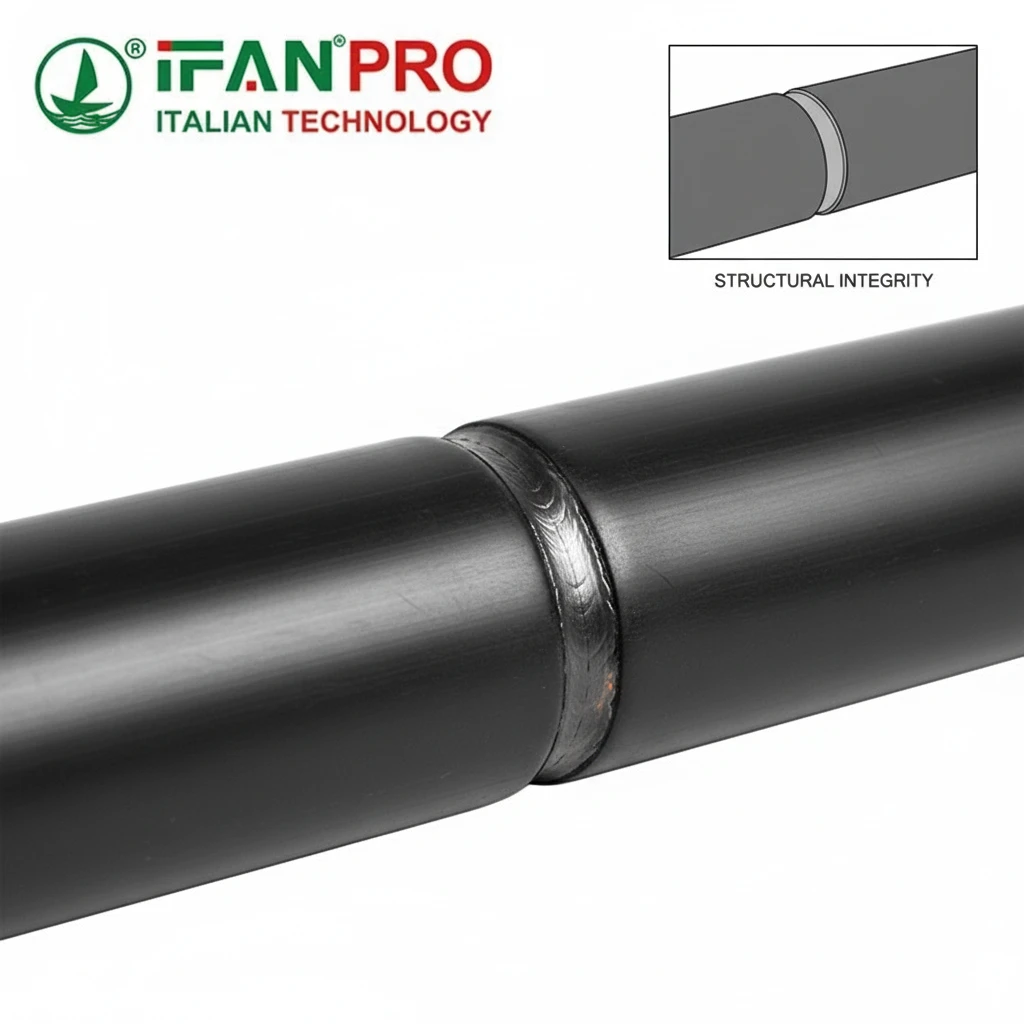

By integrating the path into one piece, the custom elbow inherently possesses greater structural integrity. It distributes system stresses—from pressure, weight, and thermal expansion—across a continuous form, rather than concentrating them at several small, welded junctions. This fundamental difference is why custom fittings are the preferred choice for critical, complex, or hard-to-maintain piping systems.

How Can a Custom Design Solve Unique Spatial Constraints That Standard Fittings Cannot?

Standard fittings come in fixed angles—90°, 45°, 22.5°. Buildings and equipment layouts don’t. I recall a retrofit where a 77-degree turn was needed, and only a custom bend saved the project.

A custom design can solve unique spatial constraints by providing an exact fit for non-standard angles, specific bend radii, and unusual offset dimensions that do not exist in catalogs. This allows the pipe to navigate tightly around existing structures, machinery, or other utilities without costly structural modifications or compromises in the pipe run’s efficiency.

The Limitation of the Standard Catalog

The world of standard fittings is a world of predefined geometry. This works perfectly for simple, repetitive layouts. However, in renovation projects, tight mechanical rooms, or around complex process equipment, the available space rarely conforms to these preset angles and dimensions.

