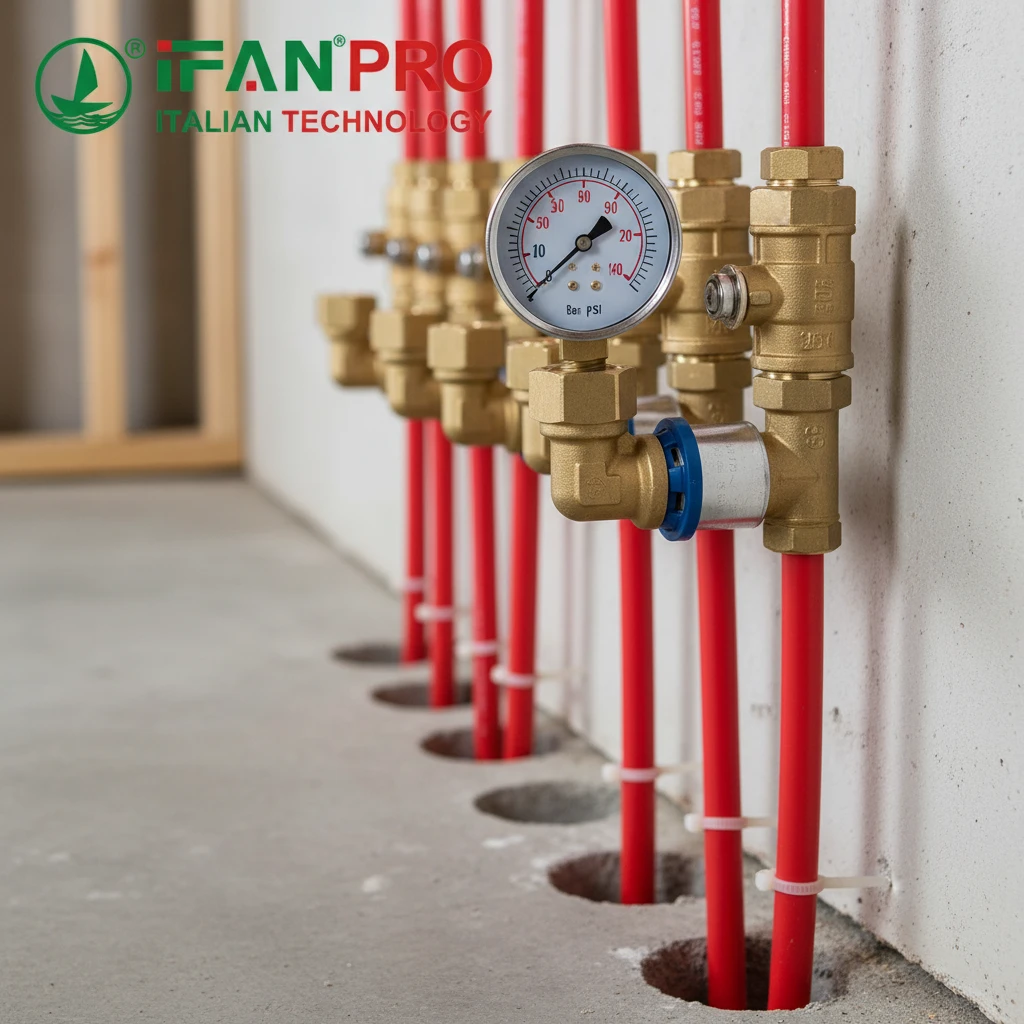

I once saw a team spend an entire day dismantling a wall to replace a single faulty valve in a complex PEX system. That costly mistake perfectly illustrates why unions are not just fittings; they are strategic tools.

Union fittings are essential in complex PEX layouts because they create intentional, serviceable connection points. They allow installers to build the system in manageable modules, enable easy future access for repairs or upgrades without cutting pipes, and make it simple to isolate and troubleshoot specific sections, saving significant time and labor during both installation and the system’s entire lifecycle.

While PEX tubing itself is flexible, a complex network for multi-zone heating or a large home’s plumbing is rigid once assembled. Unions introduce crucial flexibility where it matters most: in the serviceability of the system.

How Do Unions Allow for Modular Assembly of Complex Piping Networks?

Building a complex piping system can feel overwhelming. Unions transform this daunting task into a simple, step-by-step process.

Unions allow for modular assembly by acting as predefined connection points between sections of pipe and clusters of fixtures. Installers can build and pressure-test entire sub-assemblies—like a bathroom manifold loop or a radiant heating zone—on a workbench, then quickly connect these finished modules together on-site, dramatically improving accuracy and speed.

