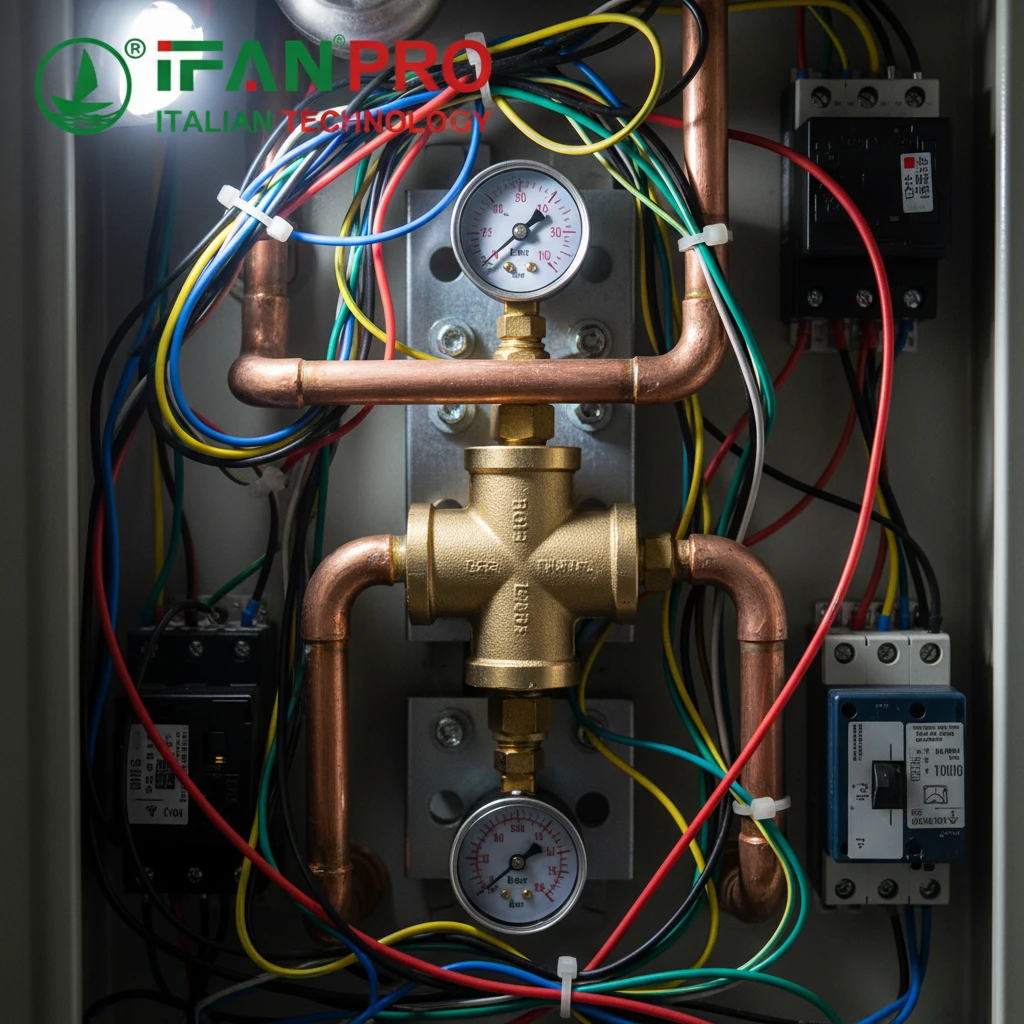

I once faced a tangled mess of pipes and tees that made repairs a nightmare. This experience taught me the true value of a simple, smart solution: the brass cross fitting.

You should choose a brass cross for distributing fluid in complex systems because it replaces multiple separate fittings with a single, integrated unit. This creates a central distribution point that simplifies layout, saves significant space, reduces potential leak points, and makes the entire system more organized and easier to maintain or modify in the future.

If you manage complex fluid systems, understanding this simple component’s impact can transform your projects. Let’s break down exactly how.

How Does a Single Cross Fitting Simplify Complex Multi-Branch Piping Layouts?

Picture a system needing flows in four directions. Without a cross, you face a puzzle of elbows and tees. A single brass cross cuts through this complexity.