The common painful choice becomes: do you modify the building (cut a beam, move a duct) to accommodate the standard pipe run, or do you create an inefficient, multi-fitting “dogleg” pipe run that wastes space, increases pressure drop, and looks unprofessional? Both options add significant cost and time.

The Precision of Custom Geometry

A custom elbow breaks this compromise. It is designed from the ground up based on the actual spatial problem. The key parameters that can be customized are:

- Bend Angle: This is the most common need. Instead of a 90° or 45° elbow, you can specify an 80°, 60°, 30°, or any angle required.

- Bend Radius: A larger radius allows for smoother flow (discussed next), but sometimes a tight radius is needed to squeeze into a narrow gap. This can be specified precisely.

- Offset Dimensions: The exact horizontal and vertical distances between the pipe’s entry and exit points can be built into a single fitting.

- Tangents: The straight lengths of pipe on either side of the bend can be incorporated into the fitting itself, ensuring it bolts directly into the existing pipeline ends.

Practical Example: Navigating a Structural Column

Imagine a pipe that must run flush against a wall but needs to pass a square structural column. A standard fitting approach might use two 90° elbows to go around it, creating a bulky “box” around the column that protrudes far from the wall.

A custom solution would be a single “U-shaped” bend or a smooth curve with a specific offset equal to the column’s width plus clearance. This single fitting would hug the wall and the column contour cleanly, taking up minimal space and looking like an intentional part of the design.

Solutions for Common Spatial Problems

| Spatial Constraint | Standard Fitting “Workaround” | Custom Elbow Solution |

|---|---|---|

| Non-Standard Angle (e.g., 70° turn) | Use a 45° + 22.5° elbow combo (inefficient, turbulent). | One 70° elbow (clean, efficient). |

| Very Tight Clearance | Impossible with large-radius standard elbows. | A tight-radius elbow designed for the exact gap. |

| Misaligned Pipe Connections | Use multiple elbows and nipples to “zigzag” into alignment. | A single offset elbow that connects the two misaligned points directly. |

| Obstacle Avoidance | Complex routing with many fittings, increasing head loss. | A smooth, engineered bend that goes around the obstacle optimally. |

This ability to make the pipe conform to the space, rather than forcing the space to conform to the pipe, is a powerful tool for engineers and installers. It turns layout challenges from major obstacles into simple specification tasks for a company like IFAN, which can then produce the exact component needed.

What Are the Flow Dynamics Advantages of a Custom Elbow Over a Segmented Bend?

Flow efficiency is often an invisible cost. In a large pumping system, a poorly designed bend can waste thousands in energy annually. Custom elbows optimize this.