From a Mess of Pipes to a Managed Project

Imagine building a large model from a single, continuous piece of plastic. It would be nearly impossible. Now, imagine building it from pre-made sections that snap together. That’s the power of modular assembly with unions.

In practice, this means a plumber can plan the system as a series of logical blocks. For example, one block could be the hot and cold water supply for a kitchen. Another block could be the manifold and loops for an upstairs bathroom group. The installer builds each block separately in a controlled environment.

The Step-by-Step Modular Process

Here is how the process typically works:

- Fabrication Off-Site: The installer measures and cuts all PEX tubing for a specific module. They solder or crimp all necessary tees, elbows, and valves directly onto the tubing. Crucially, they terminate each inlet and outlet line with a union fitting.

- Testing Off-Site: The entire completed module can be pressurized and tested on the bench. This is much easier than testing inside a cramped wall cavity. Any leaks are fixed immediately without affecting other work.

- Transport and Connection: The tested, leak-free module is brought to the installation site. The installer simply aligns the union fittings from the module with the corresponding unions on the main trunk lines or other modules. A few turns of the nuts create a perfect seal, instantly integrating the complex sub-assembly into the main system.

This method offers clear advantages over traditional “in-place” welding or crimping. It reduces errors from measuring in tight spaces, improves the quality of each connection made in a comfortable workspace, and allows different teams to work on different modules simultaneously.

The table below contrasts the two approaches:

| Assembly Aspect | Traditional In-Situ Method | Modular Method with Unions |

|---|---|---|

| Primary Workspace | Inside walls/ceilings, often in awkward positions. | On a workbench in a comfortable, well-lit area. |

| Error & Leak Risk | Higher. Each connection is made in final position, harder to test individually. | Lower. Each module is fully tested before installation. |

| Project Speed | Slower, linear process. One section must be done before the next. | Faster, parallel process. Multiple modules can be built at once. |

| Future Modification | Difficult. Requires cutting into sealed lines. | Simple. Just disconnect the union for that module. |

By using unions, you turn a complex plumbing maze into a set of simple, connectable puzzles.

Why Are They Critical for Sections That May Need Future Modification?

Buildings change over time. A system that cannot adapt creates future headaches and high costs.

Unions are critical for future modification because they provide clean, reusable disconnection points. If you need to replace a water heater, a washing machine valve, or a circulating pump, you can simply disconnect the unions instead of cutting into permanent piping. This allows for easy removal, upgrade, or repair of any component without damaging the core system.

Planning for the Inevitable

Every appliance and mechanical component has a lifespan. A water heater lasts 10-15 years. A pump may fail sooner. Building codes and fixtures evolve. A permanent pipe connection assumes the current layout will last forever, which is almost never true.

A union fitting is an admission of this reality. It is a planned service point. When a component fails, the service technician doesn’t need a saw or torch. They just need two wrenches. They loosen the union nuts on either side of the failed part, swap it out, and reconnect the unions. The job is done in a fraction of the time, with no debris, no risk of damaging other pipes, and no need for patching or re-soldering.

Common Modification Scenarios

Let’s look at specific situations where unions save the day:

- Appliance Replacement: Washing machines, dishwashers, and water heaters are common replacements. With unions at their supply and discharge connections, swapping them is a quick, drip-free job.

- System Expansion: Adding a new bathroom or a wet bar? If the main trunk lines have union tee connections at strategic points, you can easily tap into them without shutting down the whole house’s water for an extended period.

- Component Upgrade: Upgrading to a smarter manifold, a more efficient pump, or adding a filtration system is straightforward when unions are in place.

- Building Renovation: During a remodel, entire sections of plumbing may need to be temporarily moved or protected. Unions make this disconnection and reconnection process orderly.

Without unions, each of these tasks involves cutting pipes. This creates debris that can get into other lines, requires new fittings and couplings, and often results in a series of repaired sections that are weaker and more cluttered than the original installation. Unions future-proof the system, protecting your investment.

How Do They Aid in Troubleshooting and Isolating Problems in a System?

When a leak or failure occurs, the goal is to find it and stop it quickly. Unions turn a nightmare diagnosis into a simple process of elimination.

Unions aid in troubleshooting by creating natural isolation points. If a leak is suspected in a specific zone—like a bathroom or a radiant heating loop—closing the associated shut-off valves and disconnecting the unions physically separates that zone from the rest of the system. This allows you to pressure-test sections individually to pinpoint the problem rapidly and with minimal disruption.