A single brass cross fitting simplifies layouts by providing one pre-assembled connection point for four intersecting pipelines. It eliminates the need to piece together multiple elbows and tees, reducing assembly time, minimizing measurement errors, and creating a cleaner, more predictable piping structure from the start.

The Problem of Multi-Fitting Assemblies

In complex systems—think industrial machinery, HVAC units, or sophisticated irrigation—fluids often need to go to multiple places from one source. The traditional method uses a combination of tees (T-shape) and elbows (90-degree). For example, to send fluid north, south, east, and west from one point, you might need one tee and two elbows, connected with short pipe segments (nipples).

This approach creates several problems:

- More Connections: Each joint between a tee, elbow, and pipe nipple is a potential site for a leak.

- Assembly Complexity: The installer must measure, cut, and thread several small pieces accurately. A small mistake in one measurement throws off the entire assembly.

- Visual Clutter: The resulting structure is bulky and can look messy, making it hard to trace lines.

The Cross Fitting Solution

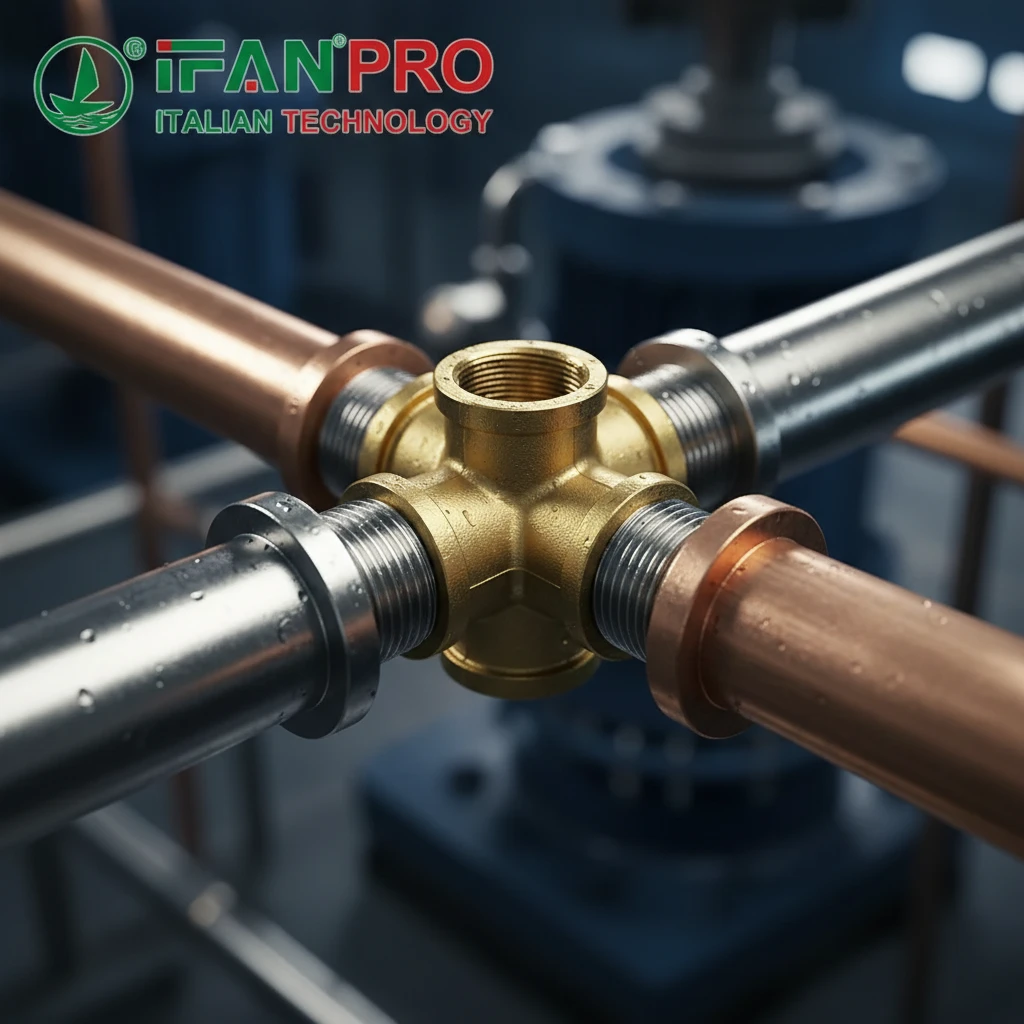

A brass cross fitting solves these problems directly. It is a single, solid piece of metal with four female threaded ports arranged at perfect 90-degree angles. You simply connect your four pipes directly into it.