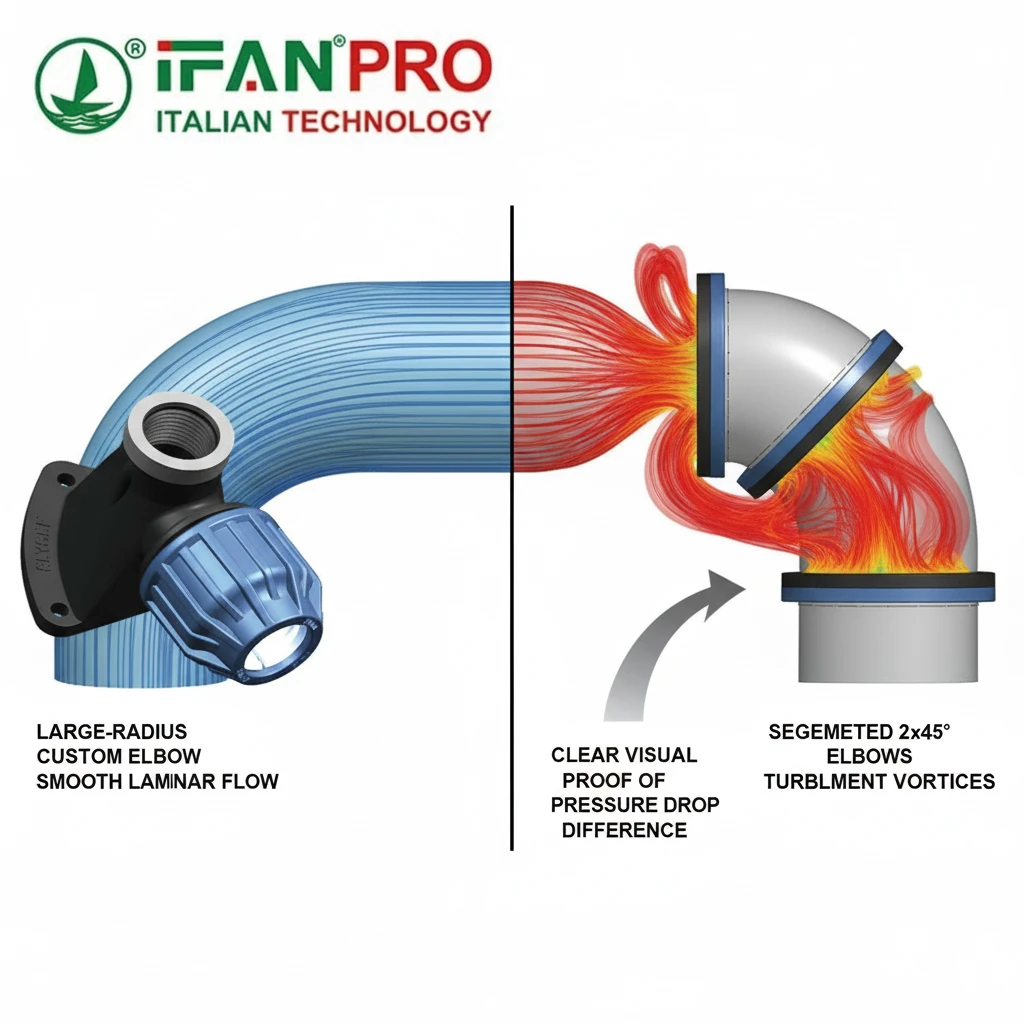

The key flow dynamics advantage of a custom elbow is its smooth, continuous curvature, which minimizes turbulence, pressure drop, and energy loss. In contrast, a segmented bend made from standard fittings creates sharp, discontinuous turns that disrupt flow, increase resistance, and can lead to vibration, noise, and accelerated internal wear.

The Physics of Fluid Flow in Pipes

When fluid (water, air, chemicals) moves through a pipe, it wants to flow in straight lines. Any change in direction forces the fluid to change velocity and creates friction against the pipe wall. The goal of good piping design is to guide the fluid as gently as possible to minimize this energy loss, which is measured as “pressure drop.”

A segmented bend—like two 45° elbows close together—forces the fluid to make two abrupt changes. After the first turn, the fluid hits a short straight section in a chaotic, turbulent state, only to immediately be forced into another sharp turn. This double disruption creates a large amount of turbulence, which consumes energy from the pump or compressor and manifests as a significant loss of pressure.

The Smoother Path of a Custom Bend

A custom elbow, especially one with a larger bend radius, creates a gradual, smooth change in direction. The fluid is guided along a continuous curve. This allows the fluid streamlines to follow the pipe wall more closely, reducing the formation of large-scale turbulence and swirling eddies.

The main advantages are:

- Lower Pressure Drop: A smooth bend has a much lower “friction loss coefficient” than multiple sharp bends. This means the pump or fan doesn’t have to work as hard to push the fluid through, leading to direct energy savings.

- Reduced Turbulence and Cavitation: Severe turbulence in segmented bends can cause localized low-pressure zones. In liquid systems, this can lead to cavitation (the formation and collapse of vapor bubbles), which is incredibly damaging to pipe walls and is very noisy.

- Minimized Erosion and Vibration: The chaotic flow in a segmented bend constantly hammers the pipe wall at the points of impact, leading to erosion over time and potentially causing pipe vibration. A smooth custom bend promotes laminar or mild turbulent flow, which is far less destructive.

Quantitative Comparison: Pressure Drop

The difference isn’t just theoretical; it’s quantifiable using standard engineering tables. The head loss (pressure drop) for pipe bends is expressed as a multiple of the equivalent length of straight pipe.

| Fitting Configuration | Approximate Equivalent Length (in pipe diameters)* | Result on System |

|---|---|---|

| One Standard 90° Elbow (Sharp) | 30 diameters | High resistance, high energy loss. |

| Two 45° Elbows (Segmented Bend) | ~20 diameters each = ~40 total | Even higher combined resistance. |

| One Long-Radius 90° Elbow (Custom) | 20 diameters | 33% less pressure drop than a sharp 90°. |

| One Smooth 45° Bend (Custom) | 16 diameters | Very efficient flow. |

Note: Values are illustrative; exact numbers depend on flow rate and pipe size.

For a large-diameter pipe in an industrial or commercial system, this difference in equivalent length can translate to many feet of additional pumping head required. This directly increases electricity consumption and operational costs year after year. Therefore, investing in a hydraulically superior custom elbow can have a fast payback period through energy savings alone, not to mention the reduced maintenance from less wear and tear.

Conclusion

Custom elbows streamline complex layouts, boost reliability, solve spatial puzzles, and optimize flow. For expertly engineered custom pipe fittings that turn layout challenges into reliable solutions, partner with IFAN.

Recent Comments