The Diagnostic Power of Segments

A complex PEX system without unions is like a string of old Christmas lights—if one bulb fails, the whole string goes dark, and you have to check each one. Unions install “bulb sockets” at logical points.

When a problem arises, such as a pressure drop or a visible leak, the installer doesn’t need to guess. They follow a logical diagnostic path made possible by the system’s design.

A Step-by-Step Troubleshooting Guide with Unions

Here is a practical example for finding a leak in a multi-zone system:

- Initial Observation: You notice a drop in pressure on the boiler gauge for a radiant floor heating system with three zones.

- Isolate with Valves and Unions: Close the shut-off valves for all three zone manifolds. Then, physically disconnect the union between the main supply line and the first zone manifold.

- Test the Main Supply: Re-pressurize the main boiler and supply piping. If pressure holds, the problem is not in the main supply. If it drops, the leak is in the common supply section.

- Test Each Zone Sequentially: Reconnect the union for Zone 1. Open Zone 1’s valve and close the others. Pressurize only Zone 1. Monitor the gauge. Repeat this process for Zone 2 and Zone 3. The zone that cannot hold pressure contains the leak.

- Further Isolation: Within the faulty zone, you can use unions at branch lines or even individual loops to further narrow down the leak to a specific room or circuit.

This method is fast, clean, and minimally invasive. Without unions, isolating a single zone would require cutting the PEX tubing, which is destructive and creates more work to repair after the leak is fixed.

The Role of Strategic Placement

For troubleshooting to be effective, unions must be placed strategically. Key locations include:

- The inlet and outlet of every major appliance (water heater, pump, filter).

- The supply and return connections to each zone manifold.

- The beginning and end of long trunk lines.

This strategic placement creates a “map” of serviceable sections, making the entire system transparent and manageable.

Can They Reduce Installation Time in Intricate Multi-Zone Systems?

Time is money on every job site. In intricate systems, unions are not a cost—they are a time-saving investment that pays off immediately.

Yes, unions can significantly reduce installation time in intricate multi-zone systems. They enable parallel work streams, where multiple pre-assembled zones can be installed simultaneously by different workers. They also eliminate time-consuming in-situ soldering/crimping in tight spaces and simplify final connections, turning a sequential, error-prone process into a fast, plug-and-play assembly.

Transforming the Workflow

Installing a multi-zone system for radiant heat or domestic water traditionally is a linear, one-pipe-at-a-time process. One crew must complete Zone A before moving to Zone B. Unions change this dynamic completely.

With a union-based modular design, the project manager can split the work:

- Crew A builds and tests the manifold assembly for Zone 1 (e.g., the basement slab) on a bench.

- Crew B builds and tests the looping layout for Zone 2 (e.g., the first floor) on another bench.

- Crew C prepares and runs the main trunk lines through the building, installing union tees at each planned zone connection point.

The Time-Saving Phases

The time savings accumulate across all phases of the project:

- Fabrication Phase: Bench work is 3-4 times faster than working overhead in ceilings or crouched in corners. Mistakes are easier to spot and fix.

- Installation Phase: Connecting pre-made modules is incredibly fast. Instead of making 20 crimps in a dark crawl space, a worker makes 2 union connections. This also reduces physical fatigue, maintaining quality and speed.

- Testing and Commissioning Phase: Since each module was pre-tested, the final system-wide pressure test is far more likely to pass on the first try. There are fewer “chase the leak” emergencies that can halt all other work.

Cost-Benefit Analysis of Using Unions

While unions have a small additional material cost, the labor savings are substantial. Consider the following comparison for a 4-zone radiant heating installation:

| Task | Traditional Method (Hours) | Modular Union Method (Hours) | Time Saved |

|---|---|---|---|

| Fabricate & Assemble 4 Zones | 40 (in-place, sequential) | 24 (parallel bench work) | 16 hours |

| Connect Zones to Main Trunk | 12 (individual pipe runs) | 4 (union connections) | 8 hours |

| System Pressure Test & Debug | 8 (likely leaks in situ) | 2 (pre-tested modules) | 6 hours |

| Total Estimated Labor | 60 hours | 30 hours | 30 hours (50% savings) |

The table shows that the labor savings can easily be double the extra cost of the union fittings. Furthermore, the reduced risk of callbacks for leaks and the faster project completion are invaluable benefits for contractors.

Conclusion

Union fittings are indispensable for building serviceable, reliable, and efficient complex PEX systems. For a full range of high-quality PEX union fittings designed for modular installation, explore the solutions from IFAN.

Recent Comments