Here is a direct comparison of the two methods:

| Assembly Task | Using Separate Tees & Elbows | Using a Single Brass Cross |

|---|---|---|

| Number of Fittings | 3 or more | 1 |

| Number of Threaded Joints | 6 or more | 4 |

| Required Pipe Nipples | Yes, multiple short pieces | No, pipes connect directly |

| Risk of Assembly Error | High (cumulative) | Low |

| Overall Structural Rigidity | Weaker (multiple joints) | Stronger (one solid block) |

Real-World Application and Benefit

From our experience at IFAN, clients who switch to using crosses in their designs report faster installation times and fewer leaks during pressure testing. The simplification is not just physical; it’s also mental. Engineers and technicians can more easily understand and work with a system built around clear, central distribution points. This streamlined approach reduces confusion and errors during both installation and future troubleshooting.

Why Is Its Central Distribution Point More Efficient Than Multiple Separate Fittings?

Efficiency in fluid systems means less pressure drop, fewer failures, and easier control. A central cross is the heart of an efficient distribution network.

The central distribution point of a brass cross is more efficient because it creates a shorter, more direct path for fluid to split into multiple branches. This reduces turbulence and pressure loss compared to fluid navigating a series of turns through separate fittings. It also centralizes potential service points, making system monitoring and balancing easier.

Understanding Fluid Flow Efficiency

When fluid moves through a pipe, every turn and connection causes friction, which slows the fluid down and reduces its pressure (pressure drop). In a system meant to supply multiple points, maintaining consistent pressure is often critical.

Flow Path Comparison:

- Through Separate Fittings: Fluid from the main line enters a tee. It might make a 90-degree turn, travel through a short nipple, make another 90-degree turn through an elbow, and then enter the branch line. This path is longer and has two sharp turns close together, which creates significant turbulence and pressure loss.

- Through a Brass Cross: Fluid from the main line enters the central cavity of the cross and can exit almost directly into any of the three branch ports. The path is much shorter, and the turn, while still 90 degrees, happens in a larger, optimized chamber designed for distribution.

The Leak Risk Multiplier

Another huge efficiency factor is reliability. Every threaded joint is a potential leak. A leak means lost fluid (cost), loss of system pressure (inefficiency), and potential damage or downtime.

Let’s calculate the leak point difference:

A typical assembly using one tee and two elbows to create a four-way intersection has:

- 3 fittings x 2 threaded ends each = 6 threaded connections.

- Plus, the pipes themselves have threads where they connect.

In contrast, a single brass cross has only 4 threaded connections for the four pipes. You immediately eliminate at least 2 major leak points. Fewer leaks mean higher system integrity, lower maintenance costs, and less wasted energy or product.

Maintenance and Control Efficiency

A central cross also acts as a natural hub. If you need to install a pressure gauge, a small valve to balance flow, or a drain port, the cross provides a logical and accessible point to do it. Trying to add these to a jumble of tees and elbows is often awkward. This centralized design makes the system easier to manage, monitor, and modify over its lifetime, which is the true mark of an efficient design.

What Space-Saving Advantages Does a Compact Brass Cross Offer in Crowded Systems?

In control panels, machinery, or tight equipment rooms, space is precious. A compact fitting can be the key to a feasible design.

A compact brass cross offers major space-saving advantages by consolidating the function of multiple, bulky separate fittings into a single, low-profile unit. Its integrated design eliminates the need for extra pipe nipples between fittings, allowing for tighter, more efficient piping runs in confined areas where every centimeter counts.

The Geometry of Saving Space

Think about the physical footprint. An assembly made of a tee and two elbows isn’t just the fittings themselves; it’s also the physical space occupied by the short connecting pipes (nipples) that stick out in various directions. This creates a bulky, three-dimensional cluster.

A brass cross is a unified block. Its ports are aligned precisely, and the distance between opposing ports is fixed and minimal. This allows pipes to connect directly and run parallel much closer to each other.

Quantifying the Savings

We often help clients redesign cramped systems. The space saving isn’t just theoretical; it’s measurable.

Consider this common scenario in a machinery side panel:

| Design Aspect | Using Tee + Elbows | Using Brass Cross | Space Saving |

|---|---|---|---|

| Projection from Main Pipe | ~150-200 mm (due to nipple and fitting depth) | ~50-70 mm (depth of the cross port) | ~60-75% reduction |

| Cluster Width | Wide and irregular | Compact and square | Cleaner layout |

| Room for Service Access | Hard to reach behind fittings | Easier to get tools on pipes | Improved maintainability |

Practical Impact on System Design

This compactness has real-world consequences:

- Smaller Enclosures: Equipment can be housed in a smaller cabinet or panel, reducing material and overall cost.

- Cleaner Layouts: Pipes can run in tighter, more organized bundles, improving aesthetics and safety by reducing snag hazards.

- Improved Accessibility: With less bulky fitting clusters clogging the space, technicians have better visual and physical access to valves, instruments, and other components nearby. This directly addresses a major client pain point: not being able to reach a valve for maintenance because a pipe fitting is in the way.

At IFAN, we stock crosses in various sizes and compact profiles specifically to help engineers solve these spatial challenges without compromising system performance.

How Does It Improve System Organization and Future Maintenance Access?

A well-organized system is a maintainable system. Chaos leads to costly downtime. The brass cross is a tool for creating order.

A brass cross improves system organization and future maintenance access by creating a logical, symmetrical hub that is easy to label and understand. It provides clear, unobstructed access to each connection point, allowing technicians to quickly identify, isolate, and service any branch without dismantling a complex web of interconnected fittings.

Creating a Logical, Service-Friendly Layout

Disorganization in piping often stems from ad-hoc solutions—adding a branch here and there with whatever fitting was on hand. Over time, this creates a confusing “spaghetti” layout. A brass cross encourages disciplined, hub-and-spoke thinking from the design phase.

Each port of a cross can be clearly labeled (e.g., “To Pump A,” “To Cooling Loop,” “Main Supply,” “Drain”). Because all connections radiate from one central, visible point, tracing a line back to its source becomes trivial. This is invaluable during emergencies or for new staff learning the system.

The Maintenance Access Advantage

Compare two scenarios when a valve on one branch needs replacing:

- In a Tee-and-Elbow Cluster: The valve is likely nestled close to other fittings and pipes. To unscrew it, you may need to first support or even disconnect adjacent pipes because the fittings are all interdependent. This turns a simple valve swap into a major, time-consuming disassembly project.

- With a Brass Cross Hub: The valve is installed on the pipe a short distance from the cross. To remove it, you only need to isolate and drain that one branch and unscrew the valve from its two connections. The cross itself and the other three pipes remain completely untouched and stable. Work is faster, safer, and less disruptive.

Strategic Recommendations for Organization

Based on common project pain points we see, here are practical tips:

- Standardize: Use crosses consistently for major distribution points. This creates a repeatable, recognizable pattern throughout the plant or machine.

- Leave Space: When installing the cross, ensure there is enough straight pipe on each port before the next bend or valve. This “service loop” allows for easy cutting and re-threading if future modifications are needed.

- Color & Label: Use color-coded tape or labels on the pipes next to each port of the cross. This visual guide speeds up all future interactions with the system.

A brass cross isn’t just a pipe fitting; it’s a commitment to a cleaner, more professional, and more maintainable system architecture. It directly answers the chronic pain points of difficult repairs and confusing layouts that so many facility managers face.

Conclusion

A brass cross fitting simplifies design, saves space, boosts efficiency, and organizes systems for the long term. For reliable, precision-machined brass crosses that support smart system design, specify IFAN Brass Cross Fittings for your next complex project.

Recent Comments